From Lab to Industry: Pressure Sensing Diaphragm at Work

In a world pulsing with technology and innovation, there exists an unsung hero—often humble in appearance but indispensable in function—that quietly safeguards our safety, drives our industries, and empowers our modern way of life. Meet the Pressure Sensing Diaphragm, a remarkable invention that elegantly converts the invisible forces of pressure into tangible insights and measurements, revolutionizing everything from industrial automation to the depths of outer space. In this journey through the intricacies of pressure-sensing diaphragms, we'll uncover their hidden significance, unravel the science behind their operation, and explore the diverse applications where they play a pivotal role. So, fasten your seatbelts and prepare to dive into the world of pressure-sensing diaphragms—a world where precision meets innovation, and where the tiniest flex can lead to monumental impact.

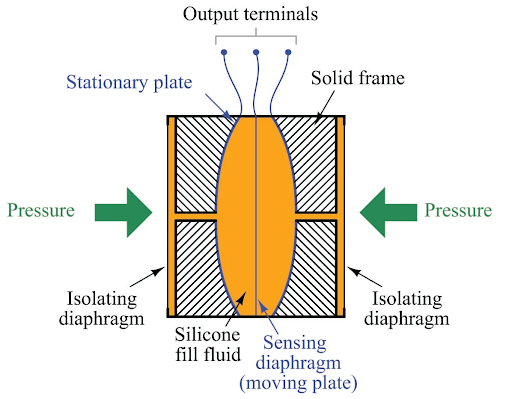

Fig 1. A diaphragm seal

What is a pressure transmitter?

A pressure transmitter is a specialized device used in industrial and commercial applications to measure, monitor, and transmit pressure data from a process or system to a control system, display, or other monitoring equipment. These transmitters are crucial in industries such as manufacturing, petrochemical, automotive, aerospace, and many others, where precise and reliable pressure measurements are essential for operational control and safety. Here are the key features and functions of a pressure transmitter:

- Pressure Sensing Element: The core component of a pressure transmitter is a pressure sensing element, often in the form of a diaphragm or a similar device. This sensing element deforms in response to changes in pressure, and this deformation is used to measure the applied pressure.

- Transduction: Pressure transmitters typically use one of several transduction methods to convert the mechanical deformation of the sensing element into an electrical signal. Common transduction methods include resistive (strain gauge), capacitive, or piezoelectric.

- Amplification and Signal Conditioning: The raw electrical signal generated by the pressure-sensing element is often very weak. Pressure transmitters include built-in amplification and signal conditioning circuitry to strengthen and refine the signal, making it suitable for transmission and processing.

- Output Signals: Pressure transmitters provide standardized electrical output signals that can be easily interfaced with control systems and data acquisition equipment. Common output signals include 4-20 mA current loops and 0-10 VDC voltage signals. Digital communication protocols such as HART (Highway Addressable Remote Transducer) or MODBUS may also be supported in advanced transmitters.

- Accuracy and Calibration: Pressure transmitters are calibrated during manufacturing to ensure accuracy. However, periodic calibration may be required to maintain accuracy over time. Calibration involves comparing the transmitter's output to a known standard and making adjustments as necessary.

- Pressure Range: Pressure transmitters are available in a wide range of pressure ratings to accommodate various applications, from very low pressures (e.g., vacuum measurements) to extremely high pressures (e.g., hydraulic systems).

- Environmental Considerations: Many pressure transmitters are designed to operate in harsh environments, with features such as corrosion-resistant materials, sealing to prevent dust and moisture ingress, and temperature compensation.

- Mounting Options: Pressure transmitters can be installed directly in the process or system being measured. They often come with various mounting options, such as threaded, flanged, or flush diaphragm designs, to suit different installation requirements.

- Applications: Pressure transmitters are used in a wide range of applications, including monitoring and controlling processes in manufacturing, measuring fluid levels in tanks, monitoring gas and liquid pressures in pipelines, and ensuring safety in industrial equipment such as boilers and pressure vessels.

- Remote Monitoring: Pressure transmitters are often used in conjunction with data acquisition systems, SCADA (Supervisory Control and Data Acquisition) systems, or PLCs (Programmable Logic Controllers) to enable remote monitoring and control of pressure-related processes.

In summary, pressure transmitters are essential instruments for accurate and reliable pressure measurement and control in industrial and commercial settings. They play a crucial role in ensuring the safe and efficient operation of various processes and systems.

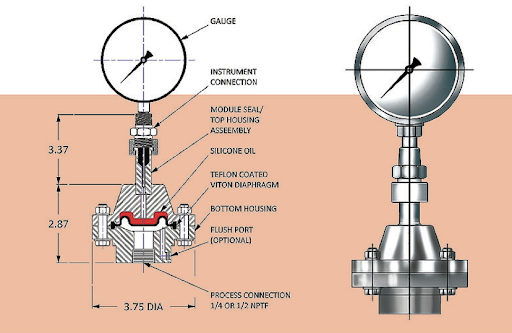

What are the pressure transmitter's internal parts?

A pressure transmitter consists of several internal parts that work together to measure the pressure of a fluid and convert it into an electrical signal. The exact internal components can vary based on the design and manufacturer of the transmitter, but here are the common internal parts you might find in a pressure transmitter:

- Pressure Sensor: This is the core component that directly interacts with the fluid's pressure. Different types of pressure sensors can be used, including strain gauge, piezoelectric, capacitive, and resonant sensors. The sensor's mechanical deformation or electrical response due to pressure changes is the foundation of pressure measurement.

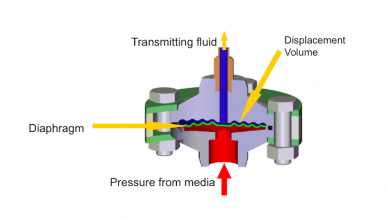

- Diaphragm: In many pressure transmitters, a diaphragm is used to transmit the pressure from the fluid to the pressure sensor. The diaphragm is a flexible membrane that deforms in response to pressure variations. It acts as the interface between the liquid and the pressure sensor, allowing the pressure to be accurately transmitted while isolating the sensor from the fluid.

