Introducing Any Pressure Sensor Use You Might Need

You may wonder where and in what applications pressure sensors are used! Well, I have to say everywhere from under the oceans to up in space. You find pressure everywhere; in the air, in the water, everywhere you have elements. Even if there is no element, the absence of pressure - vacuum - should be measured.

Pressure measuring is needed in almost all industries. The reason? I believe it’s because pressure measuring leads to calculating some other parameters, such as density, flow rate, and level.

Here you can see a list of industries and applications where a pressure sensor can be used in. They are not all the applications though.

Oil & gas industry

Generally, the oil & gas industry is classified into three primary sectors:

upstream (exploration and production):

The upstream sector consists of searching for possible underground or submarine crude oil and natural gas fields, drilling exploratory wells, and then drilling and operating the wells that extract and transport the crude oil or raw natural gas to the surface.

midstream:

The midstream industry includes the transportation (by pipeline, rail, barge, an oil tanker, or truck), storage, and wholesale marketing of crude or processed petroleum products. Transporting crude oil from production sites to refineries and delivering refined products to downstream distributors can be accomplished using pipelines and other transport networks.

Natural gas pipeline networks collect gas from natural gas purification plants and transport it to users, such as local utilities.

Downstream:

The downstream sector comprises the refining of petroleum crude oil, the processing and purification of raw natural gas, and the marketing and distribution of goods generated from crude oil and natural gas. The downstream sector supplies customers with gasoline or petrol, kerosene, jet fuel, diesel oil, heating oil, fuel oils, lubricants, waxes, asphalt, natural gas, and liquefied petroleum gas (LPG) as well as hundreds of petrochemicals.

Pressure sensor use is necessary for each sector, from extracting crude oil and gas to transporting them to refining and purification of them.

Some of the applications in need of pressure sensors in this industry are:

• Offshore drilling

• Drilling platform

• The separation process

• Refineries

• Oil platform

• Oil and gas tanker

• Oil and gas pipeline

• LNG & CNG Supply Chain

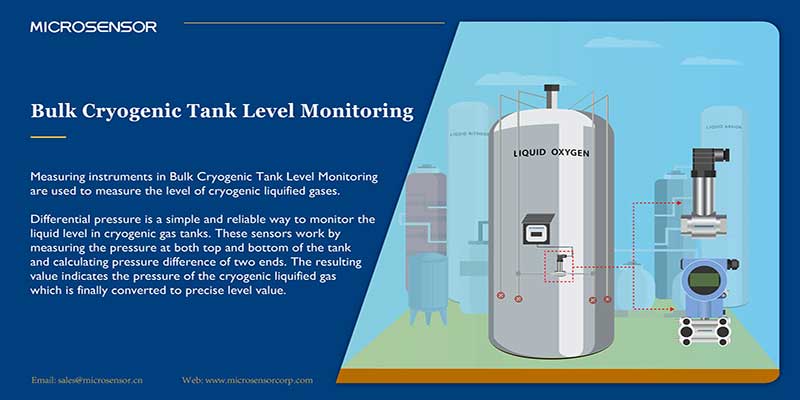

Monitoring the Level of Bulk Cryogenic Tanks

Gas Volume Corrector

Pressure and Level Sensors for the System of Chemical Injection

Chemical Industry

The Chemical industry consists of companies that manufacture industrial chemicals. This industry converts raw resources such as oil, natural gas, air, water, metals, and minerals into a wide range of products. To do so, it claims chemical processes such as chemical reactions and refining techniques. The products include agrochemicals, petrochemicals, ceramics, polymer and rubber (elastomers), explosives, oleochemicals (oils, fats, and waxes), perfumes, and flavors.

In the way of processing these products, and achieving the best quality possible, pressure measurement is a must.

Some applications requiring pressure sensor use in this industry are:

• Measurement of gas pressure

• Monitoring gas cylinder

• Process control

• Bioreactor

• Production of Agricultural Chemicals

• Production of Plastics & Polymers

• Production of Lubricants

• Production of Ethanol

• Production of Specialty Chemicals

Power Industry

The power industry includes the generation, transmission, distribution, and sale of electric power to consumers and industry.

Power generation is the process of producing electricity from primary energy sources. These sources are either non-renewable or renewable.

Coal, nuclear, oil, and natural gas are some examples of non-renewable energy sources. They are available in limited supplies. On the other hand, renewable primary energy sources include solar, wind, water (hydro), biomass, and geothermal. These energy sources replenish naturally and over a short period of time.

