Round and Round We Go: Exploring the Innovative Design of Ring Proximity Sensor

Ring proximity sensors are a type of proximity sensor that is shaped like a ring and can detect the presence of objects without physical contact. These sensors are important because they are widely used in various industries and applications where non-contact sensing is critical. Ring proximity sensors are commonly used in industrial automation and robotics to detect the position and movement of objects. They are also used in automotive and transportation industries to detect the presence of objects and obstacles, and in security systems to detect the presence of intruders.

If you're looking for high-quality ring proximity sensors for your specific needs, look no further than our range of products.

Abstract

This blog post covers everything you need to know about ring proximity sensors. We explore the types of ring proximity sensors available, including inductive, capacitive, and magnetic sensors, and how they work to detect the presence of objects. We also highlight the various applications of ring proximity sensors in different industries and provide a comprehensive buying guide to help you choose the best sensor for your needs. Whether you're new to ring proximity sensors or looking to upgrade your sensing game, this guide has got you covered. Before diving in, let’s have a quick explanation of what a proximity sensor is!

What is a Proximity Sensor?

A proximity sensor, also called a proximity switch, is an electronic device that can detect the presence or absence of an object without physical contact. This is accomplished by emitting some form of energy, such as an electromagnetic field or a beam of electromagnetic radiation, and then measuring changes in that energy caused by the presence of an object. Proximity sensors are used in a wide range of applications, from consumer electronics to industrial automation.

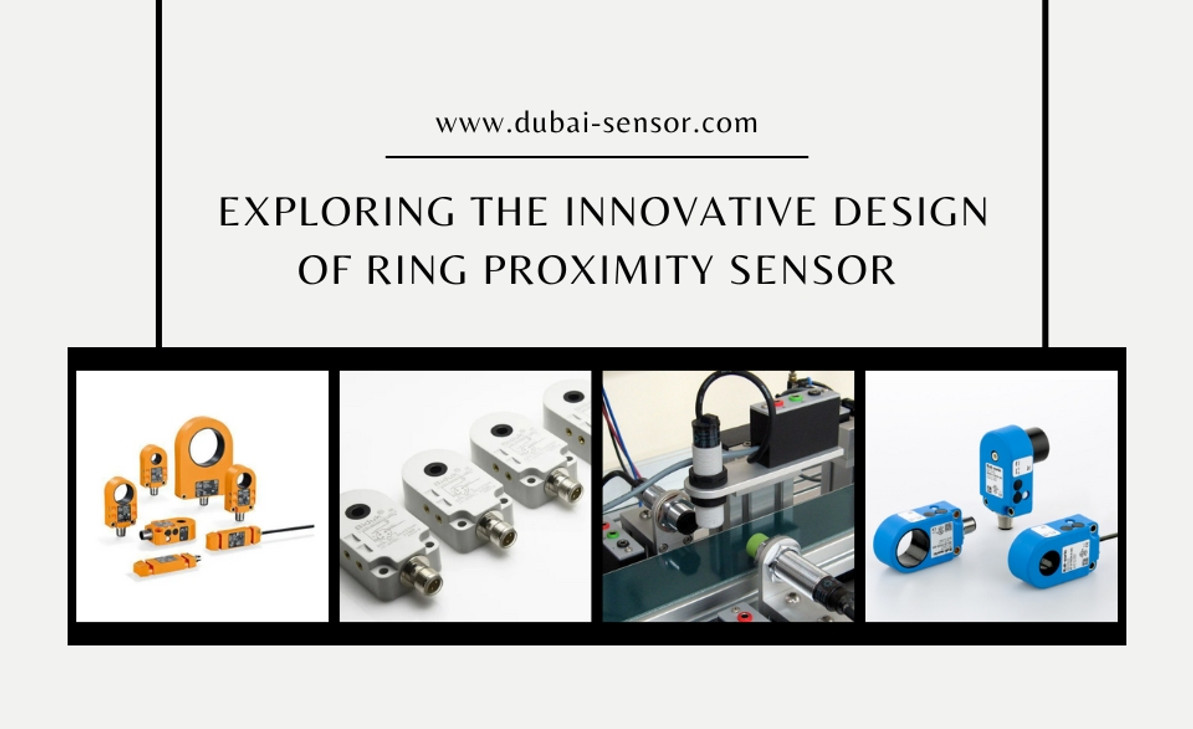

Figure 1. The proximity sensor is one of the most commonly used products in production lines.

