Unveiling the Guardians: The Role of Pressure Sensor Accessories

Welcome to the dynamic world of pressure sensor accessories, where precision meets innovation in the quest for accurate measurements and reliable performance. As essential components in the realm of pressure sensing, these accessories go beyond mere add-ons, playing pivotal roles in enhancing the capabilities and adaptability of pressure sensors across diverse applications.

Picture diaphragm seals acting as resilient guardians, shielding pressure sensors from the corrosive dance of process fluids, or envision cooling elements as silent sentinels, tirelessly dissipating excess heat to ensure optimal sensor functionality. Meanwhile, signal converters quietly orchestrate a symphony of compatibility, transforming signals to harmonize seamlessly with the intricate melodies of various control systems.

In this fascinating landscape, mounting adapters become architects of stability, providing the foundation for secure sensor installations. The nuances of pressure gauge snubbers reveal their mastery in taming pressure fluctuations, ensuring that the readings remain steady in the face of dynamic industrial environments.

This introduction invites you to explore the intriguing universe of pressure sensor accessories, where functionality meets ingenuity to propel accurate measurements and reliable performance to new heights. Join us on a journey through the intricacies of these components as we unravel the stories of diaphragm seals, cooling elements, signal converters, and more—each a crucial protagonist in the narrative of precision instrumentation.

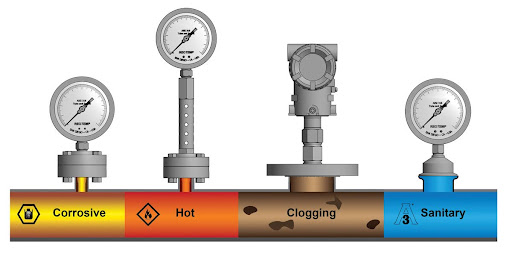

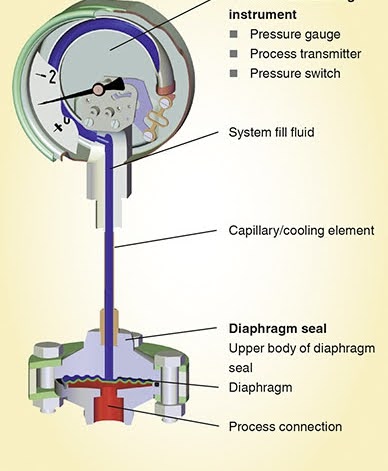

Fig 1. Diaphragm seal uses

What accessories can be installed on pressure sensors?

Pressure sensors can be used in various applications, and there are several accessories and additional components that can be installed to enhance their functionality or adapt them to specific needs. Here are some common accessories for pressure sensors:

- Mounting brackets: These provide a stable and secure way to attach the pressure sensor to a surface.

- Mounting flanges: Used to secure the sensor to pipes or other fixtures.

- Protective enclosures: Shields the pressure sensor from environmental factors such as moisture, dust, and chemicals.

- Weatherproof housings: Ensures the sensor remains operational in outdoor or harsh conditions.

- Cable assemblies: Provide a connection between the pressure sensor and the data acquisition system.

- Cable glands: Ensure a secure and sealed entry point for cables, preventing environmental damage.

- Electrical connectors: Facilitate easy and secure connections between the sensor and other electronic components.

- Calibration kits: Used for regular calibration to maintain accuracy.

- Calibration adapters: Connect the pressure sensor to calibration equipment.

- Diaphragm seals: Protect the sensor from the process fluid, making it suitable for measuring corrosive or viscous substances.

- Capillary tubes: Connect the pressure sensor to a diaphragm seal, allowing for remote pressure measurement.

- Temperature sensors: Used in conjunction with pressure sensors to compensate for temperature variations that may affect accuracy.

- Digital displays: Provide a real-time readout of pressure values.

- Analog indicators: Analog gauges or indicators for visual pressure monitoring.

- Protective caps: Shield the sensor's pressure port when not in use, preventing contamination.

- Pressure regulators: Control and regulate pressure in the system.

