Thermocouples: Where Science Meets Magic in the World of Temperature

Imagine harnessing the power of temperature to unlock the secrets of the unseen. From monitoring volcanic eruptions to ensuring the safety of spacecraft, one small device stands as the gatekeeper of thermal knowledge: the mighty thermocouple. In this era of scientific marvels, join me on a journey into the realm of heat measurement, where the humble thermocouple emerges as the unsung hero, revealing the invisible dance of molecules and transforming temperature into a language we can decipher. Prepare to be captivated by the captivating tale of the thermocouple, where science meets magic and innovation sparks new frontiers!

Fig 1. A Thermocouple

The movement of molecules and atoms leads to the production of heat (kinetic energy). The greater the motion, the more heat is generated. Temperature sensors measure how much heat or cold energy an object or system gives off. This lets us "sense" or "detect" any physical changes in temperature by giving us a digital or analog output. Thermocouples are the most commonly used type of temperature sensor.

Temperature sensor

Different types of temperature sensors have various characteristics depending on their application. A temperature sensor has two general physical types:

Contact temperature sensor

This type of temperature sensor requires physical contact with the object whose temperature it wants to "sense" and uses conduction to monitor temperature changes. These sensors can be used to detect the temperature of solids, liquids, and gas over a wide range of temperatures.

Non-contact temperature sensor

This type of temperature sensor uses convection and radiation to monitor temperature changes. These sensors can be used to find out the temperature of liquids and gases that give off radiant energy as heat rises and cold falls in their convection currents. They can also be used to find infrared waves that an object sends out as radiant energy.

These two types of contact and non-contact temperature sensors can be divided into three groups: electromechanical, resistance, and electronic sensors. Thermocouples are popular because they are simple, easy to use, and respond quickly to changes in temperature. After all, they are small. The thermocouples can also measure temperatures from -200 to over 2000°C, which is the widest range of any temperature sensor.

What exactly is a thermocouple?

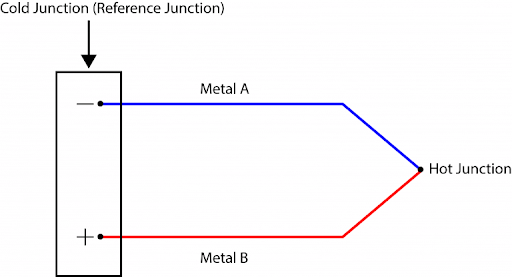

Thermocouples are the most common equipment for electrical temperature measurement in the industry. The thermocouple mechanism is based on the Seebeck phenomenon, which converts the temperature difference between two points into voltage. In a more general definition, a thermocouple is a sensor that measures temperature. It consists of two metals, and these two different metals are connected at the end. When the junction of two metals is heated or cooled, a voltage is created that can be proportional to the temperature. The thermocouple is a simple, robust, and affordable temperature sensor that is used in a wide range of temperature measurement processes.

Fig 2. A thermocouple structure

Thermocouples are generally used in acomprehensive range of applications due to their ability to function as temperature sensors, from industrial thermocouples to ordinary thermocouples found in electrical installations and typical appliances. Due to the wide variety of models and their technical specifications, it is essential to understand their basic structure, how it works, and their ranges to better determine the right type and material of thermocouple for your application.

Thermocouples come in various styles, such as thermocouple probes, thermocouple probes with connectors, transfer joint thermocouple probes, infrared thermocouples, bare wire thermocouples, or even wire thermocouples. Because there are so many different models and technical specifications, it is very important to understand the basic structure, performance, and range to choose the right type of thermocouple and material for the job.

What are common thermocouple design elements?

Thermocouple sensors are made up of thermocouples, which are wires, insulation, sheaths, end seals, and ways to connect them (extension wires, connectors, etc.). The wires are connected at one end to form a "gauge" or "hot" connection. This sensor should be hooked up to a digital or analog device that shows temperature changes.

What is the voltage range of the thermocouple?

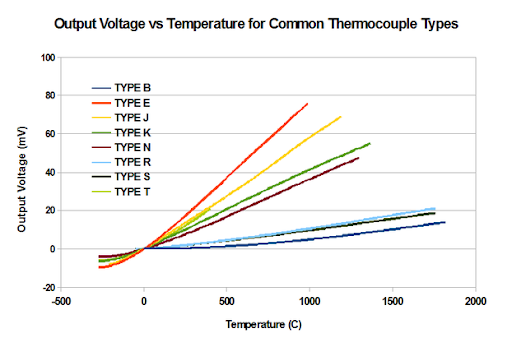

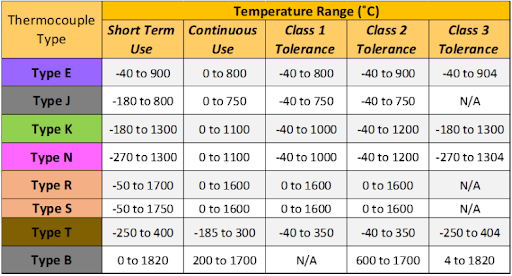

The thermocouple output depends on the type of thermocouple in it. Common thermocouple categories include types J, K, T, E, and N, which are called "base metal" thermocouples. Types R, S, and B are called "noble metal" thermocouples and types C and D are called "refractory metal” thermocouples. Output versus temperature characteristics for each type are defined in two standards: ANSI/ASTM E230 and IEC 60584.

The following criteria are used in choosing a thermocouple:

- Temperature range

- Chemical resistance of thermocouple or sheath material

- Resistance to wear and vibration

- Installation requirements (may need to be compatible with existing equipment; existing holes may dictate probe diameter)

What is the response time of a thermocouple?

Under a set of conditions, the time it takes for a sensor to reach a 63.2% change in temperature is set. Five time constants are required for the sensor to approach 100% of the phase shift value. An exposed junction thermocouple provides the fastest response. Also, the smaller the diameter of the probe sheath, the snappier the reaction will be, but the maximum temperature may be lower. But keep in mind that the probe sheath may not be able to handle the full temperature range of the thermocouple type.

Types of thermocouples

The structure of thermocouples is produced by connecting a metal and an alloy. With this simple mechanism, they can easily measure temperatures in a wide range, from -270 to about 1800 degrees. There are different types of thermocouples, which are divided into the following six categories according to the type of metal and its alloy.

