This Is Why Manufacturers are Utilizing Motion Controllers!

In the world of industrial automation, precision, and efficiency are key factors that determine the success of any manufacturing process. This is where motion controllers come into play. Motion controllers are electronic devices that enable precise control of the movement of mechanical systems, such as robots, CNC machines, and packaging systems. By offering increased speed, flexibility, automation, and cost-effectiveness, motion controllers have revolutionized the way industrial automation is conducted. In this article, we will explore the different types of motion controllers, how they work, their advantages and disadvantages, and important factors to consider when choosing and using motion controllers. We will also answer some common questions about motion controllers and their applications.

What is a Motion Controller?

A motion controller is a device or system that is used to control the movement or position of a mechanical system, such as a robot or a machine tool. It typically consists of a computer or microcontroller, software, and input/output devices such as sensors, actuators, and motors.

The motion controller receives input from sensors that detect the current position, speed, and direction of the mechanical system, and then uses this information to calculate the required motion commands to achieve the desired motion profile. The motion controller then sends these commands to the appropriate actuators, such as motors or solenoids, to control the movement of the system.

Motion controllers are used in a wide range of applications, from industrial automation and robotics to gaming and virtual reality. They can be implemented using a variety of technologies, such as microcontrollers, digital signal processors, or dedicated motion control chips, depending on the specific application requirements.

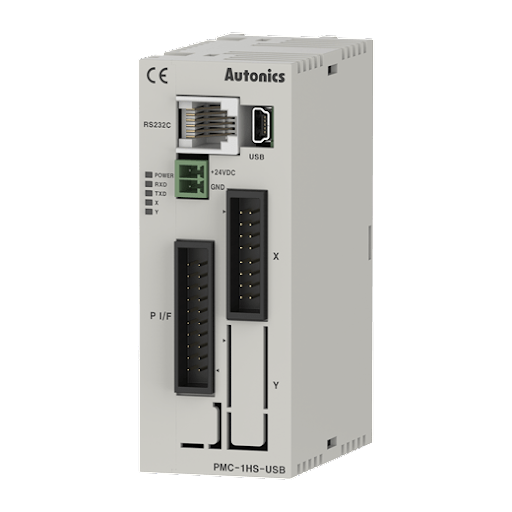

Fig 1. High-Speed Programmable Motion Controllers

Need a driver for your stepper motor? Our 5-phase stepper motor driver from well-known brand “Autonics” is here to help you!

Motion Controller History

The history of motion controllers dates back to the early days of automation and industrial control systems. The first motion controllers were simple analog systems that used potentiometers and other analog devices to control the speed and position of mechanical systems. These early systems were limited in capabilities and required significant operator intervention to achieve precise control.

The development of digital control systems in the 1960s and 1970s brought about significant advances in motion control technology. Digital controllers provided more precise control over mechanical systems and enabled the use of closed-loop feedback control systems, which improved accuracy and reliability.

In the 1980s and 1990s, the development of microcontrollers and programmable logic controllers (PLCs) further advanced motion control technology. These systems provided more processing power and flexibility, allowing for the development of more complex control algorithms and motion profiles.

In the 2000s and 2010s, the development of advanced software and algorithms, combined with advances in sensor technology and communication protocols, led to significant improvements in motion control performance and functionality. Motion controllers became more sophisticated and capable of controlling multiple axes of motion simultaneously, with higher accuracy and faster response times.

Today, motion controllers are an essential part of many industrial automation and robotic systems, as well as consumer electronics and gaming devices. They continue to evolve and improve, with advances in artificial intelligence and machine learning promising to bring even greater levels of automation and control to mechanical systems.

