Count on it: The Essential Guide to Understanding and Using Electronic Counters!

Electronic counters are essential tools for measuring and monitoring a wide range of electrical signals, and they are commonly used in science, engineering, manufacturing, and other fields. Counters can measure properties such as frequency, pulse width, duty cycle, and event counts, and they provide accurate and reliable measurements that are crucial for many applications. Whether you are a student learning about electronics, an engineer designing a new circuit, or a scientist studying electrical signals, understanding how to use electronic counters is essential. In this guide, we will explore the fundamentals of electronic counters, including how they work, the types of counters available, their applications, advantages and disadvantages, and more.

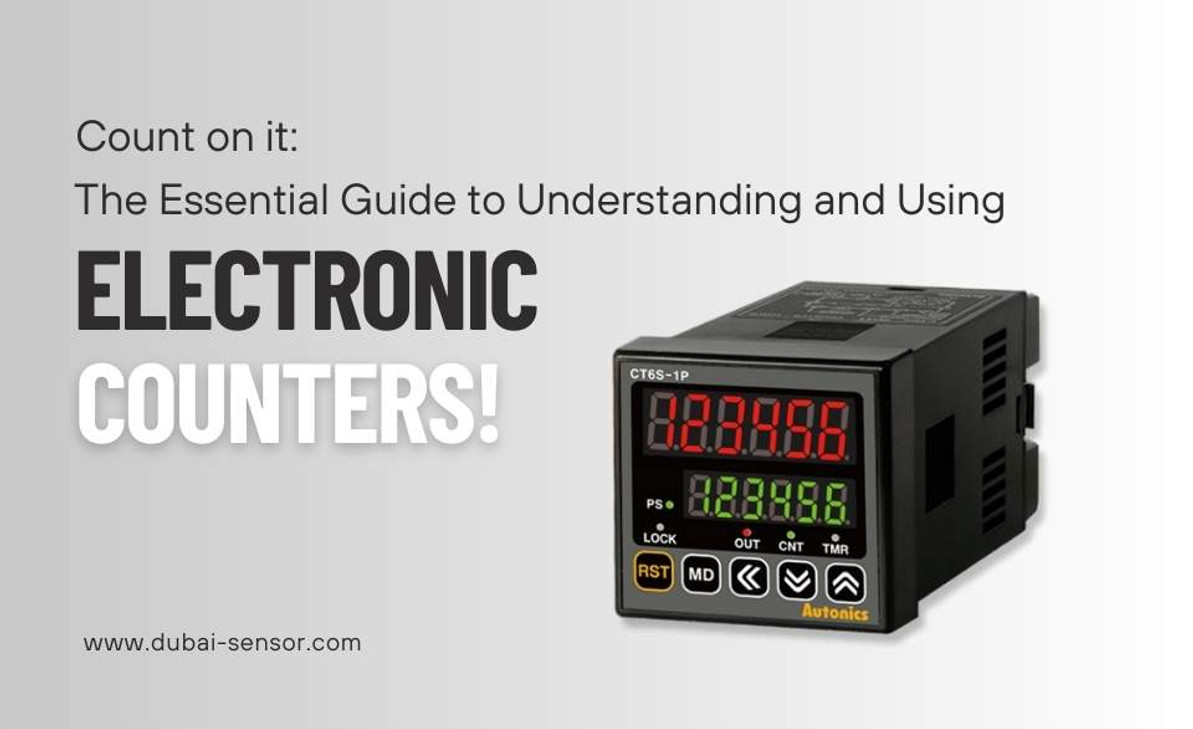

Fig 1. Electronic counters

What is an Electronic "Counter"?

A "counter" is a type of electronic device that is used to count events or occurrences of a particular signal. Counters are often used in digital electronics and are typically implemented using integrated circuits known as "counters". These devices are used in a wide range of applications, including timing circuits, frequency measurement, and event counting. Counters can be designed to count up, down, or in both directions, and they can have a range of different counting modes and outputs. So, in summary, a "counter" is not a specific electronic device, but rather a type of device used for counting events or signals.