- Valves: Allow for the isolation or control of pressure in specific sections of the system.

- Battery packs or power supplies: Ensure a stable power source for the pressure sensor, especially in remote or mobile applications.

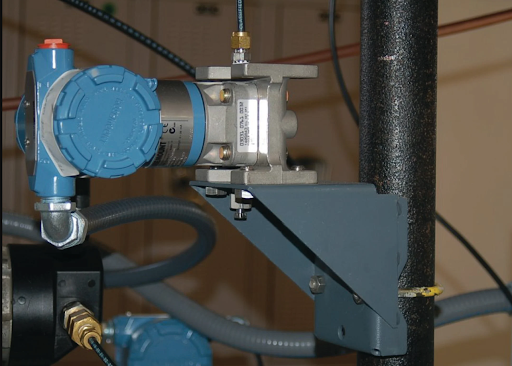

What is a Snubber for a pressure gauge?

A snubber for a pressure gauge is a device designed to dampen the effects of rapid pressure fluctuations or pulsations in a fluid system. These fluctuations can be caused by various factors such as water hammer, pump vibrations, or rapid opening/closing of valves. Without proper protection, these abrupt pressure changes can damage the delicate internal components of a pressure gauge or lead to inaccurate readings.

The primary function of a snubber is to mitigate the impact of these pressure pulses by introducing a controlled restriction to the flow of the fluid. Typically, a snubber includes a small orifice or a porous material that slows down the rate at which pressure changes reach the gauge. This helps prevent sudden spikes or drops in pressure from reaching the gauge, ensuring more stable and reliable readings over time. Snubbers are commonly used in industrial applications where precise pressure measurement is critical, and the fluid system experiences frequent pressure fluctuations.

It's important to note that while snubbers can be beneficial in certain situations, they may introduce a slight time delay in pressure response due to the damping effect. Engineers must carefully select and install snubbers based on the specific requirements of the system to strike a balance between protecting the pressure gauge and maintaining accurate and timely pressure measurements.

Fig 2. Pressure gauge snubbers

Special features of Pressure Gauge Snubbers

Pressure gauge snubbers are specialized devices with unique features designed to protect pressure gauges from rapid pressure fluctuations and pulsations in fluid systems. Some of the special features of pressure gauge snubbers include:

When choosing a pressure gauge snubber, it's essential to consider the specific needs of the fluid system and the pressure gauge. Proper selection and installation of a snubber contribute to the longevity and accuracy of pressure measurements in dynamic industrial environments.

How is the Pressure Connection for Pressure Gauge Snubber?

The pressure connection for pressure gauge snubbers is a critical aspect that determines how the snubber interfaces with the fluid system and the pressure gauge. The connection type and configuration should match the specifications of the system and the pressure gauge to ensure proper installation and functionality. Here are some common aspects related to the pressure connection for pressure gauge snubbers:

When installing a pressure gauge snubber, it is essential to follow the manufacturer's guidelines and specifications regarding the pressure connection. Proper installation helps maintain the accuracy of pressure readings and extends the lifespan of both the pressure gauge and the snubber in dynamic fluid systems.

Fig 3. Snubber for pressure sensors

What kind of Displays are needed for pressure sensors?

The choice of displays for pressure sensors depends on the specific application requirements, environmental conditions, and user preferences. Here are some common types of displays used with pressure sensors:

The selection of a display for pressure sensors depends on factors such as the application's requirements, the level of precision needed, environmental conditions, and user preferences. Additionally, integration with existing control systems and communication protocols may influence the choice of display technology.

Fig 4. A pressure sensor with a digital display

DIN connector display for pressure sensor

A DIN connector is a standard type of electrical connector that is widely used in various industries. In the context of pressure sensors, a DIN connector may be used to provide electrical connectivity between the pressure sensor and an external display or data acquisition system. Here are some considerations for a DIN connector display for a pressure sensor:

When selecting a display for a pressure sensor with a DIN connector, it's crucial to consult the documentation provided by the pressure sensor manufacturer and adhere to any specifications or guidelines for proper connectivity. If in doubt, contacting the manufacturer or consulting with a technical expert can help ensure a compatible and reliable setup.