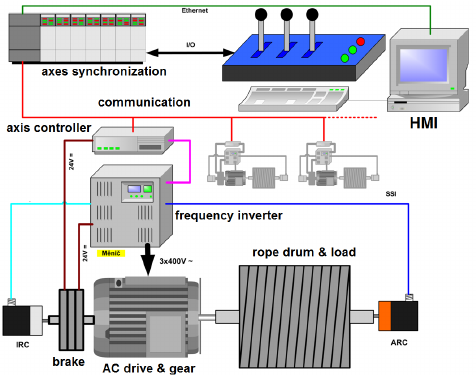

Fig 2. Controlling multiple axes of motion simultaneously while using closed-loop feedback control systems.

What is the Motion Controller Structure?

The structure of a motion controller can vary depending on the specific application, but generally, it consists of several key components:

- Central Processing Unit (CPU): This is the main processor of the motion controller, responsible for executing the software that controls the motion of the system.

- Memory: Motion controllers typically have both volatile and non-volatile memory, which is used to store program code, motion profiles, and other data.

- Input / Output (I/O) Interfaces: These are used to communicate with sensors, actuators, and other devices that are used to control the motion of the system. I/O interfaces can include digital and analog inputs and outputs, as well as specialized interfaces for communication with specific devices or protocols.

- Motion Control Software: This software is responsible for generating the motion profiles that control the movement of the system. It typically includes algorithms for position, velocity, and acceleration control, as well as other features such as path planning and error correction.

- Communication Interfaces: Motion controllers may include communication interfaces, such as Ethernet, USB, or serial ports, which allow for communication with other devices or systems, such as supervisory control systems or user interfaces.

- Power Amplifiers: These are used to drive the motors or actuators that control the movement of the system. Power amplifiers convert the low-level signals from the motion controller into high-power signals that can drive the actuators.

How does the Motion Controller Work?

The basic operation of a motion controller involves receiving input signals from sensors that detect the current position, speed, and direction of the mechanical system, and then using this information to calculate and output the required motion commands to achieve the desired motion profile.

Here's a high-level overview of how a motion controller works:

- Initialization: The motion controller is initialized with the parameters of the motion profile, such as the desired position, velocity, and acceleration. The motion controller also reads the initial position of the system from the sensors.

- Feedback: As the system moves, the motion controller continuously receives feedback signals from sensors that detect the position and velocity of the system. This feedback is used to determine how closely the system is following the desired motion profile.

- Control: The motion controller compares the feedback signals with the desired motion profile and calculates the required motion commands to achieve the desired motion profile. These commands are sent to the power amplifiers, which drive the motors or actuators that control the movement of the system.

- Error Correction: In case of any deviation from the desired motion profile, the motion controller performs error correction to adjust the motion commands and bring the system back on track.

- Termination: Once the system has reached the desired position or completed the desired motion profile, the motion controller terminates the control and stops sending motion commands.

I bet you cannot ignore this: The minimum price guaranteed for a 5-phase stepper motor driver to control the motion of 1 axis.

Motion Controller Calculations

Motion controllers involve various formulas and equations to calculate and control the movement of mechanical systems. Here are some of the key formulas used in motion control:

Position formula

The position of a moving object can be calculated using the formula:

position = initial position + velocity x time + 0.5 x acceleration x time^2

- This formula can be used to calculate the position of a mechanical system at any given time based on its initial position, velocity, and acceleration.

Velocity formula

The velocity of a moving object can be calculated using the formula:

velocity = initial velocity + acceleration x time

- This formula can be used to calculate the velocity of a mechanical system at any given time based on its initial velocity and acceleration.

Acceleration formula

The acceleration of a moving object can be calculated using the formula:

acceleration = (final velocity - initial velocity) / time

- This formula can be used to calculate the acceleration of a mechanical system based on its initial and final velocities and the time it takes to change velocity.

Torque formula

The torque required to move a mechanical system can be calculated using the formula:

torque = inertia x acceleration + friction

- This formula takes into account the inertia of the system (which depends on its mass and shape) and the friction between the moving parts.