Pressure sensor use is crucial in the related applications to this industry:

• Hydroelectric Power Generation

• Nuclear Power Generation

• Gas Power Generation

• Coal Power Generation

• Renewable Power Generation

• Combined cycle power plant

• Cogeneration / Combined Heat & Power (CHP)

• Biogas facilities

• Solar thermal energy

• Geothermal energy

• Flue gas system

• Compressor

To be more explicit, There are some machines in the power industry that pressure measurement is demanded in them. In fact, otherwise, a disaster might occur.

Here are examples of these machines:

• Generator

• Turbine

• Compressor

• Pump

• Boiler

• The wind turbine

Water & Wastewater Industry

Residential, commercial, and industrial sectors of the economy get drinking water and wastewater services (including sewage treatment) from the water and wastewater industry. The water industry covers the production and processing of raw water for supplying drinking and sanitary water, as well as water storage and distribution. Sewage treatment is the process of removing impurities from municipal wastewater. Are you wondering What municipal water is? Well, it is the wastewater containing mainly household sewage plus some industrial wastewater. Wastewater treatment is the process of eliminating pollutants from municipal effluent, which consists primarily of domestic sewage and a small amount of industrial wastewater. Physical, chemical, and biological procedures are employed to remove pollutants and generate wastewater or effluent that is safe for discharge into the environment.

As mentioned before, the water and wastewater industry consists of different sections.Every section needs pressure sensor use, each for achieving a specific purpose.

Some of these sections are:

• Water Treatment

• Wastewater Treatment

• Pumping and booster station

• Water Pipeline

• Water Distribution

• Groundwater monitoring

• Sludge treatment and disposal

• Sedimentation and filtration

• Swimming pool water

• Water desalination

• Water Softening

• Telemetry

• Level monitoring on pressure vessels

In the applications named above, there are different systems or machines. To name a few:

• Reverse Osmosis System

• Deionizer machine

• Domestic sewage Water Treatment System

• Industrial Waste Water Treatment System

• Booster pump system

• Pressure Vessel

Life Sciences & Medical Industry

Life Sciences encompass companies related to biomedical technologies, life systems technologies, biotechnology, pharmaceuticals, cosmeceuticals, food processing, nutraceuticals, cosmeceuticals, environmental, and biomedical devices. The other organizations and institutions that life science includes are those that devote most of their efforts to research, development, technology transfer, and commercialization.

Manufacturers of medical devices and life science try to provide innovative and trustworthy products that help people live healthier lives.

Pharmaceutical and biotechnology companies both produce medicine. The medications produced by biotechnology companies have a biological foundation, whereas the foundation of those produced by pharmaceutical companies is a chemical structure. Biotechnology companies manufacture their products using living organisms or their products, such as bacteria or enzymes. In contrast, pharmaceutical corporations often produce medications from synthetic compounds.

It may seem meaningless, but the pressure of these processes should be kept in a particular range, too. To do so, pressure sensor use comes in again.

Here are some procedures in this industry that need pressure measuring:

• Pharmaceutical industry

• Biotechnology processes

• Medical technology

• Sterilization

• Freeze drying

• Spray drying

• Hygienic Process

• Ultra-pure water production with reverse osmosis

• Ultra-pure water production with distillation

• Production of biological additives (Bio API)

• Packaging

And let's name a few machines in need of pressure sensors in the life sciences & medical industry:

• Sterilizing machine

• Autoclave

Food & Beverage Industry

The food & beverage industry comprises all businesses engaged in the processing, packaging, and distribution of raw food materials. This industry covers freshly produced and packed foods, in addition to alcoholic and nonalcoholic drinks. Except for medications, all products intended for human consumption pass through this industry.

Generally, the raw materials utilized are of vegetable or animal origin and are produced through agriculture, farming, fishing, and breeding.

Today's food and beverage industry has widened. It ranges from tiny, traditional, family-run businesses to massive, capital-intensive, highly automated operations.

Almost all processes in this industry, from family-run to highly mechanized ones, require pressure measurement. Otherwise, the product quality doesn't stay still. And guess what? Pressure sensor use is needed one more time.

Here are some applications in need of pressure measurement in the food and beverage industry:

• Soft drink production

• Sugar production

• Dairy production

• Breweries & Wine production

• Level measurement in the evaporation process

• Level monitoring on pressure vessel

• Centrifuge Control

• Drying Control

• Vacuum Pan Control

• Bottle & Pouch Forming

• Vapour pressure measurement

• Packaging & Filling & Sealing

• Identify package leak

• Leakage test of a tank

• Accurate concentration measurement

• Poultry Farm

Some systems and machines in need of pressure sensors in this industry are:

• CIP system

• liquid pouch filling and sealing machine

• Mixer

• Centrifuge

Pulp & Paper Industry

The Pulp & Paper industry includes corporations that manufacture pulp, paper, paperboard, office and catalog paper, glossy paper, tissue and paper-based packaging, and other cellulose-based goods.