Fig 5. DIN connector display for pressure sensor

Cooling element for pressure measuring instruments

Cooling elements for pressure-measuring instruments play a vital role in maintaining the operational efficiency and accuracy of these instruments, especially in high-temperature environments. These cooling elements are designed to dissipate excess heat generated during the operation of pressure sensors, preventing overheating and potential damage to sensitive components. The need for cooling arises in applications where the ambient temperature is elevated, or where the pressure sensor is exposed to thermal radiation from surrounding equipment or processes.

One common type of cooling element for pressure-measuring instruments is the heat sink. Heat sinks are passive cooling devices that absorb and dissipate heat away from the pressure sensor. They typically consist of metal fins or plates that provide a larger surface area for heat transfer. The heat is conducted through the fins, and natural or forced convection helps in the dissipation of heat into the surrounding air. Heat sinks are effective in preventing the pressure sensor from reaching temperatures that could affect its performance or longevity.

In more demanding applications, active cooling systems may be employed. These systems can include components such as fans or liquid cooling systems that actively remove heat from the pressure sensor. Fans provide airflow around the sensor, enhancing heat dissipation, while liquid cooling systems circulate a coolant, absorbing and carrying away heat. The choice between passive and active cooling depends on the specific environmental conditions and temperature requirements of the pressure-measuring instrument. Overall, cooling elements contribute significantly to maintaining the reliability and accuracy of pressure sensors, ensuring their optimal performance in various operational conditions.

Fig 6. Cooling elements

What are the Cooling elements for pressure sensors?

Cooling elements for pressure sensors are devices or components designed to dissipate heat generated during the operation of the sensor. Maintaining an optimal operating temperature is crucial for the accuracy, reliability, and longevity of pressure sensors, especially in applications where high temperatures can be a concern. Here are some common cooling elements used for pressure sensors:

The choice of cooling element depends on factors such as the specific application, the level of heat generated by the pressure sensor, and environmental conditions. Proper cooling helps prevent thermal drift, maintains sensor accuracy, and ensures reliable performance in various operating environments. When integrating cooling elements with pressure sensors, it is essential to consider the compatibility and effectiveness of the chosen cooling method for the given application.

What is a siphon for pressure sensors?

A siphon is a tubular device designed to protect pressure sensors and other instruments from the direct contact of high-temperature fluids, such as steam. The primary purpose of a siphon is to create a barrier between the process fluid and the pressure sensor, preventing direct exposure to extreme temperatures or corrosive materials. It consists of a U-shaped tube or coiled tubing installed between the pressure sensor and the process line. This configuration allows the siphon to trap a liquid seal, typically water, which acts as a barrier against the hot or corrosive medium while still transmitting pressure effectively.

In high-temperature applications, such as steam lines, the siphon serves as a thermal barrier, preventing direct contact between the pressure sensor and the hot fluid. This protective measure not only shields the sensor from potential damage but also ensures accurate pressure measurements by allowing the condensate inside the siphon to transmit pressure while maintaining a lower, more manageable temperature at the sensor. The use of siphons is common in various industrial settings, particularly in steam systems, where they play a crucial role in protecting pressure instruments and maintaining their functionality in challenging environments.

Fig 7. A siphon for pressure sensor

Standard Features of the pressure gauge siphon

Pressure gauge siphons are specialized components designed to protect pressure instruments from direct contact with high-temperature fluids, particularly in steam applications. While specific features can vary between manufacturers and models, here are some standard features associated with pressure gauge siphons:

When selecting a pressure gauge siphon, it is essential to consider the compatibility with the pressure instrument, the process fluid, and the environmental conditions. Following the manufacturer's guidelines and specifications ensures proper installation and reliable protection for pressure gauges in high-temperature applications.

