Process Connection or Fitting for Pressure Transmitter

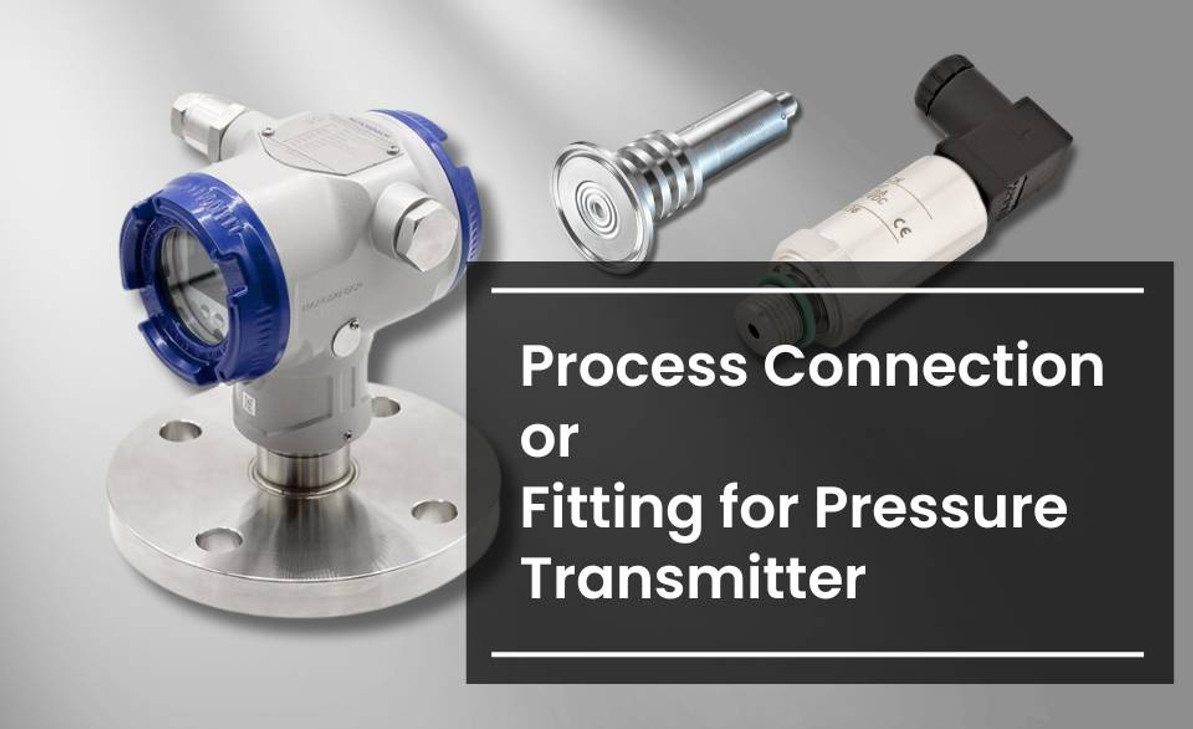

Fig 1. Pressure sensor different mounts

Process Connection or Fitting of a Pressure Transmitter

The process connection or fitting of a pressure transmitter depends on various factors such as the type of pressure being measured, the environment, and the specific requirements of the application. Here are some common types of process connections used for pressure transmitters:

- NPT (National Pipe Thread): This is a tapered thread commonly used in the United States for smaller pipes.

- BSP (British Standard Pipe): Often used in Europe and some other countries, it comes in parallel (BSPP) and tapered (BSPT) versions.

- Metric Threads: Common in many parts of the world for various applications.

- Raised Face Flanges: These have a raised surface and are used in higher-pressure applications.

- Flat Face Flanges: Used in lower-pressure applications where space is limited.

- Ring Type Joint (RTJ) Flanges: Suitable for high-pressure and high-temperature applications.

Consulting the manufacturer's guidelines and understanding the specific needs of your application is crucial in selecting the appropriate process connection or fitting for a pressure transmitter.

