Ultrasonic Sensors: Harnessing the Power of Sound Waves for Accurate Detection and Measurement

Imagine being able to detect and measure objects accurately without even touching them, using nothing but sound waves. That's the power of ultrasonic sensors. These sensors use high-frequency sound waves to detect objects and measure distances, making them a popular choice in various industries, including automotive, robotics, and medical devices. Ultrasonic sensors are not only efficient and reliable but also cost-effective compared to other types of sensors. With their ability to operate in harsh environments and detect objects regardless of color or transparency, ultrasonic sensors are quickly becoming the go-to technology for distance measurement and object detection. In this article, we'll explore the science behind ultrasonic sensors, their applications, advantages, and disadvantages, and how to choose the right type for your needs. So, let's dive into the world of ultrasonic sensors and discover the wonders of sound waves.

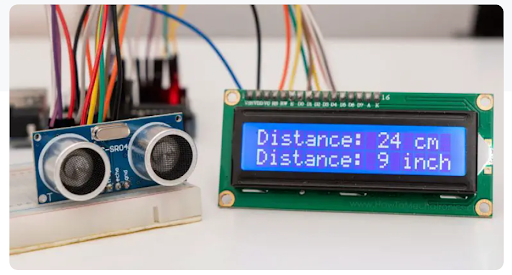

Fig 1. Ultrasonic sensor

What is the Ultrasonic wave?

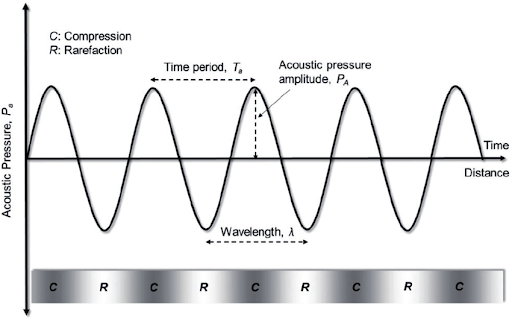

An ultrasonic wave is a type of sound wave that has a frequency higher than the upper limit of human hearing, which is typically around 20 kHz. Ultrasonic waves are typically in the frequency range of 20 kHz to several MHz, depending on the application.

Ultrasonic waves are characterized by their high frequency and short wavelength, which allows them to travel through solid objects, liquids, and gases. When an ultrasonic wave encounters an object, it can be reflected, absorbed, or transmitted through the object depending on the properties of the object.

Ultrasonic waves are used in many applications, including non-destructive testing, cleaning, welding, and medical imaging. Ultrasonic sensors, as mentioned earlier, use ultrasonic waves to measure the distance to an object.

What is the Speed of Ultrasonic Waves?

The speed of ultrasonic waves depends on the medium through which they are traveling. In general, ultrasonic waves travel faster through solids and liquids than they do through gases.

In air at room temperature and normal atmospheric pressure, the speed of sound is approximately 343 meters per second (1,125 feet per second), which corresponds to a frequency of around 20 kHz for an ultrasonic wave with a wavelength of 1.7 cm. In water, the speed of sound is much faster, at around 1,500 meters per second (4,921 feet per second), which allows ultrasonic waves to travel much further and faster through water than they do through air.

The speed of ultrasonic waves can also vary depending on other factors such as temperature, pressure, and the composition of the medium. For example, the speed of sound in the air decreases as the temperature decreases, while the speed of sound in water increases with increasing pressure.

Fig 2. Schematic of an ultrasonic wave

What is an Ultrasonic Sensor?

An ultrasonic sensor is a type of sensor that uses high-frequency sound waves to detect the distance or presence of objects. The sensor emits a sound wave at a certain frequency and then measures the time it takes for the sound wave to bounce back from the object and return to the sensor. This time measurement is used to calculate the distance to the object.

Ultrasonic sensors are commonly used in automation and robotics, as they can detect the presence of objects without physical contact. They are also used in a variety of other applications, including parking sensors, distance measurement, and level sensing in tanks and containers.

