Surviving the Elements: Maintenance Secrets for Long-Lasting Sensors

Pressure sensors are invaluable instruments that play a pivotal role in diverse industries, offering crucial insights into fluid and gas pressures. However, their performance can be significantly influenced by environmental conditions, presenting challenges that impact accuracy and longevity.

Imagine a sensor measuring pressure in an industrial setting, exposed to fluctuating temperatures, moisture, or corrosive substances. Each environmental factor poses a threat to its precision and reliability. Understanding these challenges is crucial to safeguarding these sensors and ensuring their seamless operation amidst diverse and demanding conditions.

In this exploration, we delve into the intricate relationship between pressure sensors and their environmental surroundings. Unveiling the impact of temperature variations, humidity, altitude changes, and other factors, we uncover strategies to protect and optimize these sensors' performance. Join us as we navigate the complexities of environmental influences on pressure sensors and uncover the key practices to maintain their accuracy and resilience.

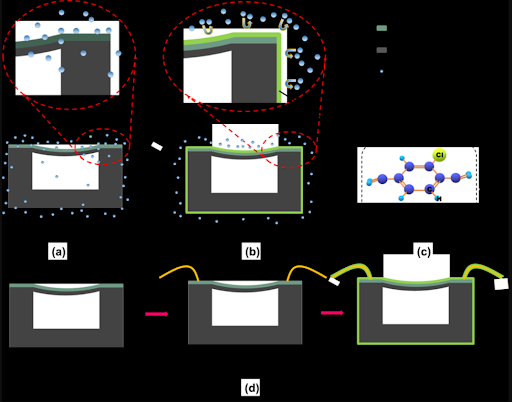

Fig 1. (a) A pressure sensor influenced adversely by environmental molecules, affecting the accuracy of the device. (b) A pressure sensor with micro-coating to resist the adverse influence of molecules affecting the accuracy of the device. (c) The chemical molecular structure of the micro-coating: perylene-C. (d) Three steps of the sensor treatment in this experience.

Evaluating environmental conditions and their impact on pressure transmitter performance

Environmental conditions play a critical role in the performance and reliability of pressure transmitters. Temperature variations, for instance, can profoundly affect these sensors. Fluctuations in temperature can lead to material expansion or contraction within the transmitter, potentially altering its calibration and accuracy. Extreme temperatures might also impact the electronic components, causing variations in sensitivity or even damaging the circuitry, thereby affecting the transmitter's functionality.

Humidity is another factor that can significantly impact pressure transmitters. High humidity levels can introduce moisture into the transmitter's casing, leading to corrosion, short circuits, or changes in insulation resistance. This moisture ingress could compromise the transmitter's internal components, thereby reducing its reliability and accuracy over time.

Vibration and shock present additional challenges. Excessive vibrations can physically damage the delicate internal components of the pressure transmitter, resulting in misalignment or fractures that affect its performance. Additionally, vibrations can induce noise or interference in the electrical signals, disrupting accurate pressure measurements.

Altitude and atmospheric pressure variations also play a role. Pressure transmitters calibrated at specific atmospheric conditions, such as sea level, may provide inaccurate readings at higher altitudes due to lower atmospheric pressure. Ensuring proper compensation or adjustment mechanisms becomes crucial in such scenarios to maintain accuracy.

Chemical exposure is yet another concern. Exposure to certain chemicals can corrode the transmitter's materials or degrade its components, leading to structural damage, contamination, or seal compromise. This could impact the transmitter's functionality and accuracy, particularly in harsh chemical environments.

Manufacturers often design pressure transmitters with protective measures, such as seals, coatings, or rugged enclosures, to mitigate these environmental impacts. Regular maintenance, adherence to environmental specifications, and selecting transmitters designed for specific environmental conditions are essential practices to uphold the accuracy and reliability of pressure transmitters amidst varying environmental challenges.

How do environmental conditions affect pressure sensors?

Environmental conditions can significantly impact the performance and accuracy of pressure sensors. Here are some ways environmental factors can affect pressure sensors:

How does temperature affect on pressure sensor?