- Transducer: The pressure sensor's mechanical response or electrical signal needs to be transformed into a usable electrical signal for output. The transducer converts this signal and often includes components like strain gauges, piezoelectric crystals, or other mechanisms that respond to the sensor's input.

- Signal Conditioning Circuitry: This circuitry processes and conditions the raw signal from the transducer to improve accuracy, and stability, and compensate for environmental factors. It might involve amplification, filtering, and temperature compensation to ensure the output signal accurately represents the pressure being measured.

- Output Electronics: These electronics convert the conditioned signal into a standardized output signal. This can be an analog signal like a 4-20 mA current loop or a 0-10 V voltage, or a digital signal using protocols like MODBUS, HART, Profibus, etc.

- Microcontroller/Processor: Many modern pressure transmitters include a microcontroller or processor that manages the signal processing, calibration, and communication with external devices. It can also implement various algorithms for temperature compensation, linearity correction, and other advanced features.

- Enclosure: The internal components are housed within a protective enclosure. The enclosure shields the sensitive parts from environmental factors and provides mechanical protection. It usually has ports for fluid connection and mounting options for installation.

- Calibration Components: Pressure transmitters require calibration to ensure accurate measurement. Calibration components, such as trim pots or digital calibration circuits, are often present to allow adjustments to the sensor's output signal to match the actual pressure.

- Power Supply Components: Pressure transmitters require a power supply to operate. Internal components related to power supply regulation and distribution may be present to ensure the transmitter receives stable and appropriate power.

It's important to note that the specific design and components can vary among different pressure transmitter models and manufacturers. The goal of these internal parts is to accurately measure pressure, condition the signal, and provide a reliable output for integration into various industrial processes and control systems.

What is a Pressure Sensing Diaphragm?

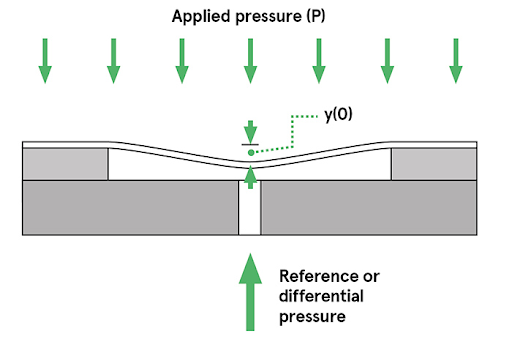

A pressure-sensing diaphragm is a key component in pressure sensors and transducers used to measure and monitor pressure in various industrial, automotive, medical, and consumer applications. The diaphragm is a thin, flexible membrane that deforms or deflects when exposed to changes in pressure. This deformation is then converted into an electrical signal that can be measured and interpreted to determine the pressure being applied.

Here's how a pressure-sensing diaphragm typically works:

- Diaphragm Material: The diaphragm is usually made of materials like silicon, stainless steel, or other flexible materials with good mechanical properties. The choice of material depends on factors like the pressure range, compatibility with the media (liquids or gases), and temperature range of the application.

- Pressure Application: When pressure is applied to one side of the diaphragm (the sensing side), it causes the diaphragm to deflect or deform. The amount of deformation is directly proportional to the pressure being applied.

- Strain Measurement: Strain gauges or piezoresistive elements are often bonded to the diaphragm's surface. As the diaphragm deforms, the resistance of these elements changes. This change in resistance is proportional to the strain on the diaphragm, which, in turn, is proportional to the applied pressure.

- Electrical Output: The change in resistance is converted into an electrical signal, usually a voltage or current signal. This electrical signal is then transmitted to signal conditioning and processing circuitry.

- Pressure Measurement: The processed electrical signal is finally converted into a pressure reading that can be displayed, recorded, or used for control purposes.

Pressure-sensing diaphragms are used in a wide range of applications, such as measuring blood pressure in medical devices, monitoring tire pressure in automotive systems, controlling industrial processes, and measuring fluid levels in tanks and pipelines. They are chosen based on factors like the required pressure range, sensitivity, accuracy, and environmental conditions in which they will operate.

Different types of pressure-sensing diaphragms and sensor designs exist to cater to various applications, including absolute pressure sensors, gauge pressure sensors, and differential pressure sensors, each designed to measure pressure relative to different reference points or conditions.

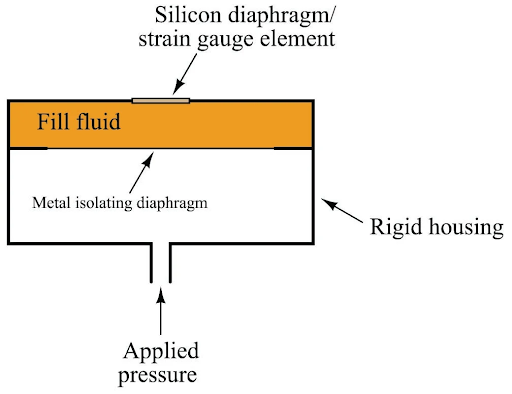

Fig 2. Cross-section of a pressure sensing diaphragm deflection under applied pressure

What is the role of a pressure-sensing diaphragm in pressure measurement?

The role of a pressure-sensing diaphragm in pressure measurement is pivotal. It serves as the primary sensing element within pressure sensors and transducers, and its purpose is to convert mechanical pressure into an electrical signal that can be measured and interpreted. Here's a detailed explanation of its role in pressure measurement:

- Pressure Sensing: The primary function of the diaphragm is to sense or respond to changes in pressure. When pressure is applied to one side of the diaphragm (the sensing side), it undergoes deformation or deflection. The extent of this deformation is proportional to the applied pressure. The diaphragm's material and design are chosen to ensure it can reliably and accurately respond to pressure changes within a specified range.

- Strain Generation: As the diaphragm deflects in response to pressure, it experiences strain or mechanical stress. In many pressure-sensing diaphragms, strain gauges or piezoresistive elements are bonded or integrated onto the diaphragm's surface. These elements change their electrical resistance in response to mechanical strain. The strain generated in the diaphragm directly correlates with the applied pressure.

- Signal Conversion: The change in resistance of the strain gauges or piezoresistive elements on the diaphragm is converted into an electrical signal. This signal can be in the form of voltage, current, or other electrical parameters, depending on the sensor design.