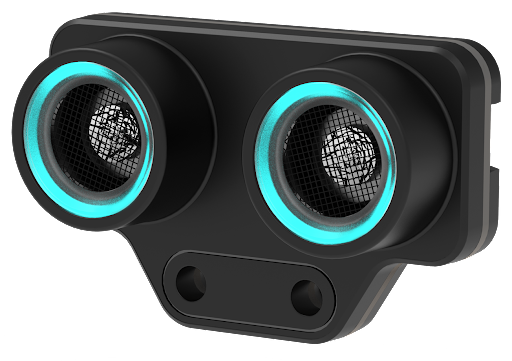

There are two types of ultrasonic sensors based on technology used in product design:

- Active

- Passive

Active sensors emit a sound wave and then detect the echo, while passive sensors detect sound waves emitted by other sources. Active ultrasonic sensors are more commonly used as they provide more accurate distance measurements.

Fig 3. One type of ultrasonic sensor

When Was the First Ultrasonic Sensor Made?

The first ultrasonic sensor was developed in the early 1940s by researchers at the US Navy's Underwater Sound Laboratory. The sensor was used to detect underwater objects, such as submarines and mines, by emitting high-frequency sound waves and measuring the time it took for the sound waves to bounce back.

Since then, ultrasonic sensors have been further developed and refined for various applications in different industries, including robotics, manufacturing, and automotive. Today, ultrasonic sensors are widely used in a variety of fields, thanks to their ability to provide accurate distance measurements without physical contact.

Ultrasonic Proximity Switch Sensors

Ultrasonic proximity switch sensors are a type of sensor that utilize ultrasonic waves to detect the presence or absence of objects within a certain range. They operate based on the principle of emitting ultrasonic waves and measuring the time it takes for the waves to bounce back after hitting an object. These sensors are commonly used in various industries and applications for object detection, obstacle avoidance, and automated control systems.

Fig 4. An ultrasonic proximity switch from Sensorpart

There are different types of ultrasonic proximity switch sensors available, each suited for specific sensing requirements and environmental conditions:

Diffuse mode ultrasonic sensor

These sensors emit ultrasonic waves and detect objects based on the strength of the reflected signal. They measure the time it takes for the waves to return and compare the received signal strength to a predefined threshold. Diffuse mode sensors are widely used in applications such as conveyor systems, robotics, and presence detection in industrial automation.

Retro-reflective ultrasonic sensor

Retro-reflective sensors consist of an ultrasonic transmitter and receiver facing a reflector. The ultrasonic waves emitted by the transmitter are reflected back by the reflector and detected by the receiver. When an object interrupts the reflected waves, the sensor triggers a response. Retro-reflective sensors are suitable for applications that require longer sensing ranges or reliable detection in challenging environments, such as automatic door systems and parking lot occupancy detection.

Through-beam ultrasonic sensor

In through-beam sensors, a separate transmitter and receiver are positioned facing each other. The transmitter emits ultrasonic waves, which are detected by the receiver. When an object breaks the ultrasonic beam, the sensor registers the interruption. Through-beam sensors provide highly accurate and reliable detection and are commonly used in applications like security systems, liquid level detection, and object counting.

Ultrasonic sensor internal parts

An Ultrasonic sensor consists of several internal parts that work together to emit and detect ultrasonic waves. The main components of an ultrasonic sensor are:

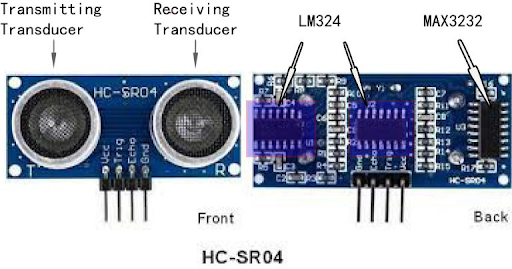

Transducer

The transducer is the main component of the sensor that emits and receives ultrasonic waves. It is typically made of piezoelectric materials that vibrate when an electrical signal is applied. When the transducer vibrates, it emits ultrasonic waves into the air.

Oscillator

The oscillator generates the electrical signal that is applied to the transducer, causing it to vibrate and emit ultrasonic waves. The oscillator typically operates at a high frequency to produce high-frequency ultrasonic waves.