Temperature can have a significant impact on the performance of pressure sensors:

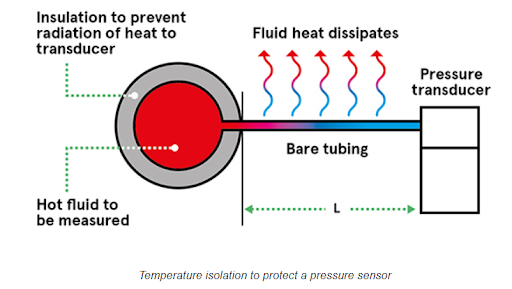

Fig 2. Temperature isolation to protect a pressure sensor

How does humidity condition affect on pressure sensor?

Humidity can affect pressure sensors in several ways:

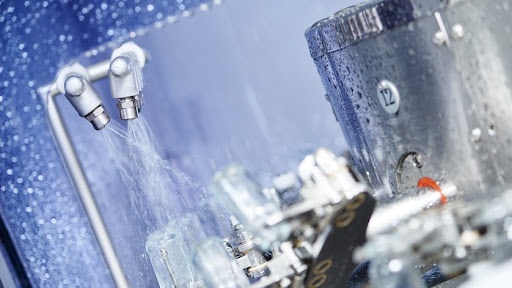

Fig 3. Protecting pressure sensors from moisture shutterstock

How do Vibration and Shock affect on pressure sensor?

Vibration and shock can have several detrimental effects on pressure sensors:

How do Altitude and Atmospheric Pressure affect on pressure sensor?

Altitude and atmospheric pressure are directly related to the operation of pressure sensors, as these sensors measure pressure variations. However, changes in altitude and atmospheric pressure can impact the way pressure sensors function:

How does Chemical Exposure affect on pressure sensor?

Chemical exposure can significantly impact pressure sensors, causing various detrimental effects:

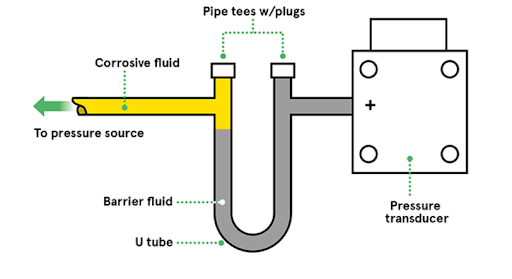

Fig 3. isolating a pressure sensor from corrosive media

How can protect pressure sensors against dust, moisture, and corrosive substances?

Protecting pressure sensors against dust, moisture, and corrosive substances is crucial for ensuring their reliability and longevity. Here are some common protective measures:

By combining these protective measures, you can enhance the resilience of pressure sensors against the adverse effects of dust, moisture, and corrosive substances, ensuring their optimal performance and longevity in challenging environments.

Housing and Enclosures:

Pressure sensors are often housed within protective enclosures designed to shield them from external environmental factors. These enclosures are constructed with materials and designs that meet specific Ingress Protection (IP) ratings, denoting their resistance to dust and moisture. For instance, IP65-rated enclosures provide excellent protection against dust ingress and are water-resistant, while IP67-rated ones offer higher resistance against immersion in water for a limited time. These housings serve as a robust barrier, safeguarding the delicate internal components of the sensor from dust particles, moisture, and even certain corrosive substances present in the environment. Additionally, they are engineered with seals and gaskets at critical points to ensure a secure, tight fit, further fortifying the sensor against external elements.

Fig 4. Pressure Sensors With Customized Housing

Seals and Gaskets:

Seals and gaskets play a pivotal role in preventing the infiltration of dust, moisture, and corrosive substances into pressure sensors. These components are meticulously selected based on their material composition and resilience to environmental conditions. Typically made from silicone, rubber, or specialized elastomers, they are strategically placed at vulnerable points, such as entry points for cables or connections, to create a reliable barrier. These seals effectively block dust particles from entering the sensor's internal components and protect against moisture ingress, maintaining the sensor's integrity. Moreover, when exposed to corrosive substances, chemically resistant seals and gaskets act as a defense, ensuring the sensor's durability and functionality over time by resisting degradation and corrosion.

Coatings and Laminates:

Applying protective coatings or laminates to pressure sensors forms an additional defense layer against dust, moisture, and corrosive substances. These coatings are carefully selected based on their compatibility with the sensor's construction materials and the specific environmental challenges the sensor might encounter. For instance, epoxy coatings or PTFE (polytetrafluoroethylene) laminates provide a barrier that shields the sensor from moisture while also offering resistance to chemicals and corrosive agents. These coatings are often applied to the sensor's external surfaces, providing a protective shield without compromising the sensor's functionality or accuracy.

