The Invisible Heroes: Piping and Tubing’s Role in Powering Accurate Pressure Sensing

In the intricate web of industrial operations and precision instrumentation, the unsung heroes often lie within the seemingly mundane yet critical elements—piping and tubing connections in pressure sensors. These connections, often overlooked, are the silent guardians ensuring the accuracy, reliability, and safety of pressure measurements within diverse industrial landscapes.

Imagine a world without these unassuming components—where pressure sensors stand vulnerable to inaccuracies, leaks, and compromised system integrity. From the choice of materials to meticulous installation techniques, each aspect plays a pivotal role in orchestrating a symphony of seamless operations and precise measurements.

In this guide, we embark on an exploration of the significance, nuances, and best practices surrounding piping and tubing connections in pressure sensors. Unraveling the intricacies and addressing pivotal questions, this journey aims to shed light on these foundational elements, underscoring their indispensable role in maintaining the efficiency, safety, and reliability of industrial systems.

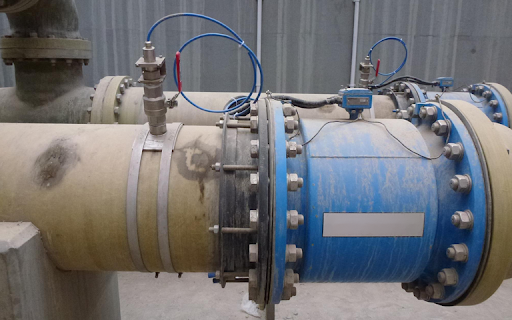

Fig 1. Pressure sensor connections

What does piping mean in pressure transmitters?

In the context of pressure transmitters, piping refers to the system of pipes or tubing used to connect the pressure transmitter to the process or the source of the pressure being measured.

Piping is crucial because it allows the pressure from the measured source to be transmitted accurately to the sensing element within the pressure transmitter. The design and installation of the piping system can significantly affect the accuracy and reliability of pressure measurements. Factors such as the material, size, length, and configuration of the pipes can impact the performance of the pressure transmitter.

Proper installation of piping involves considerations like minimizing bends, ensuring the absence of leaks or air pockets, and using appropriate materials compatible with the process conditions to maintain accuracy and reliability in pressure measurement.

What is the Tubing Connection in pressure sensors?

Tubing connections in pressure sensors refer to the method used to connect the sensor to the system or medium from which it's measuring pressure. These connections are crucial as they ensure the sensor accurately detects and measures the pressure without leakage or interference.

Common types of tubing connections for pressure sensors include

How can install Piping and Tubing Connections?

Installing piping and tubing connections for pressure sensors requires attention to detail and adherence to best practices to ensure accurate pressure measurement and system reliability. Here's a general guide to installing piping and tubing connections:

1. Gather the Necessary Tools and Materials:

- Pressure sensor/transmitter

- Piping/tubing (appropriate material and size for the application)

- Fittings (compression fittings, threaded adapters, etc.)

- Wrenches, spanners, or appropriate tools for tightening connections

- Teflon tape or sealant (if required)

2. Prepare the Work Area:

- Ensure the work area is clean and free from debris that could contaminate the system.

- Identify the entry and exit points for the piping/tubing connections on both the sensor and the system.

3. Cut and Prepare Tubing:

- Measure and cut the tubing to the required length, ensuring precise cuts without deformation.

- Remove any burrs or sharp edges from the cut ends to prevent damage to seals or O-rings.

4. Assemble the Connections:

- If using compression fittings or threaded connections, follow the manufacturer's instructions for assembly.

- Apply Teflon tape or sealant to threaded connections, if necessary, ensuring not to over-apply.

5. Install the Sensor:

- Align the sensor with the entry point for the tubing/piping on the system.

- Carefully thread or secure the sensor in place, ensuring a snug fit without over-tightening.

6. Connect Tubing/Piping to the Sensor:

- Attach the tubing to the sensor’s fittings or ports using the appropriate connection method (compression, push-to-connect, etc.).

- Ensure a secure and tight fit, but avoid over-tightening which can damage the connections.

7. Check for Leaks:

- Conduct a pressure test to check for leaks.

- Gradually apply pressure to the system and inspect all connections for any signs of leakage.

- If leaks are detected, recheck connections and fittings, and make necessary adjustments.

8. Secure and Support Tubing/Piping:

- Secure the tubing along its route to prevent movement or vibration that could stress the connections.