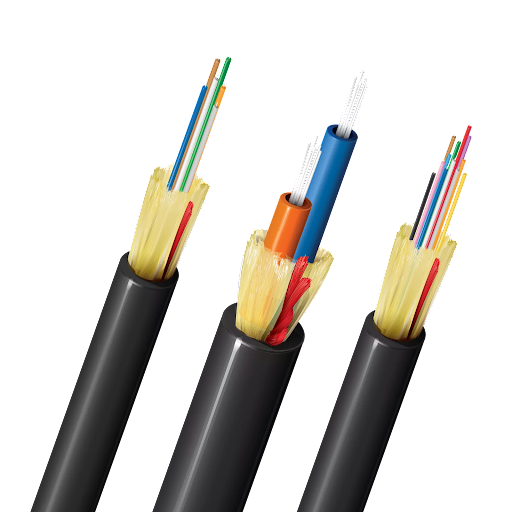

Fig 2. Counter IC in an electric circuit

When Was the First Counter Made?

The concept of counting has been around for thousands of years, but the first electronic counter was invented in the early 20th century. The first electronic counting devices were mechanical counters, which were used to count the revolutions of machines, such as steam engines. These early counters were based on mechanical linkages and gears and were not digital.

The first digital electronic counter was invented in the 1930s by the American engineer Joseph B. Johnson. This device was called the Dekatron, and it used a series of gas-filled tubes to count pulses. The Dekatron was used in early computer systems, such as the Harvard Mark II.

In the years following the invention of the Dekatron, many other types of electronic counters were developed, including vacuum tube counters, transistor counters, and integrated circuit counters. Today, digital counters are a standard component of many electronic devices and systems and are used in a wide range of applications, from simple timers to complex control systems.

Fig 3. Early counter integrated circuit

How does a Counter Work?

The operation of a counter depends on its type, but most digital counters work by counting pulses from an input signal. The basic operation of a digital counter involves the following steps:

Input Signal

The counter receives an input signal to be counted. This signal can be a series of electrical pulses or logic level changes.

Clock Signal

The counter generates a clock signal to drive the internal flip-flops. The clock signal determines the speed at which the counter counts and is usually a fixed or variable frequency.

Counting

The input signal is used to increment the count value of the counter. This is achieved by a chain of flip-flops that store the current count value. Each flip-flop can represent one bit of the count value, and the total count value is determined by the number of flip-flops on the counter.

Reset

The counter can be reset to zero using a reset signal. This signal sets all the flip-flops to their initial state, which clears the count value.

Output

The count value is available at the output of the counter. The output can be in binary, BCD (binary-coded decimal), or other formats, depending on the counter's design.

Digital counters can be implemented using a variety of technologies, including integrated circuits (ICs), field-programmable gate arrays (FPGAs), and microcontrollers. Counters can also have additional features, such as up/down counting, preset values, and counting modes.

Fig 4. Binary counter circuit

Counter Internal Parts

The internal parts of a counter depend on the type of counter being used. However, most digital counters share some common internal components.

- Input Stage

The input stage is part of the counter that receives the input signal to be counted. This signal is typically in the form of electrical pulses or logic level changes.

- Flip-Flops

Flip-flops are the basic building blocks of most digital counters. A flip-flop is a circuit that can store one bit of information (either 0 or 1) and can be set or reset based on input signals. Flip-flops are connected in a chain to create a counter that can count from 0 to 2^n-1, where n is the number of flip-flops in the chain.

- Control Logic

The control logic is part of the counter that generates the clock signals to drive the flip-flops. It also generates the control signals to reset the counter to zero or to enable/disable counting.

- Output Stage

The output stage is part of the counter that generates the output signals indicating the current count value. The output can be in binary, BCD (binary-coded decimal), or other formats, depending on the application.

- Clock

The clock is the timing signal used to drive the counter. The clock signal can be generated internally or externally and can have a fixed or variable frequency.

- Decoding Logic

The decoding logic is used to convert the binary count value into a format suitable for display or further processing. For example, BCD-to-seven-segment decoders are commonly used to display the count value on a digital display.

What Formulas do Counters Follow While Operating?

Here are some common counter formulas with examples:

Frequency Calculation

Frequency (f) = 1 / (t x N)

- Where t is the period of the signal in seconds, and N is the number of counts measured during that period.

Example: If a counter measures 1,000 counts in 10 milliseconds, what is the frequency of the input signal?

t = 10 ms = 0.01 s

N = 1000

f = 1 / (0.01 x 1000) = 100 Hz

Duty Cycle Calculation

Duty cycle (%) = (P / T) x 100

- Where P is the pulse width in seconds, and T is the period of the signal in seconds.

Example: If a signal has a period of 20 ms and a pulse width of 4 ms, what is the duty cycle of the signal?

