Sensors Types [Simple Explanation of Each Type]

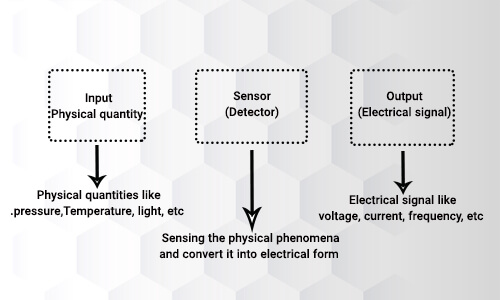

A sensor is an electrical device. It converts physical parameters into continuous or discontinuous electrical quantities. Some examples of these physical parameters are pressure, light intensity, temperature, and movement. The output of an electrical sensor is an analog or digital signal. This signal is transmitted to hardware for the required processing.

Browse our wide selection of Sensors Types products category with the highest quality.

Each sensor has different operating principles. These principles depend on the structure and physical parameters it measures. Sensors are one of the most used industrial automation equipment. They act like the five human senses for machines. Sensors are integral parts of automatic control devices. It's because of their function and ability to connect to various devices such as PLCs. In a general classification, we can divide sensors used in the industry into two categories:

- contact sensors

- non contact sensors

Contact Sensors

As mentioned before, sensors sense an object's physical quantity and send a signal. Some of these quantities are temperature, pressure, and heat. Contact sensors need physical contact with the object to do so.

Non-contact Sensors

Non-contact sensors, yet, operate at a distance from the object. As their name represents, they don't need contact with the object. For example, as an object approaches, they sense its existence and become active.

The construction of these sensors is generally more complex than the contact type. They also have higher speed and accuracy. Some examples of these sensors are capacitive sensor, inductive proximity sensor, ultrasonic sensor, etc.

Non contact sensors have several advantages: long operating life, high switching speed, and no need to touch the object to name a few.

Different Types of Sensors

There are different types of sensors, each with different applications and functions. The following is a list of different kinds of sensors available in Dubai sensor:

- Proximity Sensor

- Photoelectric Sensor

- Capacitive Sensor

- Ultrasonic Sensor

- Pressure Sensor

- Pressure Switch

- Pressure Gauge

- Rotary encoder

- Temperature Sensor

- Distance Sensor

- Color Sensor

- Contrast Sensor

- Vision Sensor

- RFID

Below, we discuss the above-mentioned sensors in brief.

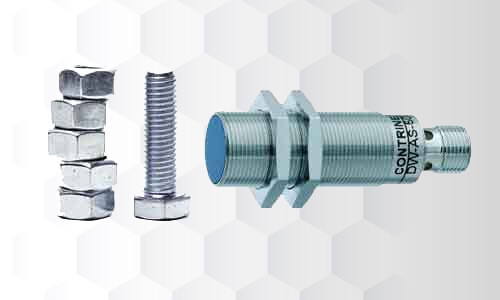

Proximity Sensor

One of the most used types of sensors is the proximity sensor. This device detects the presence of objects nearby without requiring physical contact.

This contactless or proximity sensor can only detect metallic objects. To do that, it uses currents induced by magnetic fields.

The proximity sensor uses a coil (inductor) to generate a high-frequency magnetic field. If there is a metal object near the magnetic field, the current begins to induce in the object. Check our article on the inductive sensor working principle to know more.

Check our article on the inductive sensor working principle to know more.

A proximity sensor is often used in applications that need high accuracy, safety, and reliability. You can also use them in harsh environmental conditions.

These sensors are important parts of industrial automation. Some of their applications are to detect the presence of metal objects in:

- electronics,

- mechanics,

- automobile (forklift, car, truck, etc.),

- plastic and rubber,

- and food industries.

Click on the following link, in case you'd like to view our inventory on the Inductive Sensor.

Photoelectric Sensor

The operation of a photoelectric sensor is based on a light beam that is either reflected from the object or cut off. The sensor can detect the presence or absence of an object by changing the light.

The sensor is made of a light source, an amplifier, a signal converter, and an output.

These types of sensors are used to detect most materials such as metal, plastic, and wood. They can even detect clear items like glass, plastic, and liquids depending on the type of sensor.

