The Hidden Hero of Precision Measurements: The Signal Conditioner

In today's fast-paced world, precise measurements are crucial in a wide range of industries and applications, from automotive manufacturing to medical research. However, what many people don't realize is that behind every accurate measurement lies a hidden hero - the signal conditioner. This often-overlooked electronic device plays a critical role in conditioning, modifying, and isolating signals from sensors and measuring instruments to ensure accuracy, compatibility, and safety. In this article, we will delve into the fascinating world of signal conditioners, exploring their types, applications, advantages, and disadvantages, and how to choose the right one for your specific needs. So, let's take a closer look at this unsung hero of precision measurements and discover how it can help you achieve better results and greater success.

What is a Signal Conditioner?

A signal conditioner is an electronic device used to modify and enhance electrical signals from sensors, instruments, or other sources to make them suitable for further processing by a data acquisition system, control system, or display device.

Signal conditioners typically provide amplification, filtering, isolation, linearization, and/or conversion of signals. For example, a signal conditioner may amplify a weak sensor signal, filter out unwanted noise or interference, isolate the signal from the ground or other signals to prevent electrical interference, linearize the signal to compensate for non-linearities in the sensor or system, or convert the signal from one type to another (e.g. from voltage to current, or from analog to digital).

Signal conditioners are commonly used in industrial, scientific, and medical applications where accurate and reliable measurement and control of signals is critical. Some examples of sensors that may require signal conditioning include thermocouples, strain gauges, accelerometers, pressure sensors, and flow meters.

When was the First Signal Conditioner Made?

The development of signal conditioning technology can be traced back to the early 20th century when analog electronic circuits began to be used for signal amplification, filtering, and other signal-processing tasks. However, the first signal conditioner as a dedicated electronic device was likely developed in the 1950s or 1960s with the advent of transistor technology.

Early signal conditioners were typically simple analog circuits that provided basic signal amplification and filtering. As electronic technology advanced, signal conditioners became more sophisticated and capable of performing a wider range of signal processing tasks, such as isolation, linearization, and conversion.

Today, signal conditioners are available in a wide range of types and configurations, including standalone units, modular units that can be integrated into larger systems, and integrated circuits that can be embedded in sensors or other devices. The development of digital signal processing technology has also enabled the development of digital signal conditioners that can perform complex signal processing tasks with high accuracy and precision.

What is a Signal Conditioner Circuit?

A signal conditioner circuit is an electronic circuit designed to modify or enhance a signal from a sensor or other source so that it can be processed by other circuits or devices. Signal conditioning circuits typically provide amplification, filtering, isolation, linearization, and/or conversion of signals, depending on the requirements of the particular application.

The specific design of a signal conditioner circuit will depend on the type of signal being processed, as well as the requirements of the application. For example, a signal conditioner circuit for a temperature sensor might include amplification and linearization circuits to convert the small voltage signal from the sensor into a signal suitable for input to a data acquisition system. A signal conditioner circuit for a strain gauge might include amplification, filtering, and noise reduction circuits to accurately measure the small changes in resistance of the gauge caused by changes in strain.

Signal conditioner circuits can be implemented using a wide range of electronic components, including op-amps, resistors, capacitors, inductors, and transistors. The design of a signal conditioner circuit requires a good understanding of electronic circuits and signal processing, as well as the characteristics of the specific signals being processed. Signal conditioning circuits can be found in a wide range of applications, including industrial process control, medical monitoring, and scientific research.