- Signal Processing: The electrical signal generated by the diaphragm is then processed using signal conditioning circuitry. This may involve amplification, filtering, and linearization to ensure accurate and consistent pressure measurements.

- Pressure Measurement: After signal processing, the electrical signal is interpreted to determine the pressure being applied to the diaphragm. Calibration and compensation techniques may also be applied to account for factors like temperature variations, hysteresis, and non-linearity, thus enhancing the accuracy of pressure measurements.

- Output: The final pressure measurement can be displayed on a digital or analog readout, transmitted to a control system for automated processes, or recorded for further analysis or monitoring.

In summary, a pressure-sensing diaphragm plays a crucial role in pressure measurement by converting mechanical pressure into an electrical signal that can be easily quantified and utilized for various purposes, including monitoring, control, and data analysis in a wide range of applications across different industries. The diaphragm's material, design, and sensitivity are carefully chosen to ensure accurate and reliable pressure measurements within a specific operating range.

How is the structure of the Pressure Sensing Diaphragm?

The structure of a pressure-sensing diaphragm can vary depending on its intended application, pressure range, and the materials used. However, in general, pressure-sensing diaphragms have a common structural design consisting of several key elements:

- Diaphragm Material: Pressure-sensing diaphragms are typically made of materials that are both flexible and mechanically robust. Common materials include:

- Silicon: Silicon diaphragms are widely used in microelectromechanical systems (MEMS) pressure sensors due to their excellent mechanical properties and compatibility with integrated circuit manufacturing processes.

- Stainless Steel: Stainless steel diaphragms are known for their durability and resistance to corrosion. They are often used in industrial and high-pressure applications.

- Polymer: Certain polymers can be used for diaphragms in applications where flexibility and chemical resistance are important.

- Diaphragm Shape: Diaphragms are usually circular or disc-shaped, but their exact shape can vary depending on the sensor's design and requirements. The diaphragm's shape affects its sensitivity and response to pressure.

- Sensing Elements: Strain gauges or piezoresistive elements are commonly bonded or integrated onto the surface of the diaphragm. These elements change their electrical resistance in response to mechanical strain, allowing the diaphragm to convert pressure-induced deformation into an electrical signal.

- Support Structure: The diaphragm is often supported by a rigid structure around its edges to ensure it can withstand the applied pressure without collapsing or rupturing. The support structure also helps maintain the diaphragm's shape.

- Sealing and Connections: Depending on the application, pressure-sensing diaphragms may have sealing mechanisms to prevent the ingress of liquids or gases into the sensor housing. They are also equipped with electrical connections to facilitate the transmission of the electrical signal generated by the sensing elements.

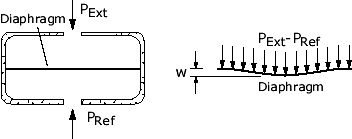

- Venting and References: Some diaphragms are designed with vent holes or ports to equalize pressure on both sides of the diaphragm or to reference the pressure to a specific point, such as atmospheric pressure in gauge pressure sensors.

- Protective Layers: In some cases, the diaphragm may have protective layers or coatings to enhance its resistance to environmental factors, such as moisture, chemicals, or abrasive materials.

The specific design and materials used for a pressure-sensing diaphragm depend on the application's requirements, including the pressure range, temperature range, sensitivity, and compatibility with the measured media (liquid or gas). Microfabrication techniques are often employed for manufacturing diaphragms used in MEMS pressure sensors, allowing for precise control over their dimensions and properties. These diaphragms are typically very small in size, making them suitable for compact and sensitive pressure-sensing applications.

Fig 3. A diaphragm seal

Design variations of Pressure Sensing Diaphragm

Pressure sensing diaphragms can vary in design to meet specific requirements and address different application needs. These design variations can include changes in diaphragm shape, size, configuration, and additional features. Here are some common design variations of pressure-sensing diaphragms:

- Circular Diaphragms: Circular diaphragms are the most common and straightforward shape. They are often used in applications where pressure is applied evenly from all directions.

- Square or Rectangular Diaphragms: These diaphragms are used when the pressure source or the sensor housing has a square or rectangular shape.

- Custom Shapes: Diaphragms can be designed in custom shapes to fit specific applications, such as irregularly shaped pressure vessels.

- Miniature Diaphragms: Miniaturized diaphragms are designed for applications with limited space or when a compact sensor is required, such as in consumer electronics.

- Large Diaphragms: In some industrial applications, larger diaphragms may be used to distribute pressure over a broader area for improved accuracy.

- Thin Diaphragms: Thin diaphragms are used when high sensitivity is required. They deform more readily under pressure.

- Thick Diaphragms: Thicker diaphragms may be employed in applications where ruggedness and durability are essential, especially in high-pressure environments.

- Corrugated diaphragms feature a series of ridges or convolutions, providing increased flexibility and sensitivity to pressure variations.

- Convex diaphragms have a slight dome shape, enhancing their mechanical strength and resistance to overpressure.

- Bellows diaphragms consist of interconnected accordion-like bellows, offering extreme sensitivity and flexibility.

- Some diaphragms may include integrated features like vent holes for pressure equalization, reference ports, or coatings to enhance their performance in specific applications.

- Certain sensors use multiple diaphragms to measure differential pressure. These diaphragms are arranged to sense the pressure difference between two points.

- Diaphragms can be made from various materials, including silicon, stainless steel, ceramics, polymers, and more, depending on the application's requirements for material properties like strength, corrosion resistance, and temperature tolerance.

- Hygienic diaphragms and flush diaphragms are designed to meet specific cleanliness requirements in industries like food processing and pharmaceuticals. They feature smooth, easy-to-clean surfaces to prevent contamination.

- These diaphragms use piezoelectric materials to generate electrical charges in response to mechanical deformation. They are designed for high-frequency and dynamic pressure measurement applications.

- Diaphragms may be coated with materials such as PTFE (Teflon) to enhance chemical resistance or protect against abrasion or wear.

- Some diaphragms may have integrated support structures or frames to maintain their shape and prevent excessive deformation.

Shape

Size

Thickness

Corrugated or Convex Diaphragms

Bellows Diaphragms

Integrated Features:

Multiple Diaphragms:

Material Selection:

Hygienic and Flush Diaphragms:

Piezoelectric Diaphragms:

Coatings and Protective Layers:

Mechanical Support Structures:

Fig 4. A differential capacitance sensor

How does various design affect Pressure-Sensing Diaphragm performance?