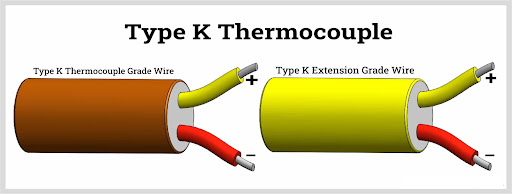

1. Type K thermocouple

This thermocouple is made of Ni-Cr metal wire (Chromel) and Ni-Al (Alumel). This thermocouple is cheap and one of the most widely used and common types of thermocouples. Its temperature performance range is between -250 °C and 1300 °C. This range is not set in stone and will change depending on who made it and how it looks. For example, K-type wire-shaped thermocouples range from -40 to 250 degrees, and their rod type can be measured up to a range of 1300 degrees. The sensitivity of the K-type thermocouple is approximately 41 µV/°C and is usually used at high temperatures. The Type K thermocouple has anti-oxidation properties due to the use of copper, so it is suitable for furnaces where oxidation occurs.

Fig 3. Type K thermocouple

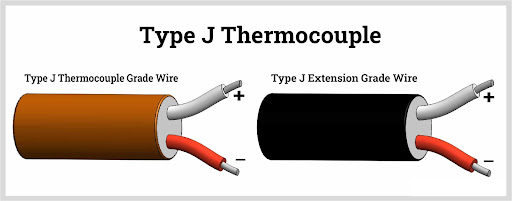

2. Type J thermocouple

This thermocouple is made of iron metal (Fe) and copper-nickel alloys (Cu-Ni) (Constantan). The temperature range of this thermocouple is between -180°C and 800°C. Due to the possibility of iron oxidation in this thermocouple, it is used in the plastic molding industry. The sensitivity of type J thermocouple is 51 µV/°C. It is better not to use J type thermocouple due to the presence of iron in places where oxidation is possible.

Fig 4. Type J thermocouple

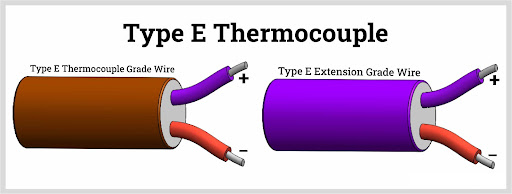

3. Type E thermocouple

This thermocouple is made using Ni-Cr (chrome) and Cu-Ni (Constantan) metals. Its temperature performance range is between -40°C and 900°C. This thermocouple has the highest sensitivity with 62 µV/°C and can be used in vacuum applications and cases where the sensor is not protected.

Fig 5. Type E thermocouple

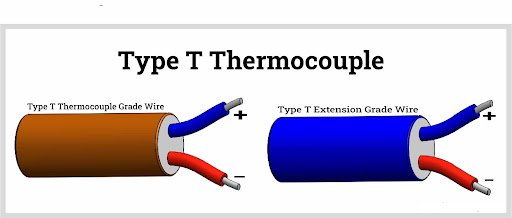

4. T-type thermocouple

This thermocouple is made of Cu copper and Cu-Ni alloy (Constantan). The temperature performance range of this type of thermocouple is between -250°C and 400°C. This thermocouple is relatively cheap, suitable for low-temperature applications, and resistant to moisture. The sensitivity of this thermocouple is 46 µV/°C. The T-type thermocouple is mostly used in the industry for the following reasons:

- It is more linear than all thermocouple types.

- Has a suitable temperature range.

- It also has good sensitivity.

Fig 6. Type T thermocouple

5. Thermocouple N-type

This thermocouple is made of Ni-Cr-Si (Nicrosil) and Ni-Si-Mg (Nisil) metals. Its temperature range is between -270°C and +1300°C. The sensitivity of this thermocouple is 30 µV/°C.It is usually used at high temperatures. Also, the tolerance of this sensor against oxidation at high temperatures is better than the K type.

Fig 7. Type N thermocouple

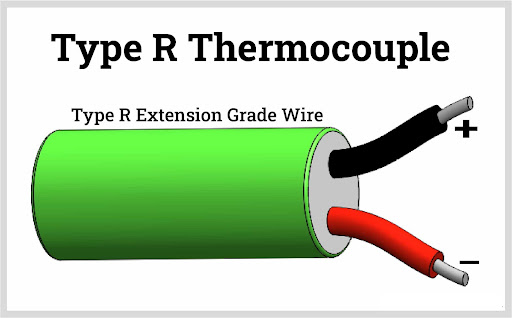

6. Thermocouple types R, S, and B:

These thermocouples are made using Pt-Rh (platinum-radium) with different compounds (the difference between these three types is in their platinum content). Their price is high, and their sensitivity is very low, around 10 µV/°C, and their temperature range is approximately -50°C and +1750°C. These thermocouple types are used in high-temperature measurements, for example, in the glass and steel industry.

Fig 8. Type R thermocouple

Comparing table

Table 1. Comparing thermocouple types

| Thermocouple Type | Positive Wire | Negative Wire | Temperature Range | Advantages | Disadvantages |

| Type K | Chromel | Alumel | -200°C to 1350°C | Wide temperature range, commonly used, low cost | Less accurate than some other types |

| Type J | Iron | Constantan | -40°C to 750°C | Wide temperature range, good for low temperatures | Limited high-temperature capability |

| Type T | Copper | Constantan | -200°C to 350°C | Excellent accuracy at low temperatures, stability | Narrow temperature range |

| Type E | Chromel | Constantan | -200°C to 900°C | Good accuracy, suitable for cryogenic temperatures | Moderate temperature range |

| Type N | Nicrosil | Nisil | -200°C to 1300°C | High resistance to oxidation, suitable for high temperatures | Less common, expensive |

| Type S | Platinum | Platinum-Rhodium (10%) | 0°C to 1600°C | Excellent accuracy and stability at high temperatures | Expensive, limited low-temperature range |

| Type R | Platinum | Platinum-Rhodium (13%) | 0°C to 1600°C | High accuracy and stability at high temperatures | Expensive, limited low-temperature range |

| Type B | Platinum | Platinum-Rhodium (30%) | 600°C to 1700°C | High-temperature capability, good accuracy | Expensive, limited low-temperature range |

Please note that the temperature ranges mentioned are approximate and can vary depending on the specific thermocouple manufacturer and design.

What is the difference between J and K-type thermocouples?