P = 4 ms = 0.004 s

T = 20 ms = 0.02 s

Duty cycle = (0.004 / 0.02) x 100 = 20%

Total Count Calculation

Total count = N x M

- Where N is the number of counts measured during one cycle of the input signal, and M is the number of cycles.

Example: If a counter measures 1,000 counts per cycle of a signal, and the signal has 10 cycles, what is the total count?

N = 1,000

M = 10

Total count = 1,000 x 10 = 10,000

Pulse Width Measurement

Pulse width (P) = (N x T) / M

- Where N is the number of counts measured during the pulse, T is the period of the signal in seconds, and M is the total number of counts measured.

Example: If a counter measures 2,000 counts during a signal with a period of 50 ms, and 500 of those counts occur during the pulse, what is the pulse width?

N = 500

T = 50 ms = 0.05 s

M = 2,000

Pulse width = (500 x 0.05) / 2,000 = 0.0125 s or 12.5 ms

These are just a few examples of common counter formulas that can be used to calculate various properties of input signals. The specific formulas and calculations used may vary depending on the type of counter and its application.

Types of Counters

There are several types of counters used in electronics, each with its advantages and disadvantages. Here are some of the most common types of counters:

Asynchronous (Ripple) Counter

This type of counter uses flip-flops connected in series, with the output of each flip-flop connected to the clock input of the next flip-flop. As each flip-flop toggles, it changes the clock input of the next flip-flop, creating a ripple effect down the chain. While simple to design, this type of counter suffers from propagation delay and is limited in its maximum operating frequency.

Fig 5. Asynchronous Counter

Synchronous Counter

In a synchronous counter, all the flip-flops are clocked by the same clock signal, ensuring that they change state simultaneously. This eliminates the propagation delay of the asynchronous counter and allows for higher operating frequencies.

Fig 6. Synchronous Counter

Up/Down Counter

An up/down counter can count up or down depending on the direction of the input signal. This type of counter is useful in applications where the count value needs to be incremented or decremented based on external signals.

Fig 7. Up/down counter

Decade Counter

A decade counter is a counter that can count from 0 to 9 and then reset back to 0, typically using a decoding circuit to convert the binary count value to a decimal output. This type of counter is useful in applications where counting in decimal format is required.

Fig 8. Decade counter

Ring Counter

In a ring counter, the output of one flip-flop is connected to the input of the next flip-flop in the chain, with the output of the last flip-flop connected back to the input of the first flip-flop. This creates a circular shift register that can count up to the number of flip-flops in the chain.

Fig 9. Rechargeable digital finger ring counter

Johnson Counter

A Johnson counter is similar to a ring counter, but it has an inverted output that changes state with each clock cycle. This creates a sequence of states that repeat after every n-clock cycle, where n is the number of flip-flops in the chain.

Fig 10. Johnson counter

These are just a few examples of the types of counters that are commonly used in electronics. The choice of counter type depends on the specific application and the requirements of the design.

Counter Applications

Counters are used in a wide range of applications where it is necessary to count events or occurrences of a particular signal. Here are some examples of how counters can be used:

Timing circuits

Counters can be used to create precise timing circuits. For example, a counter can be used to generate a pulse every second, which can be used to drive a clock display.

Frequency measurement

Counters can be used to measure the frequency of a signal. By counting the number of cycles of a signal over a fixed period, the frequency can be determined.

Event counting

Counters can be used to count events, such as the number of products produced on a manufacturing line.

Pulse width measurement

Counters can be used to measure the width of a pulse. By counting the number of clock cycles between the rising and falling edges of a pulse, the pulse width can be determined.

Control systems

Counters can be used in control systems to monitor and control processes. For example, a counter can be used to count the number of times a machine has performed a particular operation, and the count value can be used to trigger a maintenance schedule.

Testing and debugging

Counters can be used to test and debug electronic circuits. For example, a counter can be used to count the number of clock cycles in a circuit, which can be compared to the expected count value to detect errors.

Need to keep track of time or counts? Don’t panic! Our counter timers are ready to help!

Which Electronic Device Needs to Have a Counter While Working

Many electronic devices require counters to operate properly. Here are some examples:

Frequency generators

Frequency generators use counters to create precise and stable output frequencies. The counter counts the number of clock cycles to generate the desired output frequency.

Industrial machines

Industrial machines often require counters to keep track of the number of parts produced or the number of times a particular operation has been performed.