What does "process connection" mean in pressure sensors?

In pressure sensors, the term "process connection" refers to the physical interface or means by which the sensor is connected to the system or process where pressure measurement is required. It's essentially the point where the sensor interacts with the media (gas, liquid, etc.) whose pressure it's measuring.

Process connections are crucial because they ensure a reliable and secure connection between the pressure sensor and the monitored system. They vary in design and type based on the specific application requirements, the nature of the measured media, pressure levels, environmental conditions, and industry standards.

The choice of a process connection can significantly impact the sensor's performance, accuracy, reliability, and longevity. Different types of process connections include threaded connections (NPT, BSP, metric threads), flanged connections, tri-clamp connections, compression fittings, and welded connections, among others.

Factors such as pressure range, compatibility with the media being measured, installation ease, resistance to corrosion, and the need for maintenance or disassembly often influence the selection of a suitable process connection for a pressure sensor. Therefore, selecting the right process connection is an essential consideration in ensuring the optimal functioning of the pressure sensor within its intended application.

Threaded Connections

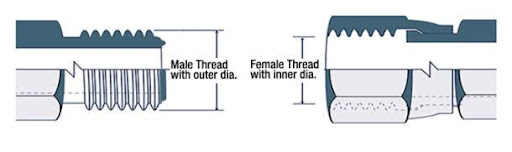

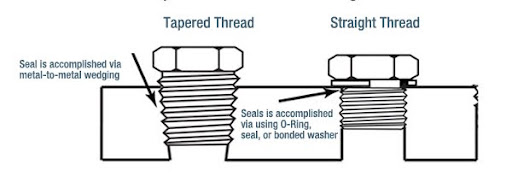

Threaded connections are a prevalent means of attaching pressure sensors to systems requiring pressure measurement. These connections utilize threads to secure the sensor onto the designated port or opening in the system.

The National Pipe Thread (NPT) is a common type of threaded connection used in the United States for pressure sensors. It features a tapered thread design that creates a seal by wedging the threads together, preventing leakage when properly tightened. This tapering characteristic aids in creating a secure and leak-resistant joint, crucial for accurate pressure measurements.

Another type is the British Standard Pipe (BSP) thread, commonly utilized in Europe and various other regions. BSP threads come in two main variations: the parallel (BSPP) and tapered (BSPT) threads. Similar to NPT threads, these threads also create a seal by joining together, ensuring a tight connection between the sensor and the system.

Metric threads, while less common in certain regions, are also used for pressure sensor connections in various parts of the world. They follow standardized metric measurements for threading and can be found in applications where metric-based systems are prevalent.

Threaded connections offer advantages such as ease of installation, especially in situations where frequent disassembly and reassembly might be necessary for maintenance or adjustments. However, proper care is crucial during installation to avoid damaging the threads, which could lead to leaks or inaccurate pressure readings.

Choosing the appropriate threaded connection for a pressure sensor involves considering factors such as the pressure range, compatibility with the measured media, adherence to industry standards, and environmental conditions. Additionally, utilizing sealants or thread tapes compatible with the system's requirements can further enhance the effectiveness of threaded connections, ensuring reliable and accurate pressure measurements.

Fig 2. Different type of threads

How to Choose Thread Process Connections?

Selecting the appropriate thread process connection for a pressure sensor involves considering several key factors to ensure compatibility, reliability, and performance within the intended application:

What does BSP stand for?

BSP stands for British Standard Pipe. It's a set of technical standards for threaded pipes and fittings used in various countries, particularly in the United Kingdom and many parts of Europe. BSP threads come in two primary variations: BSP Parallel (BSPP) and BSP Tapered (BSPT). These standards dictate the dimensions, thread angles, and tolerances for creating a reliable and standardized connection between pipes, fittings, and other components in plumbing, hydraulic, and other fluid-based systems.

