Proximity Sensor in The Core of the Nuclear Reactor!

Summary

Pressurized-water reactors, operating at a Swiss nuclear power-plant, utilize fuel rods containing radioactive material to produce energy. During operation, bundles of rods are immersed in water; a purpose-built grab removes them when the fuel is spent. Contrinex all-metal inductive sensors detect the presence of a bundle in the grab and confirm that the grab is closed before lifting commences.

Application

In a nuclear power-plant, the reactor core is built from fuel bundles, each containing 200 to 300 fuel rods. The core is immersed in water, which serves both as a coolant and to transfer energy to generating turbines. Core temperatures can exceed 300oC (572oF).

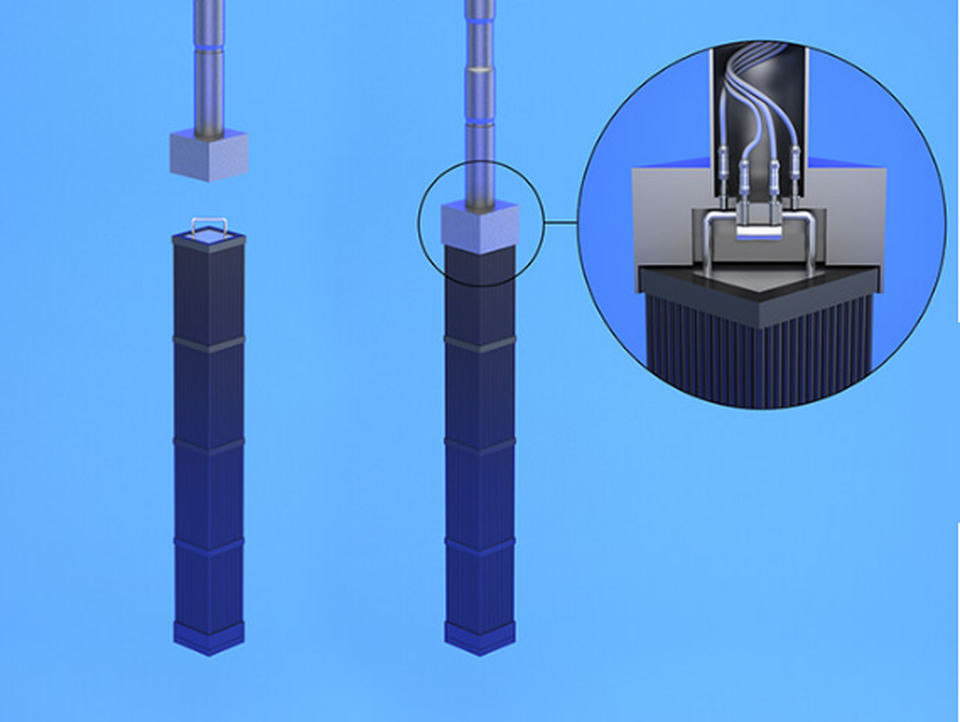

Periodically, individual bundles are removed when all the fuel rods are spent. A specially adapted crane, fitted with a CNC X-Y controller, positions a purpose-built grab directly over the bundle to be moved. The grab is lowered into the water and grips the top of the bundle, which is then lifted out of the core.

Two sensors, suitable for the hazardous and hostile environment, are required; one detects the presence of the bundle in the grab, initiating closure; the second senses the position of the grab, allowing lifting only after complete closure. Maintenance occurs only at 18- to 24-month intervals; consequently, exceptional reliability is essential.

Solution

Contrinex Extreme inductive sensors from the Full Inox family are designed for exceptionally demanding environments and ideal for this application. Constructed from single pieces of V2A/AISI 303 stainless steel with integral M12 connectors, IP68- and IP69K-rated Extreme sensors are pressure-resistant to 80 bar (1160 psi), corrosion-resistant and impervious to water ingress.

These M12-diameter embeddable sensors are only 60mm long with a 6mm sensing distance and are mounted directly in the structure of the grab. They are lightweight and function exceptionally reliably without compromising the correct operation of the grab. Vacuum-encapsulated electronics ensure excellent resistance to shock and vibration, and no additional electrical or mechanical protection is required.

The sensors are configured with an industry-standard PNP normally-closed interface, and connection to the customer’s control system is via a flexible PUR-sheathed cable. The M12 connector allows easy disconnection and removal when required.

Access to the sensors is only possible at 18- to 24-month intervals during scheduled maintenance. Because exceptional reliability is required, double redundancy allows for premature sensor failure. Four sensors are fitted to each grab, with two identical sensors operating at each sensing point. In the unlikely event that a failure occurs, normal operation is unaffected.

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025