K-type thermocouples are the most common temperature sensors on the market. The price of these thermocouples is higher than the price of J-type thermocouples, but the K-type is a versatile temperature sensor that can withstand temperatures from 0 to 1260 degrees Celsius.

This higher temperature range makes this type of thermocouple more suitable for very high-temperature contact than the J-type thermocouple. Of course, the higher price of this thermocouple means that the K-type thermocouple cannot compete with the J-type thermocouple at lower and average temperatures.

K-type thermocouple, in addition to a more broad temperature range, has another advantage, which is their resistance and capacity, due to their different metals. Type J thermocouple is made of iron and constantan, and type K is made of nickel/chromium alloy (chrome) and nickel/aluminum alloy (alumni).

These compounds make K-type thermocouples more protected against oxidation and acids than J-type thermocouple iron wires. As a result, K-type thermocouples are suitable for oxidizing environmental conditions and environments with corrosive surroundings or immersion in oxidizing or corrosive fluids.

K-type thermocouples work very efficiently in an oxidation-cleaning process, while J-type thermocouples may oxidize and become damaged in this environment. Also, K-type thermocouples are more suitable for use at very high temperatures - up to 1260 degrees Celsius - and make it possible to measure the temperature with acceptable accuracy even with such temperatures.

On the other hand, their slightly higher price compared to J-type thermocouples makes J-type still suitable for applications with lower temperatures and non-oxidizing atmospheres that are compatible with the temperature range of this type of thermocouple.

K-type thermocouples are used for measuring in different types of environments such as water, relatively weak chemical solvents, gas, and dry areas. For example, these thermocouples are used in engines, oil heaters, and boilers. They are also used as thermometers in hospitals and food industries.

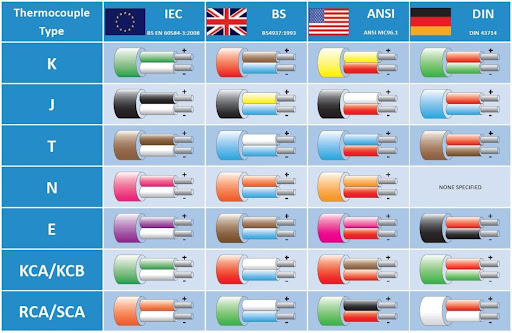

Thermocouple standards

Usually, there is a standard for determining the color of the thermocouple cable, for example, according to the American standards, it is given in the figure below:

Fig 9. Thermocouple standards

Thermocouple appearance

Thermocouples have a different appearance depending on the application.

|

Thermocouple sheathed with cap for transmitter installation

suitable for industrial applications. |

|

Probe thermocouples

with different lengths of wire suitable for remote places. |

|

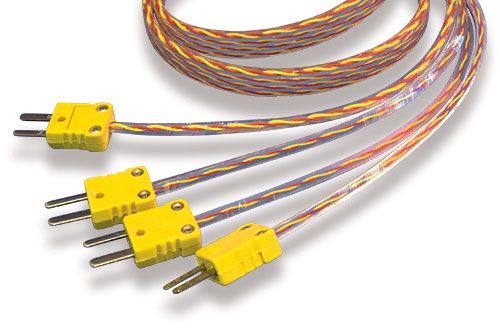

Portable probe thermocouple

suitable for testing and portable equipment such as digital thermometers. |

|

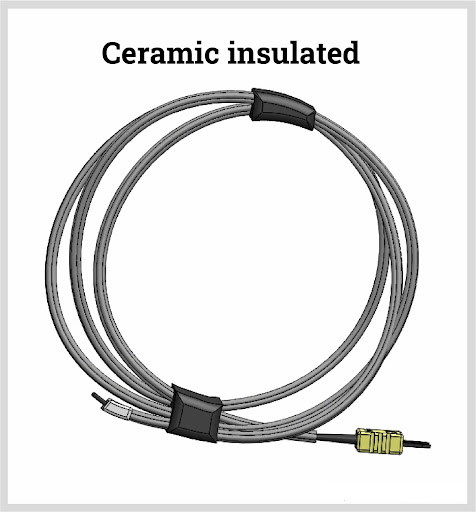

Wire thermocouples

suitable for measuring temperatures below 250 degrees Celsius |

|

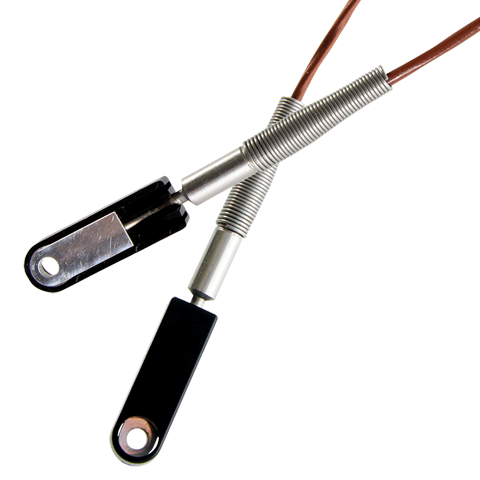

surface thermocouples

suitable for measuring the temperature of a surface such as an oven |

What is the response time of a thermocouple?

A time constant is defined as the time required for the sensor to reach 63.2% of a step change in temperature under certain conditions. Five-time constants are required for the sensor to achieve 100% of the phase shift value. An open junction thermocouple has the fastest response. Also, the smaller the diameter of the probe sheath, the quicker the response, but the maximum temperature may be lower. Be careful that sometimes the probe sheath cannot withstand the entire temperature range of the thermocouple type.

What are the most common applications of thermocouples?

Thermocouples are used in vast applications, from household appliances to industrial processes, electrical power generation, furnace monitoring and control, food and beverage processing, automotive sensors, aircraft engines, rockets, satellites, and spacecraft. When it comes to high temperature, small size, fast response, heightened shock or vibration, you will most often see thermocouples measuring temperature.

- Thermocouples suitable for food applications

can be used for a wide variety of applications in the food and beverage industry, such as clean-in-place sensors, penetration probes, oven control, food chain monitoring, oven control, and monitoring, and control. The temperature of the steam kettle.

- Thermocouples suitable for extruder

Extruders require high temperature and high pressure. They also have a unique filament conversion that is used to position the sensor tip in the existing high-pressure molten plastic.