Fig 3. BSPP pressure mount

What is BSPT?

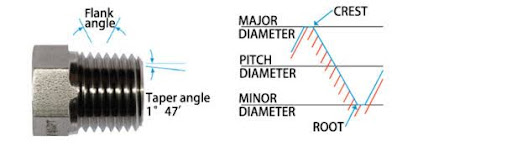

BSPT stands for British Standard Pipe Taper. It's a type of threading commonly used in pipes and fittings, particularly in the United Kingdom and various parts of Europe. BSPT threads are tapered, meaning the diameter of the threads gets smaller towards the end.

This tapering design is intended to create a tight seal when the male and female threads are joined together. The wedging action achieves the sealing as the threads are tightened, helping to prevent leakage in applications where maintaining a secure connection is crucial, such as in plumbing and fluid systems. BSPT threads are widely used in various industries and are an integral part of the British Standard Pipe standards.

Fig 4. BSPT mount type

Where can use the BSP?

BSP (British Standard Pipe) threads are used in various industries and applications where a reliable and standardized threaded connection is required for pipes, fittings, and other components. Here are some common areas where BSP threads are employed:

Which pressure sensors do have BSP fitting?

Pressure sensors with BSP (British Standard Pipe) fittings are available from various manufacturers across different industries. These sensors are designed specifically to integrate seamlessly with systems that utilize BSP threads for pressure measurement applications.

Pressure sensors with BSP fittings can be found in different types and variations, including:

How is a BSP shape and angels?

BSP (British Standard Pipe) threads come in two main variations: BSP Parallel (BSPP) and BSP Tapered (BSPT). Each variation has its specific shape and angles.

- Shape: BSPP threads have a cylindrical shape without a taper. The threads maintain a consistent diameter along the length of the threaded portion.

- Angles: The threads have a 55-degree angle. This means that the tops and bottoms of the threads are cut at a 55-degree angle to the center axis of the pipe.

- Shape: BSPT threads are tapered, meaning the diameter of the threads reduces gradually towards the end. The taper helps in creating a tight seal when the threads are connected.

- Angles: BSPT threads have a 55-degree included angle. The difference between BSPP and BSPT lies in the tapering angle and the sealing mechanism, with BSPT using the taper to create a seal.

Fig 4. threads angle

What is NPT?

NPT stands for National Pipe Thread, a standardized thread type used in the United States for creating connections between pipes and fittings in plumbing and fluid systems. NPT threads are known for their tapered design, which helps create a seal between the male and female threaded components.

Key features of NPT threads include

| UNC (2A) | UNF (2A) | ||||||

| Nominal Diameter | Major Diameter (mm) | Minor Diameter (mm) | TPI | Nominal Diameter | Major Diameter (mm) | Minor Diameter (mm) | TPI |

| 1/4” x 20 UNC | 6,322 | 4,978 | 20 | 1/4” x 28 UNF | 6,325 | 5,360 | 28 |

| 5/16” x 18 UNC | 7,907 | 6,401 | 18 | 5/16” x 24 UNF | 7,910 | 6,782 | 24 |

| 3/8” x 16 UNC | 9,491 | 7,798 | 16 | 3/8” x 24 UNF | 9,497 | 8,382 | 24 |

| 7/16” x 14 UNC | 11,076 | 9,144 | 14 | 7/16” x 20 UNF | 11,079 | 9,728 | 20 |

| 1/2” x 13 UNC | 12,661 | 10,592 | 13 | 1/2” x 20 UNF | 12,667 | 11,328 | 20 |

| 5/8” x 11 UNC | 15,834 | 13,386 | 11 | 5/8” x 18 UNF | 15,839 | 14,351 | 18 |

| 3/4” x 10 UNC | 19,004 | 16,307 | 10 | 3/4” x 16 UNF | 19,012 | 17,323 | 16 |

| 7/8” x 9 UNC | 22,176 | 19,177 | 9 | 7/8” x 14 UNF | 22,184 | 20,269 | 14 |

| 1” x 8 UNC | 25,349 | 21,971 | 8 | 1” x 12 UNF | 25,354 | 23,114 | 12 |

| 2” x 4,5 UNC | 50,726 | 44,679 | 4.5 | ||||

Hygienic

A hygienic process adapter system has been specifically developed to meet the requirements of the food, beverage, and pharmaceutical industries.

