A Full Guide to Photoelectric Sensor [Working Principle, All Types Explained, Terminology, Pros And Cons, Applications]

In today’s world, sensors play an important role in controlling, monitoring, processing of industrial processes. One of the most widely used industrial sensors is the photoelectric sensor which has the ability to recognize or identify many different physical properties.

These sensors use beams of light for the detection of the presence of target objects, hence they are also called optical sensors.

They can be used in a wide range of different industries and applications. The three main types of photoelectric sensors are through-beam, diffuse reflective, retro-reflective.

In the photoelectric Sensor (Different Types, Applications, Advantages and Disadvantages) article you will learn about photoelectric sensor, its types, working principle, the advantages and disadvantages and its applications. By reading this article, you can choose the best photoelectric sensor for your project according to your needs.

Let’s see how a photoelectric sensor works?

Photoelectric Sensor Working Principle

The operation of a photoelectric sensor is based on the use of light to recognize the presence or absence of an object.

The photoelectric sensor consists mainly of an emitter to emit a powerful beam of infrared or visible light and a receiver to receive the light. When the emitted light is interrupted or reflected by any external object, it changes the amount of light that reaches the receiver.

The receiver analyzes incoming light and detects the changes and converts it to an electrical output signal. The emitter light source is light-emitting diodes (LED), a laser diode, or an infrared emitting diode that emit light when current is applied. The receiver of the photoelectric includes a phototransistor that generates a current when light falls upon it. In front of the receiver, optical components such as lens and aperture are embedded. The detection circuit is behind it, which can filter out the effective signal and make actions.

Generally, a photoelectric is made of the following components:

• Source LED

• Photodetector

• Lens (for source and detector)

• Power Circuit (modulator and demodulator)

• Amplifier

• Output Circuit

Incomplete units are identified in production by light curtain

Long-distance photoelectric sensors sense packs of shrink-wrapped cartons throughout high-volume packing process

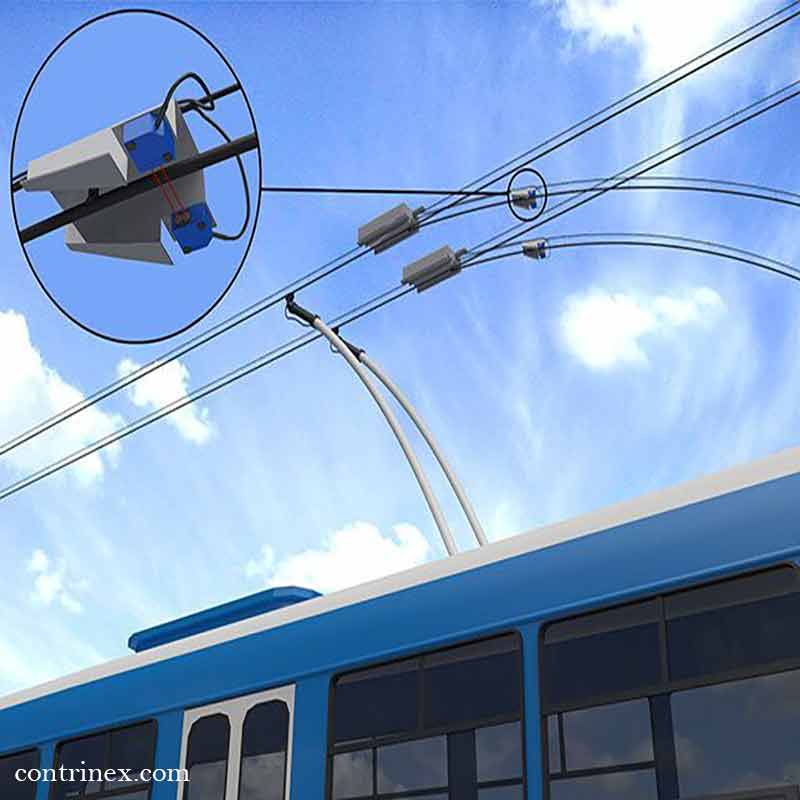

Current collector is identified by photoelectric sensor city trolley bus

Light Curtain

One type of photoelectric sensors used to protect precious objects or protect workers from potential hazards is the light curtain.

These days’ installation of safety devices is an essential need in the production lines that are enabled to act in a wide range of manual and automated functions to provide safety and productivity. So it is important to know about the features and functions of these devices.

Safety Light Curtain article is a place to discover the purpose and applications of safety light curtains, which help ensure user safety during routine operations and give information about light curtain, their working principle and their applications.