Pulp is a lignocellulosic fibrous substance produced by chemically or mechanically extracting cellulose fibers from wood, fiber crops, waste paper, or rags. Many types of paper are manufactured from wood alone, with no other materials added. this includes magazines, newspapers, and even toilet paper.

The pulp and paper industry is one of the world's major industrial sectors. It has a significant impact on global forests. This industry consumes more than 40 percent of all industrial wood sold worldwide.

Even though, There are processes in the pulp and paper industry in which pressure sensor use is a must:

• Chemical pulping process

• Cooking process

• Pulping and washing

• Screening and Oxygen Bleaching

• Washing and Bleaching

• Recovery Process

• DIP Cooking process

• Recycle Waste Paper

• Recovery Boiler

• Paper testing

• Water Treatment

Two machines that are dangerous to work without a pressure sensor in this industry are:

• Boiler

• Steaming Vessel

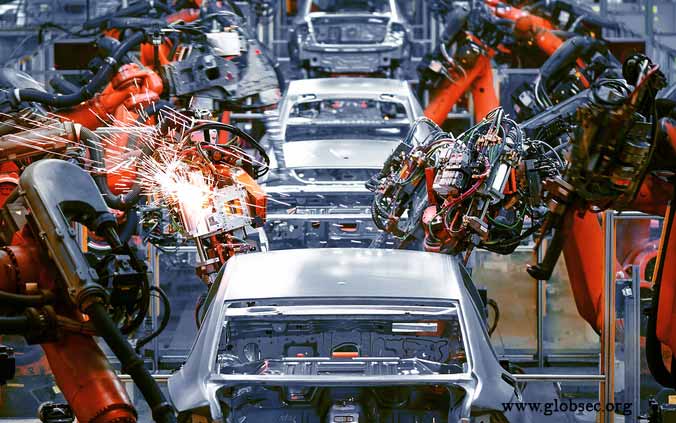

Automotive Industry

The Automotive industry is comprised of a vast array of firms and organizations engaged in the design, development, manufacture, marketing, and sale of motor cars, as well as repair shops and gas stations. It is one of the most lucrative economic sectors in the world.

The automotive industry relies on highly accurate and durable pressure sensors for testing and process control.

So, here are some sectors in need of pressure sensor application in this industry:

• Test bench

• Filter measurement

• Monitoring injection pressure

• surveillance gas pressure

• Pressure monitoring in a gas tank

• Tire pressure

• Press line

Of course, there are lots of machines in these sectors that require pressure sensor use, but one of the most important ones is:

• a hydraulic press machine.

Petrochemical Industry

The petrochemical industry generates chemicals mostly from petroleum and natural gas. Petrochemicals can transform into thousands of industrial and consumer goods, including Plastic, Paints, Rubber, Fertilizers, Detergents, Dyes, Textiles, and Solvents. This sector consists of two main sections:

• The primary petrochemical sector creates basic compounds like ethylene, from oil or gas.

• The secondary industries transform those basic petrochemicals into substances that may be utilized directly by other sectors.

There are two most popular petrochemical classes: olefins (which include ethylene and propylene) and aromatics (including benzene, toluene, and xylene isomers).

In this industry, pressure sensor use is seen in every corner:

• Pipeline

• Distillation column

• Steam drum

• Extraction vessel

• Condensate separator

• Tank farm

HVAC (Heating, Ventilation, and Air conditioning)

HVAC (Heating, Ventilation, and Air Conditioning) is the technology of environmental comfort for buildings and vehicles. Its purpose is to give thermal comfort and acceptable air quality indoors. HVAC system design is a subfield of mechanical engineering focused on thermodynamics, fluid mechanics, and heat transfer. Sometimes refrigeration is added to the field's acronym, resulting in HVAC&R or HVACR.

HVAC is an essential component of residential structures where safe and healthy building conditions are regulated concerning temperature and humidity using outdoor air. Some of these structures are single-family homes, apartment buildings, hotels, and senior living facilities, and medium to large industrial and office buildings such as skyscrapers and hospitals, ships, submarines, and marine environments.

