The Shielding Power of Housing: Fortifying Pressure Sensors Against the Elements

In the world of industrial safety and environmental protection, where precision meets peril, a unique class of equipment emerges as the sentinel of security—explosion-proof housing. Imagine a realm where volatile gases, combustible dust, and the potential for explosive atmospheres create an unforgiving environment. It is in these danger zones that explosion-proof enclosures rise to prominence, offering a fortified fortress of protection against the specter of disaster.

In this realm, where a single spark can ignite catastrophe, we delve into the world of explosion-proof housings—rugged fortresses engineered to withstand the unimaginable. Join us on a journey through the oil and gas fields, chemical plants, and mining depths where these stalwart guardians stand vigilant, ensuring the safety of both industry and the environment.

Explore the anatomy of these safety marvels, from their robust construction to intricate sealing mechanisms, and discover the critical role they play in safeguarding lives, facilities, and ecosystems. Through certifications like ATEX and IECEx, we unveil the rigorous standards that govern their deployment.

Join us as we venture into hazardous terrains, where these guardians of safety stand as silent sentinels against the forces of ignition. Welcome to the world of explosion-proof housings, where precision meets peril, and safety triumphs over danger

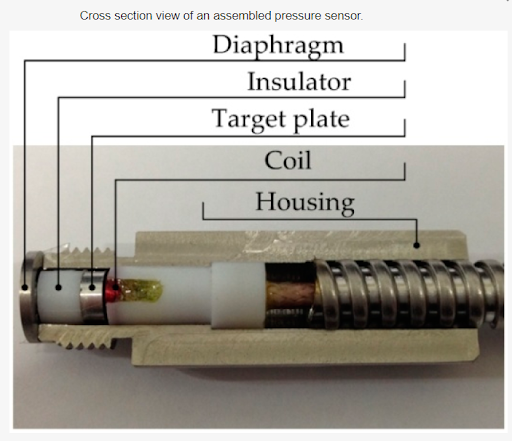

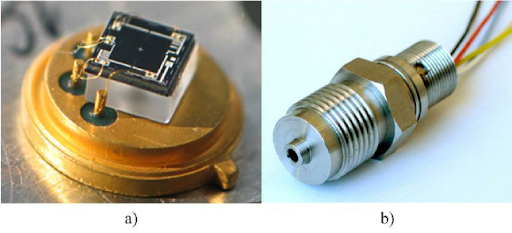

Fig 1. Cross-section view of an assembled pressure sensor

What is the Housing in electric devices?

In the context of electric devices, "housing" refers to the outer casing or enclosure that contains and protects the internal components of the device. The housing serves several important functions in electric devices:

- Protection: The primary purpose of the housing is to protect the internal electronic components from external factors such as moisture, dust, dirt, physical damage, and environmental conditions. It acts as a barrier that shields the sensitive electronics from harm.

- Safety: Housing can also provide a degree of safety by preventing users from coming into direct contact with the internal electrical components. This is especially important in devices that operate at high voltages or carry other safety risks.

- Aesthetics: Housing can have a significant impact on the appearance and aesthetics of the device. Manufacturers often design housings to be visually appealing, ergonomic, and in line with the device's intended use and market.

- Thermal Management: Some housing designs incorporate features for thermal management, such as heat sinks or vents, to help dissipate heat generated by the device's operation. Proper heat dissipation is essential for preventing overheating, which can damage components or reduce the device's performance.

- Mounting and Accessibility: Housing can provide attachment points for mounting or securing the device in place. It can also include openings, panels, or doors that allow access to internal components for maintenance or upgrades.

- Environmental Considerations: Depending on the intended application, housing may need to meet specific environmental standards, such as being waterproof, dustproof, or resistant to chemical exposure.

Housing materials can vary widely, depending on the device's purpose and requirements. Common materials include plastics, metals (such as aluminum or stainless steel), and composites. The design and choice of materials for the housing are critical considerations during the development of electric devices to ensure their functionality, safety, and durability.

How is the pressure transmitter's Housing?

The housing of a pressure transmitter is a crucial component that protects the sensitive internal electronics of the device while allowing it to perform its primary function of measuring pressure accurately. Here are some common features and considerations for the housing of a pressure transmitter:

- Material: Pressure transmitter housings are typically made from materials that are resistant to the environmental conditions they will encounter. Common materials include stainless steel, aluminum, and plastic. The choice of material depends on factors such as the pressure range the transmitter will operate in, the type of media it will be exposed to (e.g., corrosive chemicals), and the desired durability.

- Protection: The housing must protect environmental factors such as moisture, dust, and other contaminants. It should also be designed to withstand physical impact and vibration, especially if the transmitter is used in industrial or harsh environments.

- Sealing: Proper sealing is essential to prevent the ingress of moisture or dust into the transmitter's internals. O-ring seals or gaskets are often used to create a watertight and dustproof enclosure.

- Pressure Ports: Pressure transmitters have pressure ports that are typically integrated into the housing. These ports allow the device to be connected to the system or process from which it is measuring pressure. The design of these ports can vary depending on the application.

- Electrical Connections: The housing may have electrical connectors or terminals for wiring purposes. These connectors should be designed to maintain a secure and reliable electrical connection while preventing moisture or contaminants from entering.

- Mounting: Pressure transmitters often come with mounting options to facilitate installation. This could include threaded connections for direct mounting on a pipe or vessel or the use of brackets and other hardware for secure attachment.

- Display and User Interface: Some pressure transmitters may have a display or user interface integrated into the housing, allowing users to configure the device or view pressure readings directly on the transmitter itself.

- Venting: In some cases, pressure transmitters may include vents or pressure relief mechanisms to ensure that pressure differentials across the housing do not affect the accuracy of the pressure measurements.

- Temperature Considerations: The housing should be designed to handle the temperature range of the application, especially if the pressure transmitter will be exposed to extreme temperatures.