Material Selection:

The materials used in constructing pressure sensors play a crucial role in their resistance to dust, moisture, and corrosive substances. Materials such as stainless steel or certain alloys are preferred for their inherent corrosion-resistant properties. Stainless steel sensors, for instance, offer robustness against corrosion from exposure to various environments, including those with high humidity or chemical exposure. Additionally, selecting materials with appropriate chemical compatibility ensures that the sensor remains unaffected when exposed to specific substances. This thoughtful selection of materials for the sensor's construction contributes significantly to its longevity and reliability, even in challenging environmental conditions.

Breather Vents:

Breather vents or filters are integrated into pressure sensor enclosures to balance internal and external pressures while preventing the entry of contaminants. These vents allow for pressure equalization, crucial for maintaining the integrity of the sensor in varying environmental conditions. By allowing air to pass through while blocking dust particles and moisture, breather vents mitigate the risk of pressure differentials that could potentially damage the sensor. Additionally, the filters used in these vents act as a barrier, preventing the ingress of harmful substances without impeding the necessary airflow, thus safeguarding the sensor's internal components.

Remote Mounting:

Remote mounting involves installing pressure sensors in locations less exposed to adverse environmental elements. This approach is particularly beneficial in harsh conditions where dust, moisture, or corrosive substances are prevalent. By using extension cables, tubing, or other suitable connections, the sensor can be placed at a distance from the measurement point, minimizing direct exposure. This remote placement reduces the sensor's vulnerability to environmental hazards, prolonging its lifespan and preserving accuracy. It's an effective strategy for ensuring reliable measurements without compromising the sensor's performance in challenging environments.

Regular Maintenance:

Implementing a routine maintenance schedule is essential for preserving pressure sensors against dust, moisture, and corrosive substances. Regular inspections involve checking the condition of seals, gaskets, and protective coatings to ensure they remain intact and effective. Cleaning the sensor's exterior surface helps prevent the accumulation of dust or corrosive residues that could potentially compromise its performance. Moreover, proactive maintenance practices involve replacing damaged components, such as worn-out seals or coatings, to maintain the sensor's protective barriers and ensure continued reliability in harsh environments.

Environmental Monitoring:

Environmental monitoring systems are instrumental in assessing and responding to potential risks faced by pressure sensors. These systems continuously monitor environmental conditions such as humidity levels, temperature fluctuations, and chemical exposure. By detecting variations or hazards in the sensor's surroundings, they provide timely alerts or triggers for preventive measures. Monitoring allows for proactive interventions, enabling swift actions to protect the sensors, such as adjusting operating parameters or initiating maintenance routines to mitigate potential risks posed by dust, moisture, or corrosive substances. This proactive approach helps maintain the sensors' performance and longevity in challenging environmental conditions.

What are the consequences of exposing pressure sensors to extreme temperatures?

Exposing pressure sensors to extreme temperatures can have several consequences, impacting their performance and accuracy:

How does moisture ingress affect pressure sensor performance?

Moisture ingress can significantly impact the performance and reliability of pressure sensors:

What are the implications of altitude changes on pressure sensor readings?

Altitude changes can significantly affect pressure sensor readings due to variations in atmospheric pressure. As altitude increases:

Fig 5. Pressure Sensors for Harsh Environment shock Eastsensor

What happens to pressure sensors when exposed to corrosive substances?

Exposure to corrosive substances can have several detrimental effects on pressure sensors:

What role does calibration play in adapting pressure sensors to varying environments?

Calibration plays a crucial role in adapting pressure sensors to varying environments by ensuring their accuracy and reliability in different conditions. Here's how calibration impacts sensor performance in various environments:

Do pressure sensors need special protection in high-humidity environments?

Yes, pressure sensors often require special protection in high-humidity environments to ensure their performance and longevity. High humidity can introduce moisture, which can adversely affect pressure sensors in several ways:

What materials are commonly used to enhance pressure sensor durability?

Several materials are commonly used to enhance the durability and reliability of pressure sensors, especially in harsh or challenging environments:

How can pressure sensors be shielded against electromagnetic interference?