PID control formula

PID (proportional-integral-derivative) control is a common method used in motion control to adjust the output of a system based on the error between the desired and actual position. The formula for PID control is:

output = Kp x error + Ki x integral(error) + Kd x derivative(error)

- Kp, Ki, and Kd are the proportional, integral, and derivative gains, respectively.

These are just a few examples of the formulas used in motion control. The specific formulas used will depend on the specific system being controlled and the control method being used.

here's an example of using a formula to calculate the position of a stepper motor controlled by a stepper motor controller:

Assuming we have a stepper motor with a step angle of 1.8 degrees per step, and we want to move it 1000 steps in the clockwise direction. We also have a stepper motor controller that is set to operate at a maximum step frequency of 1000 steps per second.

The formula to calculate the time required to move the motor can be expressed as:

Time = Number of steps / Step frequency

Substituting the given values into the formula, we get:

Time = 1000 steps / 1000 steps per second

Time = 1 second

This means that it will take 1 second for the motor to complete the 1000-step movement.

The formula to calculate the angle of rotation of the motor can be expressed as:

The angle of rotation = Number of steps x Step angle

Substituting the given values into the formula, we get:

The angle of rotation = 1000 steps x 1.8 degrees per step

Angle of rotation = 1800 degrees

This means that the motor will rotate 1800 degrees, or 5 full revolutions, in the clockwise direction to complete the 1000-step movement.

These formulas can be useful in designing and controlling the movement of stepper motors using stepper motor controllers in various industrial and automation applications.

Motion Controller Types

There are several types of motion controllers, each designed for different applications and industries. Here are some common types of motion controllers:

- Programmable Logic Controllers (PLCs): PLCs are used primarily in industrial automation applications, and are designed to control the motion of machines and production lines. They are often used in applications that require a high degree of reliability, such as manufacturing and assembly.

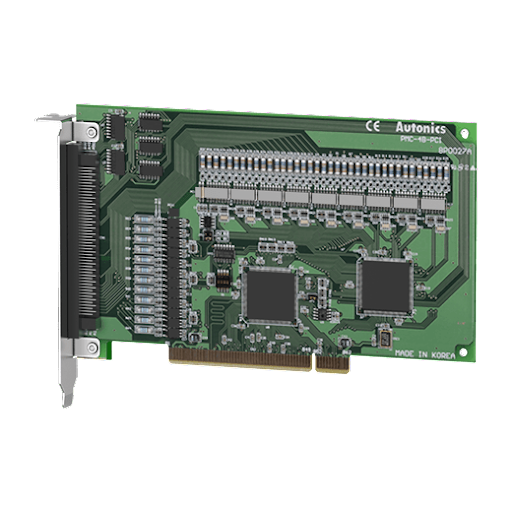

- Motion Control Cards: These are typically add-on cards for personal computers or embedded systems, and are designed for applications that require moderate to high precision motion control. They are often used in applications such as CNC machines, robotics, and test and measurement equipment.

Fig 3. 4-Axis PC-PCI Card Programmable Motion Controllers

- Dedicated Motion Controllers: These are stand-alone motion controllers that are designed specifically for motion control applications. They often have a more specialized set of features and capabilities and are typically used in high-performance applications such as semiconductor manufacturing and high-precision machining.

- Servo Drives: Servo drives are a type of motion controller that is designed specifically to control the motion of servo motors. They typically have high-performance control algorithms and are used in applications that require precise positioning and speed control, such as robotics and motion control systems.

- Stepper Motor Controllers: These are motion controllers that are designed specifically for controlling stepper motors. They typically have simpler control algorithms and are used in applications that require moderate precision, such as 3D printing and automation systems.

Fig 4. AC Power 2-Phase Closed Loop Stepper Motor System with Integrated Controller

Motion Controller With or Without VR

Motion controllers can be used with or without virtual reality (VR) systems.