Traffic control systems

Traffic control systems use counters to time the duration of signal phases and to keep track of the number of vehicles that pass through an intersection.

Security systems

Security systems often use counters to keep track of the number of people who have entered or exited a building or to monitor the number of times a particular door has been opened or closed.

Medical equipment

Medical equipment such as X-ray machines and MRI scanners use counters to keep track of the number of scans performed or the number of times a particular function has been used.

Environmental sensors

Environmental sensors such as air quality monitors and weather stations use counters to keep track of the number of measurements taken over a given time period.

In general, any electronic device that requires precise timing, counting, or monitoring of events or data may require a counter to operate effectively.

What are the Advantages and Disadvantages of Counters?

Advantages of Counter

Here are some advantages of using a counter:

Accurate measurements

Counters provide accurate and precise measurements of various properties of input signals, such as frequency, duty cycle, pulse width, and total count.

Fast and efficient

Counters are capable of processing input signals at high speeds, making them ideal for applications that require quick and efficient measurements.

Versatile

Counters can be used to measure a wide range of input signals, including analog, digital, and pulse signals.

Easy to use

Many counters are user-friendly and easy to operate, with simple interfaces and intuitive controls.

Real-time monitoring

Counters can provide real-time monitoring of input signals, allowing users to quickly and easily detect any changes or abnormalities in the signal.

Automation

Counters can be integrated into automated systems and used to control other devices, making them ideal for use in industrial and manufacturing applications.

Cost-effective

Counters are often relatively inexpensive compared to other types of test and measurement equipment, making them a cost-effective option for many applications.

Disadvantages of Counter

Here are some potential disadvantages of using a counter:

Limited accuracy

While counters are generally accurate, their accuracy can be affected by various factors, including noise, signal distortion, and the quality of the input signal.

Limited range

Counters typically have a limited range of frequencies or other properties that they can measure accurately. If the input signal falls outside of this range, the counter may not be able to provide accurate measurements.

Complexity

Some counters can be complex to set up and operate, with a variety of settings and configurations that need to be adjusted to obtain accurate measurements.

Sensitivity to interference

Counters can be sensitive to electromagnetic interference (EMI) and other sources of signal distortion, which can affect their accuracy and reliability.

Single-purpose

Some counters may be designed for specific applications or types of signals, which can limit their usefulness for other applications.

Cost

While counters are often relatively inexpensive compared to other types of test and measurement equipment, high-end counters can be expensive and may not be cost-effective for all applications.

While counters offer many benefits for measuring various properties of input signals, they do have some potential disadvantages that need to be considered when selecting and using a counter for a particular application.

Counter Buying Guide

When buying a digital counter, there are several important factors to consider. Here's a buying guide to help you make an informed decision:

1. Accuracy

Accuracy is a crucial factor, especially when dealing with precise measurements or counting tasks. Look for counters that offer high accuracy to ensure reliable and consistent results.

2. Resolution

Resolution refers to the smallest increment the counter can detect or display. Higher resolution allows for more precise measurements. Consider the resolution requirement based on the level of detail needed for your application.

3. Speed

Depending on your application, you may require a counter with high-speed counting capabilities. Some counters can handle rapid counting or timing intervals, while others may have limitations. Assess the speed requirements and choose a counter that meets your needs.

4. Response Time

Response time refers to the time it takes for the counter to react to an input signal or change in count. In certain applications where real-time monitoring is critical, a counter with a fast response time is essential.

5. Counting Modes

Different counters offer various counting modes, such as up counting, down counting, or bidirectional counting. Consider the counting mode options and select a counter that supports the modes you require.

6. Memory

Memory capabilities allow the counter to store count values or presets, which can be useful in certain applications. Determine if you need a counter with memory functions and the capacity required.

7. Integration and Compatibility

If you plan to integrate the counter with other equipment or systems, ensure it is compatible with the necessary interfaces or protocols. Common options include digital inputs/outputs, communication ports (USB, RS-232, Ethernet), or compatibility with specific software or programming languages.

8. Environmental Considerations

Depending on the operating environment, consider performance factors such as temperature range, humidity resistance, vibration resistance, or IP (Ingress Protection) rating for protection against dust and water.

9. Error Handling

Look for counters that provide error detection and handling mechanisms. This can include error codes, alarms, or automatic error correction to ensure reliable operation and minimize the risk of inaccuracies.

10. Signal Filtering and Noise Immunity

Some counters offer built-in signal filtering mechanisms to reduce the impact of noise or interference on count accuracy. This can be important in environments where electrical noise is prevalent.