- Certifications: Depending on the industry and application, pressure transmitters may need to meet specific certifications or standards for safety and performance, and the housing must comply with these requirements.

The design of the housing for a pressure transmitter is critical to its functionality and longevity. It should be carefully engineered to ensure accurate pressure measurements while protecting the internal components from environmental factors and physical damage. Additionally, the housing should be compatible with the specific requirements of the application in which the pressure transmitter is used.

What are the pressure transmitter's Housing materials?

Pressure transmitter housings can be made from various materials, and the choice of material depends on factors such as the application, the environment in which the transmitter will be used, and the specific requirements of the pressure measurement. Here are some common materials used for pressure transmitter housings:

- Stainless Steel: Stainless steel is a popular choice for pressure transmitter housings, especially in industrial applications. It offers excellent corrosion resistance, durability, and resistance to harsh environmental conditions. Stainless steel housings are often used in applications where the transmitter may be exposed to corrosive fluids or outdoor weather conditions.

- Aluminum: Aluminum housings are lightweight and offer good resistance to corrosion. They are commonly used in applications where weight is a consideration, such as aerospace or automotive applications. Aluminum housings are also suitable for some industrial and general-purpose pressure transmitters.

- Plastic: Some pressure transmitters, especially those designed for less demanding applications, use plastic housings. Plastic housings are lightweight and cost-effective but may not be as durable or resistant to extreme conditions as metal housings. They are often used in situations where cost is a primary concern, and the environment is relatively benign.

- Ceramic: Ceramic housings are used in high-pressure and high-temperature applications. Ceramic materials can withstand extreme conditions and are resistant to corrosion. They are commonly found in pressure transmitters used in the oil and gas industry and research and testing equipment.

- Exotic Alloys: In specialized applications, pressure transmitter housings may be made from exotic alloys such as titanium or Inconel. These materials provide exceptional resistance to corrosion and high-temperature environments, making them suitable for challenging industrial processes.

- Hastelloy: Hastelloy is a family of high-performance alloys known for their corrosion resistance in aggressive chemical environments. Pressure transmitters used in chemical processing and similar industries may have Hastelloy housings to ensure long-term performance.

The choice of housing material is influenced by factors such as the medium being measured, the operating temperature and pressure ranges, the chemical compatibility requirements, and the budget constraints of the application. It's important to select a housing material that not only protects the internal components of the pressure transmitter but also meets the specific needs of the application to ensure accurate and reliable pressure measurements.

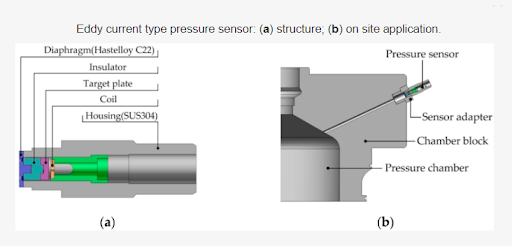

Fig 2. Eddy current type pressure sensor

How does the pressure transmitter's Housing protect the circuit?

The housing of a pressure transmitter plays a critical role in protecting the internal circuitry and components from various environmental factors and physical damage. Here's how the housing protects the circuit:

- Environmental Protection: Pressure transmitters are often used in a wide range of industrial and commercial applications where they may be exposed to harsh environmental conditions. The housing is designed to create a barrier between the internal electronics and the external environment. It helps prevent the following environmental factors from affecting the circuitry:

- Moisture and Water: The housing is typically sealed and waterproof to protect against moisture and water ingress. This is especially important in outdoor or wet environments.

- Dust and Particles: The housing prevents dust, dirt, and other particles from entering and contaminating the internal components. This is crucial for maintaining the accuracy and reliability of the pressure measurement.

- Chemical Exposure: In applications where pressure transmitters are exposed to corrosive chemicals, the housing material is chosen to resist chemical corrosion and protect the electronics inside.

- Temperature Extremes: The housing can insulate the internal electronics from extreme temperatures, either hot or cold, that could otherwise cause damage or affect performance.

- Vibration and Shock Resistance: In industrial environments, equipment may experience vibrations or physical impacts. The housing is designed to absorb and dissipate shocks and vibrations, reducing the risk of damage to sensitive electronic components.

- Electromagnetic Interference (EMI) Protection: Some pressure transmitters are used in environments with high levels of electromagnetic interference, such as near heavy machinery or electrical equipment. The housing may include shielding to minimize the impact of EMI on the transmitter's circuitry.

- Corrosion Resistance: Depending on the housing material, it can provide resistance to corrosion. For example, stainless steel or certain alloys are chosen for their corrosion-resistant properties, which is particularly important in marine or chemical processing applications.

- Pressure Equalization: The housing design may include pressure equalization features, such as vents or diaphragms, to ensure that pressure differentials across the housing do not adversely affect the performance of the pressure transmitter's internal components.

- Seals and Gaskets: Gaskets and seals are often used in the housing design to ensure a watertight and airtight enclosure. These seals provide an additional layer of protection against moisture and contaminants.

- Mechanical Protection: The housing also acts as a physical barrier to prevent accidental contact with the internal circuitry, reducing the risk of damage or injury.

In summary, the housing of a pressure transmitter is carefully engineered to provide a protective barrier that safeguards the internal circuitry and components from a variety of environmental and physical threats. This protection ensures the transmitter's longevity, accuracy, and reliability in demanding applications.

How does housing design impact environmental protection?

Housing design has a significant impact on environmental protection for electronic devices. The specific design features and materials used in the housing can determine how well the device is protected against various environmental factors. Here's how housing design impacts environmental protection:

- Sealing and Enclosure: Proper sealing of the housing is crucial to prevent the ingress of moisture, dust, and other contaminants. Well-designed housing includes gaskets, seals, and tight-fitting closures to create a barrier that keeps the internal components safe from external environmental factors.