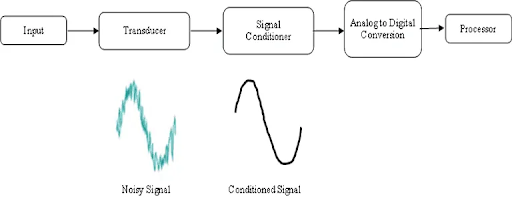

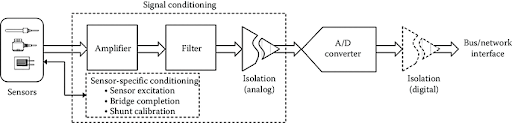

Fig 1. Digital system data acquisition

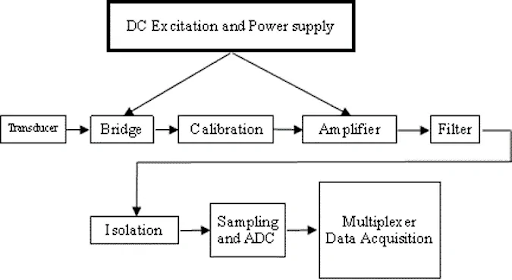

Signal Conditioner Construction

The construction of a signal conditioner will depend on its specific type and design, but some common elements are typically found in most signal conditioners. Here are some of the main components:

- Input stage: The input stage of a signal conditioner is responsible for receiving the input signal from the sensor or other source. This may include input protection circuitry to prevent damage from overvoltage or other electrical disturbances.

- Signal processing stage: The signal processing stage of a signal conditioner is where the actual signal conditioning takes place. This may include amplification, filtering, linearization, isolation, or conversion, depending on the specific type of signal conditioner.

- Power supply: Signal conditioners typically require a power supply to operate, which may be provided by an external source or by an internal battery. The power supply may be regulated to ensure stable operation and prevent noise or other disturbances from affecting the output signal.

- Output stage: The output stage of a signal conditioner is where the conditioned signal is output to the measurement or control system. This may include output protection circuitry to prevent damage to downstream devices.

- Control circuitry: Some signal conditioners may include control circuitry that enables the user to adjust various parameters of the signal conditioning process, such as gain, frequency response, or calibration.

The construction of a signal conditioner will also depend on the specific form factor and packaging, which may range from small PCB modules to rack-mounted units or standalone enclosures. The design of a signal conditioner must take into account the environmental conditions of the application, such as temperature, humidity, and vibration, to ensure reliable operation over the desired lifetime.

Fig 2. Signal Conditioning Circuit Block Diagram

What are the Types of Signal Conditioners?

There are several types of signal conditioners, each with its own working principle, applications, usage, and pros and cons. Here are some of the most common types:

Amplifiers

Amplifiers are signal conditioners that increase the amplitude of an input signal. They are used to boost the signal from a sensor so that it can be accurately measured or processed by other circuits or devices. Amplifiers can be analog or digital and are commonly used in applications such as audio amplification, instrumentation, and data acquisition.

Pros

amplifies weak signals, and improves signal-to-noise ratio.

Cons

introduces noise and distortion, and requires careful design to avoid instability or oscillation.

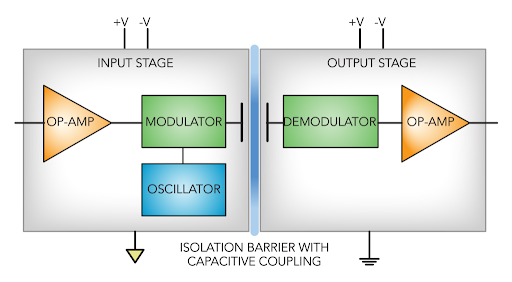

Fig 3. Simplified block diagram of an isolation amplifier.

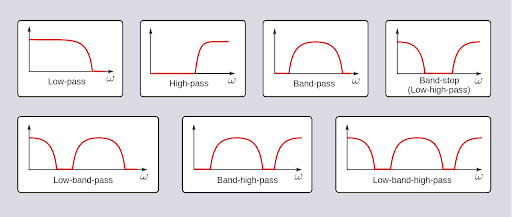

Filters

Filters are signal conditioners that attenuate certain frequencies or ranges of frequencies in an input signal. They are used to remove noise, interference, or unwanted signals from a measurement or control system. Filters can be passive or active and can be designed for specific frequency ranges or response characteristics.

Pros

removes unwanted signals, and improves signal quality.

Cons

may introduce phase shift or delay, and may reduce signal amplitude.

Fig 4. Filtering in signal conditioning

Converters

Converters are signal conditioners that convert an input signal from one form to another. For example, an analog-to-digital converter (ADC) converts an analog signal to a digital signal, while a voltage-to-current converter (V/I) converts a voltage signal to a current signal. Converters are commonly used to interface with other circuits or devices that require a different signal format.