There are several types of proximity sensors, each with its own method of detecting objects. Some of the most common types include

Inductive sensors: Inductive proximity sensors are based on the principle of electromagnetic induction. They generate an electromagnetic field and detect changes in the field caused by the presence of a metallic target object. The sensor consists of a coil of wire that is energized by an alternating current (AC) signal. The coil generates an electromagnetic field around the sensor. When a metallic object enters the field, it interacts with the field and causes a change in the field strength.

The interaction between the metallic object and the electromagnetic field induces eddy currents in the object. These eddy currents generate their own electromagnetic field, which opposes the original field created by the sensor. This results in a decrease in the field strength at the sensor.

The sensor detects this decrease in the electromagnetic field and triggers an output signal.

Figure 2. Oscillation of inductive sensor output when the object gets closed and far away.

The output signal can be either a digital signal (on/off) or an analog signal (proportional to the distance between the sensor and the target). The distance between the sensor and the target object affects the strength of the electromagnetic field and thus the amplitude of the output signal. When the target is farther away, the output signal is weaker, and when the target is closer, the output signal is stronger.

Capacitive sensors: A capacitive proximity sensor is a type of sensor that detects the presence of objects based on their capacitance, or ability to store an electric charge. The sensor generates an electric field and detects changes in the field caused by the presence of an object. The sensor consists of two electrodes, a sensing electrode and a reference electrode, separated by a non-conductive material. When a voltage is applied to the sensing electrode, it creates an electric field in the surrounding area. When an object comes into the sensing range of the electric field, it causes a change in the electric field. The object acts as a capacitor, and its presence alters the capacitance between the sensing and reference electrodes.

The change in capacitance is detected by the sensor's electronics, which generates an output signal.

Figure 3. Oscillation of capacitive sensor output when the object gets closed.

The output signal can be either a digital signal (on/off) or an analog signal (proportional to the distance between the sensor and the object). The distance between the sensor and the object affects the capacitance and thus the amplitude of the output signal. When the object is farther away, the output signal is weaker, and when the object is closer, the output signal is stronger.

Magnetic sensors: Magnetic sensors use changes to detect objects. They work by generating a magnetic field and measuring changes in the field caused by an object's proximity.

Ultrasonic sensors: Ultrasonic sensors use sound waves to detect objects. They work by emitting a high frequency sound wave and measuring the time it takes for the wave to bounce back after hitting an object.

Photoelectric sensors: Optical sensors use light to detect objects. They work by emitting a beam of light and measuring changes in the light caused by an object's proximity.

Figure 4. Various models of proximity sensors

Each type of proximity sensor has its own set of advantages and disadvantages. For example, capacitive sensors are sensitive to a wide range of materials, while inductive sensors are better suited for detecting metal objects. Ultrasonic sensors are good for measuring distance, while optical sensors are often used in applications where high precision is required.

What is a Ring Proximity Sensor?

A ring proximity sensor is a type of proximity sensor that is designed in the form of a ring. This type of sensor is also known as a ring sensor or ring-shaped sensor. It is typically used in industrial applications to detect the presence of metallic objects or targets within a certain distance. In these types of sensors, the sensing area is located inside the ring.

A ring proximity sensor consists of a ring-shaped coil that generates an electromagnetic field. When a metallic object or target enters the detection range of the sensor, it causes a change in the electromagnetic field, which is then detected by the sensor. The sensor can then provide an output signal that can be used to trigger an alarm or control a process.

What are the Types of Ring Proximity Sensors?

- Inductive ring sensor

- Capacitive ring sensor

- Magnetic ring sensor

Ring Proximity Sensors Working Principle

A ring proximity sensor works based on electromagnetic fields. It emits an electromagnetic field and detects any changes in that field caused by the presence of an object. When an

the object enters the field, it causes a disturbance in the field that the sensor can detect, and it then triggers a signal or alarm.

- Inductive ring sensors: Inductive ring sensors use an electromagnetic field to detect the presence of metallic objects within a ring area. They work by generating a high-frequency magnetic field that induces eddy currents in the metal object, which in turn produces a secondary magnetic field that is detected by the sensor.