- Use clamps or brackets to support and secure the tubing/piping as needed.

9. Final Checks:

- Verify that all connections are properly tightened and secure.

- Ensure there are no kinks or bends that could obstruct the flow or affect pressure readings.

10. Record and Document Installation:

Keep records of the installation details, including the type of connections used, torque settings, and any special considerations.

11. Follow Manufacturer Guidelines:

Always refer to the specific instructions provided by the sensor manufacturer for installation guidance and any unique requirements.

Proper installation of piping and tubing connections is crucial for accurate pressure measurement and system performance. Following these steps and manufacturer guidelines will help ensure a reliable and precise installation.

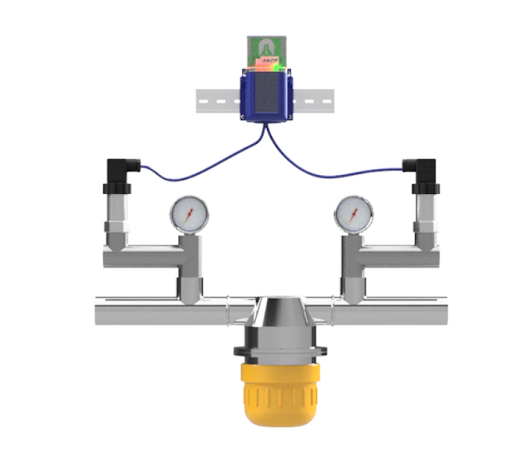

Fig 2. Pipe pressure sensor accessories

Considerations for pressure transmitter connection points

When dealing with pressure transmitter connection points, several critical considerations should be taken into account to ensure accurate readings, reliability, and safety:

What safety measures should be taken during the installation of piping and tubing connections?

Installing piping and tubing connections involves potential risks, and observing safety measures is crucial to prevent accidents, injuries, or damage to equipment. Here are some key safety measures to consider during installation:

Are there specific regulations or standards for installing these connections in certain industries?

Yes, various industries have specific regulations, standards, and guidelines that govern the installation of piping and tubing connections to ensure safety, quality, and compliance with industry-specific requirements. Some of these industries and associated standards include:

Why are proper piping and tubing connections essential for pressure sensors?

Proper piping and tubing connections are vital for pressure sensors for several crucial reasons:

Fig 3. Wireless pipe pressure sensor

Guidelines for selecting and installing suitable piping and tubing materials

Selecting and installing suitable piping and tubing materials for pressure sensor installations involves several crucial guidelines. Firstly, assess the compatibility of the material with the measured media—consider factors such as corrosion resistance, chemical compatibility, and potential reactions to the substance being measured. Next, evaluate the pressure and temperature requirements the system will encounter to ensure the chosen material can withstand these conditions without compromising performance or integrity. Additionally, consider the mechanical properties required for the application, such as flexibility, durability, and strength. Environmental factors, including exposure to outdoor elements or specific indoor conditions, should also influence material selection to prevent degradation over time. Moreover, prioritize materials that adhere to industry standards and regulations, ensuring compliance for safety and quality assurance. During installation, follow manufacturer guidelines meticulously, paying attention to proper cutting, securing, and sealing techniques to maintain system integrity and prevent leaks. Conduct thorough pressure tests to verify the effectiveness of the installed piping or tubing, ensuring accurate pressure readings and system reliability. Regular inspections and maintenance further ensure the longevity and performance of the chosen materials in pressure sensor applications.

What types of materials are commonly used for piping and tubing connections?

Several materials are commonly used for piping and tubing connections in pressure sensor installations, each chosen based on specific application requirements. Some of the frequently used materials include:

What are the factors that piping and tubing materials for pressure sensor installations depend on?

The choice of piping and tubing materials for pressure sensor installations depends on several crucial factors:

How do you select the right piping or tubing material for a specific application?

Selecting the right piping or tubing material for a specific application involves considering several critical factors:

What factors should be considered while installing piping and tubing connections?

Installing piping and tubing connections requires attention to detail and adherence to best practices to ensure optimal performance and reliability. Several factors should be considered during installation:

Fig 4. Rail tube pipe

What are the different types of fittings used for connecting pressure sensors?

Various types of fittings are used for connecting pressure sensors to piping or tubing systems. These fittings facilitate secure and leak-free connections. Some common types include:

How do you determine the appropriate size of piping or tubing for a pressure sensor?

Determining the appropriate size of piping or tubing for a pressure sensor involves considering several factors to ensure optimal performance and accurate pressure measurements:

What considerations should be made for high-pressure applications when choosing piping or tubing?