- Thermocouples suitable for low-pressure

E, K, T, and N thermocouples can be used to measure temperatures up to -200 degrees, although the alloys used in these thermocouples must be specially selected for use at these temperatures to achieve the required accuracy and precision. Most thermocouple manufacturers provide their thermocouple alloys calibrated to use at 0°C and above. The same alloys can be used up to -200 degrees Celsius, but the accuracy may have slightly deviated from the mentioned values. Individual calibrations can be purchased to determine offset values.

- Thermocouples suitable for furnaces

The furnace conditions to which the thermocouples are exposed determine the right thermocouple for that application. To choose the right thermocouple, we must consider some of these conditions:

- Temperature capacity of thermocouple wires.

- Temperature capacity of the sheath or protective cover (metal or ceramic).

- The atmosphere in which it is used (air, reducing, oxidizing, inert).

- Installation configuration.

- Thermocouples suitable for molten metal

Measuring the melted metal temperature is a difficult task because its temperature is very high, and the measurement conditions are also hard. Because of the temperature of these metals, K-type and N-type base metal thermocouples and R, S, and B platinum types are the only choices for contact measurement in this field.

When metal base thermocouples are used, the wires are usually larger diameter #8 or #14 AWG solid wires with ceramic insulation and ceramic or metal shielding tubes. Large diameter K and N wires drop more slowly, allowing time for measurement before high-temperature conditions lead to wire degradation.

Platinum thermocouple wires are usually AWG #20 to #30 solid. Unlike K and N-type base metal wires, instead of breaking down due to oxidation or corrosion, platinum wires are often due to long-term annealing and eventually fail due to grain growth.

Fig 10. Fiberglass insulated thermocouple wire

Installation and maintenance

How can use the thermocouples?

Thermocouples are commonly used in various applications for temperature measurement and monitoring. Here are some common ways to use thermocouples:

- Temperature Measurement: Thermocouples are primarily used to measure temperature in a wide range of industries. They can be inserted directly into the substance or environment being measured, such as liquids, gases, or solids. The thermocouple wires generate a voltage proportional to the temperature difference between the measurement point and the reference junction, allowing for temperature readings.

- Process Control: Thermocouples play a crucial role in process control systems, where temperature regulation is essential. By connecting the thermocouple to a temperature controller, the system can maintain a specific temperature by adjusting heating or cooling elements based on the thermocouple readings. This is common in industrial processes such as manufacturing, refining, and food processing.

- Safety Monitoring: Thermocouples are utilized in safety applications to monitor temperature levels and trigger alarms or shutdown systems in case of overheating. For example, in power plants, thermocouples are used to monitor the temperature of critical equipment like turbines or transformers and initiate protective actions if temperatures exceed safe limits.

- HVAC Systems: Thermocouples are employed in heating, ventilation, and air conditioning (HVAC) systems for temperature control and monitoring. They help regulate the heating and cooling elements in HVAC units to maintain desired temperature levels.

- Scientific Research: Thermocouples are widely used in scientific research for temperature measurements in laboratory experiments and studies. They are utilized in various fields, including physics, chemistry, materials science, and environmental research.

- Energy Management: Thermocouples can be utilized in energy management systems to optimize energy usage. By monitoring temperature variations in buildings or industrial processes, energy consumption can be adjusted to ensure efficient operation and reduce waste.

- Aerospace and Automotive: Thermocouples are crucial in aerospace and automotive industries to monitor and control temperatures in engines, exhaust systems, and critical components. They provide essential data for engine performance analysis and contribute to overall safety and efficiency.

It's important to note that the specific usage of thermocouples can vary depending on the thermocouple type, environmental conditions, and the requirements of the application. Proper installation, calibration, and maintenance are crucial for accurate and reliable temperature measurements.

How do you know that a thermocouple is not working properly?

To find out if your thermocouple is working perfectly, you need to test the device. Before you replace the device, you should check and test it to see if it works. To do this, you only need a multimeter and basic knowledge of electronics. There are generally three approaches to thermocouple testing using a multimeter, which are explained below

- Resistance Test

To perform this test, the device must be placed in a gas application line, and the required equipment is a digital multimeter and pliers.

Procedure: Connect the alligator clips to the two ends of the multimeter. Attach clamps to both ends of the thermocouple where one end bends into the gas valve. Now, turn on the multimeter and note the readings. If the multimeter displays ohms in the lower order, the thermocouple is in perfect working order. But if the reading is 40 ohms or more, the thermocouple is not good.

- Open circuit test

In this test, the equipment used is crocodile clips, a lighter, and a digital multimeter. Here, instead of measuring resistance, voltage is calculated. Now, the cigarette lighter heats one side of the thermocouple. When the multimeter shows a voltage in the range of 25-30 mV, the thermocouple is working correctly. But if the voltage is closer to 20 mV, this device should be replaced.

- Closed circuit test

In this test, the equipment used is crocodile clips, a lighter, and a digital multimeter. Here a transformer is placed inside the gas valve, and then the thermocouple is placed on the other side of the transformer. Now turn on the multimeter. If the reading is in the range of 12-15 mV, the device is in good condition. However, if the read voltage is less than 12 mV, it indicates a failure of the device.

So by using the test methods above, you can see if a thermocouple is working properly.

How to protect a thermocouple?

The construction of a thermocouple is surprisingly simple; It's just two wires of two different metals joined together at both ends. One of these two connections, the reference connection, can be placed in a safe place, away from the opposing environment. On the other hand, the measurement connection is always in a hazardous location and probably has to withstand extreme temperature and pressure measurements as well as corrosive process fluids. If these wires are left exposed to the environment, their useful life will be reduced, especially at very high temperatures, say above 800 degrees Celsius, where no other temperature sensor is used. However, there are ways to protect the thermocouple and add a shielding method to the measurement connection wires.

- Steel coating

Stainless steel is a standard coating for temperature sensors. This material is cheap and available, and it exists in many different dimensions and can be used in various designs of thermocouples. The conduit is usually ¼ inch in diameter and may be several feet or longer. The ¼-inch dimensions strike the perfect balance between cost, stiffness, strength, and practicality. Smaller diameters, such as 1/8 inch or smaller: needle-sized thermocouples are used for medical applications. The smaller the probe, the less pressure and physical stress it can withstand, and the probe will be shorter. On the other hand, there are also larger diameters, but the cost of their materials is higher, and their response is less.

You see these wide, strong thermocouples in specific industrial applications, such as in oil well measurements, where the financial cost and loss in accuracy are more important than breaking and damaging the sensor thousands of feet underground.