Receiver

The receiver is another piezoelectric transducer that receives the ultrasonic waves reflected from an object. When the ultrasonic waves strike the receiver, it generates an electrical signal that is amplified and processed to calculate the distance to the object.

Signal processing circuitry

The signal processing circuitry amplifies and filters the electrical signal generated by the receiver. The circuitry then calculates the time delay between the emission of the ultrasonic wave and the reception of the reflected wave. The time delay is used to calculate the distance to the object.

Housing

The housing protects the internal components of the sensor and provides a mounting interface for the sensor. The housing is typically made of plastic or metal and can be designed for different environmental conditions and mounting configurations.

Fig 5. The HC-SR04 internal parts

Utilizing Beam Angles for Ultrasonic Transmitters

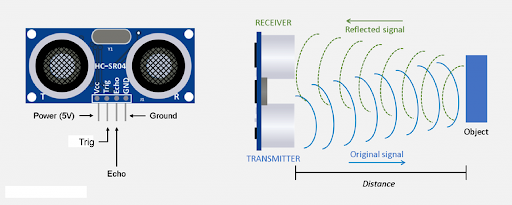

Much like a bat emits the ultrasonic chirp from its mouth and then hears the response with its ears, ultrasonic sensors also have a transmitter and receiver. Typically, these two are placed in close proximity to minimize any errors as the expectation is that the sound wave will be traveling in a straight line. Ultrasonic transceivers are another available option, where both the transmitter and receiver are combined into a single unit.

Fig 6. Ultrasonic transmitter and receiver pair in practice

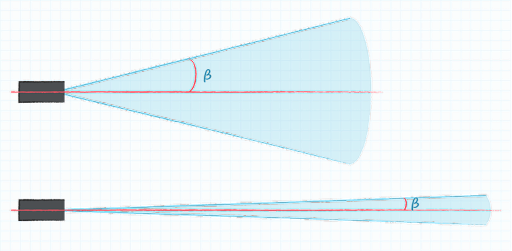

While acoustic waves travel in straight lines, they spread over time, which needs to be taken into consideration. With the spread and beam angle, these sound waves spread three-dimensionally, both vertically and horizontally.

Due to this, when reading datasheets about ultrasonic sensors, the detection area is given in beam width and angle, leaving the exact calculation up to the end-user. It should be noted that sometimes manufacturers provide the beam angle as the full angle of the beam while others provide the beam angle as the angle of deviation from the central point of the ultrasonic sensor.

Fig 7. The beam angle is an important specification in determining the detection area

As acoustic waves spread over distance, they correspondingly spread their energy as well. Usually, a narrower beam, with less spread, gives greater range. The flip side is that a wider beam usually has less range, but a wider detection area. The amount of energy initially put into the wave will play a dominant role in determining the range, regardless of beam angle. The application should determine the beam angle and power input.

How does an Ultrasonic Sensor Work?

An ultrasonic sensor works by emitting high-frequency sound waves and measuring the time it takes for the sound waves to bounce back from an object. The time delay between the emission of the sound wave and the detection of the echo is used to calculate the distance to the object.

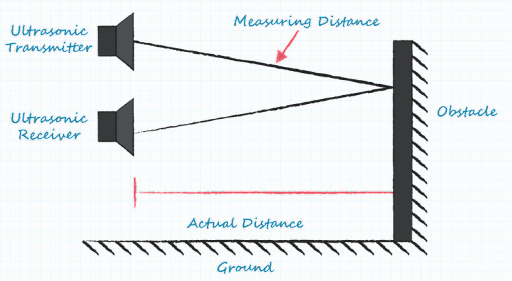

Fig 8. Distance ultrasonic sensor working principle

Here's how it works:

1.The sensor emits an ultrasonic sound wave in a specific direction, typically using a transducer.

2.The sound wave travels through the air until it reaches an object in its path.

3.When the sound wave hits the object, it reflects towards the sensor.

4.The sensor's receiver detects the reflected sound wave and measures the time it takes for the sound wave to travel back to the sensor.

5.The time delay between the emission of the sound wave and the detection of the reflected wave is used to calculate the distance to the object using the formula:

Distance = (speed of sound * time) / 2

6.The sensor can then output the distance measurement in various formats, such as voltage, current, or digital signals, depending on the sensor's design.