- Venting and Pressure Equalization: Some applications require housings to be vented to equalize pressure differences between the inside and outside of the enclosure. This prevents the housing from collapsing under external pressure or allowing moisture to be drawn inside due to pressure differentials.

- Material Selection: The choice of housing material is essential. Materials like stainless steel, aluminum, and specialized plastics are selected based on their ability to resist corrosion, withstand temperature extremes, and provide physical protection.

- Cable Glands and Conduits: Housing design often includes provisions for secure cable entry and exit. Cable glands and conduits help maintain the integrity of the housing by sealing around cables and preventing moisture or dust from entering through cable entry points.

- IP Ratings: Housing designs may conform to specific Ingress Protection (IP) ratings, indicating their level of protection against solid particles (first digit) and liquids (second digit). Higher IP ratings denote better environmental protection.

- Customization: In some cases, housing design can be customized to meet the specific needs of an application. This includes designing housings with additional features such as thermal insulation or specific mounting options.

- Size and Form Factor: The size and form factor of the housing can impact its suitability for different environments. Compact housings may be ideal for applications with limited space, while larger enclosures can accommodate additional protective features.

- Modularity: Some housing designs are modular, allowing for the addition of accessories like sun shields, rain covers, or protective cages to enhance environmental protection in specific conditions.

- Material Compatibility: Housing materials must be compatible with the chemicals and substances present in the device's environment. For example, in chemically aggressive environments, specialized materials may be necessary to resist corrosion.

- Testing and Certification: Manufacturers often subject housing designs to rigorous testing to ensure they meet industry-specific standards and regulations for environmental protection. Certifications may include UL, NEMA, or ATEX, depending on the application.

In summary, housing design plays a critical role in protecting electronic devices from environmental factors. A well-designed housing can ensure that internal components remain safe, functional, and reliable in a wide range of environmental conditions, making it a vital consideration in the design and selection of electronic equipment for specific applications.

What is the Ingress Protection (IP) rating?

The Ingress Protection (IP) rating is a standardized code that provides information about the level of protection an enclosure or housing provides against the ingress (entry) of solid particles and liquids. IP ratings are commonly used to describe the environmental protection characteristics of various electronic devices, equipment, and enclosures.

The IP rating typically consists of two digits, each with a specific meaning:

- First Digit (Protection against Solid Particles): This digit ranges from 0 to 6 and indicates the degree of protection provided against solid objects, such as dust and debris.

- 0: No special protection against solid particles.

- 1: Protection against solid objects larger than 50 mm (e.g., a hand).

- 2: Protection against solid objects larger than 12.5 mm (e.g., fingers).

- 3: Protection against solid objects larger than 2.5 mm (e.g., tools and wires).

- 4: Protection against solid objects larger than 1 mm (e.g., small tools and wires).

- 5: Limited protection against dust ingress (dust may enter but not in sufficient quantities to interfere with the operation of the equipment).

- 6: Complete protection against dust ingress (dust-tight).

- Second Digit (Protection against Liquids): This digit ranges from 0 to 9 and indicates the level of protection provided against the ingress of liquids, including water.

- 0: No special protection against liquids.

- 1: Protection against vertically falling drops of water (e.g., water dripping vertically onto the equipment).

- 2: Protection against water droplets at an angle of up to 15 degrees from vertical (e.g., light rain).

- 3: Protection against water sprayed at an angle of up to 60 degrees from vertical (e.g., heavy rain).

- 4: Protection against water splashes from any direction.

- 5: Protection against water jets (e.g., low-pressure washdown).

- 6: Protection against powerful water jets (e.g., high-pressure washdown).

- 7: Protection against temporary immersion in water up to 1 meter deep for a limited time (e.g., submersion in a tank).

- 8: Protection against continuous submersion beyond 1 meter (specific conditions are defined by the manufacturer).

- 9K: Protection against high-pressure, high-temperature water jets (often used in specific industrial applications).

The IP rating system provides a standardized and easily understood way to convey information about the level of protection an enclosure or housing offers against environmental factors. It allows users and manufacturers to select equipment and devices that are suitable for specific operating conditions and environments based on the IP rating's numerical values.

What is the purpose of the pressure transmitter's Housing?

The housing of a pressure transmitter serves several important purposes, all of which contribute to the device's functionality, safety, and longevity in various industrial and commercial applications. Here are the key purposes of a pressure transmitter's housing:

- Environmental Protection: The primary purpose of the housing is to protect the sensitive internal components of the pressure transmitter from the external environment. This includes shielding against moisture, dust, dirt, and other contaminants that could compromise the device's performance or cause damage.

- Safety: Housing provides a safety barrier between the internal electrical circuitry and the external environment. This is crucial, especially in industrial settings where pressure transmitters may be exposed to potentially hazardous conditions. It prevents accidental contact with live electrical components, reducing the risk of electrical shocks or other safety hazards.

- Corrosion Resistance: In applications where the pressure transmitter may be exposed to corrosive substances, the housing material is chosen to resist chemical corrosion, ensuring the longevity and reliability of the device.

- Mechanical Protection: Housing offers physical protection to the internal components against mechanical impacts, vibration, and shock. It helps ensure the pressure transmitter's durability and longevity in environments where physical stresses are common.

- Temperature Management: The housing can help manage temperature extremes, either by insulating the internal electronics from extreme heat or by providing heat dissipation mechanisms to prevent overheating in high-temperature applications.

- Pressure Isolation: The pressure transmitter's housing often includes a pressure port that allows it to connect to the system being measured. The housing ensures that the pressure being measured is isolated from the internal components, preventing leaks or contamination.

- Mounting and Installation: Housing often includes features for easy mounting and installation of the pressure transmitter in various industrial processes and systems. This can include mounting flanges, brackets, or threaded connections.