Fig 11. Steel coating

- Pre-packaged and protected MI cable

Mineral insulated cable or MI cable is a cable that is filled with insulating mineral material. There are different types of MI cable, but thermocouples usually consist of three things:

a stainless steel sheath, Two different thermocouple wires, and insulating powder. Let's examine each one.

The stainless steel tube is a solid container that holds the insulating powder and the thermocouple wires together. Naturally, it also covers all the protective measures we talked about above.

Fig 12. MI cables

Two different thermocouple wires are a requirement to measure two different voltages that give us the temperature of the process. For example, MI type K cable has chromel and alumel wire running along a stainless steel tube. Some MI cables can include four wires or two thermocouples to provide greater accuracy and repeatability. For example, a double J-type MI cable has two iron wires and two constantan wires. Each pair supplies its voltage difference to be measured and interpreted. Some special MI cables may have three pairs of wires inside.

Fig 13. Four-wire thermocouple

The insulation inside the MI cable is usually composed of magnesium oxide powder or MgO. As a cheaper alternative, aluminum oxide can also be used, which cannot withstand higher temperatures than MgO. When the powder is tightly packed around the wire in the sheath, the powder acts as an electrical resistance barrier, reducing the effects of moisture and allowing the thermocouple to take an accurate reading. They also provide excellent thermal conductivity; Any temperature change is transmitted instantly, allowing a fast response to be realized for the oscillatory process. A secondary effect of filling the stainless steel sheath with powder is that it makes the whole assembly stronger, thereby increasing the durability and strength of the thermocouple made with MI cable.

- Keep it clean with a vacuum

- Keep it safe in a thermowell

like in the manufacturing process, different elements can mix with the thermocouple wires over time and change their composition. These reactions fundamentally change the way the thermocouple reads. As a result, over time, they reduce the tool's accuracy, and eventually, you need to replace the device. To avoid impurities around the metal wires, you can flood (seal) a thermocouple into a vacuum. By encapsulating in a vacuum, the risk of changing the electromagnetic characteristics is reduced and the useful life of the accuracy of the reported voltages is extended.

Thermowell or heat wells are the ultimate protection for thermocouples. Generally milled from a single piece of brass or stainless steel, they are a barrier that separates the tool from the harsh process environment. This might sound similar to what the stainless steel sheath does that we talked about above, but thermowells do better than that. Under high pressure and high temperatures, conditions commonly encountered in thermocouple measurement processes, even the stainless steel sheath wears and deforms, making the instrument vulnerable to immediate destruction.

Thermocouples are stronger and sturdier than MI cable or sheathed thermocouples. Thermowells are specially designed for thermocouples that already have a stainless steel sheath. The best protection occurs when MgO protection powder, steel sheath, and thermowell barrier are used side by side.

Fig 14. Thermowell

Thermocouples are easy to use and reliable, but they can break when measured in harsh conditions. Each process is somewhat different, but there is always an optimal balance between the tool replacement cost and the protective measures taken.

Thermocouple calibration

Thermocouple calibration is the process of determining and adjusting the relationship between the output voltage or signal of a thermocouple and the corresponding temperature it is measuring. Calibration is essential to ensure accurate and reliable temperature measurements using thermocouples. Here are the key steps involved in thermocouple calibration:

- Select a Reference Temperature Standard: To calibrate a thermocouple, you need a reliable and traceable reference temperature standard. This can be a calibrated thermometer, a temperature bath, or a specialized temperature calibration device with a known and stable temperature output.

- Establish Reference Temperature Points: Determine a series of reference temperature points across the desired temperature range for calibration. These points should cover the expected operating range of the thermocouple.

- Connect the Thermocouple and Reference Standard: Connect the thermocouple and the reference temperature standard in a controlled environment, ensuring good thermal contact and minimizing temperature gradients.

- Measure Thermocouple Output: Measure the output voltage or signal of the thermocouple at each reference temperature point. Use a suitable temperature measurement instrument or data acquisition system to capture the thermocouple readings accurately.

- Record Calibration Data: Record the corresponding temperature values from the reference temperature standard along with the measured thermocouple output. Create a calibration table or data log to establish the relationship between temperature and the thermocouple's output.

- Calculate Calibration Coefficients: Use statistical or mathematical methods to determine the calibration coefficients that relate the thermocouple's output voltage or signal to the corresponding temperature. This involves curve fitting or linearization techniques to obtain accurate calibration coefficients.

- Apply Calibration Corrections: Apply the determined calibration coefficients to correct the raw thermocouple readings. This correction can be done manually or by programming the calibration coefficients into a temperature measurement device or control system.

- Verify Calibration: After applying the calibration corrections, verify the accuracy of the thermocouple by comparing it against known temperature references. Perform additional measurements and adjustments if needed.

- Calibration Certificate: Generate a calibration certificate documenting the calibration procedure, results, and the uncertainty of the calibration. This certificate provides traceability and serves as a reference for future measurements.

It's worth noting that thermocouples may require periodic recalibration due to factors such as aging, drift, or environmental influences. Regular calibration ensures the accuracy and reliability of temperature measurements and helps maintain the quality of data and process control.

Thermocouple accuracy

The accuracy of a thermocouple refers to how closely it measures the true temperature of the system or environment it is monitoring. Several factors can influence the accuracy of thermocouple measurements. Here are some key considerations:

- Thermocouple Type: Different thermocouple types have varying accuracies. Some types, such as Type S or Type R, offer high accuracy, while others like Type K or Type J may have lower accuracy. It's important to refer to the manufacturer's specifications for the specific thermocouple type you are using.

- Calibration: Proper calibration is crucial for accurate thermocouple measurements. Calibrating the thermocouple against a traceable temperature standard helps account for any inherent deviations or errors in the thermocouple's output. Regular recalibration is recommended to maintain accuracy over time.

- Measurement Range: Thermocouples may have a specified temperature range within which they provide their highest accuracy. Operating the thermocouple near the extremes of its temperature range may introduce greater measurement uncertainty and reduced accuracy.

- Cold Junction Compensation: Thermocouples require compensation for the temperature at the reference or cold junction where the thermocouple wires connect to the measurement instrument. Accurate cold junction compensation is essential to minimize errors in temperature readings.

- Interference and Noise: External factors such as electromagnetic interference or noise can impact the accuracy of thermocouple measurements. Proper shielding, grounding, and minimizing sources of interference can help improve measurement accuracy.