The design of a pressure-sensing diaphragm has a significant impact on its performance in terms of sensitivity, accuracy, durability, and suitability for specific applications. Different design variations can influence the diaphragm's behavior and its ability to accurately measure pressure. Here's how various design elements can affect pressure-sensing diaphragm performance:

- Shape:

- Circular Diaphragms: Circular diaphragms are versatile and provide uniform pressure distribution. They are commonly used and offer good sensitivity and accuracy.

- Square or Rectangular Diaphragms: These diaphragms are suitable for applications with non-circular pressure sources or sensor housings. They may have slightly different stress distributions compared to circular diaphragms.

- Custom Shapes: Custom-shaped diaphragms are tailored to fit specific applications. Their performance depends on how well the shape matches the pressure distribution in the application.

- Size:

- Miniature Diaphragms: Miniaturized diaphragms are suitable for compact applications but may sacrifice some sensitivity compared to larger diaphragms.

- Large Diaphragms: Larger diaphragms can provide better accuracy due to their increased surface area but may require more space and may be less sensitive to subtle pressure changes.

- Thickness:

- Thin Diaphragms: Thin diaphragms are highly sensitive and respond quickly to pressure changes. However, they may be more susceptible to damage or deformation at high pressures.

- Thick Diaphragms: Thick diaphragms are more robust and can handle higher pressures, but they may be less sensitive to small pressure variations.

- Corrugated or Convex Diaphragms:

- Corrugated diaphragms and convex diaphragms offer increased flexibility and sensitivity, making them suitable for applications where rapid response to pressure fluctuations is critical.

- Bellows Diaphragms:

- Bellows diaphragms are highly sensitive and provide excellent accuracy, especially for low-pressure measurements.

- Integrated Features:

- Features like vent holes, reference ports, or coatings can enhance the diaphragm's performance in specific applications by improving pressure equalization, preventing contamination, or increasing chemical resistance.

- Multiple Diaphragms:

- Multiple diaphragms in a sensor can provide accurate differential pressure measurements. The design of how these diaphragms are arranged and interconnected affects the sensor's performance.

- Material Selection:

- The choice of diaphragm material impacts its performance in terms of strength, corrosion resistance, temperature tolerance, and compatibility with the measured medium. Different materials have varying characteristics that suit specific applications.

- Hygienic and Flush Diaphragms:

- Hygienic and flush diaphragms are designed to meet stringent cleanliness requirements in specific industries. Their design ensures they can be easily cleaned and sterilized.

- Piezoelectric Diaphragms:

- Piezoelectric diaphragms are ideal for high-frequency and dynamic pressure measurements, offering rapid response and high sensitivity.

- Coatings and Protective Layers:

- Coatings can enhance the diaphragm's performance by protecting it from chemical attack, abrasion, or wear.

- Mechanical Support Structures:

- Support structures help maintain the diaphragm's shape under pressure, preventing excessive deformation that could affect accuracy.

In summary, the design of a pressure-sensing diaphragm directly affects its performance characteristics. Engineers and designers must carefully consider these design elements and tailor the diaphragm to the specific requirements of the application to ensure accurate and reliable pressure measurements. The choice of design variation depends on factors like pressure range, sensitivity, temperature range, and the environmental conditions in which the sensor will operate.

What are the materials used in a Pressure Sensing Diaphragm?

Pressure-sensing diaphragms are made from various materials, and the choice of material depends on the specific application, including factors like the pressure range, compatibility with the measured medium, temperature conditions, and cost considerations. Here are some common materials used in pressure sensing diaphragms:

- Silicon (Si):

Description: Silicon diaphragms are often used in microelectromechanical systems (MEMS) pressure sensors due to their excellent mechanical properties and compatibility with integrated circuit manufacturing processes.

Advantages: High sensitivity, suitable for miniaturization, good mechanical strength, and excellent repeatability.

Applications: Consumer electronics, automotive sensors, medical devices, and industrial applications.

- Stainless Steel:

Description: Stainless steel is a popular material for pressure diaphragms, especially in industrial applications, where durability and resistance to corrosion are essential.

Advantages: High strength, corrosion resistance, suitable for high-pressure and harsh environments.

Applications: Industrial pressure transmitters, hydraulic systems, and pressure gauges.

- Polymer (Plastics):

Description: Certain polymers can be used as diaphragm materials, offering flexibility and resistance to certain chemicals.

Advantages: Lightweight, cost-effective, suitable for applications with chemical compatibility requirements.

Applications: Some medical devices, chemical processing, and applications where weight is a concern.

- Ceramics:

Description: Ceramic diaphragms are known for their high-temperature resistance and compatibility with aggressive chemicals.

Advantages: Excellent resistance to high temperatures and chemicals, suitable for extreme conditions.

Applications: High-temperature and chemical environments, such as in the petrochemical industry.

- Aluminum:

Description: Aluminum diaphragms are lightweight and can be used in applications where weight and sensitivity are critical.

Advantages: Lightweight, good thermal conductivity, suitable for high-sensitivity applications.

Applications: Aerospace, automotive, and precision instruments.

- Tantalum:

Description: Tantalum is a corrosion-resistant metal used in specialized applications where extreme durability and resistance to aggressive chemicals are required.

Advantages: Excellent resistance to corrosion and aggressive media, suitable for demanding environments.

Applications: Chemical processing, nuclear industry, and high-pressure applications.

- Nickel Alloys:

Description: Nickel alloys, such as Inconel, offer a balance of strength, corrosion resistance, and temperature resistance.

Advantages: Good resistance to high temperatures and corrosion, suitable for challenging conditions.

Applications: Aerospace, oil and gas, and high-temperature industrial applications.

- Piezoelectric Materials:

Description: In some specialized applications, piezoelectric materials are used to create diaphragms that generate electrical charges when subjected to mechanical deformation.

Advantages: High sensitivity, suitable for dynamic pressure measurements.

Applications: Acoustic sensors, shock wave monitoring, and applications requiring rapid response.

Fig 5. A simplified illustration of a diaphragm sensor

How does a Pressure Sensing Diaphragm work in a pressure transmitter?