Shielding pressure sensors against electromagnetic interference (EMI) is crucial to maintain their accuracy and reliability in environments with electromagnetic fields. Here are several methods used to achieve EMI shielding for pressure sensors:

What maintenance practices can prolong pressure sensor lifespan in adverse environments?

Maintaining pressure sensors in adverse environments is crucial to prolong their lifespan and ensure reliable performance. Here are maintenance practices that can help:

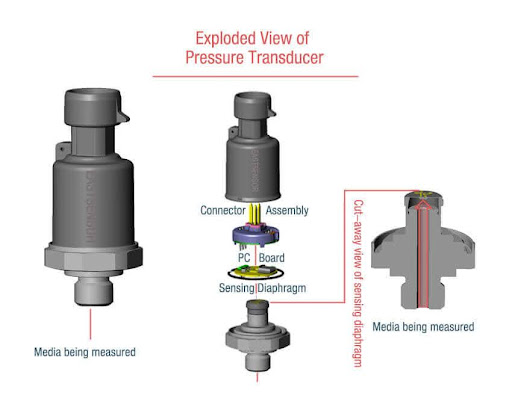

Fig 6. Exploded view of pressure transducer

what should do to reduce the effect of environmental conditions on pressure sensors?

To reduce the impact of environmental conditions on pressure sensors, consider these strategies:

Conclusion

Ensuring the reliability and accuracy of pressure sensors in varying environmental conditions is vital for their optimal performance. Environmental factors such as temperature fluctuations, humidity, altitude changes, dust, moisture, and corrosive substances can significantly impact sensor functionality.

To safeguard pressure sensors, a multi-faceted approach is necessary. This includes employing protective housings, utilizing materials resistant to environmental stressors, implementing proper sealing and coatings, and regular maintenance. Calibration and compensation mechanisms tailored to specific environmental conditions play a crucial role in maintaining accuracy.

Environmental monitoring systems help track changes in temperature, humidity, and other factors, allowing proactive interventions to mitigate risks. Proper installation, remote mounting when applicable, and adherence to manufacturer guidelines contribute to sensor longevity and reliability.

By combining these strategies, pressure sensors can withstand adverse environmental conditions, ensuring consistent and precise measurements across various settings and extending their operational lifespan.

To recap

1.How does temperature affect pressure sensor accuracy?

Temperature changes can cause material expansion or contraction within the sensor, affecting calibration and leading to inaccuracies. Some sensors incorporate temperature compensation to counter these effects.

2.Can humidity impact pressure sensor performance?

High humidity can lead to moisture ingress, corroding components, and causing malfunctions. Sensors with proper sealing or coatings are less affected.

3.What happens to pressure sensors at high altitudes?

At higher altitudes, atmospheric pressure decreases, impacting sensor readings calibrated at sea level. Sensors might require altitude compensation to maintain accuracy.

4.How does vibration affect pressure sensor reliability?

Vibration can damage internal components, leading to inaccurate readings or sensor failure. Sensors designed with shock-resistant features mitigate these effects.

5.Can pressure sensors withstand exposure to corrosive substances?

Corrosive substances can damage sensor materials and compromise their functionality. Using corrosion-resistant materials or coatings helps mitigate this risk.

6.How does atmospheric pressure variation impact pressure sensors?

Changes in atmospheric pressure affect sensor readings. Compensation mechanisms help sensors adapt and provide accurate measurements despite these variations.

7.Do pressure sensors need protection against dust and moisture?

Yes, dust and moisture ingress can damage sensors. Employing protective housings, seals, and coatings safeguards sensors in challenging environments.

8.What role does calibration play in adapting sensors to varying environments?

Calibration ensures accuracy by adjusting sensors to specific environmental conditions, compensating for factors like temperature, altitude, or humidity.

9.How can pressure sensors be shielded against electromagnetic interference?

Utilizing shielding materials, proper grounding, and isolation techniques protect sensors from electromagnetic interference, ensuring accurate readings

10.What maintenance practices prolong pressure sensor lifespan in adverse environments?

Regular inspection, cleaning, calibration, and employing protective measures like seals and housings enhance sensor durability in adverse conditions.

References

https://www.eastsensor.com/blog/pressure-sensors-for-harsh-environment/

https://my.avnet.com/abacus/solutions/technologies/sensors/pressure-sensors/harsh-environments/

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025