These industries need processing machines to be cleaned with detergents, or sterilized, with superheated steam and include precautions against contamination in their manufacturing processes.

Hygienic devices have highly polished stainless steel components exposed to the process media and are installed using clamped seals.

European Association EHEDG (European Hygienic Engineering & Design Group) and US regulations “ASME BPE” are different regulations that set guidelines for all parts used, including measuring equipment, to ensure optimum cleanability.

A very significant task is to prevent clearances, which means spaces that are so difficult to access that residues of media can remain there. Also, the surface roughness of the materials used should be as low as possible to avoid adhesion.

Popular types of hygienic connections are the Clamp, DRD, Variant, and Dairy Fitting.

Clamp

Clamp connections are a subcategory of sanitary fittings and are widely used in sanitary applications and the food, beverage, biotech, and pharmaceutical industries.

It is a means of connecting measuring instruments to process tubes in an aseptic manner and without clearances.

So, this connection type is mainly used in processes where hygiene and cleanability are particularly important, and increased cleaning effort is necessary to minimize the potential risks and eliminate contamination, bacterial growth, leaks, and deterioration of the connection material.

Fig 8. Clamp thread

Clamp connections are made up of two flanged ends, a gasket, and a clamp to secure the connection. Two flanged ends mate together with a gasket between their two faces.

There are different clamp types including two-segment single hinge, three-segment double hinge, and two-bolt high pressure. There are different sizes of clamp connections expressed by two separate parameters, the sealing face flange diameter and the diameter of the pipe.

DRD

The DRD connection is provided to connect equipment to the vessel. This connection reaches flush-mounted integration. The sealing is achieved by a common flat sealing.

Fig 9. DRD type

The device is fixed by 4 screws that minimize risks while opening the flange even if there is pressure on the process. It is most commonly used in the food industry.

Variant

The Variant process connection is a type of flush flange connection. It is similar to the Clamp connection in that it depends on a clamp to hold the flange of the sensor together with a matching flange on the process fitting.

Variant connections provide an O-ring seal around the internal diameter of the connection. Variant connections are widely used in breweries, dairies, and other food applications.

Dairy Fitting

This type of aseptic process connection, defined in the German standard DIN 11851, was developed for the design of pipe works in milk and food processing.

This connection has round thread screw connections. In the production line, it's important to minimize the risk of contamination and stagnation in the pipe systems.

Fig 10. Dairy fitting

Dairy fittings for milk have inside and outside sufficient smoothness and can be easily dismantled and cleaned and consist of a round slotted nut, a welded male piece, a liner piece the nut slides over, and a gasket.

Because of its design, it can also provide the hygienic requirements of the food industry as well as the pharmaceutical and chemical industries.

| Thread Type | Standard | Highlight Features | Common Materials | Limitations | Suitable Industries |

| NPT (National Pipe Thread) | ANSI | Easy installation, tapered design for tight fit | Stainless steel, brass, carbon steel, Hastelloy, Monel | Potential for leaks, not suitable for ultra-high pressure | Oil and gas, water treatment, HVAC, process industries |

| BSP (British Standard Pipe) | BSI | Parallel and tapered types available, globally recognized | Stainless steel, brass, carbon steel, Hastelloy, Monel | Requires thread sealant, not ideal for high-pressure applications | Oil and gas, water treatment, HVAC, process industries |

| Metric | ISO | Globally recognized, various pitch options | Stainless steel, brass, carbon steel, Hastelloy, Monel | Not universally compatible, may require thread sealant | Automotive, industrial machinery, process industries |