- Electromagnetic Interference (EMI) Shielding: In environments with high levels of electromagnetic interference, the housing may be designed to provide EMI shielding to prevent external electrical noise from affecting the accuracy of pressure measurements.

- User Interface: Some pressure transmitters have user interfaces or displays integrated into the housing, allowing users to configure settings, calibrate the device, or view pressure readings without needing to access the internal circuitry.

- Compliance with Standards: The housing may be designed to meet specific industry standards or regulations, ensuring that the pressure transmitter is suitable for its intended application and complies with safety and performance requirements.

In summary, the housing of a pressure transmitter is a critical component that serves multiple purposes, including protecting internal electronics, ensuring safety, maintaining performance in challenging environments, and facilitating installation and use. The design and materials used for the housing are carefully chosen to match the specific requirements of the application and industry in which the pressure transmitter will be used.

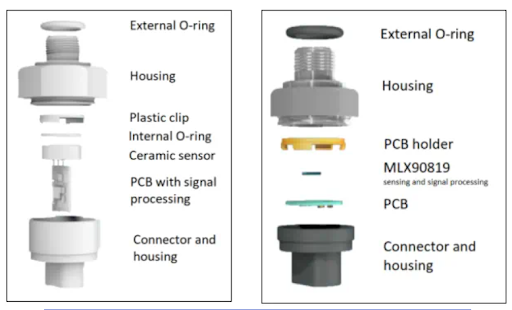

Fig 3. Different pressure sensor housing

Why the pressure transmitter's Housing is important?

The housing of a pressure transmitter is of paramount importance for several crucial reasons:

- Environmental Protection: One of the primary functions of the housing is to protect the sensitive internal components of the pressure transmitter from the external environment. Pressure transmitters are often used in a wide range of industrial and commercial applications where they may be exposed to harsh conditions such as moisture, dust, dirt, and corrosive substances. The housing acts as a barrier, preventing these environmental factors from compromising the device's performance or causing damage.

- Safety: The housing provides a critical safety barrier between the internal electrical circuitry and the external environment. In industrial settings, where pressure transmitters are commonly used, there can be safety risks associated with electrical equipment. The housing helps reduce the risk of electrical shocks or other safety hazards by preventing accidental contact with live electrical components.

- Longevity and Reliability: By protecting the internal components from environmental factors, mechanical stresses, and potential damage, the housing significantly contributes to the longevity and reliability of the pressure transmitter. This is especially important in applications where the device needs to operate continuously with minimal downtime.

- Corrosion Resistance: In many industrial processes, pressure transmitters are exposed to corrosive substances, which can degrade the device over time. The choice of housing material is critical in such environments because it can resist chemical corrosion, ensuring that the pressure transmitter maintains its performance and accuracy.

- Mechanical Protection: Housing offers physical protection to the internal components against mechanical impacts, vibration, and shock. This is particularly important in industrial environments where equipment can experience physical stresses. The housing helps ensure the device can withstand these stresses without sustaining damage.

- Temperature Management: Depending on the application, the housing may include features for managing temperature extremes. It can insulate the internal electronics from extreme heat or provide heat dissipation mechanisms to prevent overheating in high-temperature environments.

- Pressure Isolation: The housing typically includes a pressure port that allows the transmitter to connect to the system being measured. Proper housing design ensures that the pressure being measured is isolated from the internal components, preventing leaks or contamination.

- Mounting and Installation: Many pressure transmitters need to be securely mounted within a system or process. The housing often includes features such as mounting flanges, brackets, or threaded connections to facilitate easy installation.

- User Interface: In some cases, pressure transmitters have user interfaces or displays integrated into the housing, allowing users to configure settings, calibrate the device, or view pressure readings without needing to access the internal circuitry.

- Compliance with Standards: The housing may be designed to meet specific industry standards or regulations, ensuring that the pressure transmitter is suitable for its intended application and complies with safety and performance requirements.

In summary, the housing of a pressure transmitter is a critical component that ensures the device's functionality, safety, and longevity in diverse industrial and commercial applications. Its design and material selection are carefully considered to match the specific requirements and challenges of the application and industry where the pressure transmitter will be deployed.

What are the pressure transmitter's Housing types?

Pressure transmitter housings come in various types and designs to meet the specific requirements of different applications and industries. The choice of housing type depends on factors such as the environment, the pressure range, the type of media being measured, and the installation method. Here are some common types of pressure transmitter housings:

- General-Purpose Housings: These are typically compact and versatile housings designed for use in a wide range of applications. They are often made of materials like stainless steel or aluminum and provide basic protection against moisture and dust. General-purpose housings are suitable for many industrial and commercial applications.

- Weatherproof Housings: Weatherproof housings are designed to withstand outdoor environments and exposure to the elements. They offer enhanced protection against rain, wind, and temperature variations. These housings are often used in applications where pressure transmitters need to be installed outdoors.

- Explosion-Proof Housings: In hazardous or explosive environments, explosion-proof housings are necessary to prevent the ignition of flammable gases or vapors. These housings are built to withstand explosions and are typically made of robust materials. They are often used in oil and gas, chemical, and petrochemical industries.

- Submersible Housings: Submersible pressure transmitter housings are designed to operate underwater or in liquid environments. They are sealed tightly to prevent water ingress and are commonly used in applications like water level measurement in tanks, wells, and other submerged locations.

- Sanitary Housings: Sanitary housings are designed for use in industries such as food and pharmaceuticals, where cleanliness and hygiene are critical. They have smooth, easy-to-clean surfaces and are often made of stainless steel to resist corrosion and meet sanitation standards.

- Hygienic Housings: Similar to sanitary housings, hygienic housings are used in applications that require cleanliness and contamination control. They are designed to meet specific hygienic standards and regulations.

- High-Pressure Housings: These housings are built to withstand extremely high-pressure conditions. They are often used in applications like hydraulic systems and high-pressure industrial processes. Materials like stainless steel and exotic alloys are common choices for high-pressure housings.