Figure 5. Ring inductive sensors

- Capacitive ring sensors: Capacitive ring sensors use changes in capacitance to detect the presence of objects. They work by generating an electric field around the ring-shaped sensor. When an object enters the field, it causes a change in the electric field, which is then detected by the sensor.

Figure 6. Ring capacitive sensor

- Magnetic ring sensors: Magnetic ring sensors use changes in magnetic fields to detect the presence of objects. They work by generating a magnetic field around the ring-shaped sensor. When an object enters the field, it causes a change in the magnetic field, which is then detected by the sensor.

Sensing Distance Range

The sensing distance range of a ring proximity sensor depends on several factors, including the type of sensor, the size and shape of the ring, and the material and size of the target object being detected. Generally, the sensing distance of a ring proximity sensor can range from a few millimeters up to several centimeters.

The sensing distance of a ring proximity sensor is often specified by the manufacturer and can be influenced by several factors, including the frequency of the sensor, the size of the coil or sensor element, and the type of material being detected. Other factors, such as the shape and size of the ring, the presence of interfering objects, and the ambient temperature and humidity, can also affect the sensing distance of a ring proximity sensor.

It's important to note that the sensing distance of a ring proximity sensor is not a fixed value, and it can vary depending on the specific conditions of the application. For example, the sensing distance may be reduced if the target object is not perfectly aligned with the sensor or if there are other objects in the detection range that can interfere with the sensor's electromagnetic field or sound waves.

Applications of Ring Proximity Sensor

Ring proximity sensors can be used in various applications such as object detection, security systems, robotics, and automation systems.

Applications of ring proximity sensor

Ring proximity sensors are widely used in various industrial and commercial applications where it is necessary to detect the presence or absence of objects in a given space. Some of the most common applications of ring proximity sensors include:

Parts Transportation Control

In industrial manufacturing, parts transportation control is essential to ensure the smooth movement of parts from one process to another. Ring inductive sensors can be used to monitor the movement of parts as they pass through a conveyor system or tube. By detecting the presence of parts, the sensor can control the flow of the production line and ensure that parts are transported to the right location at the right time.

Parts Detection

Ring inductive sensors can also be used for parts detection in various manufacturing processes. For example, in the automotive industry, ring inductive sensors are used to detect the presence of metal parts during assembly. By detecting the parts, the sensor can trigger the assembly process and ensure that each part is in the correct position before the assembly begins.

Clogging Control

Clogging control is another important application of ring proximity sensors in industrial automation. By detecting the flow of materials, such as liquids, powders and metal objects through pipes or tubes, the sensor can monitor for any clogs or blockages in the system. This allows for preventative maintenance or corrective action to be taken before a more serious problem occurs.

Blanking Detection

Blanking detection is a process where the sensor is programmed to ignore the detection of certain parts of a passing object, such as the edges or holes, while still detecting the overall presence of the object. This can be useful in applications where it is necessary to detect the presence of an object but not necessarily its specific features.

Bar Material Monitoring

Ring inductive sensors can be used to monitor the movement of bar materials in industrial processes such as metal fabrication or machining. By detecting the presence of the bar material, the sensor can control the flow of the production line and ensure that the material is being processed correctly.

Tiny Metal Object Detection

Ring inductive sensors are also useful for detecting small metal objects such as screws or bolts. By detecting the presence of these objects, the sensor can trigger the assembly process and ensure that each object is in the correct position before the assembly begins.

Position Monitoring

Ring inductive sensors can also be used to monitor the position of objects in industrial processes. By detecting the presence of an object at a specific location, the sensor can trigger the next process in the production line.

Spring Detection or Count

Ring inductive sensors can be used to detect the presence of springs in industrial processes such as automotive manufacturing. By detecting the presence of the spring, the sensor can trigger the assembly process and ensure that the spring is in the correct position before the assembly begins. The sensor can also be used to count the number of springs that have been processed.

Installation of Ring Proximity Sensor

Ring proximity sensors can be installed in a variety of ways depending on the specific application and the type of sensor being used. Here are some general guidelines for installing a ring proximity sensor:

Determine the mounting location: The sensor should be mounted in a location that allows it to detect the target object within the desired range. It's also important to ensure that the sensor is mounted securely and is protected from damage or interference.

Connect the sensor: The sensor should be connected to the appropriate power source and control device using the specified wiring connections.