- Thermocouple Age and Degradation: Over time, thermocouples may experience aging effects, such as wire contamination or oxidation, which can affect their accuracy. Regular inspection and replacement of thermocouples as needed can help maintain accuracy.

- Measurement Instrumentation: The accuracy of the temperature measurement instrument or data acquisition system used with the thermocouple can impact the overall accuracy of the measurements. Choosing a high-quality and well-calibrated instrument is important for accurate temperature readings.

- Environmental Conditions: Extreme environmental conditions, such as high humidity, corrosive gases, or rapid temperature fluctuations, can introduce additional errors or affect the accuracy of the thermocouple. Ensuring suitable environmental conditions for accurate measurements is essential.

When assessing the accuracy of a thermocouple, it's essential to consider the combined uncertainty arising from all relevant factors, including the thermocouple itself, the measurement instrument, and the environmental conditions. Manufacturers typically provide accurate specifications for their thermocouples, and it's important to consult these specifications and follow proper calibration procedures to ensure accurate temperature measurements.

What are the advantages and disadvantages of using thermocouples?

The advantages of using thermocouples include

- Wide Temperature Range: Thermocouples can measure a broad range of temperatures, spanning from extremely low (-200°C) to very high (over 2000°C) temperatures, depending on the thermocouple type.

- Quick Response Time: Thermocouples offer fast response times, allowing for real-time temperature monitoring and control.

- Durable and Rugged: Thermocouples are built to withstand harsh environments, making them resistant to shock, vibration, and corrosive substances. This durability ensures their reliability and longevity in various industrial applications.

- Wide Application Range: Thermocouples are widely used in industries such as manufacturing, automotive, aerospace, food processing, HVAC, and scientific research due to their versatility and compatibility with different environments.

- Cost-Effective: Thermocouples are generally more affordable compared to other temperature sensing devices like resistance temperature detectors (RTDs) or thermistors. This makes them a popular choice for applications where cost is a significant factor.

Disadvantages of using thermocouples include:

- Relatively Lower Accuracy: Compared to other temperature sensors like RTDs, thermocouples generally have lower accuracy. The accuracy of a thermocouple is influenced by factors such as the thermocouple type, temperature range, and measurement conditions.

- Non-Linear Output: The output voltage or signal generated by a thermocouple is non-linear, meaning the voltage change is not proportional to the temperature change. This non-linearity requires additional linearization techniques or correction curves for accurate temperature measurements.

- Cold Junction Compensation: Thermocouples require compensation for the reference or cold junction temperature. The measurement accuracy can be affected if the cold junction temperature is not properly accounted for.

- Limited Sensitivity: Thermocouples have a relatively low sensitivity to small temperature changes, particularly in comparison to RTDs or thermistors. This can make them less suitable for applications requiring high precision or fine temperature control.

- Potential for Measurement Errors: Thermocouples can introduce measurement errors due to factors like thermal gradients along the wires, aging effects, and electromagnetic interference. Careful installation, calibration, and proper shielding are essential to minimize these errors.

It's important to consider these advantages and disadvantages in the context of the specific application and requirements when choosing a temperature-sensing solution.

Why use a thermocouple?

Temperature can be sensed and measured in different ways and with different tools and equipment. Performance, cost, and durability are all three factors to consider. What positive features and advantages do thermocouples have that are better than other sensors?

- accuracy and validity

Most thermocouples are accurate within two or three degrees of the actual temperature. Some are naturally more accurate due to the characteristics of the metals used. For example, platinum and rhodium thermocouples can measure temperatures down to 0.5 degrees Celsius. Other metals and alloys may not be as accurate. On the other hand, a few degrees of error can be ignored because the measurement ranges are generally more sweeping.

- Cost

As we mentioned in this article, thermocouples are simple tools. The whole sensor consists of two dissimilar metal wires. Some are physically short, only a few inches. Some may be several feet. As a result, the number of materials used affects the cost.

Also, the price of thermocouples is different because they are made of various materials. For example, platinum has ideal properties but is a much more expensive metal than nickel. Also, additional features can improve the sensor and lead to a special and unique way to measure temperature. For example, a sheath made of stainless steel with magnesium oxide insulation can be used. These measures are used because they do not allow the thermocouple wire to be exposed to a corrosive environment. This custom protection helps to slow down wear and tear and extend the useful device life. In this way, the need to buy and replace is reduced, but the initial cost or purchase device price is higher.

- Rugged

Since there are no moving parts or fragile parts in the thermocouple, it is relatively difficult to break or damage the thermocouple. However, some environments and conditions they have to measure may be overly destructive, so this is all relative. On the other hand, over time, the thermocouples will eventually break and fall. Metal wires get oxidized or corroded, and as a result, the accuracy of the readings decreases. Measures can be taken to extend the life of thermocouples. For example, covering the sensor inside the vacuum or filling it with inert gas to avoid oxidation increases its useful life.

- Versions or variations

On the cooler side, T-type thermocouples can measure down to -200 degrees Celsius. At the other end of the spectrum are B-type thermocouples. They can measure temperatures up to 1700 degrees Celsius. In addition to the temperature range, you can customize the thermocouple in terms of length, components, and degree of protection according to your needs.

Fig 15. Thermocouple temperature

Thermocouples are ideal choices for temperature measurement due to their wide range, low cost, and simple structure. They sense temperatures for a wide variety of processes and are used in many different industries.

How to choose a thermocouple?

Since a thermocouple may come in many forms, it is necessary to know how to select the proper sensor. The most common criteria used for selection are temperature range, chemical resistance, vibration and wear resistance, and installation requirements. Installation requirements may also dictate your choice of thermocouple probe.

There are different types of thermocouples with further applications. An exposed thermocouple is more suitable where a high response time is required, but an ungrounded thermocouple is a fitter for a corrosive environment. To choose the best thermocouple for your purposes, consider these five things:

- Specify the application in which you want to use the thermocouple sensor.

Thermocouples can be used in various industries and applications, so choosing the right type for your purposes starts with knowing your application and where and how you intend to use it.

- Specify the temperature range you want the probe to be exposed to

know the temperature range you need for your thermocouple, you can refer to the thermocouple range table to help you determine which thermocouple is right for your temperature range.