11. Scalability and Expandability

If you anticipate future growth or changes in your counting requirements, consider counters that offer scalability or expandability options. This can involve the ability to connect multiple counters together or upgrade the counter's capabilities through modular components.

Remember to assess these performance characteristics based on the specific needs of your application to ensure the digital counter can deliver the required performance and accuracy levels.

Conclusion

In conclusion, counters are electronic devices that can measure various properties of input signals, such as frequency, duty cycle, pulse width, and total count. They provide accurate and precise measurements and are capable of processing input signals at high speeds. Counters are versatile, easy to use, and can provide real-time monitoring of input signals. They are widely used in science, engineering, manufacturing, and other fields.

However, counters also have some potential disadvantages, including limited accuracy and range, complexity, sensitivity to interference, and cost. These factors need to be considered when selecting and using a counter for a particular application.

Overall, counters offer many benefits and are a valuable tool for a wide range of applications.

To Recap

1. What is a counter?

A counter is an electronic device that can measure various properties of input signals, such as frequency, duty cycle, pulse width, and total count.

2. What is the purpose of a counter?

The purpose of a counter is to measure the properties of input signals accurately and efficiently. Counters are used in a wide range of applications, including science, engineering, manufacturing, and other fields.

3. How does a counter work?

Counters typically use a clock signal to count input signals and produce an output that represents the count. The input signals are typically converted to digital signals and then processed by the counter.

4. What are the types of counters?

There are several types of counters, including binary counters, decade counters, up/down counters, and frequency counters.

5. What are some applications of counters?

Counters are used in a wide range of applications, including frequency measurement, pulse width measurement, duty cycle measurement, event counting, and timing control.

6. Does the counter need to be calibrated?

Yes, counters may need to be calibrated periodically to ensure that they are operating correctly and providing accurate results. The calibration process involves comparing the output of the counter to a known reference signal or standard and making adjustments as necessary to correct any discrepancies.

The calibration interval and process may vary depending on the type of counter and its application. Some counters may require frequent calibration, while others may only need to be calibrated occasionally or when there is a change in the operating environment or conditions.

In general, it is important to follow the manufacturer's recommended calibration procedures and intervals for any electronic device that uses a counter to ensure accurate and reliable operation.

7. How do I choose the right counter for my application?

When choosing a counter, it is important to consider factors such as the properties of the input signal, the required accuracy and range of measurement, and the cost of the counter.

8. How can I calibrate a counter?

Counters can be calibrated using a reference signal with a known frequency or other property. The counter can then be adjusted to provide accurate measurements of the input signal.

9. Can counters be used in automated systems?

Yes, counters can be integrated into automated systems and used to control other devices, making them ideal for use in industrial and manufacturing applications.

10. What is the accuracy of a counter?

The accuracy of a counter can vary depending on the quality of the input signal, the type of counter, and other factors. However, modern counters are typically very accurate, with errors of less than 0.1%.

11. What is the difference between a counter and a timer?

A counter is used to count input signals and produce an output that represents the count, while a timer is used to measure the duration of a signal or event. Both counters and timers can be used to measure frequency, duty cycle, and other properties of input signals.

12. What is a prescaler?

A prescaler is a device that is used to divide the frequency of an input signal before it is counted by a counter. Prescalers are often used in frequency counters to extend their range and improve accuracy.

13. Can counters be used to measure non-electrical signals?

Yes, counters can be used to measure non-electrical signals by using a sensor to convert the non-electrical signal into an electrical signal that can be counted by the counter.

14. What is the maximum frequency that a counter can measure?

The maximum frequency that a counter can measure depends on the type of counter and the specific model. However, modern counters are capable of measuring frequencies up to several gigahertz.

15. How can I connect a counter to my circuit or system?

Counters typically have input and output ports that can be connected to other devices using cables or connectors. Some counters also have USB or Ethernet ports for remote control and monitoring.

16. Can counters be used in educational settings?

Yes, counters are commonly used in educational settings to teach students about electronics, digital circuits, and signal processing. There are many affordable and easy-to-use counters available that are suitable for educational use.

References

https://www.circuitbasics.com/what-are-counters/

https://www.elprocus.com/types-of-electronic-count...

https://www.circuits-diy.com/binary-counter-circui...

https://www.aliexpress.us/item/2255800907640023.ht...

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecting millions …16th Apr 2025