Adjust the sensing distance: Depending on the specific sensor, it may be possible to adjust the sensing distance using potentiometers or other controls. This can help optimize the performance of the sensor for the specific application.

Are there any Limitations for Installation?

- Limited sensing range: Ring proximity sensors typically have a limited sensing range, which can make them unsuitable for applications where longer sensing distances are required.

- Limited target material compatibility: Some types of ring proximity sensors may be more sensitive to certain types of materials than others. For example, capacitive sensors may have difficulty detecting targets made of certain materials, such as glass or paper.

- Interference from other objects: Other objects in the environment, such as nearby machinery or electromagnetic fields, can interfere with the operation of ring proximity sensors, which can result in false readings or reduced performance.

- Sensitivity to temperature and humidity: Ring proximity sensors may be affected by changes in temperature and humidity, which can impact their performance and accuracy.

Overall, when selecting and installing a ring proximity sensor, it's important to carefully consider the specific application and any limitations or constraints that may impact the performance of the sensor.

What are the Pros & Cons of Ring Proximity Sensors?

Ring proximity sensors have several advantages and disadvantages that should be considered when choosing a sensor for a specific application. Here are some of the pros and cons of ring proximity sensors:

Advantages

- High accuracy: Ring proximity sensors can provide high levels of accuracy and precision in detecting the presence of objects. They can detect objects within a specific range, providing consistent and reliable results.

- Non-contact sensing: Ring proximity sensors do not require physical contact with the target object, which can reduce wear and tear on the sensor and the target object. This can also reduce the risk of damage to the sensor or the object being detected.

- Wide range of applications: Ring proximity sensors can be used in a wide range of applications, including automation, robotics, machine monitoring, and material handling. They can detect a variety of object types, including metallic and non-metallic objects.

- Low maintenance: Ring proximity sensors require little maintenance once installed, making them a cost-effective and reliable option for many industrial applications.

Disadvantages

- Limited range: Ring proximity sensors typically have a limited detection range, which can make them unsuitable for applications where longer sensing distances are required.

- Sensitivity to interference: Ring proximity sensors can be sensitive to interference from other objects in the environment, such as nearby machinery or electromagnetic fields. This can result in false readings or reduced performance.

- Limited target material compatibility: Some types of ring proximity sensors may have difficulty detecting targets made of certain materials, such as glass or paper.

- Temperature and humidity sensitivity: Ring proximity sensors can be sensitive to changes in temperature and humidity, which can impact their accuracy and performance.

- Cost: Ring proximity sensors can be more expensive than other types of sensors, especially when compared to simpler contact sensors.

Buying Guide: How to Choose a Ring Proximity Sensor?

When buying a ring proximity sensor, there are several factors to consider to ensure that the sensor is suitable for the specific application. Here is a buying guide with some key factors to consider:

Sensing technology: There are different types of ring proximity sensors, each using a different sensing technology, such as inductive, capacitive, or magnetic. Consider the target material to be detected and choose a sensor that is compatible with it.

Sensing range: Consider the sensing range required for the specific application. Ring proximity sensors can have a sensing range from a few millimeters up to several centimeters. Choose a sensor that has a sensing range that is appropriate for your application.

Output type: Ring proximity sensors can have either analog or digital output. Digital output sensors are easier to use and require less wiring but have a fixed output voltage. Analog output sensors provide a continuous output voltage proportional to the distance from the sensor to the target object.

Mounting style: Ring proximity sensors can be mounted in different ways, including flush mounting or non-flush mounting. Flush mounting sensors are mounted inside a hole and are suitable for applications where the sensor needs to be flush with the surface. Non-flush mounting sensors are mounted on the surface and are suitable for applications where the sensor needs to be exposed.

Operating conditions: Consider the operating conditions of the application, such as temperature, humidity, and the presence of electromagnetic interference. Choose a sensor that is suitable for the operating conditions of the application.

Quality and reliability: Consider the quality and reliability of the sensor, and choose a sensor from a reputable manufacturer that provides a warranty and customer support.

Cost: Consider the cost of the sensor, and choose a sensor that is within the budget for the application.

Conclusion

In summary, ring proximity sensors are an important type of sensor that can be used in various applications. They work based on electromagnetic fields, have a range of a few millimeters to several centimeters, and are easy to install and maintain.

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025