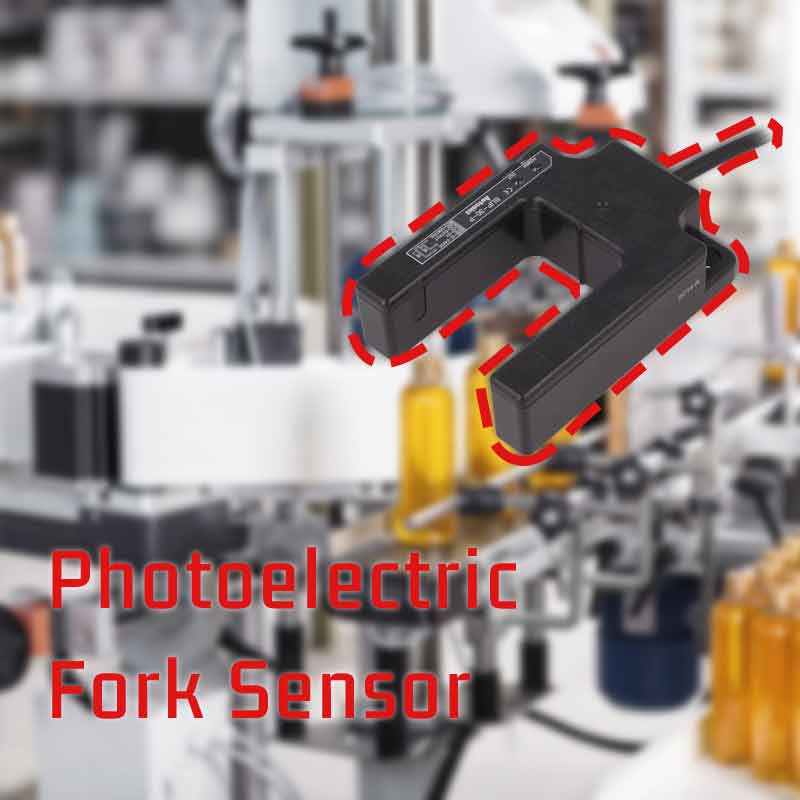

Fork Sensor

One of the most common types of photoelectric sensors is fork sensor which works by sending and receiving modulated light. The transmitter and receiver face each other in the two arms of the sensor and detect the presence or absence of the object. The Fork Sensor [How it Works, Features and Applications] article tries to provide a complete explanation of what a fork sensor is and explains the types, features and applications.

Color Sensor

The use of colors has greatly expanded since Galileo's discovery of the spectrum of colors through prisms and with the advent of computers, cell phones, and video media, the need for color recognition devices was felt more than ever; Therefore, devices were made for this purpose that could recognize colors.

With the advancement of science and technology, sensors have gained an important place in the industry. One of the sensors considered in industrial automation and production lines is the color sensor.

The basis of the work of these devices is based on the reflection of light from the surface of the material and recognition of the material color. Color Sensor [Working Principle, Feature, Industries and Applications] article takes a look at the color sensor that can detect a large number of colors, its working principle, and its application.

Contrast Sensor

On production lines and packaging conveyor belts photoelectric sensors help a lot by counting the right product and detecting faulty ones. There are other types of sensor which differentiate between two product based on color. These sensors are contrast sensors and are especially well suited for the detection of contrast differences between two products color or their back ground and the presence and absence of an object or mark.

In Contrast Sensor [How It Works, Adjusting, Features and Applications] article, we tried to provide you a complete explanation of what a contrast sensor is and its features and applications.

Laser Sensor

Laser sensors are one of the most accurate tools for measuring displacement, distance, and the position of the object in the industry. Laser sensors are optical sensors that use laser light to detect the objects and their distance.

These sensors are widely used in industry. In Laser Sensor [Working Principle, Types, Features, Applications] article, you will get learn about the concept of laser sensors, how they work, types of models, and also their application.