Fig 8. A mini siphon

Applications of the pressure gauge siphon

Pressure gauge siphons find applications in industries where pressure measurement is required in the presence of high-temperature fluids, particularly steam. The primary purpose of a pressure gauge siphon is to protect pressure instruments, such as pressure gauges and transmitters, from the damaging effects of direct exposure to elevated temperatures and corrosive substances. Some common applications include:

In these applications, pressure gauge siphons play a crucial role in maintaining the functionality and accuracy of pressure instruments while ensuring the safety and reliability of industrial processes where high temperatures or corrosive fluids are present.

Fig 9. Application of siphon for pressure sensor

What are the Mounting Adaptors for pressure sensors?

Mounting adapters for pressure sensors are essential components that facilitate the proper installation and attachment of pressure sensors in various applications. These adapters come in different forms to accommodate diverse mounting requirements. Threaded adapters provide a secure connection by matching the threads on the pressure sensor with those on the system being measured, ensuring a tight and leak-free fit. Flange mounts offer a flat, flanged surface for industrial applications where the pressure sensor needs to be securely bolted onto a flat surface. Bracket mounts utilize brackets or clamps to affix the pressure sensor to a fixed support structure, offering versatility in orientation. Panel mounts are designed for installation on control panels or equipment panels, while DIN rail mounts integrate pressure sensors into DIN rail systems commonly found in industrial environments. Pipe mounts are tailored for mounting on pipes or tubing, and magnetic mounts use magnets to attach pressure sensors to metal surfaces without the need for screws or bolts. Adjustable mounts provide flexibility in positioning, accommodating different installation angles with swivel joints or articulated arms.

The selection of a mounting adapter depends on factors such as the specific application, available mounting options, and environmental conditions. Mounting adapters play a critical role in ensuring the stability, alignment, and reliable performance of pressure sensors in diverse settings, ranging from industrial processes to laboratory equipment. Here are some common types:

The specific type of mounting adapter required depends on the application, space constraints, and the mounting options available in the given environment. When selecting a mounting adapter, it is important to consider factors such as material compatibility, load-bearing capacity, and ease of installation to ensure a secure and reliable mounting solution for the pressure sensor.

Fig 10. Pipe brackets

What are the Installation Tool Kits for pressure sensors?

Installation tool kits for pressure sensors are sets of tools and accessories that aid in the proper installation, maintenance, and calibration of pressure sensors. These tool kits are designed to provide users with the necessary equipment to ensure accurate and secure sensor installations. While the specific contents of installation tool kits may vary, common components include:

The specific tools and accessories included in installation tool kits may vary based on the manufacturer, the type of pressure sensor, and the intended application. Always refer to the manufacturer's recommendations and guidelines for proper use of the tools and equipment provided in the kit.

Table 1. Installation tool kit

| Pressure Sensor Model | Manufacturer | Key Features | Included in Installation Tool Kit |

| XYZ-123 | ABC Sensors | High accuracy, stainless steel construction, suitable for industrial use | Adjustable wrench, Teflon tape, torque wrench, calibration tool, carrying case |

| 456PQ | DEF Instruments | Compact design, suitable for HVAC applications | Tube cutter, threaded adapters, pressure test equipment, instruction manual |

| LMN-789 | GHI Technologies | Submersible for liquid applications, corrosion-resistant materials | Thread sealants, cleaning supplies, calibrated pressure gauge, carrying case |

Fig 11. Installation tool kits

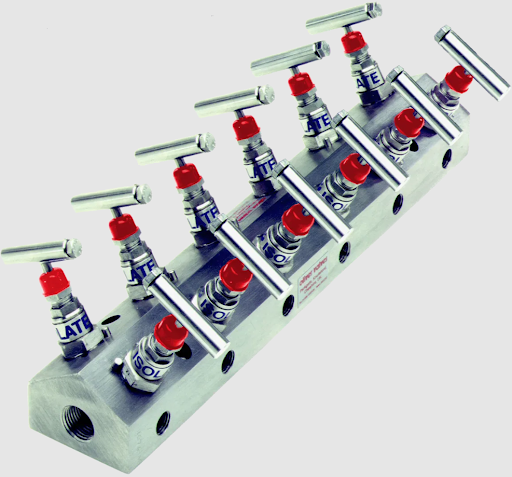

What are the pressure sensor manifolds?