In high-pressure applications, selecting the right piping or tubing is crucial to ensure safety, reliability, and accurate pressure measurements. Several considerations should be made when choosing piping or tubing for high-pressure applications:

Fig 5. Piping pressure sensor

How do you prevent leaks in piping and tubing connections?

Preventing leaks in piping and tubing connections involves a series of meticulous steps and adherence to best practices:

Best practices for achieving leak-free connections

Achieving leak-free connections is critical in various applications to ensure safety, accuracy, and efficiency. Here are some best practices to achieve leak-free connections:

What steps can be taken to troubleshoot leaks in piping and tubing connections?

Troubleshooting leaks in piping and tubing connections involves a systematic approach to identify and address potential issues. Here are steps you can take to troubleshoot leaks:

Fig 6. Common tube pipe

How does temperature affect the choice of materials for these connections?

Temperature plays a significant role in determining the suitability of materials for piping and tubing connections. Different temperature ranges can affect materials in various ways, influencing their mechanical properties, chemical reactions, and overall performance. Here's how temperature considerations impact material choice:

How do you account for expansion and contraction in piping and tubing connections due to temperature changes?

Accounting for expansion and contraction in piping and tubing connections due to temperature changes is crucial to prevent issues such as leaks, structural stress, or damage. Here's how it can be managed:

Conclusion

Ensuring reliable and efficient piping and tubing connections involves a comprehensive understanding of the factors influencing their performance. Proper material selection, installation techniques, and adherence to safety measures are fundamental to establishing leak-free, durable, and safe connections in various industries.

From selecting the appropriate materials based on application-specific needs to considering factors like temperature variations, pressure requirements, and industry regulations, each step in the process contributes to the integrity of the system.

Preventing leaks, accommodating thermal expansion, and maintaining system safety require a combination of meticulous planning, adherence to standards, and regular maintenance. By following best practices, conducting thorough inspections, and implementing suitable measures to address potential issues, it's possible to ensure the long-term reliability, safety, and efficiency of piping and tubing connections within diverse industrial applications.

To recap

1.Why are proper piping and tubing connections crucial for pressure sensors? A: Proper connections ensure accurate pressure measurement, and system reliability, and prevent leaks, ensuring the sensor functions optimally within its operational parameters.

2. How do I choose the right piping or tubing material for a pressure sensor? A: Consider the measured media, pressure and temperature requirements, corrosion resistance, and compatibility with the application. Stainless steel, copper, and brass are common choices based on specific needs.

3.What factors should I consider during piping or tubing installation for pressure sensors? A: Consider cleanliness, proper sealing, correct alignment, appropriate torque, support, environmental conditions, adherence to guidelines, and safety precautions.

4. What are the best practices for achieving leak-free connections? A: Ensure proper preparation, correct sealing techniques, secure tightening of connections, avoiding cross-threading, and thorough inspections post-installation.

5.What happens if I don't choose the proper piping or tubing connections? A: Improper connections can lead to inaccuracies in pressure readings, leaks, system malfunctions, safety hazards, and premature sensor failure.

6.How do I troubleshoot leaks in piping or tubing connections? A: Perform visual inspections, and pressure tests, check fittings, seals, and gaskets, use leak detection solutions, and consider thermal expansion effects.

7.How does temperature affect the choice of materials for connections? A: Temperature influences material strength, expansion rates, chemical reactions, and sealing properties, guiding material selection for specific temperature ranges.

8. Are there specific regulations for installing piping or tubing connections in certain industries? A: Yes, industries like oil and gas, chemical processing, water treatment, and others have specific standards (API, ASME, ASTM, etc.) governing installation practices

9. What steps can I take to account for expansion and contraction due to temperature changes? A: Incorporate flexible joints, proper material selection, expansion devices, guided supports, slip joints, and monitor for stress and displacement. 10. How do I ensure safety during the installation of piping or tubing connections? A: Use proper PPE, handle materials safely, avoid confined spaces, ensure tool safety, maintain ventilation, perform safety checks, follow guidelines, and prepare for emergencies.

References

https://www.gridconnect.com/products/wireless-pipe-pressure-sensor

https://www.alibaba.com/product-detail/standpipe-pressure-sensor-with-2-1502_1600128033862.html

https://www.alibaba.com/product-detail/Common-Rail-Tube-Pipe-DRV-Pressure_1600621595534.html

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025