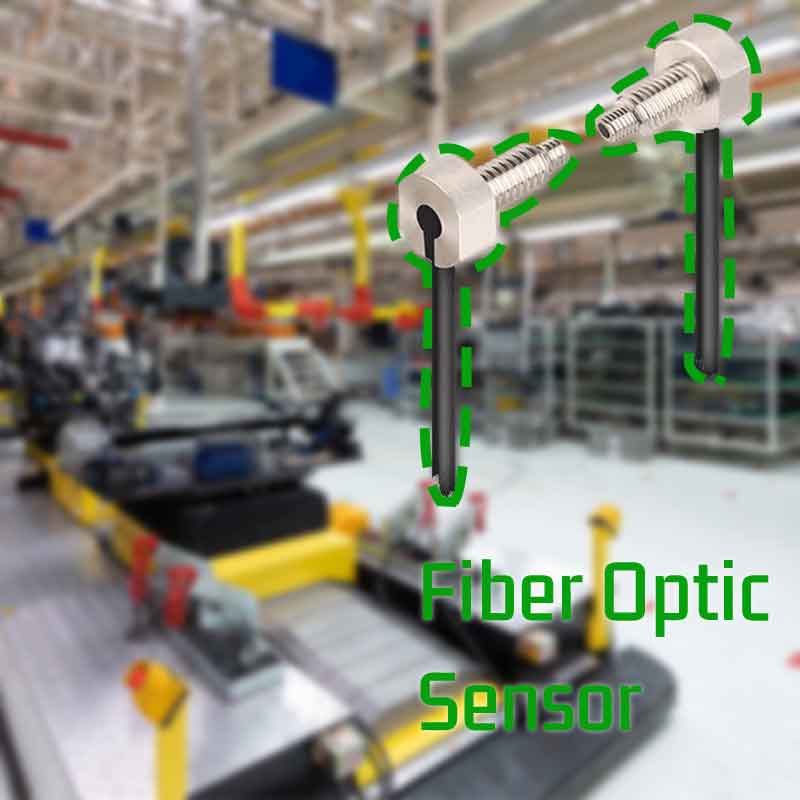

Fiber Optic Sensor

Needs for sensor miniaturization, versatile measurement solutions, and improving the performance of measurements in difficult operating environments have led to significant research on optical fiber sensors for multi-parametric measurements.

Fiber optic sensors not only activate the functions of the new sensors but can improve the achievable measurement performance for some of the most often measured parameters.

Fiber optic sensors are fiber-based devices using optical fibers to detect certain quantities and are mainly used in remote sensing applications.

Fiber Optic Sensor [Working Principle, Fiber Optic Cables Types, Features and Applications] article helps you to have understanding of the working principle, different types of sensors, features, and their application of fiber optic sensors.

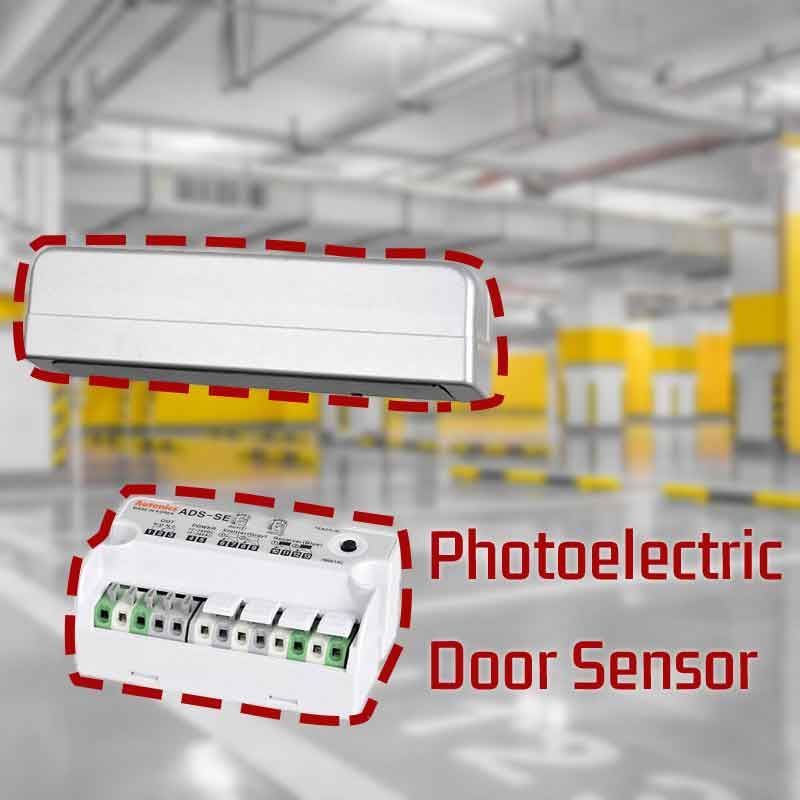

Door Sensor

Doors and windows are the main entrance parts of a house. One of the most widely used sensors in the security sector is smart door and window sensors.

