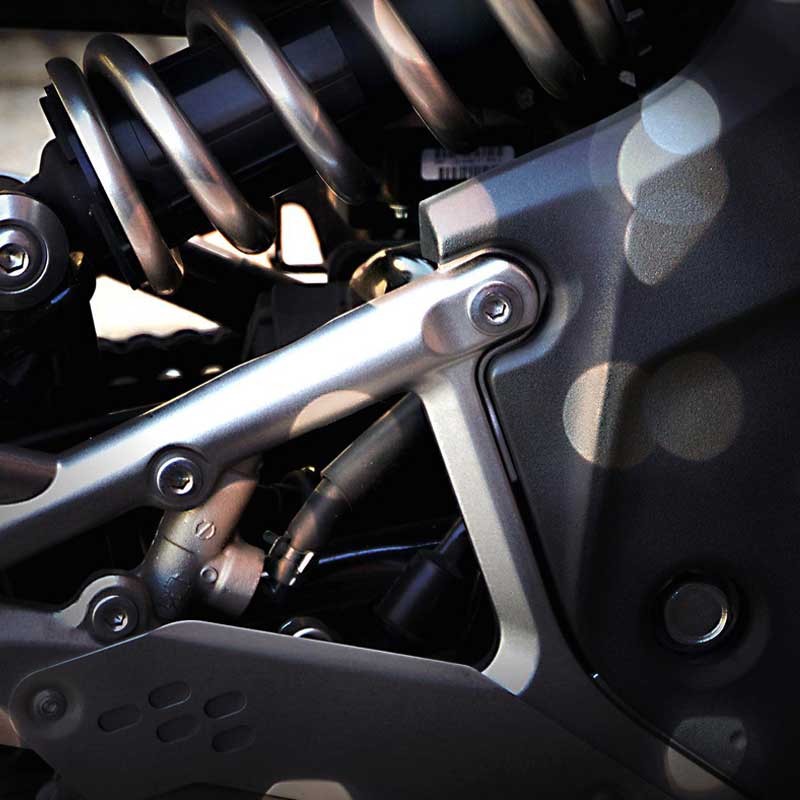

Analog Inductive Sensors for Permanent Measuring of Primary Spring Status on Tramcar Suspension

In rail road industry, engineers need sensors to warrant efficiency and safety. These sensors are also needed to optimize the environmental function of trams. Such sensors should calculate movement of the primary spring in the suspension.

Since digital sensors only provide a switching point, they are inappropriate.

The requirements of an appropriate sensor for this purpose:

• An analog output to capture all spring motion, including all vibrations.

• Vigorousness

• Being non-contact

• A long sensing distance

• Resistance to corrosion

• Resistance to dirt

Inductive sensors, the analog output range are ideal for this application.

Features of Inductive sensors:

•Excellent resolution (in µm range)

• Vibration tracking

• Motion detection

• Travel controlling

• Improved and high-environmentally stability

• Temperature-resistance, Due to their Patented Condist oscillator technology

• Longer sensing distance (three times more than that of a conventional sensor)

Analog sensors output spring motion, such as vibrations, as a constant analog signal. The collected Data is saved on an external hard disk. It is possible to define the corresponding spring movement and mechanical loads for each point in a journey. This is done using the accurate GPS position data.

Check out inductive proximity sensors if you are interested in viewing related products.

As one of the largest manufacturers of mobile equipment sensors, Contrinex stands out. Find out more about Contrinex company.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

A Remote and Wireless Monitoring System for Firefighting Devices

Monitoring Seals for Water Penetration in Deep Sea Engineering Using Liquid Level Sensing

Lowering Maintenance Expenses and Raising Efficiency of Concrete Pumps Using High Pressure Resistant Sensors

Related Products