The three most common types of this sensor are:

- Through-beam

- Retro reflective

- Diffused photoelectric sensor

You can use them in a wide range of applications in factory automation. To name a few:

- detection of empty and transparent bottles in production lines,

- conveyors,

- gates,

- and entrance doors.

Like any other device, these sensors have multiple pros and cons. Check out our article to get the full report on photoelectric sensor advantages and disadvantages.

Check our article to read more about photoelectric sensor advantages.

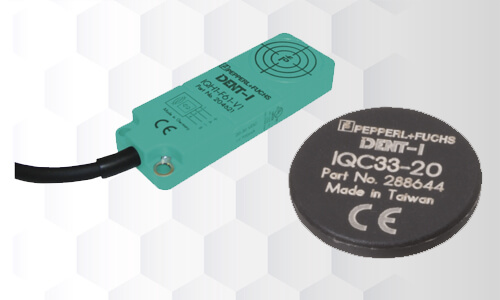

Capacitive Sensor

A capacitive sensor is a non-contact sensor. It can detect the presence or absence of metallic and non-metallic objects.

As its name declares, a capacitive proximity sensor acts similar to a capacitor. As its name declares, a capacitive sensor acts like a capacitor. A metal plate in the sensor is connected to an internal oscillator. The sensing target acts as the second plate of the capacitor. This way the capacitive sensor generates an electrostatic field and senses the object based on this field.

These sensors consist of four parts: amplifier, Schmidt Tracker, Demodulator, and Oscillators.

They are sensitive to everything. That's one of the reasons why you can use them in several applications:

- controlling the levels of tanks,

- counting objects in the Production line,

- separation of metal parts from non-metal,

- control of Fabric movement,

- detecting longitudinal tears of a conveyor belt

- and controlling surfaces in tanks filled with powder, liquid, or granular material.

But that’s not all. Check our article on capacitive sensor applications to know more.

Ultrasonic Sensors

The ultrasonic sensor is another type of contactless sensor. This sensor uses ultrasonic sound waves to measure the distance of an object. Its structure consists of a sound transmitter source and a receiver.

The sensing target reflects the high-frequency sound waves, creating distinct echo patterns. The ultrasonic sensor receives pulses. This way it gets information about the presence of an object.

The most common use of ultrasonic sensors is to measure distance in small and large projects. Some of these applications are:

- Obstacle-avoiding robots

- people detection

- presence detection

- box sorting

- bottle counting

Another popular application of ultrasonic sensors is the measurement of liquid levels, no matter what color the liquid is. That's because these sensors are not affected by the color of the objects.

Pressure Sensor

In most industrial process control, pressure measurement is very important. The pressure sensor converts the pressure information into an electrical signal.

They are generally used to control and monitor the pressure of liquids and gases. Pressure sensors also have the ability to measure a variety of variables indirectly.

Here is a simple explanation of a pressure sensor working principle: applied pressure to them makes diaphragm deformation. This change occurs due to differences in pressure applied on both sides of the sensor.

The choice of pressure sensor type can vary depending on where it is used and whether it is used in harsh or corrosive conditions or in medical equipment or moving instruments.

Are you curious about pressure sensor types? Check out our article to know more about them, especially the difference between transmitter and transducer.

Pressure Switch

A pressure switch is a device that operates an electrical contact when preset fluid pressure is reached.

The switch makes an electrical contact on either pressure rise or pressure fall from a certain preset pressure level.

Typically, the pressure switch is activated mechanically, like a pressure gauge with Bourdon or diaphragm mechanisms, and the jumper at the set point or relay setting and acts as an On and Off controller with its contact command at the output.

Pressure switches play an important role in establishing safety and control in pressurized systems, also they have different types according to use, working pressure, and fluid.

They are used in systems that work with pressure and need to be turned on and off at a certain pressure range and in boilers, gas compressors, automobiles, Pumping systems, steam turbines, steam power plants.