- Low-Pressure Housings: Conversely, low-pressure housings are designed for applications where the pressure range is relatively low. They are often used in applications such as HVAC systems and pneumatic controls.

- Heavy-Duty Housings: Heavy-duty housings are built to withstand rugged industrial environments with significant mechanical stresses, including vibrations and shocks. They are used in applications like heavy machinery and construction equipment.

- OEM-Specific Housings: Original equipment manufacturers (OEMs) sometimes require custom-designed housings to integrate pressure transmitters into their products. These housings are tailored to the specific needs and form factors of the OEM's equipment.

- Flush Diaphragm Housings: In applications where the sensing diaphragm needs to be flush with the surrounding surface (e.g., for viscous or sticky fluids), flush diaphragm housings are used. They prevent the buildup of debris on the diaphragm.

- Compact Housings: Compact housings are small and space-efficient, making them suitable for applications with limited installation space.

The choice of housing type is crucial to ensure that the pressure transmitter can perform accurately and reliably in its intended environment. Manufacturers often provide a range of housing options to meet various industry standards and application requirements.

General-Purpose Housings:

Description: General-purpose housings are typically compact and versatile, designed to protect the internal components of the pressure transmitter from moisture, dust, and other contaminants.

Operation: They provide basic protection against environmental factors and physical damage, making them suitable for a wide range of industrial and commercial applications.

Applications: General-purpose housings are used in applications where the pressure transmitter is not exposed to extreme conditions. They are commonly found in HVAC systems, manufacturing processes, and general automation.

Pros: Versatile, cost-effective, and suitable for a variety of applications.

Cons: Limited protection in harsh or hazardous environments.

Weatherproof Housings:

Description: Weatherproof housings are designed to withstand outdoor environments and exposure to the elements, including rain, wind, and temperature variations.

Operation: They offer enhanced protection against environmental factors, ensuring the pressure transmitter remains functional in outdoor settings.

Applications: Weatherproof housings are used in outdoor applications such as weather stations, environmental monitoring, and remote monitoring systems.

Pros: Protection against weather conditions, suitable for outdoor use.

Cons: Limited protection in hazardous or explosive environments.

Explosion-Proof Housings:

Description: Explosion-proof housings are built to prevent the ignition of flammable gases or vapors in hazardous environments. They are robust and rugged.

Operation: These housings are designed to contain any explosion that might occur within them, protecting the surrounding environment.

Applications: Common in oil and gas, chemical, and petrochemical industries, as well as mining and other hazardous locations.

Pros: Provides safety in explosive environments, and complies with strict safety standards.

Cons: Typically more expensive, may be larger and heavier than other housing types.

Submersible Housings:

Description: Submersible housings are designed for underwater or liquid environments. They are sealed tightly to prevent water ingress

. Operation: These housings ensure the pressure transmitter can operate reliably while submerged in liquid.

Applications: Used in water level measurement in tanks, wells, and marine applications.

Pros: Allows for accurate underwater pressure measurements.

Cons: Limited to liquid environments, and may require specialized installation.

Sanitary Housings:

Description: Sanitary housings are designed for applications where cleanliness and hygiene are critical. They have smooth surfaces for easy cleaning.

Operation: These housings meet strict hygiene standards and are resistant to corrosion.

Applications: Common in the food, pharmaceutical, and biotechnology industries.

Pros: Maintains cleanliness and hygiene, and resists corrosion.

Cons: May be more expensive than standard housing.

High-Pressure Housings:

Description: High-pressure housings are designed to withstand extremely high-pressure conditions.

Operation: They ensure that the pressure transmitter can measure and withstand pressures beyond the capabilities of standard housings.

Applications: Used in hydraulic systems, high-pressure industrial processes, and oil and gas applications.

Pros: Handles extreme pressure ranges.

Cons: Typically more expensive, maybe over-engineered for low-pressure applications.

Low-Pressure Housings:

Description: Low-pressure housings are designed for applications where the pressure range is relatively low.

Operation: They provide accurate measurements in low-pressure environments.

Applications: Used in HVAC systems, pneumatic controls, and other low-pressure applications.

Pros: Accurate in low-pressure ranges, cost-effective.

Cons: Unsuitable for high-pressure applications.

Heavy-Duty Housings:

Description: Heavy-duty housings are built to withstand rugged industrial environments with significant mechanical stresses.

Operation: They protect the internal components from vibrations, shocks, and impacts.

Applications: Common in heavy machinery, construction equipment, and industrial automation.

Pros: Durable and rugged. Cons: May be larger and heavier, limiting some installation options.

OEM-Specific Housings:

Description: OEM-specific housings are custom-designed to integrate pressure transmitters into specific OEM equipment.

Operation: They are tailored to the form factors and requirements of the OEM's equipment. Applications: Used in various industries where pressure transmitters are integrated into OEM machinery and products.

Pros: Ensures seamless integration with OEM equipment. Cons: Customized design may be expensive and limited to specific applications.

Flush Diaphragm Housings:

Description: Flush diaphragm housings are designed for applications where the sensing diaphragm needs to be flush with the surrounding surface.

Operation: They prevent debris buildup on the diaphragm and ensure accurate pressure measurements.

Applications: Used in applications with viscous or sticky fluids, such as pulp and paper processing.

Pros: Maintains accuracy in challenging fluid conditions.

Cons: Limited to specific applications requiring flush diaphragms.

Compact Housings:

Description: Compact housings are small and space-efficient, suitable for applications with limited installation space.

Operation: They provide basic protection in a compact form factor.

Applications: Used in applications where space is constrained, such as embedded systems and small machinery.

Pros: Space-efficient, suitable for tight spaces.

Cons: Limited protection in extreme environments.

Each type of pressure transmitter housing is designed to address specific needs and challenges, making it essential to choose the appropriate housing type based on the application's requirements and environmental conditions.