Photoelectric door sensors work based on through beam sensor technology and when the light beam is cut off by an object or person it sends the electrical signal to the processor for the required action.

A house can benefit a great deal from door sensors. In Door Sensor [How it Works, Types and Advantages] article, we’re going to discuss an overview of every aspect of the door sensor, its working principle, types, and advantages.

Infrared Temperature Sensor

Sometimes measuring the temperature of an object is not possible with common contact temperature sensors and means, in such situation you need to use a solution which do this measurement non-contact. Infrared temperature sensors pick up the heat by the infrared light beam reflected from the target and gives you the number or send an electrical signal for your controller.

Read our article Infrared Temperature Sensor [How it Works, Applications, Advantage and Usage Considerations], to know the details on working principle, types and applications.

Photoelectric Sensor Terminology

LED: Light Emitting Diode

A semiconductor diode sends out light when an electric current passes through it. The component, construction ratio, and impurities of PN junction for improving single crystal made with gallium(Ga) to mixed crystal determine the color and brightness of the LED. There are different types of LED such as Infrared LED: Using P-N junction for GaAs, Red LED: Adding impurities Zn, O to GaP, Green LED: GaP/Green light-emitting/ Yellowish green-emitting is used because of its low efficiency, Yellowish green LED: Adding N to GaP / Higher emitting, efficiency than Green emitting.

IRED is the most common emitting element for a photoelectric sensor that has high emitting efficiency and large outputs. Also, Red or green LED is frequently selected based on applications.

Photodiode

A photodiode is a sort of diode that can convert light into either current or voltage when the light arrives at the P layer. PN or PIN junction utilized. Si is generally well suited for semiconductors. For getting optical signals with high response and frequency, the PIN photodiode is usually used as a receiving element. It can be used for photoelectric sensor’s receiving elements, PCM transmission for optical communication, and TV/ VTR remote controller’s receiving parts.

Phototransistor

Unlike photodiodes, a phototransistor has amplifying action by the transistor. Easy control can be achieved because of the high receiving sensitivity for Base current. Therefore, it exists in a wide range of photoelectric sensors.

Sensing target

It is a reference for measuring basic performance.

Beam angle

It indicates the angle range for normal sensing by the sensors.

Blind zone

The blind zone is produced on the surface in retro-reflective type, diffuse reflective type, narrow beam reflective type, convergent reflective type, and BGS reflective type photoelectric sensor or color mark sensor close to the emitter and receiver. None of the objects can be sensed in the blind zone, so when installing the product, the blind zone must be checked.

Operation mode

• Light ON

The sensor's output switching elements (transistor or Relay) will be ON when the emitting light reaches the receiver.

• Dark ON

The sensor's output switching elements (transistor or Relay) will be ON when the emitting light does not reach the receiver.

Hysteresis (reflective type)

It is defined as the distance difference between operating distance and returning distance.

Response time

The amount of time between the light received point and the point at which output operation becomes ON. Commonly, response time is indicated as operation time.

Advantages and Disadvantages of Photoelectric Sensor

Advantages

• It can sense all kinds of materials

• The sensor has long operation life, long-distance range, and very reliability

• Non-contact detection

• Fast Response Time

• Color Indentation

• Fewer Restrictions on Detecting Objects

• High Resolution

• High Accuracy

• Easy to Adjust

• low cost

• Used for almost all product types

Disadvantages

• Over time lenses get contaminated

• The color and reflectivity of the target can affect the sensing range

Photoelectric Sensor Application

• Barcode Scanner

• Counting manufactured products

• Defect detection in the appearance of products

• Detection of compounds inside metal cans

• locate the positioning of cars in the final assembly line

• Detection of change in color, contrast, and luminescence of target

• Detection of missing labels on bottles

• Used in Automatic doors

• Elevator cab detection

• Detecting reflective and small objects.

• Pallet detection for agricultural product lines

• Detection of tab threads

• Detection of parts for woodworking machines

• Accurate detection of cars in the parking lot

• Detection of the presence of transparent films (used in food, medical and chemical industries)

• Remote detection of glass layers

• Detection of low diameter pins (used in automation, machine tools, and robotics)

• Bottle cap position detection (used in food, medical and chemical industries)

• Detection of glass layers in vacuum chambers (used in electronics and semiconductors)

• Detection of transparent bottles (used in food, medical and chemical industries)

• Prevent twisting of textiles on the production line

• Remote detection of black tires (used in casting machines, rubber, and plastic)

• Detection objects in narrow spaces (used in automation, machine tools, and robotics)

• Detection of chips in taping machines