Are you curious to know the pressure sensor application in HVAC systems? Here are some of them:

• Heating System

• Solar Thermal System

• Combined Heat & Power Plant

• Heat Pump

• Condensing boiler

• Solid fuel boiler

• Heat Transfer & Distribution Station

• Air Handling Units, Components, and systems

• Refrigeration Sytem

In every HVAC application, there are machines that need pressure sensor use:

• Chillers

• Boiler & Burner

• Booster pump

• Chiller compressor

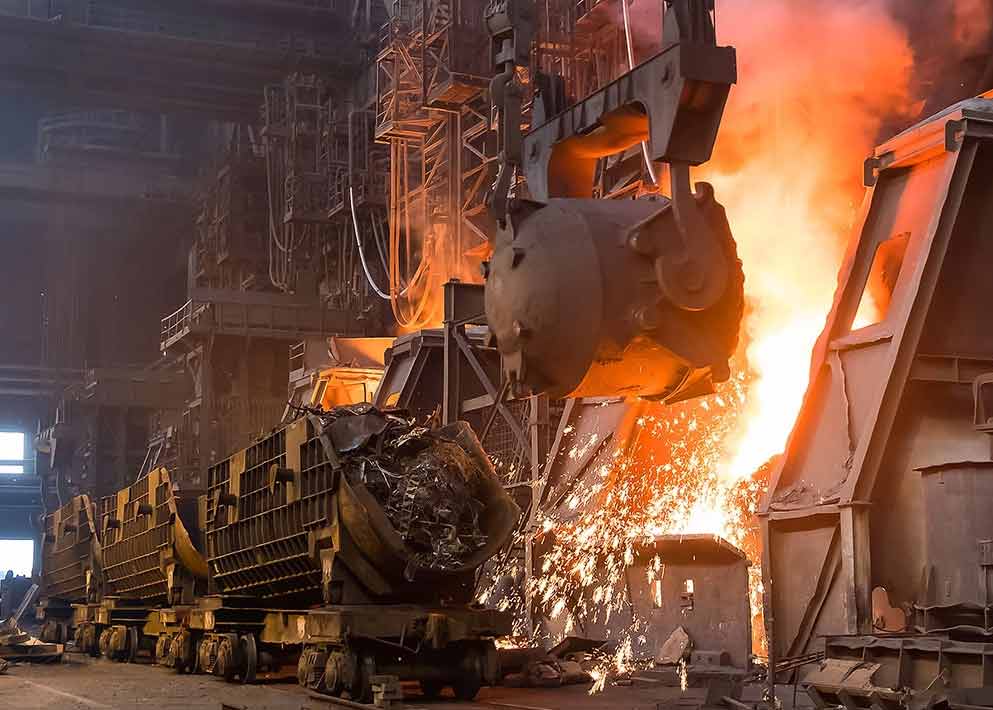

Mining, Minerals & Metals

The Metals and Mining industry focuses on the exploration and extraction of metals, precious minerals, and other geological elements from the Earth's crust. Mining is necessary to obtain any substance that cannot be produced by agricultural methods or synthesized in a laboratory. In a broader sense, mining encompasses the extraction of any non-renewable resource, like petroleum, natural gas, and even water.

Metals, coal, oil shale, gemstones, limestone, chalk, dimension stone, rock salt, potash, gravel, and clay are among the ores extracted by mining.

Metals and minerals are fundamental to several other industries. For instance, the construction and machinery industries require iron ore for steel production. Coal, which is still one of the world's greatest energy resources, and uranium, the essential raw element for the production of nuclear energy, are both prominently mined commodities.

There are lots of applications in the mining industry requiring pressure sensor use. To name a few:

• Highwall Mining

• Surface Mining

• Underground Mining

• Mining Water Treatment

• Extractive Metallurgy

• Mining Excavation

• Monitors and controls hydraulic pressure

Machines:

• Hydraulic excavator

• Mining Equipment

Marine and Shipbuilding

• Heating and cooling system

• Water Treatment

• Wastewater Treatment

• Ballast water management system

• Level measurement in Diesel tank

• Power generation

• HVAC

• Deck machinery and cargo handling

• Crane

Machines:

• Compressor

• Crane

Refrigeration

The refrigeration process involves transferring heat from a low-temperature reservoir to a high-temperature reservoir. Conventionally, heat transfer is powered by mechanical means, although it can also be powered by heat, magnetic, electricity, laser, or other means. There are several applications for refrigeration, including domestic refrigerators, industrial freezers, cryogenics, and air conditioning.

The influence of refrigeration on industry, lifestyle, agriculture, and settlement patterns is significant.

There are lots of applications in this industry requiring pressure sensor use:

• Food processing, preservation, and distribution

• Chemical and process industries

• Cold treatment of metal

• Medical

• Construction

• Ice skating

• Evaporating and condensing pressure

• Monitoring of filter dryer

• Ventilator control

• Control of compound system

• Measuring the coolant pressure

• Level monitoring on pressure vessel

• Air conditioning

Machine Building

The Machine Building industry is a subsector of the manufacturing sector that produces a variety of items, including power tools, various types of machines, household technology, and factory equipment, among others.