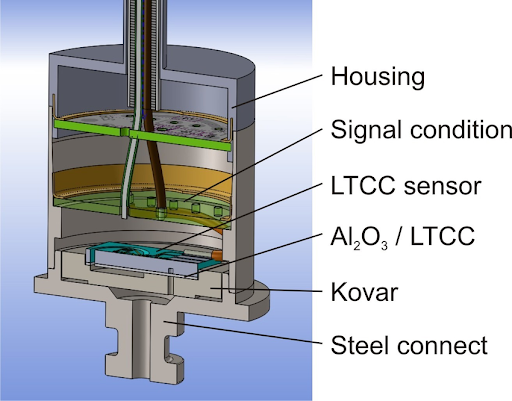

Fig 4. LTCC-pressure-transmitter-and-corresponding-drawing-of-inner-setup

Comparing table

Here's a comparative table summarizing the different types of pressure transmitter housings, including their descriptions, operations, typical applications, and pros and cons:

| Housing Type | Description | Operation | Typical Applications | Pros | Cons |

| General-Purpose | Compact and versatile | Basic protection against environmental factors | HVAC, manufacturing, automation | Versatile, cost-effective | Limited protection in harsh environments |

| Weatherproof | Designed for outdoor use | Enhanced protection against weather conditions | Weather stations, environmental monitoring | Protection against weather conditions | Limited protection in hazardous locations |

| Explosion-Proof | Rugged and robust | Prevents ignition of flammable gases or vapors | Oil and gas, chemical, and petrochemical industries | Safety in explosive environments complies with standards | Typically more expensive, larger, and heavier |

| Submersible | Sealed tightly for underwater use | Operates reliably when submerged in liquid | Water level measurement, marine applications | Accurate underwater pressure measurements | Limited to liquid environments, may require specialized installation |

| Sanitary | Hygienic, easy-to-clean surfaces | Meets strict hygiene standards and resists corrosion | Food, pharmaceutical, and biotechnology industries | Maintains cleanliness and hygiene, corrosion resistance | May be more expensive than standard housings |

| High-Pressure | Withstands extremely high pressure | Accurate measurement and withstands high pressures | Hydraulic systems, high-pressure industrial processes | Handles extreme pressure ranges | Typically more expensive |

| Low-Pressure | Designed for low-pressure environments | Accurate measurements in low-pressure settings | HVAC, pneumatic controls | Accurate in low-pressure ranges, cost-effective | Unsuitable for high-pressure applications |

| Heavy-Duty | Built to withstand mechanical stresses | Protects against vibrations, shocks, and impacts | Heavy machinery, construction equipment | Durable and rugged | Larger and heavier, limiting some installation options |

| OEM-Specific | Custom-designed for OEM integration | Tailored to OEM equipment requirements and form factors | Various industries with OEM machinery integration | Ensures seamless integration with OEM equipment | Customized design may be expensive, limited to specific applications |

| Flush Diaphragm | Designed for flush diaphragm use | Prevents debris buildup on diaphragm for accuracy | Pulp and paper processing | Maintains accuracy in challenging fluid conditions | Limited to specific applications requiring flush diaphragms |

| Compact | Small and space-efficient | Provides basic protection in compact form factor | Embedded systems, small machinery | Space-efficient, suitable for tight spaces | Limited protection in extreme environments |

Please note that the suitability of a specific housing type depends on the unique requirements and environmental conditions of the application in which it will be used. The choice of housing type should be made carefully to ensure accurate and reliable pressure measurements while meeting safety and performance standards.

Which Housing type is used in dangerous environments?

In dangerous or hazardous environments where there is a risk of explosion due to the presence of flammable gases, vapors, or combustible dust, explosion-proof housings (also known as Ex-proof or Exd housings) are commonly used. Explosion-proof housings are specifically designed and certified to prevent the ignition of potentially explosive atmospheres, making them essential for safety in such environments.

Here are some key features of explosion-proof housings and the environments where they are typically used:

Features of Explosion-Proof Housings:

- Robust Construction: Explosion-proof housings are built to withstand explosions and prevent them from propagating to the surrounding hazardous area. They are typically constructed from rugged materials like cast aluminum or stainless steel.

- Sealing and Gaskets: These housings are equipped with tight seals and gaskets to prevent the ingress of flammable gases or dust into the enclosure.

- Pressure Relief Mechanisms: In the event of an internal explosion, explosion-proof housings are designed to release pressure safely without causing further damage or igniting external flammable substances.

- Certifications: Explosion-proof housings must meet stringent certifications and standards, such as ATEX (Europe), IECEx (International), NEC (National Electrical Code), and others, to ensure their safety and effectiveness.

Environments Where Explosion-Proof Housings Are Used:

- Oil and Gas Industry: Explosion-proof housings are commonly used in oil refineries, petrochemical plants, drilling rigs, and gas processing facilities where flammable gases and vapors are present.

- Chemical Industry: Chemical manufacturing and processing facilities often use explosion-proof equipment to mitigate the risk of explosions from volatile chemicals.

- Mining: In underground mining operations, the presence of combustible dust and gases necessitates explosion-proof enclosures for electrical equipment.

- Pharmaceutical Industry: Areas where pharmaceuticals are produced or stored may require explosion-proof housing due to the potential presence of flammable solvents and dust.

- Grain Handling and Processing: Grain elevators and processing facilities dealing with grain dust are at risk of dust explosions, making explosion-proof enclosures crucial.

- Aerospace: In aerospace manufacturing and testing, where flammable propellants or chemicals are used, explosion-proof enclosures are used for safety.

- Utilities: Utility facilities with gas pipelines, electrical substations, and wastewater treatment plants may require explosion-proof equipment to ensure safe operation.

- Paint and Coating Industry: The presence of flammable solvents and powders in paint and coating facilities necessitates explosion-proof enclosures.