Ultrasonic Sensor Calculations With Example

Several formulas are commonly used in ultrasonic sensor applications:

1.Speed of sound: The speed of sound in a medium can be calculated using the formula

v = f * λ

where v is the speed of sound, f is the frequency of the wave, and λ is the wavelength of the wave.

For example, in the air at room temperature and normal atmospheric pressure, the speed of sound is approximately 343 meters per second at a frequency of 20 kHz and a wavelength of 1.7 cm.

2.Time of flight: The time it takes for an ultrasonic wave to travel from the sensor to an object and back can be used to calculate the distance to the object using the formula

d = (v * t) / 2

where d is the distance, v is the speed of sound, and t is the time of flight.

3.Signal attenuation: The amplitude of an ultrasonic wave can be attenuated as it travels through a medium due to absorption and scattering effects. The amount of attenuation can be calculated using the formula

A = 10^(-α * d),

where A is the amplitude of the wave after traveling a distance d, and α is the attenuation coefficient of the medium.

4.Reflection coefficient: When an ultrasonic wave encounters a boundary between two different media, some of the waves is reflected toward the source. The amount of reflection can be quantified using the reflection coefficient, which is given by the formula

R = (Z2 - Z1) / (Z2 + Z1),

where Z1 and Z2 are the acoustic impedances of the two media. The reflection coefficient can be used to determine the amount of signal loss or interference at the boundary.

These are just a few examples of the formulas used in ultrasonic sensor applications. The specific formulas used will depend on the specific application and the properties of the medium and objects being measured.

Table 1. Ultrasonic sensor formulas

| Formula | Description |

| Distance = (Speed of sound × Time)/2 | Calculates the distance to an object based on the time it takes for an ultrasonic wave to travel to and from the object |

| Speed of sound = 331.3 + (0.606 × Temperature in Celsius) | Calculates the speed of sound in air based on the temperature |

| Beam angle = 2 × arcsin(Diameter of transducer/Distance to object) | Calculates the beam angle of an ultrasonic sensor based on the diameter of the transducer and the distance to the object |

| Frequency = Speed of sound/Wavelength | Calculates the frequency of an ultrasonic wave based on the speed of sound and the wavelength |

| Attenuation = 10 × log10 (Power at the source/Power at the receiver) | Calculates the attenuation of an ultrasonic wave based on the power at the source and the power at the receiver |

| Resolution = (Distance to object × Beam angle)/Number of cycles in a pulse | Calculates the resolution of an ultrasonic sensor based on the distance to the object, beam angle, and number of cycles in the pulse |

Example of all Ultrasonic Sensor Formulas

Here are some examples of how to use all of the ultrasonic sensor formulas from the table:

1.Distance

Let's say the time it takes for the ultrasonic waves to travel to and from an object is 0.02 seconds and the speed of sound in air is approximately 346.2 meters per second (at 25 degrees Celsius). Using the formula, we can calculate that the distance to the object is:

Distance = (346.2 m/s × 0.02 s)/2 = 3.46 meters

Therefore, the object is approximately 3.46 meters away from the ultrasonic sensor.

2.Speed of sound

Let's say the temperature of the air is 20 degrees Celsius. Using the formula, we can calculate that the speed of sound in air is:

Speed of sound = 331.3 + (0.606 × 20) = 343.5 meters per second

Therefore, the speed of sound in air at 20 degrees Celsius is approximately 343.5 meters per second.

3.Beam angle

Let's say the diameter of the transducer is 2 cm and the distance to the object is 5 meters. Using the formula, we can calculate that the beam angle of the ultrasonic sensor is:

Beam angle = 2 × arcsin(0.02 m/5 m) = 0.45 radians

Therefore, the beam angle of the ultrasonic sensor is approximately 0.45 radians.

4.Frequency

Let's say the speed of sound in air is 343.5 meters per second. The wavelength of the ultrasonic wave is 2 cm. Using the formula, we can calculate that the frequency of the ultrasonic wave is:

Frequency = 343.5 m/s ÷ 0.02 m = 17.175 kHz

Therefore, the frequency of the ultrasonic wave is approximately 17.175 kHz.