On the one hand, the machine industry provides means and supporting equipment for:

- Businesses in agriculture, mining, and construction industry

- Public utilities like the production and distribution of electricity, gas, and water

- All economic sectors, such as heating, ventilation, and air conditioning of a building

As a matter of fact, there are lots and lots of applications that run with machine building. Each one requires a special kind of pressure sensor use.

Some of these applications are:

• Hydraulic Power Pack

• Lubrication System

• Screw Compressor

• Piston Compressor

• Pump and System

• Filter system

• Cooling lubricant system

• Granulate preparation

• Temperature control unit

• Machine tools

• Plastics machinery

• High-pressure application

• Textile machinery

• Controlling the turbo pressure in the Diesel engine

• Filling & packing machinery

• Test bench

• Ink pressure measurement in a printer

• Plasma cutting

• Monitors and controls hydraulic pressure

• Waterjet Cutting Machinery

Basic Materials

Primary industries are those that produce the raw materials for manufacturing. Agriculture, forestry, fishing, mining, quarrying, and mineral extraction are all examples of primary industries.

The primary industry classifies into two categories: genetic and extractive.

The genetic industry includes the production of raw materials that can be increased by human intervention in the production process. It includes agriculture, forestry, livestock management, and fisheries. This industry is subject to the scientific and technical development of renewable resources.

On the other hand, the extractive industry includes the production of non-renewable raw materials that cannot be increased through cultivation. The extractive industries include mineral ore mining, stone quarrying, and the extraction of mineral fuels.

In both genetic and extractive industries, it is crucial to measure pressure changes, cause it can affect the quality of the raw material.

Here is a list of industries that require pressure sensor use:

• Iron & steel Industry

• Glass production

• Plastics production

• Cement production

• Copper and aluminum production

• Pulp and paper

• Rubber and plastic industries

• Agricultural Industry

• Mining industry

• Wood industry

Railway technology

• Pressure monitoring in tank

• Pressure monitoring in the brake circuit

• Air conditioning system

• Hydraulic power transfer

• Compressed-air system

• Diesel traction

• Electric traction

• Waste and fire-fighting water tank

• The entry and intermediate door

• The pneumatics Systems

• The wheel flange lubrication system

• The sander

• Toilet system

Textile

The textile industry focuses on the design, manufacture, and distribution of yarn, fabric, and clothing. The raw material may be natural or synthesized employing chemical industry products.

Therefore, the textile industry is responsible for taking raw materials, such as cotton or wool, and spinning them into yarn, which is then employed to manufacture fabric.

The development, production, manufacturing, and distribution of textiles are all activities involved in the transformation of raw material into a completed product.

It may seem irrelevant, but even in the textile industry, pressure sensor use is a must.

Here are some of its uses:

• Pumping System

• Monitoring the actual pressure in the process

• Cotton or, Yarn Production

• Fiber Production

• Dyeing and Printing

• Water Treatment System

Cryogenic

In physics, cryogenic refers to the creation and behavior of substances at exceedingly low temperatures.

Scientists specify the cryogenic temperature range as -238 °F to -460 °F, which is absolute zero, the temperature at which molecular motion is as close to theoretically achievable to stay still entirely.

Therefore, temperatures exceeding -238 °F cannot be termed cryogenic. Any procedures performed at such temperatures will not be considered cryogenic.

One of the most popular applications of cryogenic gas liquefaction processes is liquefied natural gas storage and transmission. Natural gas is a combination of flammable gases including ethane, methane, and others. When a substance is liquefied, it can compress considerably at room temperature, making it transportable in insulated tankers.

You can not reach the cryogenic temperature range without the use of specialist equipment and cryogenic gases, such as liquid nitrogen and liquid helium.

Only then is it likely to drop the temperature to the region where cryogenic hardening of metals may be performed.

To achieve such low temperatures, it’s necessary to lower the pressure. That’s why pressure sensor use is crucial in this industry. Without a pressure sensor, it’s almost impossible to reach cryogenic circumstances.

Here is a list of pressure sensor applications in the cryogenic industry:

• Liquefied gases storage in flask

• Aerospace-cryogenic engine

• Medical Field

• Manufacturing field

• Fuels research

• Cryogenic distillation

I know, It is mind-blowing just how much use an instrument can have. I want to remind you once more that these are not the only pressure sensor applications, but a small list of them.