| SAE Straight Thread (O-ring Boss) | SAE J1926 | Straight thread with O-ring seal, high-pressure compatibility | Stainless steel, brass, carbon steel, Hastelloy, Monel | Limited adjustability due to O-ring | Hydraulic systems, aerospace, automotive |

| UN/UNF (Unified National, Coarse/Fine) | ASME B1.1 | Coarse and fine thread options, widely used in North America | Stainless steel, brass, carbon steel, Hastelloy, Monel | Not universally compatible, may require thread sealant | Automotive, industrial machinery, aerospace |

| G-series (ISO/BSP Parallel) | ISO 228 | Parallel design, requires gasket or O-ring for sealing | Stainless steel, brass, carbon steel, Hastelloy, Monel | Not ideal for high-pressure applications, requires separate seal | Water treatment, HVAC, automotive, process industries |

| JIC (Joint Industrial Council) Fittings | SAE J514 | 37-degree flare for tight seal, high-pressure compatibility | Stainless steel, brass, carbon steel, Hastelloy, Monel | Specialized design, not a threaded connection | Hydraulic systems, aerospace, automotive |

| Thread Type | Nominal Diameter | Thread Pitch | Max Pressure Rating |

| NPT1/2 | 0.5 in (12.7 mm) | 14 TPI | 1500 psi (10.34 MPa) |

| NPT1/4 | 0.25 in (6.35 mm) | 18 TPI | 1000 psi (6.89 MPa) |

| NPT1/8 | 0.125 in (3.18 mm) | 27 TPI | 500 psi (3.45 MPa) |

| G1/2 | 0.5 in (12.7 mm) | 14 TPI | 1500 psi (10.34 MPa) |

| G1/4 | 0.25 in (6.35 mm) | 19 TPI | 1000 psi (6.89 MPa) |

| M20x1.5 | 20 mm | 1.5 mm | 1500 psi (10.34 MPa) |

| M12x1.5 | 12 mm | 1.5 mm | 1000 psi (6.89 MPa) |

| R1/4 | 0.25 in (6.35 mm) | 19 TPI | 1000 psi (6.89 MPa) |

| R1/8 | 0.125 in (3.18 mm) | 28 TPI | 500 psi (3.45 MPa) |

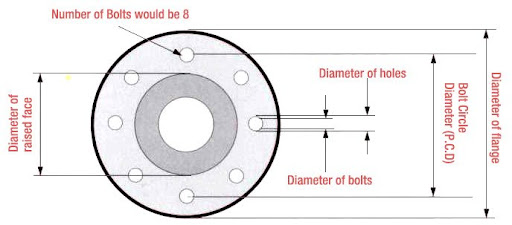

Flanged Connections

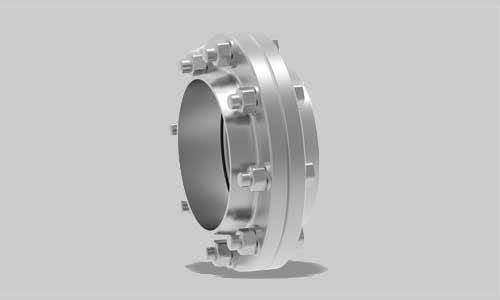

A flange is a method of process connection used for creating airtight and removable connections between segments of a tube.

A flanged connection consists of three parts:

- Pipe Flanges

- Gasket

- Bolting

Flanged connections are made by bolting together two flanges with a gasket between them to create a seal. The gasket is placed between the two circular seal points, which are usually tightly joined with screws.

Fig 11. Flanged connection

The following are standard flange systems:

- GB series (national standard)

- JB series (mechanical department)

- HG series (Ministry of Chemical Engineering)

- ASME B16.5 (American standard)

- BS4504 (British standard)

- DIN (German standard)

- JIS (Japanese standard)

Among the above flange systems, the two main used ones are the German DIN and the American ANSI.