Pros

enables compatibility with different devices, and improves signal resolution.

Cons

may introduce noise or distortion, and may require calibration.

Fig 5. Universal Temperature Converter

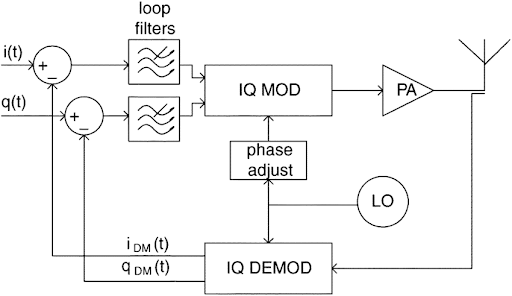

Linearizers

Linearizers are signal conditioners that correct for nonlinearities in an input signal. They are used to ensure that the output signal accurately reflects the physical parameter being measured, even if the sensor produces a nonlinear output signal. Linearizers can be analog or digital and can be designed for specific sensor types or measurement ranges.

Pros

improves accuracy, and enables better control.

Cons

may introduce noise or distortion, and may require calibration.

Fig 6. Feedback linearizer

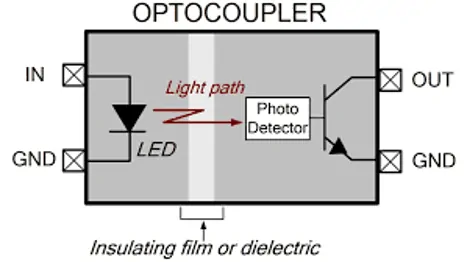

Isolators

Isolators are signal conditioners that provide galvanic isolation between an input signal and other circuits or devices. They are used to prevent ground loops and other sources of interference that can affect the accuracy and reliability of a measurement or control system. Isolators can be analog or digital and can be designed for specific voltage or current ranges. Pros

improves noise immunity, and prevents ground loops.

Cons

introduces cost and complexity, and may reduce signal amplitude.

Fig 7. Optocoupler for Isolation

Signal Conditioner Comparing Types Table

Here is a table comparing some common types of signal conditioners based on their working principle, applications, usage, and pros and cons:

Table 1. Comparing different types of signal conditioners

| Type of Signal Conditioner | Working Principle | Applications | Usage | Pros | Cons |

| Amplifier | Increases amplitude of input signal | Audio amplification, instrumentation, data acquisition | Boosts weak signals and improves signal-to-noise ratio | Amplifies weak signals improve signal quality | Introduces noise and distortion, and requires careful design to avoid instability or oscillation |

| Filter | Attenuates certain frequencies or ranges of frequencies in the input signal | Removing noise, interference, and unwanted signals | Removes unwanted signals, improves signal quality | Removes unwanted signals, improves signal quality | May introduce phase shift or delay, may reduce signal amplitude |

| Converter | Converts input signal from one form to another | Analog-to-digital conversion, voltage-to-current conversion | Enables compatibility with different devices, improves signal resolution | Enables compatibility with different devices, improves signal resolution | May introduce noise or distortion, may require calibration |

| Linearizer | Corrects for nonlinearities in the input signal | Nonlinear sensors, control systems | Improves accuracy, enables better control | Improves accuracy, enables better control | May introduce noise or distortion, may require calibration |

| Isolator | Provides galvanic isolation between the input signal and other circuits or devices | Preventing ground loops, improving noise immunity | Improves noise immunity, prevents ground loops | Improves noise immunity, prevents ground loops | Introduces cost and complexity, may reduce the signal amplitude |

Note that this is not an exhaustive list of all types of signal conditioners, and the specific pros and cons may vary depending on the particular design and implementation of each type. The choice of signal conditioner will depend on the specific requirements of the application and the desired performance characteristics.

Fig 8. All types of signal conditioners

What are the Signal Conditioner Applications?

Signal conditioners are used in a wide range of applications where accurate and reliable measurement or control of signals is required. Here are some common applications of signal conditioners:

Industrial process control

Signal conditioners are often used in industrial process control applications to measure and control various parameters such as temperature, pressure, flow rate, or level. They may be used to condition signals from sensors or transducers to ensure accurate and reliable measurement.

