Unlocking Precision: Understanding Incremental Encoders

In this text, we will explain the general definition of encoders and their first subset, incremental encoders, the classification of incremental encoders, and their applications, the difference between incremental and absolute encoders, along with the features and advantages of incremental encoders.

A rotary encoder is an electrical mechanical device that converts rotational or linear motion to digital or even analog pulses or bits in response to the rotational motion of the shaft (for use in a variety of control systems and AVRs).

Thus, for each complete 360-degree rotation of the encoder shaft, a digital package is generated and then this package is decoded by another equipment or decoder.

This package contains important information such as speed, displacement, acceleration of speed, angular velocity or rotation angle, distance traveled, and...

What is an Incremental Encoder?

An incremental encoder is known as one of the most commonly used rotary encoders and the most common method of position and speed measurement in processor systems.

Incremental Encoder is a type of encoder device that creates information about the position, angle, and rotation counts and converts this information such as angular motion or position of a shaft into an analog or digital code by means of an optical disk to detect position or motion.

An incremental encoder can only measure the relative movement of the shaft or slider, and for measuring the absolute position other means must be used and need a power supply to detect movement.

Each time an incremental encoder is turned on, the pulse is counted from 0, which means that the position is not saved, and before the encoder starts counting, a reset or reference position must be obtained.

Types of incremental encoders

Incremental rotary encoders have different designs with different technologies, each with its own advantages and disadvantages. The most common technologies used are as follows:

Quadrature incremental encoder: A quadrature encoder, also known as an incremental rotary encoder measures the speed and direction of a rotating shaft. Quadrature encoders can use different types of sensors, optical and hall effect are both commonly used.

Optical incremental encoder: Optical incremental encoder is one of the most widely used encoders. These encoders are available in two general types. One type has a single detector and the other has two detectors, also known as fiber optic encoders.

They are cost-effective and offer high resolution. However, if there is a risk of contamination by dust, oil, etc., the optical scanning system may malfunction.

Magnetic incremental encoder: In this encoder, the pulses are generated by magnets. This technology is also widely used in industry because magnetic encoders are less at risk of contamination.

How does an Incremental Encoder work?

An incremental encoder is a device that generates electrical pulses if its shaft is rotating. After moving an incremental encoder, a stream of binary pulses is proportional to the rotation of the shaft generated.

Phase differences of generated pulses show the direction of motion, and the counting of those pulses gives us the position of the shaft. The incremental rotary encoder consists of a rotating slot in black and a fixed slot between the transmitter and receiver elements.

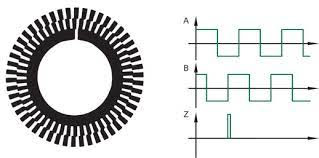

As the encoder shaft rotates, light emitted from the transmitter passes through these gaps and is converted into a current signal by the receiver. This signal generates a square wave at the output. The incremental encoder has at least 1 output A or typically 2 outputs, called B and A.

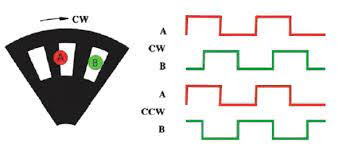

These 2 signals are 90° out of phase with each other, which is required to detect the encoder rotation. The rotation of the encoder produces pulse A and the rotation of the motor shaft produces pulse B.

Moving the encoder clockwise, pulse A and by rotating the shaft clockwise, pulse B goes 90° ahead of pulse A.

Also, some incremental encoders have a third output channel, called Z, a zero or reference signal, which provides a single pulse per revolution. This single pulse is used for the accurate determination of a reference position.

Incremental versus Absolute

| Incremental | Absolute | |

| Function | When power is lost the pulse is counted from zero and needs reference position | Position is retained even if the encoder is not powered and measure the absolute position |

| Complexity | Simpler | More complex |

| Output | Speed, Displacement, Velocity, and Direction | Velocity, and Absolute Position |

| Resolution | Up to 10k PPR | Up to 22bit |

| Communication via protocol? | No | Yes |

| Cost | Generally Lower | Generally Higher |

Pulses Per Revolution (PPR)

Pulses per Revolution or PPR represents encoder resolution. It is the number of high pulses an encoder will have on either of its square waves outputs A or B over a single revolution and it shows how many mechanical degrees each pulse and period is equal to.

The incremental encoder produces a certain amount of pulse per cycle. If this PPR number is high, the angle between each pulse is smaller.

Applications

An incremental encoder is designed to be versatile and customizable for use in a wide variety of applications. There are three broad categories of applications based on the environment as follows:

Heavy Duty: Harsh environmental conditions with a high probability of pollution and humidity, high temperature, impact, and vibration requirements such as pulp, paper, steel, and wood production centers.

Industrial Duty: In the food and beverage industry, textile, general factory automation for the general operating conditions, which require standard IP ratings, moderate resistance to shock, vibration, and temperature.

Light Duty/Servo: In robotics, electronics, and semiconductors to control environments with high accuracy and temperature needs.

One of the applications of these encoders is used in the manufacture of computer hardware. For example, in the new trackball mouse, this encoder is used to detect the position of the mouse. The encoder in this system gives us the current position of the mouse by counting the positional changes.

- Aeronautics, defense, railway, medical, oil exploration, telecommunications

- Cut to length applications

- Jacks for railroad cars

- Bottle rotation for label application

- Printing applications

- Food industry

- Drink technology

- Quality control

- Cranes and construction

- Precise position control of lathe in automatic industrial machine

- Accurate measurement of wood layer area

- Detection of speed in elevators

- Automated assembly lines

- Packaging machines

Features and Advantages

- Suitable for counting simple pulses or monitoring frequencies such as speed, direction and position

- Simple to integrate and easy to maintain

- High-resolution

- Simple and low-cost

- Magnetic measurements

- Compact in size

- Elevator position applications

- Robust and flexible

- Accurate position and speed detection even in demanding environments

- High noise immunity

Still curious? Click on the below links to know more:

Guess the Dominating Brand in Middle East for Rotary Encoder

Linear Encoder (Types, Applications, Advantages)

Absolute Encoder (Working Principle, Types, Applications, Advantages)

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025