5.Attenuation

Let's say the power at the source is 100 mW and the power at the receiver is 1 mW. Using the formula, we can calculate that the attenuation of the ultrasonic wave is:

Attenuation = 10 × log10 (100 mW/1 mW) = 20 dB

Therefore, the attenuation of the ultrasonic wave is 20 decibels.

Where are Ultrasonic Sensors Used?

Many types of ultrasonic sensors are available, each with its specific application and features. Here are some examples of ultrasonic sensors:

- Distance ultrasonic sensor sensors are used to measure the distance between the sensor and an object. They are commonly used in robotics, automation, and automotive applications.

- Ultrasonic proximity sensor: These sensors detect the presence of objects in a given area without making physical contact. They are often used in automated doors, security systems, and robotics.

- Ultrasonic level sensor: These sensors measure the level of liquid in a tank or container. They are commonly used in industrial and agricultural applications.

- Ultrasonic flow sensor: These sensors measure the flow rate of liquids or gases. They are commonly used in industrial applications such as chemical processing and water treatment.

- Ultrasonic cleaning sensor: These sensors generate high-frequency sound waves to clean surfaces by removing dirt and contaminants. They are often used in the manufacturing and cleaning industries.

- Parking sensor: These sensors are used in automotive applications to assist drivers in parking by detecting the distance between the car and other objects.

- Ultrasonic imaging sensor: These sensors are used in medical imaging to create images of internal organs and tissues. This is known as ultrasound imaging.

Table 2. Comparing ultrasonic sensor types

| Ultrasonic Sensor Type | Working Principle | Detection Range | Accuracy | Cost | Applications |

| Ultrasonic Proximity Sensors | Time of Flight | 2-500 cm | High | Low | Object detection, distance measurement |

| Ultrasonic Ranging Sensors | Time of Flight | 2-1000 cm | High | Medium | Distance measurement, object detection |

| Ultrasonic Level Sensors | Time of Flight | Up to 10 m | Medium | High | Liquid level measurement |

| Ultrasonic Flowmeter | Doppler Effect | 0.25-6 m/s | High | High | Liquid flow measurement |

Ultrasonic sensors' advantages and disadvantages

Ultrasonic sensors have several advantages and disadvantages, including:

Advantages of Ultrasonic Sensor

Non-contact

Ultrasonic sensors do not require physical contact with the object being measured, which can be an advantage in applications where contact may be difficult or undesirable.

Wide range

Ultrasonic sensors can be used to measure distances ranging from a few centimeters to several meters, depending on the model and application.

High accuracy

Ultrasonic sensors can provide accurate distance measurements, often with a resolution of less than a millimeter.

Fast response time

Ultrasonic sensors can provide rapid distance measurements, with response times on the order of microseconds.

Low cost

Ultrasonic sensors can be relatively inexpensive compared to other types of distance sensors.

Disadvantages of Ultrasonic Sensor

Limited detection range in air

Ultrasonic sensors can be limited in range when used in air, due to the attenuation and scattering of ultrasonic waves in air.

Susceptible to interference

Ultrasonic sensors can be susceptible to interference from other ultrasonic sources or environmental factors such as wind or temperature changes.

Limited accuracy in certain conditions

Ultrasonic sensors may have reduced accuracy in certain conditions, such as when measuring distances to soft or irregular surfaces.

Limited resolution at long ranges

Ultrasonic sensors may have reduced resolution at longer ranges, which can limit their usefulness in certain applications.

Limited performance in certain media

Ultrasonic sensors may have limited performance in certain media, such as in liquids or highly attenuating materials.

Ultrasonic Sensor Performance Characteristics

What is the Range of Ultrasonic Sensors?

The range of an ultrasonic sensor depends on several factors, including the frequency of the sound wave, the power of the sensor, and the size of the target object. In general, ultrasonic sensors have a range of several meters, but the effective range can vary depending on the specific sensor model and the application.