When used with VR, motion controllers are often designed to track the movement and orientation of the user's hands, allowing them to interact with virtual objects and environments in a more immersive way. VR motion controllers typically use sensors, such as accelerometers, gyroscopes, and magnetometers, to track the position and orientation of the controller in 3D space.

On the other hand, when used without VR, motion controllers are typically used to control the movement of mechanical systems, such as robots, CNC machines, and packaging systems. These controllers often use closed-loop control algorithms and feedback sensors to precisely control the movement of the mechanical system, allowing for increased precision and efficiency in industrial automation applications.

In either case, motion controllers can offer a range of benefits, including increased speed, accuracy, and efficiency in controlling the movement of mechanical systems.

Motion Controller Application

Motion controllers are used in a wide range of applications across various industries. Some common applications of motion controllers include:

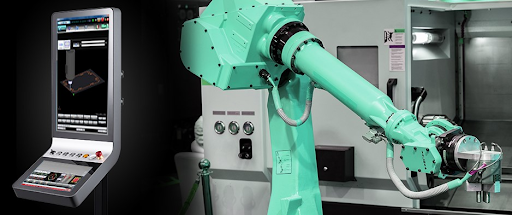

- Robotics: Motion controllers are often used in robotics applications, where they control the movement of robot arms, grippers, and other components. They provide precise and accurate control over the movement of the robot, allowing it to perform tasks such as pick-and-place operations, welding, and assembly.

- CNC Machines: Motion controllers are used in computer numerical control (CNC) machines, such as lathes, mills, and routers. They control the movement of the machine tool, allowing it to accurately cut and shape materials to the desired specifications.

- Semiconductor Manufacturing: Motion controllers are used in semiconductor manufacturing equipment, such as wafer handling and testing systems. They provide precise control over the movement of the equipment, allowing for high-precision testing and manufacturing processes.

- Aerospace and Defense: Motion controllers are used in aerospace and defense applications, such as satellite positioning and missile guidance systems. They provide precise control over the movement of the systems, allowing them to accurately navigate and target their intended destinations.

- Medical Devices: Motion controllers are used in medical device applications, such as surgical robots and imaging equipment. They provide precise control over the movement of the devices, allowing for high-precision procedures and imaging.

- Automotive: Motion controllers are used in automotive applications, such as engine and transmission testing systems, as well as in assembly line robots that help assemble car components.

Fig 5. Motion controllers are widely used in robotics to control the robot movement.

How to Use a Motion Controller?

To use a motion controller, you will typically need to follow these steps:

- Choose the appropriate motion controller for your application: There are many different types of motion controllers available, each with different capabilities and features. You will need to select a motion controller that is appropriate for your application and meets your requirements for precision, speed, and functionality.

- Install the motion controller: Depending on the type of motion controller, you may need to install it in a computer or other control system or connect it to a servo motor or other actuator. Follow the manufacturer's instructions for installation and configuration.

- Connect sensors and actuators: Connect the sensors that will provide feedback on the motion of the system, as well as the actuators that will control the movement of the system. Ensure that the connections are secure and that the sensors and actuators are properly calibrated.

- Configure the motion controller: Set up the motion controller to meet your requirements for motion control, including the motion profile, speed, and acceleration parameters.

- Test the motion controller: Verify that the motion controller is functioning properly by testing it with a simple motion profile. Check that the motion controller can accurately track the desired motion profile and that it responds appropriately to changes in the system.

- Integrate with control software: If you are using a motion controller in a larger automation system, you will need to integrate it with your control software to enable coordinated motion control. This may involve programming the motion controller or using software tools provided by the manufacturer.

- Fine-tune the motion controller: Once the motion controller is integrated into your system, you may need to fine-tune it to achieve the desired level of precision and control. This may involve adjusting the feedback gains, tuning the control algorithm, or adjusting the motion profile.

The Important Factors for Choosing a Motion Controller

There are several important factors to consider when choosing a motion controller for a specific application. Here are some of the key factors to consider:

- Type of motion control: Different types of motion controllers are designed for different types of motion control, such as servo control, stepper motor control, or hydraulic control. It is important to choose a motion controller that is designed for the specific type of motion control required for the application.

