Safety Light Barrier

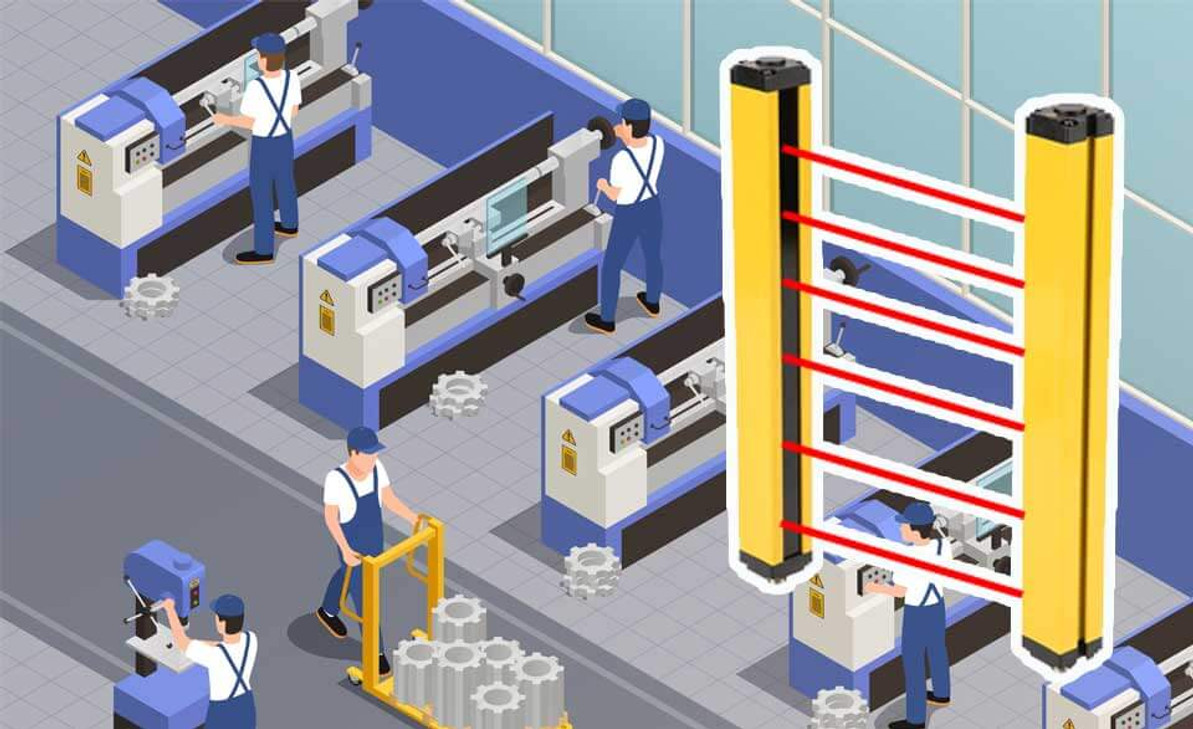

Light barrier sensors are a family of sensors and have many applications in the industry. A light barrier sensor, also named a safety light curtain sensor, light screen, and optical guard is a device that makes a virtual boundary around risk. It's used to protect valuable objects as well as to prevent access to dangerous and hazardous places in factories. Its products can be found in the Light curtain category.

Light barrier sensors are an advanced method of safeguarding personnel from dangerous machinery during routine operations like maintenance, whereas also giving the operator more freedom and flexibility in an industrial environment.

Dangerous machinery can be defined as any machine or piece of instrument that moves in a way that may cause harm or kill personnel.

How Light Barrier Made and How it Works

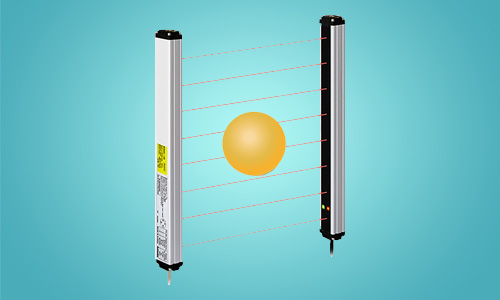

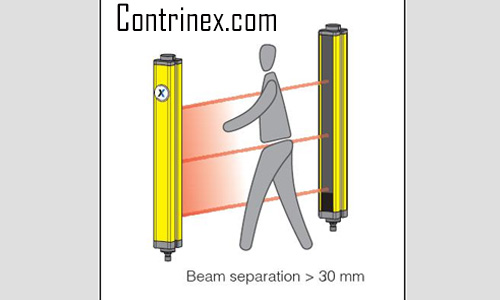

Light barriers are composed of a set of sensors or beams arranged in a vertical array with the different spacing configurations that make a barrier.