For example, some ultrasonic sensors have a range of up to 10 meters or more, while others may only have a range of a few centimeters. The effective range of an ultrasonic sensor can also be affected by environmental factors such as temperature, humidity, and air pressure.

It is important to choose an ultrasonic sensor with the appropriate range for your application. If the sensor range is too short, it may not be able to detect objects at the required distance. If the range is too long, the sensor may pick up unwanted signals and interfere with other sensors in the area.

Fig 9. The ultrasonic proximity sensors in different diameters

Is the Ultrasonic Sensor Analog or Digital?

Ultrasonic sensors can be either analog or digital, depending on the sensor's design and the output signal it provides.

Analog ultrasonic sensors output an analog voltage or current signal that varies proportionally with the distance to the detected object. These sensors typically have a linear output range and can be used with analog signal processing circuits.

Digital ultrasonic sensors, on the other hand, output a digital signal that provides distance measurements in a numerical format, such as a pulse width or a serial data stream. These sensors typically have higher accuracy and resolution than analog sensors and are often used in applications that require precise distance measurements or object detection.

Some ultrasonic sensors also have a combination of analog and digital outputs, allowing them to be used with a variety of signal processing circuits and control systems.

How Accurate is an Ultrasonic Sensor?

The accuracy of an ultrasonic sensor depends on several factors, including the sensor's design, the frequency of the sound wave, and the environmental conditions in which it is used. In general, ultrasonic sensors can provide high-accuracy measurements, with typical accuracy levels ranging from a few millimeters up to a few centimeters.

However, the accuracy of an ultrasonic sensor can be influenced by factors such as temperature, humidity, and air pressure, which can affect the speed of sound in the environment. Additionally, the accuracy can also be affected by the size, shape, and reflectivity of the object being detected, as well as any interfering signals in the environment.

To ensure optimal accuracy, it's important to choose an ultrasonic sensor that is appropriate for your specific application and to carefully consider the environmental conditions in which the sensor will be used. Additionally, it's important to calibrate the sensor regularly and to take into account any factors that may affect its performance.

Do Ultrasonic Sensors Work at Night?

Yes, ultrasonic sensors can work at night as they are not affected by changes in ambient light levels. The time of flight process does not rely on visible light, so the sensor can operate in complete darkness.

However, it's important to note that ultrasonic sensors may be affected by other factors that could impact their performance at night. For example, changes in temperature, humidity, or air pressure can affect the speed of sound and the accuracy of the sensor's measurements. Additionally, the presence of other sound sources or reflective surfaces in the environment may cause interference and affect the sensor's readings.

All in all, while ultrasonic sensors can operate in low-light or nighttime conditions, it's important to carefully consider the environmental factors that may affect their performance and take steps to mitigate any potential issues.

Installation and Maintenance

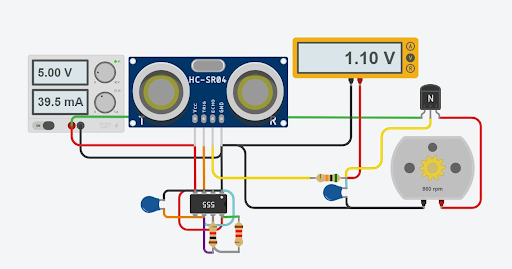

To use an ultrasonic sensor to detect, you would typically follow these steps:

Power up the ultrasonic sensor

Connect the ultrasonic sensor to a power source (usually 5V DC) and turn it on.

Set the trigger and echo pins

The trigger pin sends a signal to the sensor to emit an ultrasonic pulse, while the echo pin receives the reflected signal. Set these pins according to the specifications of your sensor and microcontroller.

Send a trigger signal

Send a short pulse to the trigger pin to initiate the ultrasonic pulse.

Measure the time between sending the trigger and receiving the echo

Measure the time elapsed between sending the trigger and receiving the echo signal. This can be done using a timer on your microcontroller.

Convert the time to distance

Use the speed of sound in air (typically 343 meters per second at room temperature) to convert the time elapsed to distance traveled by the ultrasonic pulse.

Analyze the distance

Use the distance measured to detect objects or obstacles, control a robotic system, or perform any other function based on the input from the ultrasonic sensor.