A pressure-sensing diaphragm in a pressure transmitter works by converting applied mechanical pressure into an electrical signal that can be transmitted and interpreted to determine the pressure being measured. Pressure transmitters are commonly used in industrial and process control applications to provide accurate and continuous pressure readings. Here's how a pressure-sensing diaphragm functions within a pressure transmitter:

- Pressure Application: The pressure transmitter is installed in a location where pressure needs to be measured. This could be in a pipeline, tank, or any environment where pressure changes occur. The diaphragm is exposed to the pressure of the medium (gas or liquid) being measured.

- Diaphragm Deformation: When pressure is applied to one side of the diaphragm (the sensing side), it causes the diaphragm to deform or deflect. The amount of deflection is directly proportional to the pressure being applied. The diaphragm's material and design are chosen to ensure it can accurately respond to pressure changes within the specified range.

- Sensing Elements: Strain gauges or piezoresistive elements are typically bonded or integrated onto the surface of the diaphragm. These elements change their electrical resistance in response to the mechanical strain experienced by the diaphragm. As the diaphragm deflects under pressure, it generates mechanical strain in the sensing elements.

- Electrical Signal Generation: The change in resistance of the strain gauges or piezoresistive elements is converted into an electrical signal. This signal is typically a change in voltage or current and is directly proportional to the pressure-induced strain on the diaphragm.

- Signal Conditioning: The electrical signal generated by the diaphragm is often quite small and may be affected by temperature variations and other factors. Therefore, the signal is conditioned using electronics within the pressure transmitter. This may include amplification, filtering, and compensation for temperature effects to ensure accuracy and stability.

- Output: The conditioned electrical signal is then sent to the output stage of the pressure transmitter. The output can be in the form of a standardized current signal (such as 4-20 mA), a voltage signal, or a digital communication protocol (e.g., HART, Profibus, or Foundation Fieldbus).

- Pressure Measurement: The receiver or control system connected to the pressure transmitter interprets the electrical signal to determine the pressure being applied to the diaphragm. The pressure transmitter may also provide additional information, such as temperature compensation data or diagnostics, depending on its capabilities.

- Display and Communication: Some pressure transmitters feature built-in displays to show pressure readings locally. Additionally, they can communicate with control systems, data loggers, or SCADA (Supervisory Control and Data Acquisition) systems to provide real-time pressure data for monitoring and control.

In summary, a pressure-sensing diaphragm in a pressure transmitter serves as the core sensing element that responds to applied pressure, converts this mechanical response into an electrical signal through strain gauges or piezoresistive elements, and then transmits this signal for further processing and interpretation. This allows for precise and continuous measurement of pressure in industrial and process control applications.

How many types does a Pressure Sensing Diaphragm have?

Pressure-sensing diaphragms come in various types and designs to suit different pressure measurement applications. The choice of diaphragm type depends on factors such as the pressure range, the medium being measured (liquid or gas), the required accuracy, and the environmental conditions. Here are some common types of pressure-sensing diaphragms:

- Flat Diaphragm: Flat diaphragms are simple, flat, and typically circular diaphragms. They are often used in low-pressure applications where a larger surface area is needed for accurate measurement. They are relatively easy to manufacture and are suitable for applications like HVAC (Heating, Ventilation, and Air Conditioning) systems.

- Corrugated Diaphragm: Corrugated diaphragms have a corrugated or convoluted shape, which allows for greater flexibility and deformation under pressure. They are commonly used in applications where the pressure ranges from low to moderate. Corrugated diaphragms are often found in pressure switches and control devices.

- Bellows Diaphragm: Bellows diaphragms consist of a series of interconnected bellows, which are accordion-like structures that expand and contract under pressure. They are suitable for applications requiring high sensitivity and can handle both low and moderate pressure ranges. Bellows diaphragms are used in instruments like barometers and some pressure gauges.

- Capsule Diaphragm: Capsule diaphragms consist of two diaphragms welded together at their edges to form a sealed, flexible capsule. These diaphragms are highly sensitive and can measure very low pressures accurately. They are often used in precision instruments such as aneroid barometers and some types of pressure switches.

- Membrane Diaphragm: Membrane diaphragms are commonly used in microelectromechanical systems (MEMS) pressure sensors. They are thin and flexible, making them suitable for applications where space is limited, and high sensitivity is required. Silicon is a common material for membrane diaphragms in MEMS sensors.

- Differential Diaphragm: Differential diaphragms have two sensing elements separated by a diaphragm. The pressure difference between the two elements provides a measurement of differential pressure. These diaphragms are used in applications where it's necessary to measure the pressure drop across a filter, flow restriction, or other components.

- Flush Diaphragm: Flush diaphragms are designed to have a flat, flush surface that comes into direct contact with the medium being measured. They are used in applications where hygiene and cleanliness are essential, such as in the food and pharmaceutical industries. The flush surface prevents debris or contaminants from getting trapped.

- Hygienic Diaphragm: Similar to flush diaphragms, hygienic diaphragms are designed for sanitary applications. They have a design that facilitates easy cleaning and sterilization, making them suitable for use in the biopharmaceutical and food processing industries.

- Piezoelectric Diaphragm: In some specialized applications, piezoelectric materials are used to create diaphragms. These materials generate an electrical charge when subjected to mechanical deformation. Piezoelectric diaphragms are used in certain high-frequency and dynamic pressure measurement applications.

These are just a few examples of the types of pressure-sensing diaphragms available. The choice of diaphragm type depends on the specific requirements of the pressure measurement application, including the pressure range, accuracy, sensitivity, and environmental conditions in which the sensor will operate.

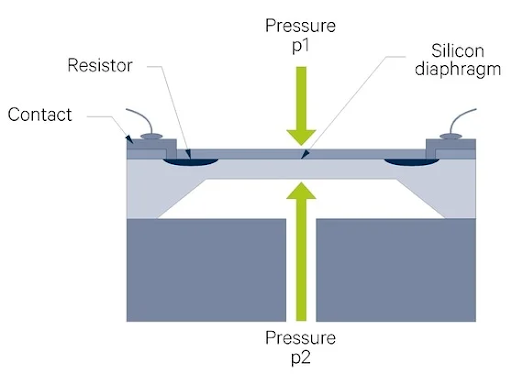

Fig 6. Basic design of a piezoresistive differential pressure sensors

- Description: Flat diaphragms are simple, flat, and circular, providing a large surface area.