There are five types of flange connections:

- Flat welding

- Butt welding

- Socket welding

- Loose sleeve

- Thread

Flanged Connection Types

Flanged connections are widely used in various industries and applications to create secure and reliable joints between pipes, valves, and other equipment. There are several types of flanged connections, each designed for specific purposes and operating conditions:

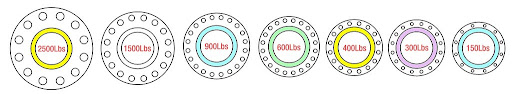

Fig 12. Transmitter Flange Pressure Class under ASME Standard 1

What are the differences between threaded connections and Flanged Connections?

Threaded connections and flanged connections are two common methods used to join pipes, valves, and fittings in various applications, but they differ in several aspects:

- Threaded Connections: Involve screwing two threaded components together, creating a secure joint. Threads can be tapered (like NPT) or parallel (like BSP) and are directly engaged to form the connection.

- Flanged Connections: Utilize two mating flanges with bolt holes and gaskets. The flanges are bolted together to create a sealed joint, often using gaskets or sealants for added security. Flanged connections can have raised faces, flat faces, or special designs like tongue and groove or ring-type joints.

- Threaded Connections: Generally easier to install compared to flanged connections. They require less space and involve simply screwing the components together, making them suitable for smaller pipes and quick installations.

- Flanged Connections: Usually require more space and alignment during installation. They involve aligning two flanges, inserting gaskets, and tightening bolts uniformly to achieve a leak-tight seal.

- Threaded Connections: Generally used in lower-pressure applications due to potential leak points and limitations in handling high pressures and temperatures. Tapered threads like NPT may not handle extreme pressures well.

- Flanged Connections: Preferred for higher-pressure and temperature applications, especially when properly sealed with gaskets. Flanged joints can handle a wider range of pressures and temperatures due to their robust design and sealing mechanisms.

- Threaded Connections: These can be easier to disassemble for maintenance or modifications due to their simpler structure. However, repeated disassembly and reassembly may affect the integrity of the threads.

- Flanged Connections: This may require more effort for disassembly due to multiple bolts and gaskets. However, they allow easier access to the interior of the system, making maintenance simpler in some cases.

- Threaded Connections: Suitable for smaller pipes and simpler installations but may not be ideal for larger pipes or systems requiring higher pressures.

- Flanged Connections: Offer more versatility and adaptability for a wide range of pipe sizes and pressure requirements. They can handle larger diameters and higher pressures with proper selection and installation.

Comparing table

Here's a comparative table outlining the differences between threaded connections and flanged connections:

| Aspect | Threaded Connections | Flanged Connections |

| Design | Engage two threaded components directly. | Utilize two flanges with bolt holes and gaskets. |

| Installation Ease | Generally easier to install, suitable for smaller pipes. | May require more space and alignment during installation. |

| Pressure Rating | Commonly used in lower-pressure applications. | Preferred for higher-pressure applications with proper seals. |

| Temperature Handling | Limited in handling high temperatures and pressures. | Can handle wider temperature and pressure ranges. |

| Maintenance & Disassembly | Easier disassembly but may affect thread integrity. | More effort for disassembly but allows easier access. |

| Versatility | Suitable for smaller pipes; may not handle high pressures. | More adaptable for various pipe sizes and pressure needs. |

These differences highlight the distinct characteristics and applications where threaded connections and flanged connections are commonly utilized. The choice between the two depends on specific requirements such as pressure, temperature, ease of installation, maintenance needs, and the nature of the system being installed or maintained.

Fig 13. Pressure Transmitter Flange

Which type of pressure sensor process connection is proper for sanitary applications?