Pressure sensor manifolds, also known as pressure manifolds or sensor manifolds, are devices that provide a centralized platform for the installation of multiple pressure sensors. These manifolds are designed to streamline the connection of several pressure sensors to a common fluid system, enabling simultaneous monitoring or control of multiple pressure points. They are commonly used in industrial applications where multiple pressure measurements are required, such as in process control, fluid power systems, and testing environments. Here are some key features and applications of pressure sensor manifolds:

Key Features:

Applications:

Pressure sensor manifolds provide a convenient and organized solution for managing multiple pressure sensors in complex fluid systems. Their use contributes to system efficiency, ease of maintenance, and the ability to gather comprehensive pressure data for various applications.

Fig 12. High pressure sensor manifold

When can use the signal converter for the pressure sensor?

Signal converters for pressure sensors are used in situations where the output signal from the pressure sensor needs to be modified or converted to a different format to meet the requirements of the monitoring or control system. Here are some scenarios where the use of a signal converter for pressure sensors may be necessary:

The use of signal converters provides flexibility in adapting pressure sensor signals to the specific requirements of the overall system. It allows for the seamless integration of pressure sensors into a variety of control, monitoring, and automation applications, ensuring accurate and reliable data acquisition.

Fig 13. A signal converter

What are the types of signal converters for pressure sensors?

Signal converters for pressure sensors come in various types, each serving specific purposes in adapting and processing the output signals from pressure sensors. Here are some common types of signal converters used in conjunction with pressure sensors:

The choice of a signal converter depends on the specific requirements of the pressure sensor, the characteristics of the receiving system, and the overall application needs. It's important to carefully match the type of signal converter with the signal output and input requirements for seamless integration and accurate data processing.

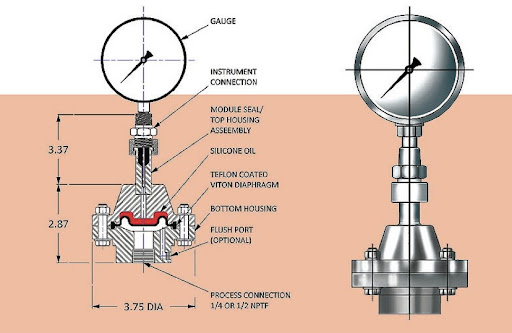

What is a diaphragm seal for a pressure sensor?

A diaphragm seal for a pressure sensor is a protective barrier designed to isolate the sensing element of the pressure sensor from the process fluid it is measuring. The diaphragm seal is typically a thin, flexible membrane made from materials compatible with the fluid being measured, such as stainless steel or other corrosion-resistant alloys. It acts as a physical barrier that prevents direct contact between the pressure sensor's sensing element and the potentially harsh or corrosive process medium. This isolation is crucial in applications where the process fluid could damage or contaminate the pressure sensor, compromising its accuracy and longevity.

The diaphragm seal is installed between the pressure sensor and the process fluid, forming a barrier that transmits pressure while keeping the sensor protected. This configuration allows pressure measurements to be accurately taken from the process medium without exposing the sensor to the corrosive or abrasive effects of the fluid. Diaphragm seals find applications in various industries, including chemical processing, pharmaceuticals, and food and beverage, where precise pressure measurements are required in challenging environments.

Fig 14. A diaphragm seal

Fig 15. A diaphragm seals

Conclusion

In conclusion, pressure sensors play a vital role in monitoring and controlling pressure in diverse applications, ranging from industrial processes to scientific research. These sensors come in various types, including piezoelectric, strain gauge, and capacitive sensors, each suitable for specific use cases. To enhance the performance and longevity of pressure sensors, several accessories and components are employed, such as diaphragm seals, cooling elements, and mounting adapters.

Diaphragm seals act as protective barriers, isolating the pressure sensor's sensing element from potentially corrosive or abrasive process fluids. They ensure accurate pressure measurements without compromising the sensor's integrity. Cooling elements, such as heat sinks and fans, are employed to dissipate excess heat generated during sensor operation, especially in high-temperature environments. Mounting adapters provide a means for secure and proper installation of pressure sensors, accommodating various mounting requirements.