- Operation: They deform uniformly when pressure is applied, with the degree of deformation directly proportional to the pressure.

- Applications: Commonly used in low-pressure applications like HVAC systems, industrial pressure switches, and some types of pressure gauges.

- Pros: Simple design, suitable for low-pressure applications.

- Cons: Limited sensitivity for high-pressure ranges.

- Description: Corrugated diaphragms have a convoluted or corrugated shape, offering flexibility and deformation under pressure.

- Operation: They flex and deform to accommodate pressure changes, making them suitable for moderate-pressure applications.

- Applications: Used in pressure switches, control devices, and some pressure transducers.

- Pros: More flexible than flat diaphragms, suitable for moderate pressures.

- Cons: Limited sensitivity for very high or very low pressures.

- Description: Bellows diaphragms consist of interconnected bellows, providing high sensitivity and flexibility.

- Operation: The bellows expand and contract under pressure changes, making them highly sensitive to pressure variations.

- Applications: Used in precision instruments like barometers, manometers, and some pressure switches.

- Pros: High sensitivity, suitable for low to moderate pressures.

- Cons: Limited to specific precision applications.

- Description: Capsule diaphragms are formed by welding two diaphragms together to create a sealed, flexible capsule.

- Operation: They offer high sensitivity and can measure very low pressures accurately.

- Applications: Found in aneroid barometers, sensitive pressure switches, and some vacuum measurement devices.

- Pros: Extremely sensitive, suitable for low-pressure applications.

- Cons: Limited to specific precision and low-pressure applications.

- Description: Membrane diaphragms are thin, flexible, and typically used in MEMS pressure sensors.

- Operation: They deform under pressure, with silicon being a common material in MEMS sensors.

- Applications: Utilized in compact and sensitive pressure sensors, such as those used in consumer electronics and automotive applications.

- Pros: Compact, highly sensitive, and suitable for space-constrained applications.

- Cons: Limited to specific MEMS sensor applications.

- Description: Differential diaphragms have two sensing elements separated by a diaphragm to measure pressure differences.

- Operation: Measures the pressure difference between two sides of the diaphragm.

- Applications: Used in applications where differential pressure measurements are required, such as flow rate measurement or filter monitoring.

- Pros: Suitable for differential pressure measurements, and provides insights into system behavior.

- Cons: Not ideal for absolute pressure measurements.

- Description: Flush diaphragms have a flat, flush surface for direct contact with the medium, ideal for sanitary applications.

- Operation: Respond to pressure changes, providing accurate measurements in hygienic environments.

- Applications: Commonly used in food and pharmaceutical industries, as well as cleanroom applications.

- Pros: Easy to clean and sanitize, minimizes contamination risk.

- Cons: Limited to specific sanitary applications.

- Description: Similar to flush diaphragms, designed for sanitary applications, and equipped with features to facilitate cleaning and sterilization.

- Operation: Respond to pressure changes in hygienic environments.

- Applications: Widely used in biopharmaceutical and food processing industries.

- Pros: Designed for easy cleaning and sterilization, minimizes contamination risk.

- Cons: Limited to specific sanitary applications.

- Description: Piezoelectric diaphragms use piezoelectric materials to generate electrical charges in response to mechanical deformation.

- Operation: Mechanical deformation generates electrical charges, offering high-frequency response and dynamic pressure measurements.

- Applications: Used in high-frequency and dynamic pressure measurement applications, such as acoustic sensors and shock wave monitoring.

- Pros: High sensitivity, suitable for dynamic pressure measurements.

- Cons: Limited to specific high-frequency applications and may require external power.

Flat Diaphragm:

Corrugated Diaphragm:

Bellows Diaphragm:

Capsule Diaphragm:

Membrane Diaphragm:

Differential Diaphragm:

Flush Diaphragm:

Hygienic Diaphragm:

Piezoelectric Diaphragm:

Each type of pressure-sensing diaphragm has its unique characteristics, advantages, and limitations. Choosing the right diaphragm type depends on the specific requirements of the pressure measurement application, including pressure range, sensitivity, accuracy, and environmental conditions. It's essential to select the most appropriate diaphragm type to ensure accurate and reliable pressure measurements in a given application.

Comparing table

Here's a comparative table summarizing the different types of pressure-sensing diaphragms, including their descriptions, operations, common applications, and pros and cons:

| Type of Diaphragm | Description | Operation | Common Applications | Pros | Cons |

| Flat Diaphragm | Simple, flat, circular | Uniform deformation under pressure | HVAC systems, industrial pressure switches, gauges | Simple design, suitable for low-pressure applications | Limited sensitivity for high-pressure ranges |

| Corrugated Diaphragm | Convex, flexible | Flexes and deforms under pressure changes | Pressure switches, control devices, some transducers | More flexible than flat diaphragms, moderate pressures | Limited sensitivity for very high or very low pressures |

| Bellows Diaphragm | Interconnected bellows | Expands and contracts under pressure variations | Barometers, manometers, some pressure switches | High sensitivity, suitable for low to moderate pressures | Limited to specific precision applications |

| Capsule Diaphragm | Two diaphragms welded | High sensitivity for measuring low pressures | Aneroid barometers, sensitive pressure switches | Extremely sensitive, suitable for low-pressure apps | Limited to specific precision and low-pressure apps |

| Membrane Diaphragm | Thin, flexible, often MEMS | Deforms under pressure, commonly silicon-based | Consumer electronics, automotive pressure sensors | Compact, highly sensitive, suitable for limited spaces | Limited to specific MEMS sensor applications |

| Differential Diaphragm | Two sensing elements | Measures pressure difference between two sides | Flow rate measurement, filter monitoring | Suitable for differential pressure, insights into systems | Not ideal for absolute pressure measurements |

| Flush Diaphragm | Flat, flush surface | Direct contact with medium, ideal for hygienic areas | Food, pharmaceutical industries, cleanrooms | Easy to clean and sanitize, minimizes contamination risk | Limited to specific sanitary applications |

| Hygienic Diaphragm | Sanitary design | Designed for cleanliness, facilitates cleaning/sterilization | Biopharmaceutical, food processing industries | Designed for easy cleaning and sterilization | Limited to specific sanitary applications |

| Piezoelectric Diaphragm | Piezoelectric materials | Generates electrical charges in response to deformation | Acoustic sensors, shock wave monitoring | High sensitivity, suitable for dynamic pressure measurements | Limited to high-frequency applications, external power may be needed |

This table provides a concise overview of the different types of pressure sensing diaphragms, highlighting their characteristics and typical use cases. When selecting a diaphragm type for a specific pressure measurement application, it's important to consider the requirements and constraints of the application to ensure accurate and reliable results.