Data acquisition

Signal conditioners are used in data acquisition systems to prepare signals for digitization and analysis. They may be used to amplify, filter, linearize, or convert signals from sensors or other sources.

Instrumentation

Signal conditioners are used in instrumentation applications to improve the accuracy and reliability of measurements. They may be used to compensate for nonlinearities in sensors, improve the signal-to-noise ratio, or provide galvanic isolation.

Audio amplification

Signal conditioners are used in audio amplification applications to amplify signals from microphones or other sources. They may be used to provide gain, filtering, or impedance matching.

Medical devices

Signal conditioners are used in medical devices such as patient monitors, ECGs, or blood glucose meters to measure and condition biological signals. They may be used to filter out noise, improve signal quality, or provide isolation.

Power electronics

Signal conditioners are used in power electronics applications to measure and control various parameters such as voltage, current, or power. They may be used to condition signals from sensors or transducers to ensure accurate and reliable measurement.

These are just a few examples of the many applications of signal conditioners. The choice of signal conditioner will depend on the specific requirements of the application and the desired performance characteristics.

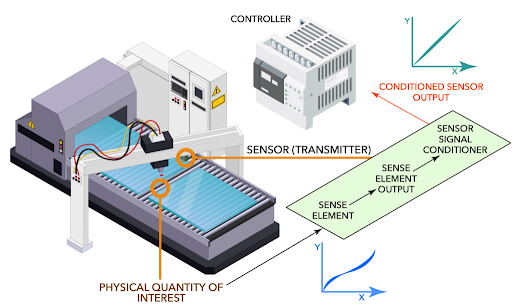

Fig 9. Signal conditioners are often used in data-acquisition applications.

Installation and Maintenance

How to Use a Signal Conditioner?

To use a signal conditioner, you need to follow these general steps:

- Identify the input and output signals: Determine the type and range of the input signal that you want to condition, as well as the type and range of the output signal that you need.

- Select the appropriate signal conditioner: Choose a signal conditioner that is compatible with the input signal and has the desired features to condition the signal to the desired output.

- Connect the input signal: Connect the input signal to the appropriate input terminals of the signal conditioner. Make sure to follow the manufacturer's instructions for proper wiring.

- Set the signal conditioning parameters: Depending on the type of signal conditioner, you may need to adjust various parameters such as gain, filtering, or offset to condition the signal to the desired output. Follow the manufacturer's instructions for setting the parameters.

- Connect the output signal: Connect the output signal from the signal conditioner to the appropriate instrument or system that requires the conditioned signal.

- Test the signal conditioner: Verify that the signal conditioner is operating properly by testing the output signal under various operating conditions.

It is important to note that the specific steps for using a signal conditioner may vary depending on the type and model of the device. Always follow the manufacturer's instructions and safety guidelines when using a signal conditioner.

Signal Conditioner Calibration

Calibration of a signal conditioner is the process of verifying and adjusting the output of the signal conditioner to ensure that it provides accurate and reliable conditioning of the input signal. Calibration is important to ensure that the conditioned signal is within the desired range and that the accuracy and precision of the conditioned signal meet the requirements of the application.

The specific steps for calibrating a signal conditioner may vary depending on the type and model of the device but generally include the following:

- Determine the calibration requirements: Identify the calibration parameters, such as the input and output ranges, accuracy, and linearity, as well as any specific calibration procedures required by the manufacturer.

- Prepare the calibration equipment: Select and set up the calibration equipment, such as a reference signal source, a multimeter, and any necessary cables or connectors.

- Apply the reference signal: Apply a known reference signal to the input of the signal conditioner and measure the output signal with the calibration equipment.

- Compare the output signal to the reference signal: Compare the output signal of the signal conditioner to the reference signal and calculate any discrepancies or errors.

- Adjust the signal conditioner: Adjust the signal conditioner as needed to correct any errors or discrepancies in the output signal.

- Repeat the calibration: Repeat the calibration process until the output signal of the signal conditioner is within the desired range and meets the required accuracy and precision.