Furthermore, signal converters are essential in situations where the output signal from pressure sensors needs modification or adaptation to meet the requirements of control systems. These converters can transform signals between voltage and current, analog and digital formats, or perform signal conditioning tasks.

The diverse range of pressure sensor accessories and components reflects the adaptability of these devices to different environmental and application needs. As technology continues to advance, innovations in pressure sensor technology and associated accessories contribute to improved accuracy, reliability, and versatility in pressure measurement systems.

To recap

1. What is the purpose of a diaphragm seal for a pressure sensor?

Answer: A diaphragm seal serves as a protective barrier for pressure sensors, isolating the sensor's sensing element from potentially corrosive or abrasive process fluids. It ensures accurate pressure measurements without exposing the sensor to substances that could damage its components.

2. Why are cooling elements used with pressure sensors?

Answer: Cooling elements, such as heat sinks and fans, are used with pressure sensors to dissipate excess heat generated during sensor operation, especially in high-temperature environments. Proper cooling prevents overheating, ensuring the sensor's optimal performance and longevity.

3. What are the key features of pressure gauge snubbers?

Answer: Pressure gauge snubbers are designed to dampen pressure pulsations and fluctuations. They feature a porous element that slows down the pressure changes, protecting the pressure gauge from rapid movements and ensuring stable readings.

4. How do signal converters enhance the performance of pressure sensors?

Answer: Signal converters modify the output signal from pressure sensors to meet the requirements of specific control systems. They can convert signals between voltage and current, analog and digital formats, ensuring seamless integration into various monitoring and control systems.

5. What types of materials are commonly used for diaphragm seals?

Answer: Diaphragm seals are often made from materials such as stainless steel or other corrosion-resistant alloys. The material selection depends on the compatibility with the fluid being measured and the environmental conditions.

6. What role do mounting adapters play in pressure sensor installations?

Answer: Mounting adapters provide a secure and proper means of installing pressure sensors. They accommodate various mounting requirements, ensuring stability and alignment in diverse applications.

7. Why are pressure sensor cooling elements crucial in industrial applications?

Answer: In industrial applications, pressure sensors may operate in high-temperature environments. Cooling elements prevent overheating, maintaining the accuracy and reliability of pressure measurements in industrial processes.

8. How do pressure sensor accessories contribute to accuracy in pressure measurements?

Answer: Accessories such as diaphragm seals, cooling elements, and signal converters contribute to accuracy by protecting the sensor from environmental factors, dissipating heat, and ensuring compatibility with different monitoring and control systems.

9. What is the purpose of a snubber in a pressure gauge installation?

Answer: A snubber in a pressure gauge installation helps dampen rapid pressure fluctuations and pulsations, preventing damage to the pressure gauge and ensuring stable and accurate readings.

10. When is the use of signal converters for pressure sensors necessary?

Answer: Signal converters are necessary when the output signal from a pressure sensor needs modification to match the input requirements of a control or monitoring system. They are used to convert signals between different types, such as voltage to current or analog to digital, ensuring compatibility.

References

https://www.pcb.com/sensors-for-test-measurement/pressure-transducers/accessories

https://www.wika.com/en-us/910_32.WIKA

https://sabadejlah.com/pressure-gauges-snubbers/

https://www.highpressure.com/products/valves-fittings-tubing/pressure-gauges/gauge-snubber/

https://m.indiamart.com/proddetail/pressure-transmitter-with-in-built-led-display-21866460612.html

https://www.keyence.com.my/products/process/pressure/ap-c40/

https://control.com/textbook/continuous-pressure-measurement/pressure-sensor-accessories/

https://www.spectrapremium.com/en/aftermarket/north-america/manifold-absolute-pressure-sensor

https://blog.wika.com/products/pressure-products/how-diaphragm-seals-working/

https://www.valves.co.uk/products/high-pressure-distribution-manifold-dm/

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025