Flow Meter Vs. Flow Transmitter Vs. Flow Switch

To control the flow of a fluid in your system you need to measure it first and then based on what you want to do with that flow, you should choose a device in flow measurement family. Flow meter, flow transmitter and flow switches are members of this family with the same goal but different functions.

Flow Transmitters

Flow transmitters offer electrical outputs which are proportional to flow inputs. They make use of flow meters to measure the flow of gasses and liquids.

Flow transmitters use three basic forms of measurement: velocity, mass, and volume.

What is a Flow Transmitter and what is its function?

A flow transmitter is an upgraded model of a flow meter. It is a flow meter that has an integrated electronic circuit as an operational system.

In a flow transmitter, the function of flow rate measurement is executed through the electronic circuit, based on the instruction made by operator.

Since the flow transmitters are equipped with an electronic circuit, they enable engineers to control and observe the fluid flow.

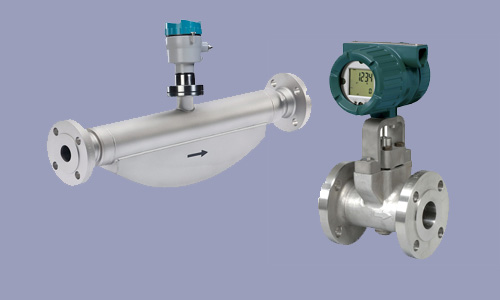

Flow Meter vs. Flow Transmitter:

In the fluid transmission system, numerous forms of tools are used to measure and manipulate the process parameters.

The flow meter and the flow transmitter are crucial tools used in these systems. Since Sometimes their functions are interchanged, these two devices are regularly assumed as one.

However, their functions and structure are pretty different from each other.

Differences between a Flow Meter and a Flow Transmitter:

- The flow meters’ function is to measure the flow rate. Alternatively, the flow transmitters not only measure the flow rate, but also, assist in controlling and observation of the flow.

- A flow meter is a standard mechanical device like orifices, venturi meters, etc. Alternatively, a flow transmitter is a mechanical structure and electronic functioning circuitry.

- A flow meter works for manual, on-field applications, however, a flow transmitter can be remotely operated.

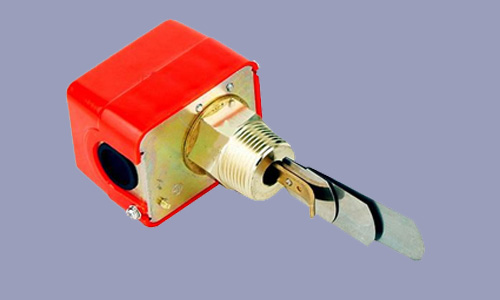

What is a Flow switch?

A flow switch is a mechanical switch that is switched on or off in reaction to the action of flowing or non-flowing of a fluid such as air or water.

The switch generally works via using a paddle that gets displaced in response to the pressure of fluid moving past it.

"The flow switch includes a paddle system that has an everlasting magnet, placed at its top end. A reed contact is located outside the flow above this magnet. Another magnet with opposite polarity is used to provide a reset force."

A flow switch senses the flow of fluids in pipes. In regular Flow switches “paddles” are used as the flow-sensing elements, the movement of which actuates one or greater switch contacts.

A flow switch is also a unique electric-powered tool with a totally easy layout and a small size. However, despite its simplicity, the flow switch performs a crucial function in different applications.

The objective of using these tools is to protect a pump and to check the flow of air, gas, or liquid in a specific line when needed. Furthermore, they could make alarms sound on the occasion of necessity.

The “normal” condition of a switch is the resting status with no stimulation. A flow switch will be in its “normal” position when it senses minimal flow (i.e. no fluid moving through the pipe).

A simple paddle located in a fluid stream can sense a mechanical pressure that can be used to actuate a switch mechanism:

Similar to the whole other process switches, flow switches exhibit Deadband (also called differential) in their switching action.

For instance, a flow switch that activates at 15 GPM rising, will now no longer be reset at 15 GPM falling. This switch might much more likely reset at some lower flow rate inclusive of 14 GPM.

Due to the “trip” and “reset” points being different, the switch prevents useless cycling if the process flow rate hovers close to one critical value.

Possible reasons for the wrong activation of flow switches:

- Entrapped air or gas

- Turbulence in tubing or unit

- Damaged Mechanical sensor assembly

- The liquid is too viscous

- Not using the fittings supplied by the producer

Applications:

One application for these switches can be the detection of fluid flow and measurement of fan speeds.

Also flow switch is used to protect a HVAC heating element from getting too energized too early before the airflow reaches this element to cool it down.

Flow switches may additionally be used to alarm if a ventilation fan in an risky region fails and the airflow is halted.

Other application for flow switches:

- Pump protection

- Safety spray nozzle tracking

- Cooling water or heat exchangers

- Oil well machine testing

- Drain line flow

- Relief valve tracking

You can also read the following article to get more familiar with flow meters:

Flow Rate (Volume Flow Rate, Mass Flow Rate)

Flow meter (Working Principle, Different Types and FAQs)

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecting millions …16th Apr 2025