One of the advantages of light barriers is that they are simple and small compared to mechanical shields. The light barrier as it is a type of photoelectric sensor is made of two parts: a transmitter and a receiver.

They create a barrier of photoelectric cells between the transmitter and the receiver. The transmitter sends a set of synchronized, parallel infrared light beams to a receiver.

If an object passes through the barrier and enters in the sensing field, this presence is detected by the system and causes to trigger the connected device or stop the machinery.

The number of beams, the distance between the beams, and etc. are among the components that play an essential role in determining the type of application of light barriers.

Main specifications of Light Barrier

Types:

Defines the safety and self-monitoring instructions in the device. Light barriers are mainly available in two types,

- Type 4

- Type 2

Type 4 optical curtains are used to protect people and machines from damage and also to protect cars against damages. In this type of light curtain, the degree of accuracy is high and the control performed is very reliable. also, these curtains have different standards that can be used to design the safety-related parts of the control system.

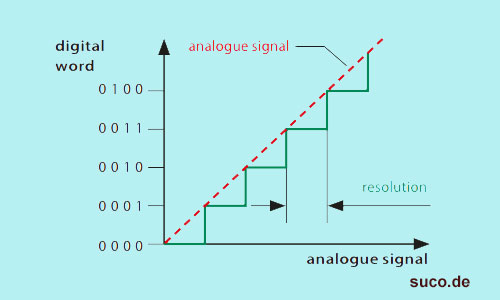

Resolution:

The resolution of a light barrier is actually the detection of object with the smallest physical size that, if placed in a controlled area, can be detected by the optical curtain and cause the curtain to stop the dangerous movement of the device.

This device can also have different resolutions or beam separations (e.g. 20 mm, 40 mm, 200 mm, etc.). if the resolution of the device is high, the detection capability of it is better for the safety light barrier, so the device can be installed closer to the hazard.

Protected Height:

It is the height that is detected and protected by the light barrier and must be chosen based on the access to the hazard.

If the light barrier is placed horizontally, this number will indicate the depth of the protected area.

Range:

The maximum operating distance that can exist between sender and receiver.

Response Time:

It is the time for the light barrier to produce an alarm signal after detecting an object or person in the danger zone.

Light Barrier Types Based on Application

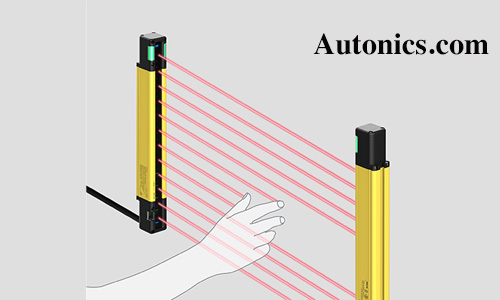

Finger Protection:

In this type of light barrier, the number of beams is high and the distance between the beams is very small. This type of light barrier is used in very sensitive cases.

Due to the high number of beams and also the short distance of the beams, this type of light barrier is capable of detecting very small objects about the size of a human hand.

Hand Protection:

In this type of light barriers, the number of beams is less and the distance of the beams is more than in the previous case, but nevertheless, this type of light barrier also has acceptable accuracy and resolution.

Access Control Barriers:

This type of light barrier has 3 to 6 beams and generally, the distance between the beams is 300, 400, and 500 mm. This type of light barrier is used to protect people from possible dangers.

Features and Advantages of light barriers:

- Provide effective protection and safety in case of operator fatigue or distraction

- Limit and reduce the risk of any external interference, because any manipulation in the area under the control of the light barrier, will stop the operation of the device.

- Quick and easy installation, with great flexibility for installation on devices even in cases where there is a need to constantly relocate the device.

- The possibility of establishing protection on a large scale, linearly or over an environment, in different directions at a low cost.

- Increase the useful life of devices and machines

- These devices meet the highest safety standards

Applications of the light barrier

Manufacturers and industrial facilities employ light barriers as a safety mechanism in two general situations: point of operation and perimeter.

Point of operation: For these guards, users install a light barrier at the site of material handling, such as under a hydraulic press, to ensure that no one can enter the danger zone while the machine is operating.

Perimeter: In contrast, perimeter guards refer to outlining a whole working space or room, such as for a robotic arm. These guards can ensure that no person or object enters the boundary of the machine’s movement.

They used in:

- Train station

- Elevators and lifts

- Production lines

- Pressing machine

- Mechanical and hydraulic power presses

- Molding presses

- Stamping

- Forming

- Riveting

- Eyelet

- Automated assembly machinery

Listed below are articles you might find interesting:

Dubai top selling safety light curtain brands in 2022

Photoelectric Sensor (Different Types, Applications, Advantages and Disadvantages)

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025