Note that the specific steps may vary depending on the type of ultrasonic sensor and the microcontroller or circuit used for processing the sensor data.

Fig 10. Using an ultrasonic sensor in a circuit

Ultrasonic Sensor Calibration

Calibrating an ultrasonic sensor involves adjusting the sensor's readings to ensure they are accurate and reliable. Calibration is important because factors such as temperature, humidity, and air pressure can affect the speed of sound and therefore the accuracy of the sensor's measurements. Here are some general steps for calibrating an ultrasonic sensor:

Set up a test environment

Choose a location with stable environmental conditions, such as a temperature-controlled room, and ensure there are no objects or obstacles that could interfere with the sensor's readings.

Establish a reference distance

Measure the distance between the ultrasonic sensor and a target object using a ruler or other measuring device. This reference distance will be used to compare the sensor's readings to actual distances.

Take multiple readings

Take several distance measurements using the ultrasonic sensor and record the readings. Make sure to take measurements from different angles and distances to ensure a representative sample.

Calculate the average

Calculate the average of the distance measurements to get an accurate representation of the sensor's readings.

Compare reference distance

Compare the average of the sensor's readings to the reference distance. If there is a significant difference between the two, adjust the sensor's calibration settings accordingly.

Repeat: Repeat the calibration process until the sensor's readings are consistent and accurate.

The specific calibration process may vary depending on the ultrasonic sensor and its manufacturer's instructions. Be sure to consult the sensor's documentation for specific instructions on calibration procedures and recommended calibration tools.

Want to detect and measure the distance of an object without direct contact? Let’s take a ride into the world of distance sensors!

Safety Tips While Using Ultrasonic Sensors

Some safety tips should be followed to ensure safe and proper operation:

Read the user manual

Always read and follow the instructions provided by the manufacturer for the safe and proper use of the ultrasonic sensor.

Wear appropriate personal protective equipment (PPE)

Depending on the application, appropriate PPE may include safety glasses, ear protection, and gloves.

Avoid direct contact with the ultrasonic sensor

Ultrasonic sensors emit high-frequency sound waves that may be harmful to the human body if exposed to them directly for prolonged periods. Avoid placing your body or any part of it directly in front of the ultrasonic sensor.

Use the ultrasonic sensor in a well-ventilated area

Ultrasonic sensors may produce ozone gas, which can be harmful if inhaled in large amounts. Use the ultrasonic sensor in a well-ventilated area to reduce the risk of ozone exposure.

Do not use the ultrasonic sensor in explosive or flammable environments

Ultrasonic sensors may produce sparks or static electricity, which can be a fire or explosion hazard in environments with flammable or explosive materials.

Use the ultrasonic sensor within its rated specifications

Exceeding the rated specifications of the ultrasonic sensor may cause damage to the sensor or produce inaccurate results. Follow the manufacturer's recommendations for the operating range, power supply, and other specifications.

By following these safety tips, you can help ensure the safe and effective use of ultrasonic sensors in your applications.

Important Factors to Choose the Right Type of Ultrasonic Sensors

Choosing the right type of ultrasonic sensor for a specific application can be crucial for achieving accurate and reliable results. Here are some important factors to consider when choosing the right type of ultrasonic sensor:

Measuring range

Determine the required measuring range for the application. Choose an ultrasonic sensor with a range that covers the distance to be measured.

Accuracy

Consider the required level of accuracy for the application. Choose an ultrasonic sensor with an accuracy level that meets the requirements of the application.

Operating environment

Consider the operating environment for the ultrasonic sensor, including temperature, humidity, and the presence of any dust, moisture, or other contaminants. Choose an ultrasonic sensor that is designed for the specific operating environment.

Object characteristics

Consider the characteristics of the object being measured, including its shape, size, and material. Choose an ultrasonic sensor that is suitable for the specific object characteristics.

Output type

Consider the required output type, whether it is analog or digital, and whether it requires specific communication protocols.

Power supply

Consider the power supply requirements for the ultrasonic sensor, including voltage, current, and power consumption. Choose an ultrasonic sensor that is compatible with the power supply available in the application.

By considering these factors, you can choose the right type of ultrasonic sensor for your specific application, ensuring accurate and reliable results.