Fig 16. Thermocouple temperature ranges

The K-type thermocouple offers a wide temperature range and is one of the most commonly used thermocouples. On the other hand, if your thermocouple probe is going to be exposed to extreme temperatures, the N model is more stable at high temperatures and the T-type thermocouple is suitable for very, very low temperatures.

- Determine how important fast response time is to you

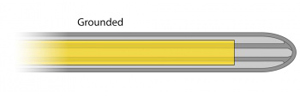

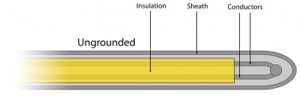

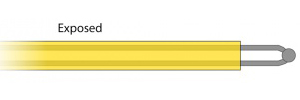

There are three types of thermocouple connections: exposed, grounded, or ungrounded.

An open connection has the fastest response time. However, if the probe is exposed to corrosive gas or high pressure, an open connection should not be used. The ungrounded thermocouple has the slowest response time, but if you want to keep the thermocouple electronically isolated and protected by a sheath, the ungrounded one is the best choice.

- Consider any chemical resistance, abrasion, and vibration

The use of an open thermocouple is limited to non-corrosive applications. Grounded and ungrounded thermocouples can be used in corrosive or high-pressure environments, but the ungrounded probe is the best choice if you want to keep the thermocouple electronically isolated and protected by a sheath. If faster response times are important in a corrosive environment, a grounded thermocouple is the best choice.

- Consider all installation requirements

Your thermocouple may need to be compatible with your existing equipment. For example, the existing holes may determine the diameter of the probe.

How do I know which type of connection to use?

Sheathed thermocouple probes are available with one of three connection types: grounded, ungrounded, or open. Check out our video on thermocouple connections:

- Grounded junction thermocouples

At the tip of the grounded probe, the thermocouple wires are physically attached to the inside of the probe wall. It allows heat transfer from the outside, passing through the probe wall to the thermocouple junction. Grounded junction thermocouples. It means the grounded thermocouple has a faster response time than the ungrounded one.

Fig 17. Grounded junction thermocouples

Thermocouple connection is recommended for static or flowing liquid or gas temperature measurement and corrosive and high-pressure applications. The connection of the grounded thermocouple to the protective sheath is welded and as a result, its response is faster than the ungrounded type. On the other hand, grounded thermocouples are highly vulnerable to noise generated by ground loops, and as a result, their reading accuracy will be lower.

- ungrounded junction thermocouples

In an ungrounded probe, the thermocouple connection is isolated from the probe wall. The response time is slower than the grounded model.

Fig 18. ungrounded junction thermocouples

On the other hand, the connector is electrically isolated from the sheath. Thereby preventing electrical noise from interfering with the signal. In a way, the temperature measurement is done with much higher accuracy, especially in low-level signals.

An ungrounded connection is recommended for measuring corrosive environments, where it is desirable to have the thermocouple electronically isolated from the sheath and protected. The welded wire thermocouple is physically insulated from the thermocouple sheath using MgO (soft) powder.

- Open junction thermocouples

In an open model junction, the thermocouple protrudes from the tip of the sheath and is exposed to the surrounding environment (or is open). This type has the best response time, but can only be used in non-corrosive, non-pressure applications.

Fig 19. Open junction thermocouples

An open connection is recommended for static gas temperature measurement or at non-corrosive flow when a faster response time is required. The connector is larger than the protective metal sheath to provide a fast and accurate response. The insulating sheath where the joint protrudes is sealed (sealed) to prevent ingress of moisture or gas and possible errors.

Important parameters for choosing a thermocouple

| Type of thermocouple and its temperature range |

E (-40 to 900°C)

J (-180 to 800°C) K (-250 to 1300°C) R (-50 to 1700°C) S (-50 to 1750°C) T (-250 to 400°C) B (0 to 1800°C) N (-270 to 1300°C) |

| Number of wires | 2, 3, or 4 wire |

| Output type |

sensor-output (mV)

Voltage/current (with transmitter) |

| Length of connector cable-probe | Example: 1 meter or more |

| Element size (diameter and length) | Example: 8mm-5cm |

Top brands of thermocouples

There are several reputable brands that manufacture thermocouples known for their quality and reliability. While the market is diverse and preferences can vary based on specific application requirements, here are some top brands of thermocouples:

- Omega Engineering: Omega Engineering is a well-known manufacturer of industrial and scientific instrumentation, including a wide range of thermocouples. They offer a variety of thermocouple types and designs suitable for various industries and applications.

- Pyromation: Pyromation is a leading manufacturer of temperature sensors, including thermocouples. They provide a range of thermocouple options, including standard and custom designs, for industries such as automotive, aerospace, power generation, and food processing.

- Watlow: Watlow is a global provider of thermal solutions, offering a wide range of temperature sensors, including thermocouples. Their thermocouples are designed for accuracy and reliability in demanding applications, such as semiconductor manufacturing, medical equipment, and industrial processes.

- REOTEMP Instruments: REOTEMP Instruments specializes in manufacturing temperature and pressure instruments, including thermocouples. They offer a variety of thermocouple types and configurations for applications in industries like oil and gas, chemical processing, and HVAC.

- Durex Industries: Durex Industries is a leading manufacturer of electric heaters and temperature sensors, including thermocouples. They provide thermocouples designed for high-performance applications, with a focus on industrial heating processes, aerospace, and semiconductor manufacturing.

- Heraeus Nexensos: Heraeus Nexensos is a renowned manufacturer of temperature sensors, including thermocouples. They offer a range of thermocouples for applications in industries like automotive, energy, and research, known for their accuracy, stability, and high-temperature capabilities.

- WIKA: WIKA is a global leader in pressure and temperature measurement solutions, including thermocouples. They provide a wide range of thermocouples suitable for various industries, such as petrochemical, pharmaceutical, and energy, emphasizing accuracy, reliability, and safety.

It's important to note that while these brands have established a strong reputation in the field of thermocouples, there are also other reputable manufacturers worth exploring. It's recommended to consider specific application requirements, technical specifications, and customer reviews when selecting a thermocouple brand for your particular needs.

Conclusion

In conclusion, thermocouples are invaluable tools for temperature measurement and monitoring in a wide range of industries and applications. They offer advantages such as a wide temperature range, quick response time, durability, and versatility. However, it's important to be aware of their limitations, including relatively lower accuracy compared to other temperature sensors, non-linear output, and the need for cold junction compensation.

