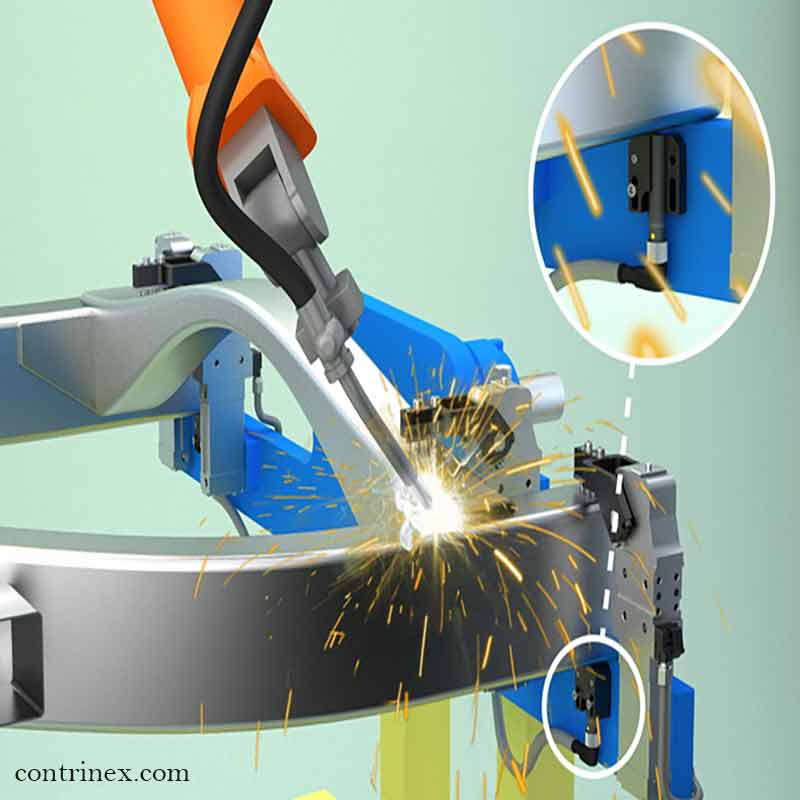

Miniature Inductive Sensors for Detecting Jaw Position for High Precision Robot Grippers

Gripper systems are designed for the manufacturing and assembly of small components in automation industry. Some Small-part grippers have steel jaws on which consumer adjustable cams are established for the accurate querying of position. Special sensors are needed to warrant most flexibility and reliability for end-users, especially concerning space constraints while mounting the grippers.

Miniature inductive sensors are suitable for this application. As the smallest self-contained inductive sensors available, they resolve even the most demanding end-consumer applications concerning space constraints and reliability. With a diameter of three mm, these miniature sensors are perfect for small grippers in restricted spaces. Thanks to completely integrated evaluation electronics, they may be simply as efficient as large sensors. High switching frequencies (as much as 5000 Hz) simply deal with the short cycle times of small-part gripper applications.

When established opposite the cam on the gripper jaw, these sensors define and transmits jaw position accurately. These sensors have a switching distance of 0.6 mm in steel and repeat accuracy of 0.01 mm which ensures accurate jaw position sensing and gripping point optimization. When the cam is within the switching range, an integral LED instantly shows this matter. The stainless steel housing is rated as IP67.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Related Products