In sanitary applications, where hygiene and cleanliness are paramount, the process connections for pressure sensors need to meet specific standards to ensure cleanliness, ease of cleaning, and avoidance of contamination. The most suitable process connection types for sanitary applications include:

Tri-clamp connections are often preferred in sanitary environments due to their ease of use, cleanliness, and compatibility with cleaning processes like CIP (Clean-in-Place) and SIP (Sterilize-in-Place). However, the specific choice of connection depends on the industry standards, regulations, and specific requirements of the sanitary application.

Welded Connections

Welded connections are a method of joining components that involve fusing or welding two pieces together using heat or pressure, creating a permanent and robust joint. In the context of pressure sensors or transmitters, welded connections involve directly welding the sensor housing or body to the process connection, such as a pipe or vessel, to form a sealed and integral unit.

Key aspects of welded connections for pressure sensors include

When selecting welded connections for pressure sensors, it's crucial to adhere to industry standards and best practices, ensuring proper welding procedures, material compatibility, and quality control measures to achieve reliable and long-lasting joints.

Fig 14. Welded connection

Submersible connections

Submersible connections refer to specialized fittings or connections designed for pressure sensors or devices intended to operate underwater or in submerged environments. These connections are crucial for maintaining the integrity of the sensor while ensuring accurate and reliable measurements in underwater applications, such as in marine, offshore, or subsea industries.

Key aspects of submersible connections include:

When selecting submersible connections for pressure sensors, considerations such as the depth of operation, water pressure, material compatibility, environmental conditions, and adherence to industry standards are essential to ensure optimal performance and longevity of the sensor in underwater applications.

What are the factors that affect pressure sensor process connections?

Several factors can significantly impact pressure sensor process connections, influencing their performance, reliability, and suitability for specific applications:

Temperature Effects on Process Connections

Temperature can have significant effects on process connections used in pressure sensors. Some key impacts include:

Fig 14. Threads

What are the important factors for choosing the proper process connections and fitting?

Selecting the proper process connections and fittings for pressure sensors involves considering various critical factors to ensure compatibility, reliability, and optimal performance within specific applications:

Glossary

| Term | Definition |

| NPT (National Pipe Thread) | A tapered thread standard commonly used in the United States for sealing pipe connections. |

| BSP (British Standard Pipe) | A parallel thread standard used in various countries, including the UK, for pipe fittings. |

| Flanged Connection | Method using two flanges with bolt holes and gaskets for a secure joint. |

| Tri-Clamp Connection | Sanitary fitting with a clamp mechanism used in hygienic applications. |

| Welded Connection | Fusion of materials using heat or pressure to create a permanent joint. |

| Thread Size | Dimension specifying the diameter and pitch of a threaded connection. |

| Pressure Rating | Maximum pressure a fitting or connection can withstand without failure. |

| Sealing Mechanism | Methods like gaskets, O-rings, or sealants used to prevent leaks in connections. |

| Hermetic Seal | Completely airtight or watertight seal preventing substance passage. |

| Compression Fitting | Connection involving compression of a fitting onto a pipe or tubing. |

| RTJ (Ring Type Joint) Flanges | Flanges with a groove for a metal ring gasket, commonly used in high-pressure applications. |

| Raised Face Flanges | Flanges with a raised surface for better gasket sealing. |

| Flat Face Flanges | Flanges with a flat surface for lower-pressure sealing connections. |

| Gasket | Material is placed between surfaces to create a seal, often made of rubber, silicone, or metal. |

| Corrosion Resistance | Ability of a material to withstand corrosion from harsh environments or substances. |

| Temperature Resistance | Capability of a material or fitting to withstand various temperature ranges without damage. |

| Hygienic Threaded Connection | Threaded connections are designed for use in sanitary applications, adhering to cleanliness standards. |

| Submersible Connection | Specialized fitting designed for submerged or underwater applications. |

| DIN Rail Mount | Standardized metal rail used for mounting industrial components like pressure sensors. |

| Lapped Joint Flanges | Flanges are used with a stub end and lap joint for alignment and rotation. |

Wrap up

Selecting the right process connections and fittings for pressure sensors is a critical decision that significantly impacts the sensor's performance, reliability, and suitability for specific applications. Considering various factors such as pressure ratings, media compatibility, temperature conditions, environmental factors, industry standards, installation requirements, sealing mechanisms, maintenance needs, and compatibility with existing systems is essential.