It's important to note that selecting and installing explosion-proof equipment should be done in accordance with local regulations and industry standards to ensure the safety of personnel and facilities in hazardous environments.

Fig 6. Photographs-of-a-SP-9-sensing-element-mounted-on-a-TO-5-housing-b-industrial-pressure

What is the internal pressure transmitter's Housing?

In the context of a pressure transmitter, the "internal housing" typically refers to the enclosure or casing within the device that houses the critical internal components responsible for measuring pressure and transmitting the measurement signal. This internal housing plays a crucial role in protecting sensitive electronics and ensuring the accuracy and reliability of pressure measurements.

Here's a breakdown of the internal pressure transmitter housing:

Description: The internal housing is typically a sealed, protective chamber or casing within the pressure transmitter. It is designed to house components such as the pressure sensor or transducer, electronic circuitry (including the signal conditioning and amplification circuits), and wiring connections. The design of the internal housing is engineered to withstand the specific environmental conditions and pressures encountered in the application.

Operation: The primary function of the internal housing is to shield the internal components from external factors that could affect their performance or damage them. This includes protection against moisture, dust, dirt, chemicals, and mechanical stresses. The housing also helps maintain a stable and controlled environment for the pressure sensor to ensure accurate measurements.

Applications: The internal housing of a pressure transmitter is a critical component in a wide range of industrial and commercial applications where pressure measurements are required. These applications can include industrial automation, process control, HVAC systems, automotive, aerospace, and many others.

Pros:

- Ensures the protection of sensitive internal components.

- Maintains the stability and integrity of pressure measurements.

- Enables reliable and accurate pressure readings.

- Customizable to meet the specific requirements of different applications and industries.

- May include features such as thermal insulation and shielding to enhance performance.

Cons:

- While the internal housing is essential for protecting internal components, it may add some bulk to the overall size of the pressure transmitter.

- In certain extreme environments, the housing material and design may need to be carefully selected to ensure it can withstand high temperatures, corrosive chemicals, or other challenging conditions.

It's important to note that the internal housing is just one part of the pressure transmitter's overall housing system. Many pressure transmitters have an external housing as well, which provides additional protection against external environmental factors and physical damage. The combination of the internal and external housings ensures the pressure transmitter's functionality and longevity in a wide range of applications.

What are the Environmental protection ratings in pressure transmitters?

Environmental protection ratings, often referred to as Ingress Protection (IP) ratings, are standardized codes used to indicate the level of protection provided by the housing or enclosure of electronic devices, including pressure transmitters. These ratings specify the device's ability to resist the ingress of solid particles (like dust) and liquids (such as water) under various environmental conditions. IP ratings are important in determining the suitability of a pressure transmitter for specific operating environments.

The IP rating typically consists of two digits, with each digit representing a specific aspect of protection:

- First Digit (Protection against Solid Particles): This digit ranges from 0 to 6 and indicates the degree of protection against solid objects, such as dust and debris.

- 0: No protection against solid particles.

- 1: Protection against solid objects larger than 50 mm (e.g., a hand).

- 2: Protection against solid objects larger than 12.5 mm (e.g., fingers).

- 3: Protection against solid objects larger than 2.5 mm (e.g., tools and wires).

- 4: Protection against solid objects larger than 1 mm (e.g., small tools and wires).

- 5: Limited protection against dust ingress (dust may enter but not in sufficient quantities to interfere with the operation of the equipment).

- 6: Complete protection against dust ingress (dust-tight).

- Second Digit (Protection against Liquids): This digit ranges from 0 to 9 and indicates the level of protection against the ingress of liquids, including water.

- 0: No protection against liquids.

- 1: Protection against vertically falling drops of water (e.g., water dripping vertically onto the equipment).

- 2: Protection against water droplets at an angle of up to 15 degrees from vertical (e.g., light rain).

- 3: Protection against water sprayed at an angle of up to 60 degrees from vertical (e.g., heavy rain).

- 4: Protection against water splashes from any direction.

- 5: Protection against water jets (e.g., low-pressure washdown).

- 6: Protection against powerful water jets (e.g., high-pressure washdown).

- 7: Protection against temporary immersion in water up to 1 meter deep for a limited time (e.g., submersion in a tank).

- 8: Protection against continuous submersion beyond 1 meter (specific conditions are defined by the manufacturer).

- 9K: Protection against high-pressure, high-temperature water jets (often used in specific industrial applications).

For pressure transmitters, the IP rating provides information about their ability to withstand the environmental conditions where they are installed. The specific IP rating required depends on the application and the level of protection needed. For example, pressure transmitters used in outdoor settings may require a higher IP rating to protect against moisture and dust, while those used in clean indoor environments may have a lower IP rating.

When selecting a pressure transmitter, it's important to consider the IP rating along with other factors like temperature, pressure range, and chemical compatibility to ensure it is suitable for the intended application.

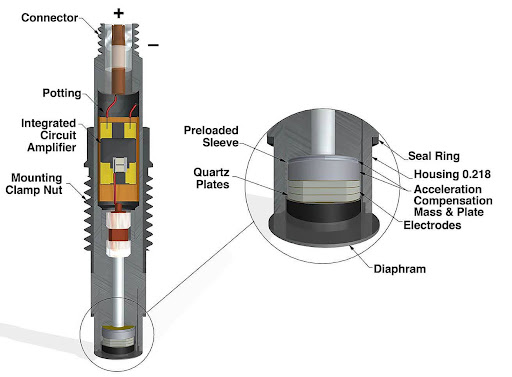

Fig 7. Typical quartz pressure sensor cross-section

What is the Environmental protection rating's significance?