Thermocouple calibration is a critical step in ensuring accurate temperature measurements. Through the calibration process, the relationship between the thermocouple's output and the corresponding temperature is established and calibration coefficients are determined. Regular recalibration is recommended to maintain accuracy over time.

Factors such as thermocouple type, calibration, measurement range, cold junction compensation, interference, thermocouple age, measurement instrumentation, and environmental conditions can influence the accuracy of thermocouple measurements. Proper attention to these factors, along with adherence to manufacturer specifications and best practices, is essential for achieving reliable and accurate temperature readings.

Thermocouples continue to be widely used in various industries, including manufacturing, automotive, aerospace, HVAC, and scientific research. Their ability to withstand harsh environments, provide real-time temperature data, and contribute to process control and safety makes them indispensable in many applications.

Overall, understanding the strengths, limitations, and proper calibration procedures associated with thermocouples ensures their effective and accurate use, allowing us to harness the power of temperature measurement in diverse fields of endeavor.

To recap

Finally, we will review some frequently asked questions about thermocouples.

- Do thermocouples tell us the temperature?

Yes, but their method is different from other thermometers. When one side of a thermocouple is heated, it creates a voltage, also known as a potential difference. The difference in temperature between the reference junction and the measurement junction is proportional to the voltage that is made. Using the tables provided, we can convert this voltage reading to a temperature reading.

- Is a thermocouple a thermometer?

Yes, a thermocouple is a thermometer. Let's first define a thermometer. "Thermo" means "temperature," and "meter" means measurement. So a thermometer is a device that "measures temperature." We can investigate how other types of thermometers measure temperature. A mercury thermometer works by measuring the level of mercury inside a tube, which expands and contracts as the temperature changes. A "resistance temperature detector," or RTD, measures the resistance of an electrical signal that changes with temperature. And the a thermocouple produces a measurable voltage that is proportional to a certain temperature. All of these things measure temperature and turn it into a signal that can be read, so they are all thermometers.

- Why two different types of metal are needed in a thermocouple?

How the electrons behave inside the thermocouple wires is determined by how the metal itself works. For example, the movement and flow of electrons inside iron are different from those inside copper. In the measurement junction, two thermocouple wires are exposed to the same temperature, and the electrons are excited and create a current. On the other hand, the electric current in each wire is a different amount, so if you measure the voltage at the reference connection, one wire will have a higher potential than the other. It is this difference in potential that we use to calculate the temperature. If our thermocouple has two wires of the same metal, electrons will flow in both wires and there will be no difference between the two, allowing us to calculate the temperature because there will be no voltage.

- Do thermocouples only measure hot temperatures?

No, thermocouples can measure hot and cold temperatures. All temperatures from -200 to 2300 degrees Celsius can be measured with this device. Two dissimilar wires form a thermocouple. These metals can be pure elements or a combination of elements (alloys) that have different characteristics. A certain combination of metals leads to the creation of thermocouples that perform well in certain temperature ranges. Some thermocouples can be used to measure very hot temperatures, and some can be used to measure very cold temperatures. To choose the right thermocouple for a given application, you need to know the typical range of measurements it can make.

- Do thermocouples need heat to work?

No, thermocouples do not need heat to work. For them to work, there has to be a difference in temperature between the measuring junction and the reference junction. This difference is realized by heating or cooling one end of the thermocouple. This does not mean that we must have a hot object; it only means that the measured temperature must be different from the reference junction temperature.

- What is "cold junction compensation"?

"Cold junction" is not a new thermocouple that we haven't talked about. A "reference connection" is traditionally called a "cold connection." The measuring junction and the reference junction of a thermocouple have different voltages, which can be used to figure out the temperature by calculating with standard tables. Sometimes the reference compound is not always at a temperature that can be used with the standardized table; the calculated temperature of the thermocouple will be wrong. In this case, "cold junction compensation" is used. It is simply a mathematical adjustment to the reference connection. Now, no matter what the cold junction temperature is, the measured temperature of the thermocouple can still be calculated with high accuracy. In the figure below, we take the cold junction measurement (in degrees Celsius) and compare it to the measured thermocouple voltage (in mV across the body) to get the hot junction temperature (in degrees Celsius left).

- Do thermocouples need a thermometer?

It may sound ridiculous, but yes, thermocouples need a thermometer to work. The measuring voltage of thermocouples changes based on the difference in temperature between the measuring junction and the reference junction. So we have three variables: voltage, which we can use a voltmeter to measure; reference junction temperature, which we need another tool to tell us; and the temperature of the measuring junction, which in practice is always unknown because the goal is to measure it with a thermocouple. If we know two of these three variables, we can calculate the third. So yes, we need to know the temperature at the reference junction and have a way to measure the thermocouple voltage. We can figure out the temperature at the measurement junction with just two of these pieces of information.

- It seems that measuring temperature with a thermocouple is a complicated task. Why use a thermocouple?

There are many different ways to measure temperature besides thermocouples, such as thermistors, RTD sensors, semiconductor sensors, and mercury thermometers. You can even use your hand as a thermometer, like when your parents put their hand on your forehead to see if you have a fever. Each of these temperature measurement methods has its advantages and disadvantages. For example, thermocouples can measure much higher temperatures than RTDs, but RTDs are usually more accurate. Finally, it is important to choose a temperature sensor that suits your needs. Measurement interval, accuracy and precision, cost, operational environment conditions, and other variables are examples of variables.

References

https://www.iqsdirectory.com/articles/thermocouple.html

https://www.onetemp.com.au/tm-ph-type-k-thermocouple-with-12bsp-connection-and-aluminium-head

https://blog.endaq.com/thermocouples-function-types-selection-and-application

https://www.processparameters.co.uk/thermocouple-types/

https://www.watlow.com/products/sensors/thermocouples/true-surface-thermocouples

https://www.amazon.com/Handheld-Thermocouple-Straight-Replacement-Response/dp/B0C7QJYLMK

https://www.engineeringtoolbox.com/thermocouples-d_496.html

https://www.schmierersea.com/index.php/products/temperature/thermowell

https://www.omega.nl/pptst/304_INC_DUAL_CLAD.html

https://www.zw-cable.com/news/Mineral_Insulated_Cable_A_better_choice_over_open_wire_cables.html

https://www.okazaki-mfg.com/en/SpecialProducts/MICable.html

https://www.nanmat.com/eg.html/metal-eg.html

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025