A thorough assessment of these factors allows for the informed selection of connections and fittings that can withstand the intended pressure, temperature, and environmental conditions while ensuring compatibility, reliability, and safety within industry standards. Whether it's choosing between threaded, flanged, welded, or specialized connections like those used in sanitary or submersible applications, the right choice is pivotal for seamless integration, accurate measurements, and long-term functionality of pressure sensors in diverse industrial settings. Striking a balance between these considerations ensures optimal performance and longevity of pressure sensors in their respective applications.

To recap

1.What are process connections in pressure sensors?

Process connections are the interface points used to attach pressure sensors to the system they are measuring, ensuring a sealed and reliable connection.

2.What types of process connections are commonly used?

Common types include threaded connections (NPT, BSP), flanged connections, welded connections, tri-clamp connections, and specialized connections for specific applications.

3.How do I choose the right process connection for my pressure sensor? Consider factors such as pressure rating, media compatibility, temperature conditions, environmental factors, industry standards, installation requirements, sealing mechanisms, maintenance needs, and compatibility with existing systems.

4.What is the difference between NPT and BSP threaded connections?

NPT (National Pipe Thread) is a tapered thread commonly used in the United States, while BSP (British Standard Pipe) is a parallel thread used in many parts of the world, including the UK.

5.Which process connection is suitable for sanitary applications? Sanitary applications often use connections like tri-clamp fittings due to their ease of cleaning, hermetic sealing, and suitability for hygienic environments.

6.What factors affect the performance of process connections in pressure sensors?

Pressure range, media compatibility, temperature effects, environmental conditions, industry standards, installation, sealing, maintenance, and size compatibility all influence performance.

7.How do temperature changes affect process connections? Temperature fluctuations can impact the material properties, sealing mechanisms, structural integrity, and dimensions of connections, potentially leading to leaks or compromised performance.

8.What is the significance of industry standards in selecting process connections?

Adhering to industry standards ensures the compatibility, reliability, safety, and performance of connections within specific applications and industries.

9.Can I use the same process connection for various media types?

Not necessarily. It's crucial to ensure compatibility between the materials used in the connection and the properties of the media to avoid corrosion, degradation, or chemical reactions.

10.Are welded connections suitable for all applications?

While welded connections offer strength and permanence, they may not be easily disassembled and could be less suitable for applications requiring frequent modifications or disassembly.

11.What considerations are vital for selecting threaded connections? Factors such as thread type (NPT, BSP), pressure ratings, compatibility with media, temperature limitations, and proper installation techniques are crucial.

12.Do process connections require specific maintenance?

Depending on the type, some connections may require periodic checks for seals, corrosion, or wear to ensure continued reliability.

13.Which connection types are suitable for submersible applications?

Submersible applications often utilize specialized connections with hermetic seals and corrosion-resistant materials to withstand underwater environments.

14.Can process connections be modified or adapted for different systems?

In some cases, adapters or specialized fittings can be used to modify connections to suit different systems or standards.

15.How can I ensure the longevity of process connections in pressure sensors?

Regular inspection, adherence to maintenance schedules, choosing suitable materials, proper installation, and compliance with industry standards contribute to the long-term reliability of connections.

References

https://www.dubai-sensor.com/blog/process-connection-or-fitting-for-pressure-transmitter/

https://www.eastsensor.com/blog/pressure-sensor-process-connection/?highlight=process%20connection

https://www.eastsensor.com/blog/knowledge-thread-process-connection/?highlight=process%20connection

https://www.efihardware.com/products/3133/single-bosch-pressure-sensor-mount

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025