Linear Encoder (Types, Applications, Advantages)

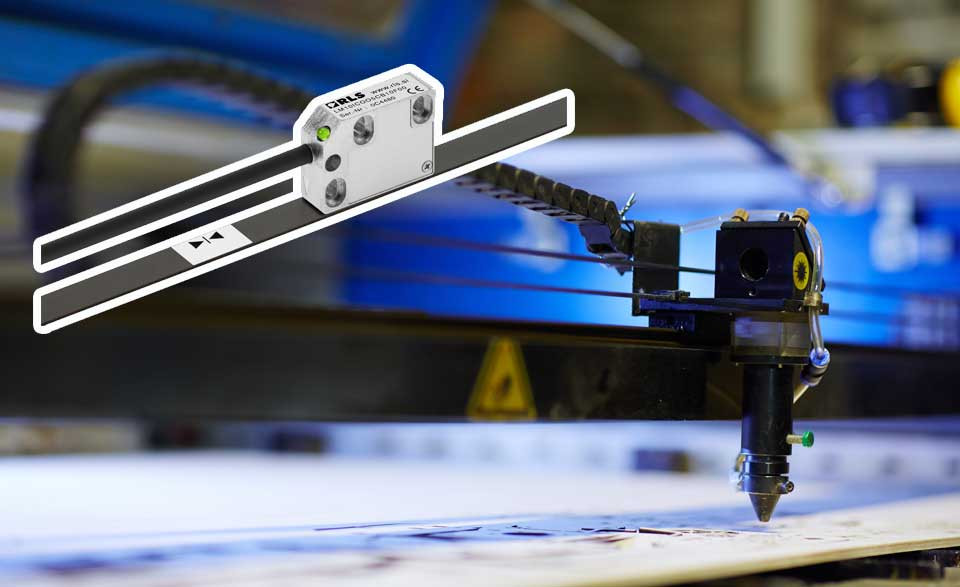

In this guide, we are going to introduce linear encoder. Linear encoders are actually position sensors or transducers and are designed to measure the linear movement of an object, rather than rotary motion. The sensor first reads the scale and encodes the read position into an analog or digital signal that is transformed into a digital readout. This signal can be decoded by a position controller. The linear encoder detects motion according to position changes over time.

These encoders are used to detect speed, distance, direction, and displacement and control linear movements to the left and right with nanometer accuracy.

Linear measurement range, that is the full range of travel that can be encoded, counts per distance defined as the minimum linear position increment, and lines per distance, the actual marks of the moving linear element, are some important performance specifications of linear encoders.

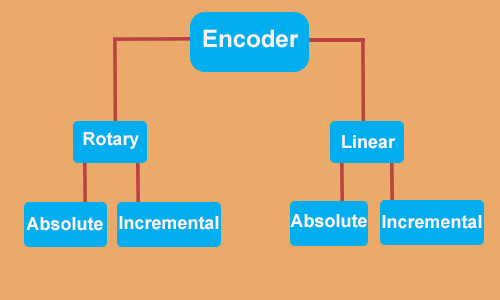

Linear encoder types: Absolute or Incremental

Linear encoders use an incremental or absolute measuring method.

Absolute encoders give a unique digital code or word to each position, which allows them to maintain precise position information, even when power is interrupted.

Incremental encoders generate a specific number of pulses per unit of travel and count those pulses as the load moves.

Incremental linear encoders will lose their position reference if the power supply is lost. Absolute linear encoders generate a digital output, or word, that gives information about the actual position of the object.

Resolution for an absolute encoder is defined by the number of bits in the word. In contrast, incremental encoders create quadrature output, with two channels A, and B, for the monitoring position and direction that are 90 degrees out of phase.

Some incremental encoders produce the third channel Z, as the index or reference position with a single pulse. The resolution of an incremental encoder is determined by the number of pulses per distance.

Linear encoder technology: Optical or Magnetic

After deciding about incremental or absolute feedback, the next consideration is about the sensing technology: optical or magnetic.

In optical encoders, the position is determined by using a light source and a photo-detector, but the use of light in these encoders creates sensitivity to dirt and debris, which can disrupt the signal.

The gap between the sensor and the scale can affect the performance of the optical encoder, so to prevent this issue, it must be properly adjusted and maintained to ensure that the integrity of the signal is not compromised.

Therefore mounting must be done carefully, and shocks and vibrations should be avoided because these factors interfere with the operation of these encoders.

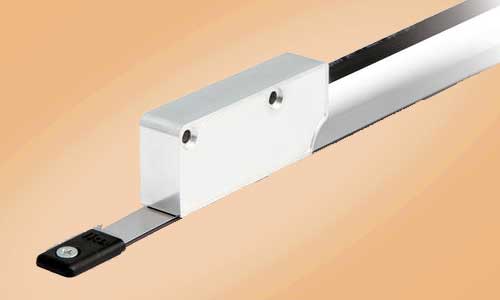

Magnetic encoders provide position detection by using a magnetic reader head and a magnetic scale. Because a magnetic field is used instead of light, this type of encoder is suitable for use in contaminated environments.

Magnetic encoders are more resistant than optical encoders and are often used in environments exposed to dirt, debris, or liquid contamination, pollution, steam, vibration, and other types of environmental interference.

But magnetic chips, such as steel or iron, can affect their performance because they may interfere with the magnetic field.

The optical linear encoder has a digital output and the magnetic linear encoder has an analog output. However, the resolution or accuracy of optical encoders is higher.

You may also want to browse our selection of encoder with great prices on this link.

Application

Linear encoders are used in two main areas:

Measurements; include coordinate-measuring machines (CMMs), laser scanners, calipers, gear measurements, traction testers, and digital readouts (DROs) and motion control and positioning systems; including servo motor systems and valves, robotics, machine tools, pick-and-place PCB assembly equipment, semiconductor testing equipment, Wire-Bonder machines, printers, and digital presses.

Linear encoders can be also used in:

- Machine tools such as calipers, CMM machines, CNC machines, and stepper motors with more than one contactor

- Press the machine to measure the longitudinal movement of the piston jack

- Rollers to measure the longitudinal distance between the rollerballs

- Elevators

- Milling machines

- Hydraulic cylinders

- Press brakes

- Linear actuators

- Conveyors Cranes

- Stepper motor

- Jig borers

- Grinding machines

Advantages

- High accuracy, resolution, and repeatability

- High traversing speed

- High scale accuracy

- Large mounting tolerances

- Resistant to dust, swarf, oil, and other harsh environmental conditions

- No mechanical wear characteristics

- Requires no cleaning or maintenance

- High tolerance to shock and vibration

- High reliability

- Ease of installation and use

- A minimum number of errors in pulse counting or their complete absence

- Highly immune to external interferences

Here is a Encoder article for you, if you're interested to know more about them:

Incremental encoder (Working Principle, Types, Applications, Advantages)

Explained: Rotary Encoder [Working principle, Types, Applications, Features]

Absolute Encoder (Working Principle, Types, Applications, Advantages)

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025