- Performance requirements: The performance requirements of the application, such as speed, accuracy, and resolution, will also influence the choice of motion controller. It is important to choose a motion controller that can meet the required performance specifications.

- Input and output requirements: The input and output requirements of the application, such as the number of axes, the type of sensors used, and the communication protocols required, will also need to be considered when choosing a motion controller.

- Programming and software: The programming and software tools provided by the motion controller manufacturer will also be an important factor to consider. It is important to choose a motion controller that has a programming environment that is easy to use and provides the required functionality for the application.

- Cost: The cost of the motion controller will also be an important consideration. It is important to choose a motion controller that provides the required performance and functionality at a cost that is within the budget for the application.

The choice of motion controller will depend on a range of factors specific to the application, including the type of motion control required, the performance requirements, the input and output requirements, the programming and software tools provided, and the cost.

Revolutionize Your Control: Learn more about the power of stepper motors!

How can I Calibrate a Motion Controller?

Calibrating a motion controller is an important step in ensuring accurate and precise control over the movement of mechanical systems. Here are the general steps involved in calibrating a motion controller:

- Set up the system: Set up the mechanical system that the motion controller will be controlling, including the motors, sensors, and other components. Make sure that the system is properly connected to the motion controller.

- Define the motion parameters: Define the motion parameters for the system, including the maximum speed, acceleration, and deceleration, as well as the target positions for the motors.

- Run the calibration routine: Most motion controllers will have a calibration routine that can be run to calibrate the system. This routine will typically involve moving the motors to a series of predefined positions and measuring the actual position using the sensors. The calibration routine will then adjust the control parameters of the motion controller to ensure that the motors move to the correct positions.

- Verify the calibration: Once the calibration routine is complete, verify that the system is calibrated correctly by running some test movements and comparing the actual positions of the motors with the target positions.

- Repeat if necessary: If the system is not calibrated correctly, repeat the calibration routine and adjust the control parameters until the desired level of accuracy and precision is achieved.

How to Measure the Motion Controller's Accuracy?

The accuracy of a motion controller can be measured by comparing the actual position of the mechanical system being controlled by the motion controller with the desired or target position. Here are some common methods for measuring the accuracy of a motion controller:

- Encoder feedback: Most motion controllers use encoder feedback to measure the position of the motor shaft. By comparing the actual encoder feedback with the desired position, the accuracy of the motion controller can be determined.

- Laser interferometer: A laser interferometer can be used to measure the actual position of the mechanical system with high precision. This can be compared with the target position to determine the accuracy of the motion controller.

- Dial gauge: A dial gauge can be used to measure the actual position of the mechanical system. This can be compared with the target position to determine the accuracy of the motion controller.

- Step response: The step response of the motion controller can also be used to measure its accuracy. This involves sending a step command to the motor and measuring the time it takes for the motor to reach the desired position. The accuracy can then be calculated based on the difference between the actual and desired position.

Overall, the specific method used to measure the accuracy of a motion controller will depend on the type of motion control and the specific motion controller being used. It is important to consult the manufacturer's documentation and follow the recommended testing procedures to ensure accurate measurements of the motion controller's accuracy.

Motion Controller Advantages and Disadvantages

Advantages

Motion controllers offer several advantages over traditional control methods such as manual or basic electronic control. Here are some of the key advantages of motion controllers:

- Precision: Motion controllers can provide very precise control over the movement of mechanical systems, allowing for accurate positioning and smooth motion.

- Speed: Motion controllers can respond quickly to changes in position or speed, allowing for fast and efficient operation of mechanical systems.

- Flexibility: Motion controllers can be programmed to control a wide range of different mechanical systems, allowing for flexibility in design and operation.

- Automation: Motion controllers can automate the control of mechanical systems, reducing the need for manual control and increasing productivity and efficiency.