Top Brands of Ultrasonic Sensors

Here's a brief explanation of each brand of ultrasonic sensors:

- Pepperl+Fuchs: Pepperl+Fuchs is a global leader in industrial automation technology, including ultrasonic sensors for object detection, distance measurement, and level sensing. Their sensors are known for their durability, high accuracy, and versatility.

- SICK: SICK is a multinational company that produces a wide range of sensors and sensor systems, including ultrasonic sensors for level measurement, distance sensing, and object detection. Their sensors are known for their high precision and reliable performance.

- Sensopart: Contrinex is a global provider of sensors and sensing solutions, including ultrasonic sensors for distance measurement, object detection, and level sensing. Their sensors are known for their high accuracy, ruggedness, and versatility.

Fig 11. A collection of ultrasonic sensor from “Sensopart”

3.Omron: Omron is a leading provider of industrial automation solutions, including ultrasonic sensors for object detection, level sensing, and distance measurement. Their sensors are known for their high precision, reliability, and ease of use.

4.Contrinex: Contrinex is a multinational conglomerate that produces a wide range of products and solutions, including ultrasonic sensors for level sensing, distance measurement, and object detection. Their sensors are known for their high precision, reliability, and versatility.

Note that this is just a brief overview of each brand, and there may be other factors to consider when choosing the right brand and sensor for your specific application.

Conclusion

In summary, ultrasonic sensors use high-frequency sound waves to detect objects and measure distances. They are widely used in various applications, including industrial automation, automotive systems, and medical devices. Ultrasonic sensors come in different types, including through-beam, reflective, and proximity sensors, and they can be analog or digital. When choosing the right type of ultrasonic sensor, factors to consider include the measuring range, accuracy, operating environment, object characteristics, output type, and power supply requirements. Following safety guidelines is also essential when using ultrasonic sensors.

To recap

1.Which type of sensor is the Ultrasonic sensor?

The Ultrasonic sensor is a non-contact distance sensor that uses sound waves to measure the distance to an object. It is a type of active sensor, meaning that it emits a sound wave and then detects the echo that reflects off an object. The time delay between the emission of the sound wave and the detection of the echo is used to calculate the distance to the object.

2.Can ultrasonic sensors detect transparent objects?

Ultrasonic sensors cannot detect transparent objects, as the sound waves pass through them without being reflected.

3.How do ultrasonic sensors work in dusty environments?

Ultrasonic sensors can work in dusty environments by using a self-cleaning mechanism that removes any dust or debris from the sensor surface.

4.How can I test the accuracy of an ultrasonic sensor?

You can test the accuracy of an ultrasonic sensor by measuring the distance between the sensor and a target object and comparing it to the reading displayed by the sensor. Repeat the test at different distances to ensure the accuracy is consistent.

5.Can ultrasonic sensors work underwater?

Yes, ultrasonic sensors can work underwater, as sound waves can travel through water. However, the operating range and accuracy may be affected by the water's temperature, salinity, and other factors.

6.Can ultrasonic sensors be used to measure fluid levels?

Yes, ultrasonic sensors can be used to measure fluid levels in tanks or other containers. However, the accuracy may be affected by factors such as the type of fluid and the shape and size of the container.

7.How do ultrasonic sensors compare to other types of sensors, such as lidar and radar?

Ultrasonic sensors are typically less expensive and have a shorter range than lidar and radar sensors. However, they are more suitable for indoor applications and can provide more accurate distance measurements than infrared sensors.

References

https://www.allaboutcircuits.com/industry-articles...

https://www.hackatronic.com/ultrasonic-sensor-with...

https://osoyoo.com/2018/09/18/micro-bit-lesson-usi...

https://education.makeblock.com/help/mbuild-ultras...

https://www.azosensors.com/article.aspx?ArticleID=...

https://www.researchgate.net/figure/Schematic-diag...

https://www.theengineeringprojects.com/2017/08/ult...

https://www.circuito.io/component/hc-sr04/

https://www.motioncontroltips.com/what-are-ultraso...

https://www.magnetrol.com/en/ultrasonic-non-contac...

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025