Measuring Principle of Pressure Sensors

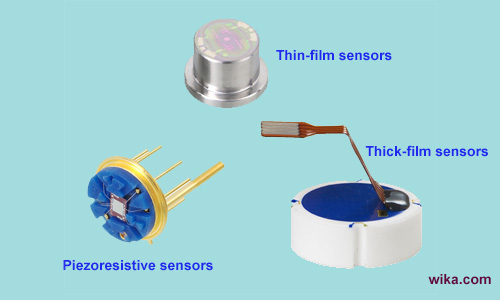

Pressure sensing devices detect the changes in the pressure in gasses or liquids and convert them with high accuracy to an electrical output signal that is proportional to the pressure. This electrical output signal is used to represent the magnitude of the pressure. Electronic pressure sensors use several different technologies or sensing principles capable of converting pressure into a measurable and standardized electrical signal. The pressure sensor technology used in a pressure sensor can be important based on the application. Pressure sensors are made with different technologies, some of them that are explained in this article are;

- Thin-film sensors

- Thick-film sensors

- Piezoresistive sensors

You can see our selection of pressure sensor by clicking here.

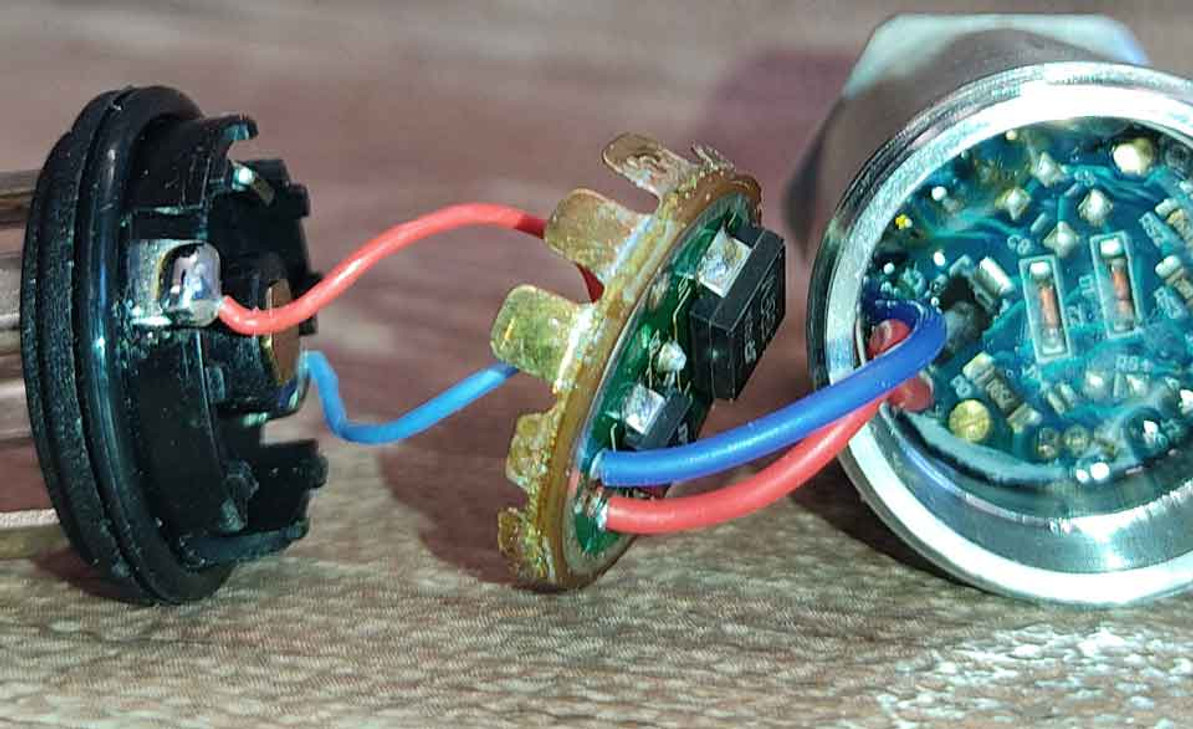

Thin-film sensors

Pressure measurement in this sensor is based on strain gauge technology. There are a total of four resistors that are arranged on a diaphragm to form a Wheatstone bridge. Tap here to get more information about Pressure measurement.

The change in resistance due to deformation of the diaphragm as a result of pressure is measured to determine the pressure.

In thin-film sensors, the membrane is both the separator and the membrane and there is no need for internal transmission fluid.

This technology is provided only to measure the relative pressure because the creation of a vacuum behind the membrane requires a wide effort in terms of construction.

The advantage of the thin- film is its excellent ability to be resistant to high peak pressures and bursting pressures. Also, extremely high pressures can be measured even when there are high shock and vibration loads.

Thick-film sensors

This sensor also utilizes strain gauge concepts, and uses a ceramic base. Thick-film sensors, like thin-film sensors, are also based on the Wheatstone bridge principle.

Here, the resistors are applied to a ceramic sensor body. The change in resistance due to deformation of the diaphragm as a result of pressure is measured to determine the pressure.

When producing this type of sensor, the resistors are printed on the body of the sensor and baked at a high temperature. Resistors and other circuits are set on a membrane using a thick film process.

Thick film sensors provide long-term stability and good corrosion resistance. Since ceramics cannot be welded to the process connection, it is necessary for using media separation.

Step here to view information's about ZHYQ, one of leaders in pressure measuring field.

Piezoresistive sensors

Piezoresistive sensors have a more complex structure in contrast to the previously mentioned sensors. Piezoresistive pressure sensors use the change in electrical resistance of a strain gauge connected to the semiconductor measuring diaphragm in which piezo-resistive resistors are placed and are exposed to the pressure medium.

By changing the shape of the diaphragm, created by compression or expansion due to the applied pressure, the pressure measurement is taken by the piezoresistive effect.

The material used in most sensors of this type is silicon. This type of measurement technology is most often suitable for use in high dynamic pressures.

| Thin-film sensors | Thick-film sensors | Piezoresistive sensors | |

| Measurement of the absolute pressure | * | - | |

| Very low pressure ranges | - | ||

| Very high pressure ranges | - | ||

| Shock and vibration resistance | - | * | * |

| Long term stability | - | * | - |

- Requirement fulfilled

* Requirement partly fulfilled

Please refer to other pressure sensor articles for more information:

An Eye-Opening Guide To Pressure sensor Types: Everything You Need To Know

Process Connection or Fitting for Pressure Transmitter

Certificates and Approvals Related to Pressure Transmitters

Special Types of Pressure Sensors

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecting millions …16th Apr 2025