What are pressure-sensing diaphragm applications?

Pressure-sensing diaphragms find applications in a wide range of industries and fields due to their ability to accurately measure pressure in various environments and under different conditions. Some common applications of pressure-sensing diaphragms include

- Industrial Automation:

Pressure-sensing diaphragms are used in industrial automation for tasks like monitoring hydraulic and pneumatic systems, controlling manufacturing processes, and ensuring the proper functioning of machinery.

- Aerospace:

Aircraft and spacecraft use pressure-sensing diaphragms in systems like altitude measurement, cabin pressure control, and fuel pressure monitoring.

- Automotive:

In vehicles, diaphragms are used for measuring manifold pressure in engines, monitoring tire pressure, and controlling airbag deployment.

- HVAC (Heating, Ventilation, and Air Conditioning):

Diaphragms are employed in HVAC systems to measure and control air pressure, ensure efficient ventilation, and maintain temperature and humidity levels.

- Medical Devices:

Pressure sensors with diaphragms are used in medical devices like blood pressure monitors, ventilators, and anesthesia machines to ensure precise pressure control and monitoring.

- Oil and Gas:

Pressure sensing diaphragms are essential in the oil and gas industry for wellhead pressure monitoring, pipeline pressure control, and reservoir pressure measurement.

- Pharmaceuticals:

Pharmaceutical manufacturing relies on pressure sensors for processes like filtration, fermentation, and chemical reactions, where pressure control is crucial.

- Food Processing:

Pressure sensing diaphragms play a role in food processing to monitor pressure in tanks, control filling and packaging operations, and maintain hygiene standards.

- Water and Wastewater Treatment:

Diaphragms are used in water treatment facilities to monitor and control water pressure, ensuring proper treatment and distribution.

- Environmental Monitoring:

Pressure sensors with diaphragms are used in weather stations, barometers, and environmental monitoring systems to measure atmospheric pressure and monitor weather conditions.

- Hydraulics and Pneumatics:

Diaphragms are widely used in hydraulic and pneumatic systems to monitor fluid or gas pressure, control actuators, and ensure system safety.

- Laboratory and Research:

Pressure sensing diaphragms are used in laboratory equipment, research instruments, and experiments where precise pressure control and measurement are critical.

- Chemical Processing:

Chemical plants use pressure sensors with diaphragms to monitor and control pressure in reactors, distillation columns, and other equipment.

- Biotechnology:

Pressure sensing diaphragms are used in bioreactors, chromatography systems, and cell culture processes to monitor and control pressure during bioprocessing.

- Renewable Energy:

In renewable energy applications, such as wind turbines and solar panel systems, diaphragms can be used for monitoring hydraulic systems, air pressure, and gas flow.

- Safety Systems:

Pressure sensing diaphragms are employed in safety systems like pressure relief valves, fire suppression systems, and gas leak detectors to ensure safe operating conditions.

- Aviation:

Diaphragms are used in aircraft systems to measure and control cabin pressure, airspeed, and altitudes.

- Marine:

In marine applications, pressure sensors with diaphragms are used to monitor water pressure, control ballast tanks, and ensure the safety and efficiency of maritime operations.

These are just a few examples of the diverse range of applications for pressure sensing diaphragms. They are essential components in various industries where accurate and reliable pressure measurement and control are crucial for operational efficiency, safety, and product quality.

Fig 7. Differential diaphragm

Installation and Maintenance

How can use the Pressure Sensing Diaphragm?

Using a pressure-sensing diaphragm involves integrating it into a measurement or control system to accurately monitor or control pressure in a specific application. Here are the general steps to use a pressure-sensing diaphragm effectively:

- Select the Appropriate Diaphragm Type:

Choose the pressure-sensing diaphragm type that best matches your application's requirements, considering factors like pressure range, sensitivity, temperature conditions, and compatibility with the measured medium.

- Ensure Proper Installation:

Install the pressure-sensing diaphragm in the desired location within your system, ensuring that it is securely mounted and sealed if necessary to prevent leaks. The diaphragm should be exposed to the pressure source being measured.

- Connect Electrical Leads:

If your pressure-sensing diaphragm incorporates strain gauges or piezoresistive elements, connect the electrical leads from the diaphragm to your measurement or control instrumentation. Ensure proper wiring connections and consider the electrical signal type (voltage, current, or digital) that the diaphragm generates.

- Calibration and Zeroing:

Calibrate the pressure sensor if required by the manufacturer or as part of your system setup. Calibration ensures accurate measurements and can be done using known pressure standards.

Zeroing or offset adjustment may also be necessary to account for any initial offsets in the sensor's output. Follow the manufacturer's guidelines for zeroing procedures.

- Apply Power:

If your pressure-sensing diaphragm is an active sensor, apply the appropriate power source to the sensor. Ensure that the power supply meets the sensor's specifications.

- Read and Interpret Output:

Monitor and record the output signal from the pressure sensor. Depending on the sensor type, this could be a voltage, current, or digital signal. Use suitable instrumentation or data acquisition systems to read and interpret the output.

- Implement Control Strategies (if applicable):

If the pressure sensor is used for control purposes, integrate it into your control system. Implement control strategies based on the pressure readings to maintain the desired pressure setpoints.

- Ensure Proper Grounding and Shielding:

In electrically noisy environments, ensure proper grounding and shielding of the sensor to minimize interference and maintain signal integrity.

- Periodic Maintenance and Calibration:

Perform routine maintenance checks and periodic calibrations to ensure the pressure sensor continues to provide accurate and reliable measurements. Follow the manufacturer's recommended maintenance schedule.