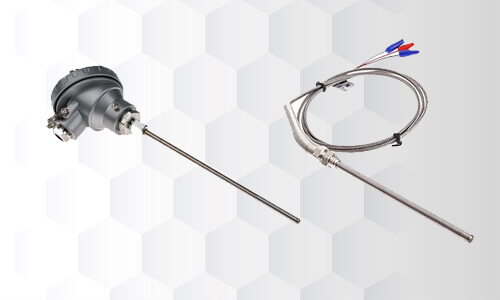

Temperature Sensor

A temperature sensor is a device that converts measured temperature into an electrical signal. Temperature sensors are available in different types, shapes, and sizes.

In general, temperature measurement methods can be divided into two categories:

contact:

non-contact: Infrared light is used to measure temperature in the non-contact method, and it can measure its temperature without the sensor touching the target object.

When the temperature of an object is measured by direct contact with it, such temperature sensors fall into the group of contact types such as RTDs, Thermocouples. They can be used to detect solids, liquids, or gases over a wide range of temperatures.

Encoder

A rotary encoder is a type of motion sensor and the name of a device that gives you a pulse by rotating its shaft at the output.

More fully, the encoder is a sensor that attaches to the axis of the gear or motor and can measure the amount of rotation, and by measuring the amount of rotation you can determine the "speed", acceleration, or angle of rotation.

Encoders are usually optical, with a transmitter and an infrared receiver on either side of a rotating mechanical object that generates electrical pulses.

They are in two categories: rotary and linear. They are used in industry and factories, steel factories, textile machines, wood and CNC cutting machines, ceramic tile production machines, and cement factories.

want to know more? Click on the link to get the full report on the rotary encoder working principle.

Distance Sensors

A distance sensor is a sensor that measures the distance of an object without physical contact. In these sensors, the distance measurement method is based on sending and receiving a type of signal.

A signal is sent with specific characteristics and then the characteristics of the return signal such as return time, change in signal shape, and so on are checked.

They use technologies like laser, IR (infrared) triangulation, ultrasonic, LED-TOF (light-emitting diode-time-of-flight).

These types of sensors are used in many industrial applications and processes. They are usually used to control the quality or accurate location of products.

Color Sensor

Color sensors are used for detecting the color of the target object. These types of sensors act like human eyes and work based on the reflection of light from the surface of the object.

Color sensors detect waves emitted by the object and then report it in one of the currents, voltage, or frequencies types. Color sensors are also widely used in industry, medical and security systems, for example, to classify products based on color.

Contrast Sensor

It is a high-efficiency device that is used to distinguish between two colors. These colors are usually used in print marks and backgrounds.

Contrast sensor evaluates the process of detecting the brightness or level of light received from the sample provided to the sensor.

For each new sample presented, the sensor compares the value of the new sample with what was taught to determine if it looks more like a print mark or a background.

For better performance, most contrast sensors use color-variable LEDs, which allow the detection of very small contrasts. The color of the emitted light is automatically selected based on the sensor conditions.

Contrast sensor applications and industries:

- Printing machines

- Packaging plants

- Labeling machines

- Food, beverage

- Pharmaceutical industries

Vision Sensors

A vision sensor is an easy-to-use camera product that is used as a solution for image-processing tasks and inspects, positions, and measures parts and also reads codes.

Visions sensors are adjusted using parameters. Features like area, the center of gravity, length, or position, and outputs the data or judgment results rendered by these sensors.

When color, light, or structure plays a role in the detection process a vision sensor is used. They are suitable for controlling the quality applications including presence/absence verification, matching, label inspection, verifying the correct color or shade of an object, etc.

RFID

RFID stands for Radio Frequency Identification, which means identification through radio waves, and is actually a wireless identification system capable of exchanging data by establishing information between a reader (tag reader) and a tag (identifier)attached to a product, object, card, etc. is.

In other words, RFID systems use electronic and electromagnetic signals to read and write data without contact.

RFID technology is one of the new methods of automatic identification and electronic data collection, in which equipment, whether hardware or software, can read and recognize data without the intervention of manpower, including barcodes, two-dimensional codes, fingerprint systems, and corneal and voice recognition systems.

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025

![Sensors Types [Simple Explanation of Each Type] Sensors Types [Simple Explanation of Each Type]](https://cdn11.bigcommerce.com/s-sgprcd6/images/stencil/1193x795/uploaded_images/sensor.jpg?t=1644402632)