- Cost-effectiveness: Motion controllers can be cost-effective compared to traditional control methods, especially for complex or high-precision systems.

- Real-time feedback: Motion controllers can provide real-time feedback on the performance of mechanical systems, allowing for quick diagnosis and correction of issues.

motion controllers offer a range of advantages that make them an attractive choice for controlling the movement of mechanical systems in a wide range of applications.

Disadvantages

While motion controllers offer many advantages, there are also some potential disadvantages to consider. Here are some of the key disadvantages of motion controllers:

- Cost: Motion controllers can be expensive compared to simpler control methods, which can make them less accessible for some applications.

- Complexity: Motion controllers can be more complex than traditional control methods, requiring specialized knowledge and expertise to program and operate.

- Compatibility: Motion controllers may not be compatible with all types of mechanical systems, which can limit their usefulness in certain applications.

- Maintenance: Motion controllers may require more maintenance and upkeep than traditional control methods, which can add to the overall cost and complexity of the system.

- Response time: While motion controllers can provide very fast response times, there may be a delay between the input command and the resulting motion, which can be a disadvantage in certain high-speed applications.

- Dependence on software: Motion controllers rely on software to operate, which can be vulnerable to errors and crashes, potentially causing system downtime or damage.

Conclusion

In conclusion, motion controllers are electronic devices that are used to control the movement of mechanical systems. They provide precise and accurate control over the movement of these systems, offering a range of benefits such as increased speed, flexibility, automation, and cost-effectiveness. However, motion controllers have potential disadvantages, including cost, complexity, and maintenance requirements.

To use motion controllers effectively, it is important to understand their structure, how they work, their types, applications, and calibration methods. Choosing the right motion controller requires considering factors such as accuracy, speed, and flexibility. Additionally, motion controllers involve various formulas and equations to calculate and control the movement of mechanical systems, including position, velocity, acceleration, torque, and PID control formulas. By understanding the capabilities and limitations of motion controllers, it is possible to select and utilize them effectively for a wide range of mechanical systems and applications.

To Recap

1.What is a motion controller?

A motion controller is an electronic device that is used to control the movement of mechanical systems, such as robots, CNC machines, and industrial automation systems.

2.What are the types of motion controllers?

There are various types of motion controllers, including servo controllers, stepper motor controllers, hydraulic controllers, and pneumatic controllers.

3.How does a motion controller work?

A motion controller receives input signals from sensors, such as encoders, and generates output signals to control the movement of mechanical systems. The controller uses algorithms and control loops to regulate the movement of the system.

4.What are the advantages of using a motion controller?

Motion controllers provide precise and accurate control over the movement of mechanical systems, allowing for increased speed, flexibility, automation, and cost-effectiveness.

5.What are the disadvantages of using a motion controller?

Motion controllers can be more expensive, complex, and maintenance-intensive than traditional control methods. Additionally, there may be a delay between the input command and the resulting motion, which can be a disadvantage in some applications.

6.How do you calibrate a motion controller?

Calibration of a motion controller involves adjusting the controller settings to ensure that the output signals accurately correspond to the desired movement of the system. Calibration can be done using various methods, such as tuning PID parameters and adjusting the encoder feedback.

7.Can motion controllers be used without VR?

Yes, motion controllers can be used without VR in a wide range of industrial and automation applications.

8.What are some important factors to consider when choosing a motion controller?

Important factors to consider include accuracy, speed, flexibility, compatibility with mechanical systems, and cost.

9.What are some common formulas used in motion control?

Common formulas used in motion control include position, velocity, acceleration, torque, and PID control formulas.

10.Where can motion controllers be used?

Motion controllers can be used in a wide range of industrial and automation applications, such as robotics, CNC machining, and packaging systems.

Reference

https://www.esa-automation.com/en/what-is-a-motion...

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecting millions …16th Apr 2025