Environmental protection ratings, often referred to as Ingress Protection (IP) ratings, are significant for several reasons:

- Equipment Suitability: IP ratings help users and manufacturers determine the suitability of electronic equipment, including pressure transmitters, for specific operating environments. They provide valuable information about the device's ability to withstand exposure to solid particles (like dust) and liquids (such as water) under various conditions.

- Environmental Compatibility: Understanding the IP rating of a device is crucial in ensuring that it can function reliably in the intended environmental conditions. For example, a pressure transmitter used in an outdoor industrial setting with exposure to rain and dust may require a higher IP rating than one used in a clean indoor laboratory.

- Protection against Damage: IP ratings help protect equipment from external factors that can potentially damage or interfere with its operation. For instance, a pressure transmitter with a high IP rating is less likely to be affected by moisture ingress, which could cause short circuits or corrosion.

- Safety: In certain industries and applications, safety is paramount. IP ratings, especially in hazardous environments, can be critical in preventing accidents and ensuring the safety of personnel. For example, in explosive environments, using equipment with an appropriate IP rating can help prevent the ignition of flammable gases or dust.

- Maintenance and Reliability: Understanding the IP rating can influence maintenance schedules and practices. Equipment with higher IP ratings may require less frequent cleaning or maintenance, contributing to greater reliability and reduced downtime.

- Compliance with Regulations: Some industries and regions have specific regulations and standards that require equipment to meet certain IP ratings. Adhering to these standards is often necessary to ensure compliance with safety and environmental regulations.

- Product Selection: For manufacturers and buyers, IP ratings play a crucial role in product selection. They allow for informed decisions about which equipment is best suited for a particular application, taking into account factors such as the potential for exposure to moisture, dust, or chemicals.

- Product Differentiation: Manufacturers often use IP ratings as a way to differentiate their products in the market. Higher IP ratings can be seen as a mark of quality and reliability, especially in industries where equipment durability is critical.

- International Standardization: IP ratings are internationally recognized and standardized, making them a useful tool for specifying equipment requirements in a global context.

In summary, the significance of environmental protection ratings, such as IP ratings, lies in their ability to inform users and manufacturers about the protective capabilities of electronic equipment in various environments. These ratings help ensure equipment reliability, safety, and compliance with regulations, ultimately contributing to the efficient and safe operation of industrial and electronic systems.

Conclusion

In conclusion, the housing of a pressure transmitter serves as a critical protective barrier that safeguards the device's internal components and ensures its functionality, safety, and longevity in diverse industrial and commercial applications. The choice of housing type and its associated environmental protection rating, often denoted as an Ingress Protection (IP) rating, is crucial for determining the device's suitability for specific operating conditions. These ratings indicate the extent to which the housing can resist the ingress of solid particles (like dust) and liquids (such as water) under various environmental conditions.

Understanding the significance of environmental protection ratings, such as IP ratings, is essential for equipment users, manufacturers, and industries as a whole. These ratings inform decisions about equipment selection, maintenance practices, safety considerations, and compliance with regulations. Ultimately, environmental protection ratings play a pivotal role in ensuring the reliable and safe operation of pressure transmitters and other electronic equipment in a wide range of applications and industries.

To recap

1. What is the purpose of housing in electronic devices?

The housing of electronic devices serves to enclose and protect internal components from external environmental factors, and physical damage, and ensure safe operation.

2. How does housing protect electronic circuits?

Housing protects electronic circuits by providing a physical barrier against moisture, dust, chemicals, and mechanical stress, preventing damage or interference.

3. What are common housing materials for electronic devices?

Common housing materials include plastics, metals (e.g., aluminum, stainless steel), and specialized materials like polycarbonate for their durability and protective properties.

4. How does housing design impact environmental protection?

Housing design affects environmental protection by incorporating features like seals, gaskets, and venting to safeguard against specific environmental factors, such as water ingress or dust contamination.

5. What is the Ingress Protection (IP) rating?

The IP rating is a standardized code that indicates the level of protection provided by an enclosure against the ingress of solid particles and liquids.

6. How do IP ratings work?

IP ratings consist of two digits; the first indicates protection against solids, and the second indicates protection against liquids. Higher numbers signify greater protection.

7. What is the significance of IP ratings in electronic devices?

IP ratings help users select devices suitable for specific environmental conditions, ensuring functionality and safety.

8. What is the role of weatherproof housing?

Weatherproof housing is designed to withstand outdoor conditions, protecting devices from rain, wind, and temperature variations.

9. How does explosion-proof housing enhance safety?

Explosion-proof housing prevents ignition of flammable gases or vapors in hazardous environments, ensuring safety in industries like oil and gas.

10. When are submersible housings used?

Submersible housings are used when electronic devices need to operate underwater or in liquid environments, such as water level sensors.

11. What are the benefits of using sanitary housing in industries like food and pharmaceuticals?

Sanitary housings maintain cleanliness, hygiene, and corrosion resistance in environments where strict sanitary standards apply.

12. In what industries are high-pressure housings commonly used?

High-pressure housings are used in industries like hydraulics, high-pressure industrial processes, and oil and gas for measuring extreme pressures.

13. When are flush diaphragm housings preferred?

- Flush diaphragm housings are used in applications with viscous or sticky fluids to prevent debris buildup on the diaphragm.

14. What are the advantages of using compact housings?

Compact housings are space-efficient and suitable for applications with limited installation space.

15. Why is it important to consider housing when selecting electronic devices for specific applications?

Considering housing is crucial to ensure that electronic devices can withstand the intended environmental conditions, ensuring reliability and longevity.

References

https://www.mdpi.com/1424-8220/15/12/29866

https://www.mdpi.com/1424-8220/16/7/1025

https://www.instrumart.com/products/47690/eh-deltapilot-fmb70-pressure-sensor

https://appmeas.co.uk/wp-content/uploads/Pressure-Sensor-Diagram.gif

https://slideplayer.com/slide/4156573/13/images/16/Piezoelectric+Pressure+Sensors..jpg

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025