- Document the calibration: Record the calibration data, including the calibration results, any adjustments made, and the date and time of the calibration.

It is important to follow the manufacturer's instructions and safety guidelines when calibrating a signal conditioner and to periodically re-calibrate the device as needed to maintain accurate and reliable signal conditioning.

Signal Conditioner Accuracy

The accuracy of a signal conditioner refers to how well the device conditions the input signal to the desired output signal. The accuracy of a signal conditioner is typically expressed as a percentage of the full-scale output (FSO) and is specified by the manufacturer.

The accuracy of a signal conditioner depends on various factors such as the type of signal conditioner, the quality of the components used, and the calibration of the device. The accuracy can be affected by temperature variations, power supply fluctuations, and other environmental factors.

To ensure the accuracy of a signal conditioner, it is important to follow the manufacturer's instructions for proper installation, calibration, and use of the device. Regular calibration of the signal conditioner is also recommended to maintain the accuracy and reliability of the conditioned signal.

When selecting a signal conditioner, it is important to consider the required accuracy for the application and to choose a device that meets or exceeds these requirements. The accuracy of the signal conditioner should be compatible with the accuracy requirements of the measuring instrument or control system that receives the conditioned signal.

It is important to note that the accuracy of a signal conditioner may vary depending on the specific model and manufacturer. It is recommended to carefully review the product specifications and consult with the manufacturer if necessary to ensure the accuracy and reliability of the signal conditioner for the desired application.

Advantages and Disadvantages of Using Signal Conditioner

Advantages of Using a Signal Conditioner:

Signal conditioning improves accuracy and reliability

Signal conditioners can improve the accuracy and reliability of the output signal by eliminating noise, filtering out unwanted frequencies, and compensating for environmental factors such as temperature and humidity.

Signal conditioning enables compatibility

Signal conditioners can convert signals from one type to another, allowing different types of instruments and devices to communicate with each other and enabling compatibility between different systems.

Signal conditioning increases flexibility

Signal conditioners can be used to modify or adjust the output signal to meet the specific requirements of the application, allowing greater flexibility in system design and operation.

Signal conditioning enhances safety

Signal conditioners can be used to isolate and protect sensitive instruments and devices from potentially damaging signals, enhancing safety and reducing the risk of equipment damage or failure.

Disadvantages of Using a Signal Conditioner:

Signal conditioning can add cost

Signal conditioners can add cost to the system design and implementation, particularly if multiple signal conditioners are required to condition different types of signals.

Signal conditioning can add complexity

Signal conditioners can add complexity to the system design and operation, particularly if the system requires multiple signal conditioners with different configurations and settings.

Signal conditioning can introduce errors

Signal conditioners can introduce errors or inaccuracies into the output signal if they are not calibrated properly or if they are not compatible with the input signal or the measuring instrument.

Signal conditioning can reduce signal resolution: Signal conditioners can reduce the resolution of the output signal, particularly if they use filtering or averaging techniques to smooth the signal.

Overall, the advantages of using a signal conditioner do outweigh the disadvantages, particularly in systems that require accurate and reliable signal conditioning or that require compatibility between different types of instruments and devices. It is important to carefully consider the specific requirements of the application and to choose a signal conditioner that is compatible with the input signal and that meets the accuracy and reliability requirements of the system.

Important Factors to Choosing Signal Conditioner

When selecting a signal conditioner, there are several important factors to consider, including:

1.Signal type

What type of signal does the sensor or measurement instrument produce? Is it a voltage, current, frequency, or some other type of signal? Ensure that the signal conditioner you choose can handle the specific signal type.

2.Sensor compatibility

Does the signal conditioner work with the specific type of sensor you are using? Make sure the signal conditioner is compatible with the sensor's output and sensitivity range.

3.Accuracy and precision

What level of accuracy and precision do you require for your measurement application? Look for a signal conditioner with a high level of accuracy and resolution to ensure reliable and consistent measurements.

4.Operating environment

What are the temperature range, humidity level, and other environmental factors in the location where the signal conditioner will be used? Ensure that the signal conditioner can operate reliably in these conditions.

