Flow meter (Working Principle, Different Types and FAQs)

Flow meters are tools that measure the flow rate of a fluid. They are flow measuring devices able to measure the linear, non-linear, mass or volumetric flow rate of a gas or a liquid and are also named Flow Gauges or flow measurement devices. Precise flow measurements of fluids are required for the efficient quality and control of industrial processes.

Types of Flow Meters:

Generally, two types of flow meters are known:

Volumetric Flow Meter

They are called volumetric flow meters because they measure the volume of fluid passing through a particular location over a specified period of time.

These tools provide us with an instantaneous analog, digital or pulse output of the volume flow rate of the gas or liquid.

In the following, different types of flow meters will be mentioned.

Mass Flow Meter

Mass flow meters measure the fluid mass flow rate that travels through a tube per unit of time.

Types of Volumetric Flow Meters:

- Differential Head type

- Variable Area type (Rota meters)

- Magnetic flow meters

- Ultrasonic flow meters

- Turbine flow meters

- Vortex flow meters

- Positive Displacement Meters

Types of Mass Flow Meters

- Coriolis Mass flow meter

- Thermal Mass flow meters

What comes next is the explanation of different type of flow meters which are popular in the industries.

What is a Differential Head Flow Meter

There is a pressure difference between the upstream & downstream sides of a restriction in a confined fluid stream, which is related to the square of fluid velocity.

Q α √ ΔP

(Q = Volume flow rate and ΔP = Differential pressure between taps)

A Differential Head Flow Meter itself has three distinct types.

Orifice plates

There are two different types of Orifice plates

- Concentric orifice plates: they are the most commonly used Orifice plates.

- Segmental & Eccentric orifice plates: they are used for fluids containing suspended solids.

Venturi Meters

A venturi tube measures flow rates by compressing fluids and measuring the differential pressure drop. In the upstream cone of the Venturi meter, the velocity is higher, and the pressure is lower.

Pressure drop in the upstream cone is used to estimate the rate of flow through the device.

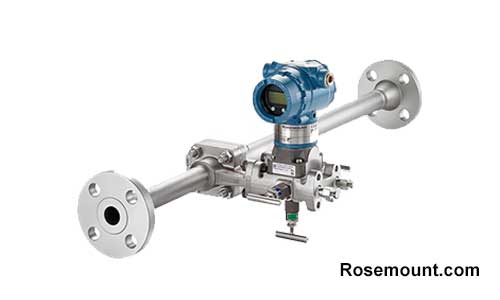

Annubar

It is an instrument used for measuring the fluid flow (liquid, vapor, or gas) in a pipeline. The flow is measured by creating a differential pressure.

As per Bernoulli’s theorem, this differential pressure is proportional to the square of the fluid velocity in the pipeline.

These flow meters measure the differential pressure which is then converted to flow rate using another instrument.

What is a Variable Area Flow Meter (Rota meters)?

Variable area flow meters or Rota meters are one of the widely used common flow meter types.

They include a vertical glass or plastic tube. The dimension of the tubes varies from top to bottom; that’s why they're called variable area flow meters. Within the tubes, there is a free-moving metering float.

What is a Magnetic Flow Meter?

According to Faraday's law of electromagnetic induction, a conductive liquid flow through a magnetic field makes electrodes that are installed on the walls of flow tubes to detect the voltage signal.

The quicker the motion of the fluid, the more the generation of the voltage is. The generated voltage will be proportional to the movement of the liquid that is flowing.

Faraday's law is applied in magnetic flow meters. To distinguish the flow of the liquid, the voltage signal will be processed by the electronic transmitter.

The technology of magnetic flow meters generates signals that are linear with the flow. This is one of the differences between this type of technology and other flow meter technologies.

This allows the turndown of the magnetic flow meters to reach 20: 1 or even better, without compromising accuracy. These flow meters are very popular.

What is an Ultrasonic Flow Meter?

Their structure and function are as follows: A pair (or pairs) of transducers, each of which has its transmitter and receiver, are placed on the pipe wall, one (set) on the upstream and the other (set) on the downstream.

The time for acoustic waves to travel from the upstream transducer to the downstream transducer (td) is shorter than the time it requires for the same waves to travel from the downstream to the upstream (tu).

The more the difference, the higher the flow speed.

Only clean liquids and gasses can be measured by these sensors. These flow meters are applied in various industries including:

- Oil and gas

- Water and wastewater

- Power

- Chemical

- Food and beverage

- Pharmaceutical

- Metals and mining

- Pulp and paper

What is a Turbine Flow Meter?

In order to rotate a “pinwheel” (rotor) in the flow stream, the turbine flow meters utilize the mechanical energy of the fluid.

The rotor has angled blades on it to transform energy from the flow steam into rotational energy. The rotor shaft rotates around bearings.

The faster the motion of the fluid, proportionally faster the rotor’s rotation.

Today, Turbine flow meters account for 7% of global sales of flow meters.

The shaft’s rotation can be detected by sensing the movement of the blades or in a mechanical way. Each blade or embedded piece of metal produces a pulse and this makes magnetically detection of blade movement possible.

If wetted sensors are used, material of construction constraints may occur. That's why turbine flow meter sensors are usually installed external to the flowing stream. Faster the movement of the fluid, the more the number of generated pulses.

In order to determine the fluid flow, the transmitter processes the pulse signal. Sensing systems and transmitters are present to detect flow in forward and reverse flow directions.

What is a Vortex Flow Meter?

In this type of flow meters, Along with the fluid flow vortices are shed from the body’s alternating sides and this shedding frequency is exactly proportional to fluid velocity.

Distinguishing the vortices will be done through pressure changes in the vortex stream. The rate of vortices’ development is exactly proportional to the rate of flow.

What is a Positive Displacement Flow Meter?

The only flow measurement technology which straightly measures the volume of the fluid passing through the flow meter is Positive displacement flow meter technology.

Positive displacement flow meters do this via frequently entrapping fluid and measuring its flow. We can think of this process as frequently filling a bucket with fluid before dumping the contents downstream.

The number of times the bucket gets full and empty shows the flow through the flow meter.

Many positive displacement flow meter geometries are available.

What is a Coriolis Mass Flow Meter?

- When a moving mass is subjected to an oscillation perpendicular to its direction of movement, Coriolis forces arise relying on the mass flow.

- When the tube is moving upward throughout the first primary of a cycle, the fluid flowing into the meter resists being forced up with the aid of pushing down on the tube.

- On the other side, the fluid flowing out of the meter resists having its vertical motion reduced with the aid of pushing up on the tube. This motion makes the tube twist.

- This twisting motion is sensed with the aid of a pick-up and is immediately associated with the mass flow rate

What is a Thermal Mass Flow Meter?

Thermal flow meters are most routinely utilized to measure the mass flow of clean gasses, such as air, nitrogen, hydrogen, helium, ammonia, argon, and other industrial gasses.

Their function is as follows:

- They work by monitoring the cooling effect of a gas stream as it travels over a heated transducer.

- Gas flow passes over two PT100, RTD transducers.

- The temperature transducer monitors the actual gas process temperature, while the self-heated transducer is kept at a constant differential temperature by changing the current through it.

- The more the mass flow passes over the heated transducer, the more current is needed to maintain a constant differential temperature.

- The estimated heater current is, hence, an estimation of the gas mass flow rate.

Note: Most thermal flow meters are used to measure gas flows.

You can also read the following article to get more familiar with flow meter:

Flow Meter Vs. Flow Transmitter Vs. Flow Switch

Flow Rate (Volume Flow Rate, Mass Flow Rate)

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025