5.Isolation and noise reduction

Does the signal conditioner provide sufficient isolation and noise reduction to eliminate interference and ensure signal integrity? Look for signal conditioners with advanced isolation and filtering capabilities.

6.Power supply

What is the power supply voltage and type available at the location where the signal conditioner will be used? Choose a signal conditioner with a compatible power supply.

7.Cost and maintenance

What is the cost of the signal conditioner, and what is the expected maintenance schedule and requirements? Choose a signal conditioner that fits your budget and requires minimal maintenance.

By considering these factors, you can choose a signal conditioner that meets your specific needs and helps you achieve accurate and reliable measurements.

Top 5 Brands of Signal Conditioner

There are several well-known and reputable brands of signal conditioner available in the market. Some of the top brands of signal conditioners are:

Phoenix Contact

Phoenix Contact is a leading manufacturer of industrial automation and control solutions, including signal conditioners. Their signal conditioning products include analog signal conditioners, temperature transmitters, and frequency converters.

Omega Engineering

Omega Engineering is a leading provider of industrial measurement and control solutions, including signal conditioners. Their signal conditioning products include signal isolators, converters, amplifiers, and temperature transmitters.

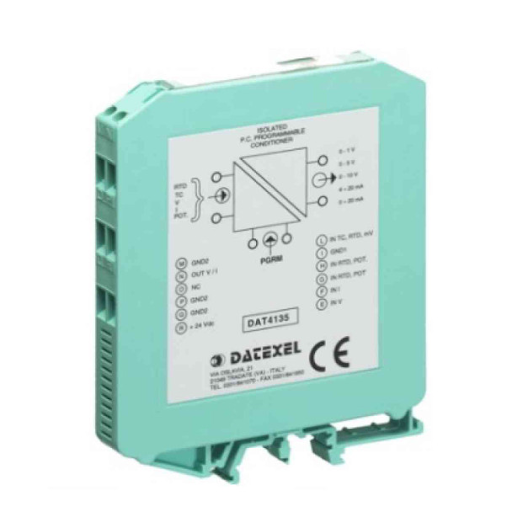

Datexel

datexel is a leading manufacturer of measurement and control solutions for industrial applications, including signal conditioners. Their signal conditioning products include signal isolators, amplifiers, converters and transmitters.

Analog Devices

Analog Devices is a leading provider of semiconductor solutions for industrial, automotive, and consumer applications, including signal conditioning. Their signal conditioning products include analog-to-digital converters, digital-to-analog converters, and signal amplifiers.

Schneider Electric

Schneider Electric is a global provider of energy and automation solutions, including signal conditioning products. Their signal conditioning products include analog signal conditioners, digital signal isolators, and temperature transmitters.

Other notable brands of signal conditioner include Pepperl+Fuchs, Wago, Turck, and Weidmuller. When selecting a signal conditioner, it is important to consider the specific requirements of the application and to choose a device from a reputable and reliable manufacturer.

Conclusion

In conclusion, signal conditioners are an essential component of many measurement and control systems, providing accurate and reliable signal conditioning, conversion, and isolation. Signal conditioners can improve system performance, compatibility, and flexibility while enhancing safety and protecting sensitive instruments and devices.

To Recap

Here are some frequently asked questions and their answers related to signal conditioners:

1.What is a signal conditioner?

A signal conditioner is an electronic device that is used to condition and modify analog or digital signals from sensors or measuring instruments for processing, recording, or control purposes.

2.What are the types of signal conditioners?

The types of signal conditioners include amplifiers, filters, converters, isolators, and transmitters.

3.What is the working principle of a signal conditioner?

The working principle of a signal conditioner depends on its type. Amplifiers amplify signals, filters remove unwanted frequencies, converters convert signals from one type to another, isolators provide electrical isolation, and transmitters convert sensor signals into a standardized output signal.

4.What is the difference between a signal conditioner and a transducer?

A signal conditioner and a transducer are both electronic devices used in the measurement and control of physical parameters, but they perform different functions.

A transducer is a device that converts a physical parameter (such as temperature, pressure, or strain) into an electrical signal that can be measured or processed by other electronic circuits or devices. Transducers are available in a wide range of types and configurations, including thermocouples, pressure sensors, accelerometers, and load cells. The output of a transducer is typically a low-level analog signal, such as a voltage or current proportional to the physical parameter being measured.

A signal conditioner, on the other hand, is a device used to modify or enhance the signal from a transducer or other source so that it can be processed by other circuits or devices. Signal conditioning circuits typically provide amplification, filtering, isolation, linearization, and/or conversion of signals, depending on the requirements of the particular application. The specific design of a signal conditioner will depend on the type of signal being processed, as well as the requirements of the application.

5.Why do we need a signal conditioner?

There are several reasons why a signal conditioner may be necessary for a measurement or control system:

Amplification: Sometimes, the signal from a sensor may be too weak to be accurately measured or processed by other circuits or devices. A signal conditioner can amplify the signal to a level that is suitable for further processing.

Filtering: In many applications, there may be unwanted noise or interference present in the signal. A signal conditioner can filter out this noise or interference to improve the accuracy and reliability of the measurement.

Isolation: In some cases, it may be necessary to isolate the signal from other signals or from the ground to prevent electrical interference. A signal conditioner can provide galvanic isolation to prevent ground loops and other sources of interference.

Linearization: Some sensors may produce nonlinear output signals that need to be corrected to accurately measure the physical parameter being measured. A signal conditioner can perform linearization to ensure that the output signal is proportional to the physical parameter being measured.

Conversion: In some cases, it may be necessary to convert the signal from one form to another (e.g. from voltage to current, or from analog to digital) to interface with other circuits or devices. A signal conditioner can perform this conversion.

6.What are the applications of signal conditioners?

Signal conditioners are used in a wide range of industries and applications, including process control, industrial automation, automotive, aerospace, medical, and scientific research.

7.What is the difference between a signal conditioner and a transducer?

A signal conditioner modifies and conditions the output signal from a transducer, while a transducer converts a physical quantity into an electrical signal.

8.Why do we need a signal conditioner?

Signal conditioners are needed to improve signal accuracy, reliability, compatibility, and safety, as well as to provide flexibility and customization to the measurement and control system.

9.How can signal conditioners be calibrated?

Signal conditioners can be calibrated by comparing the output signal to a known reference signal and adjusting the calibration settings accordingly.

10.What is signal conditioner accuracy?

Signal conditioner accuracy refers to the degree to which the output signal accurately represents the input signal, taking into account factors such as noise, distortion, and offset.

11.What are the advantages of using a signal conditioner?

The advantages of using a signal conditioner include improved accuracy and reliability, compatibility, flexibility, and safety.

12.What are the disadvantages of using a signal conditioner?

The disadvantages of using a signal conditioner include added cost, complexity, potential errors, and reduced signal resolution.

13.What are some top brands of signal conditioners?

Some top brands of signal conditioners include Phoenix Contact, Omega Engineering, Datexel, Analog Devices, and Schneider Electric.

14.How do you choose the right signal conditioner?

To choose the right signal conditioner, you should consider the specific requirements of the application, including the type of signal, the required accuracy and reliability, and compatibility with the measuring instrument or control system.

15.Can a signal conditioner be used with multiple sensors or instruments?

Yes, a signal conditioner can be used with multiple sensors or instruments as long as the input signal is compatible with the conditioner's input range and configuration.

16.Can a signal conditioner be used in hazardous environments?

Yes, there are signal conditioners that are designed for use in hazardous environments and are certified for use in explosive or flammable atmospheres.

17.How do you troubleshoot a signal conditioner?

To troubleshoot a signal conditioner, you should check the input signal, power supply, grounding, and calibration settings. You may also need to check the wiring and connections between the signal conditioner and the measuring instrument or control system.

References

https://www.designworldonline.com/signal-conditioner-basics/

https://www.tronicszone.com/blog/signal-conditioning-iot-sensors/

https://www.newteksensors.com/lvdt-signal-conditioning/

https://www.researchgate.net/figure/Cartesian-feedback-linearizer_fig4_3041116

https://www.pepperl-fuchs.com/global/en/classid_1827.htm

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecting millions …16th Apr 2025