- Safety Considerations:

Be mindful of safety considerations, especially in applications where pressure control is crucial for safety. Implement safety features and alarms as needed to respond to pressure anomalies.

- Data Logging and Analysis (optional):

If required, set up data logging and analysis systems to record pressure data over time. This can be valuable for performance analysis, troubleshooting, and compliance with regulatory requirements.

- Troubleshooting:

If you encounter issues with the pressure-sensing diaphragm's performance, consult the sensor's documentation, check wiring and connections, and verify that the sensor is within its specified operating conditions.

- Record Keeping:

Maintain detailed records of the sensor's installation, calibration, maintenance, and any observed anomalies. These records can be valuable for quality control and troubleshooting.

Using a pressure-sensing diaphragm effectively involves careful consideration of your specific application, adherence to manufacturer guidelines, and proper integration into your measurement or control system. Regular maintenance and calibration are essential to ensure accurate and reliable pressure measurements over time.

Pressure-Sensing Diaphragm Calibration

Calibrating a pressure-sensing diaphragm is a crucial step to ensure accurate and reliable pressure measurements. Calibration involves adjusting the sensor's output to match known reference values under controlled conditions. Here are the general steps to calibrate a pressure-sensing diaphragm:

Note: The specific calibration procedure may vary depending on the type and model of the pressure sensor, so always refer to the manufacturer's instructions and guidelines for precise calibration steps.

- Prepare Calibration Equipment:

Gather the necessary calibration equipment, which typically includes a calibrated reference pressure source, pressure regulators, pressure gauges, and any additional instrumentation required for measurement.

- Ensure Proper Environment:

Perform calibration in a controlled environment with stable temperature and humidity conditions to minimize environmental factors' impact on the calibration.

- Inspect the Pressure Sensing Diaphragm:

Visually inspect the diaphragm and its connections for any damage, wear, or contamination that could affect its performance. Ensure proper electrical connections are in place.

- Zero the Sensor:

Zero the pressure sensor by adjusting its output to a reference value when there is no applied pressure. This step compensates for any initial offset or bias in the sensor's output.

- Apply Calibration Pressure:

Gradually apply a known and stable reference pressure to the sensor using the reference pressure source. Ensure that the pressure source is accurate and calibrated.

- Record Sensor Output:

Measure and record the output signal from the pressure sensor at each calibration point. Use appropriate measurement instruments, such as a digital multimeter or data acquisition system, to record voltage, current, or digital readings.

- Adjust Sensor Output:

Compare the sensor's output readings with the corresponding reference pressure values. If the sensor output deviates from the expected values, make the necessary adjustments to the sensor's output signal, often done using calibration software or hardware.

- Repeat Calibration Points:

Perform the calibration procedure at multiple pressure points across the sensor's range to create a calibration curve or table. This ensures accuracy across the entire measurement range.

- Verify Accuracy:

After calibration, verify the sensor's accuracy by rechecking its output against the reference values. Repeat the calibration if necessary until the sensor's output closely matches the reference values within specified tolerances.

- Document Calibration Data:

Maintain detailed records of the calibration process, including the calibration points, reference pressures, sensor readings, adjustments made, and any calibration certificates provided by the reference pressure source.

- Calibration Interval:

Establish a regular calibration interval for the pressure sensor based on its manufacturer's recommendations and industry standards. Sensors can drift over time, so periodic recalibration is essential to maintain accuracy.

- Label and Certify:

Label the pressure sensor with calibration details, including the calibration date, the person or facility that performed the calibration, and the next due calibration date. If applicable, obtain a calibration certificate from an accredited calibration laboratory.

- Return to Service:

Once calibrated and verified, return the pressure sensor to its intended application, ensuring that it operates within its specified range and performance criteria.

- Maintain Traceability:

Maintain traceability of the calibration results by keeping records of all calibration procedures, adjustments, and certificates. This is important for quality control and regulatory compliance.

Regular calibration is essential to ensure that pressure sensing diaphragms provide accurate and reliable measurements in various applications. It helps to maintain product quality, safety, and compliance with industry standards and regulations.

Pressure-Sensing Diaphragm Accuracy

The accuracy of a pressure sensing diaphragm refers to how closely the sensor's measurements or output values correspond to the true or actual pressure being measured. Accurate pressure measurements are crucial in many applications, as inaccuracies can lead to errors, safety concerns, and quality issues. Pressure sensing diaphragms are typically specified with an accuracy rating that indicates how well they can measure pressure under specific conditions. Here are some key factors that influence the accuracy of pressure sensing diaphragms:

- Sensor Quality:

The quality of the pressure sensor itself plays a significant role in accuracy. High-quality sensors tend to have better manufacturing tolerances, lower drift over time, and more consistent performance.

- Calibration:

Proper calibration is essential to ensure accuracy. Sensors should be calibrated against known reference standards to correct for any inherent offsets or inaccuracies in the sensor's output. Regular recalibration is necessary to account for drift over time.

- Temperature Effects:

Temperature can affect the accuracy of pressure sensors. Some pressure sensing diaphragms are equipped with compensation mechanisms to account for temperature variations. However, extreme temperature fluctuations can still impact accuracy.

- Hysteresis:

Hysteresis is the phenomenon where a sensor's output value may differ when the pressure is increasing compared to when it is decreasing. The hysteresis error can affect accuracy, especially in dynamic pressure applications.

- Non-Linearity:

Non-linearity refers to deviations from a linear response to pressure changes. Highly accurate sensors have minimal non-linearity, meaning their output closely follows a linear relationship with pressure.

- Repeatability:

Repeatability is the sensor's ability to provide consistent readings when the same pressure is applied multiple times. A high repeatability indicates better accuracy.

- Resolution:

The resolution of a sensor refers to the smallest pressure change it can detect and is closely related to accuracy. Sensors with higher resolution can provide more accurate measurements, especially for low-pressure applications.

- Environmental Conditions:

Environmental factors like humidity, vibration, and electromagnetic interference can influence the accuracy of pressure sensors. Proper shielding and environmental protection measures are essential.

- Pressure Range:

Sensors may have different accuracy specifications for different pressure ranges. It's important to select a sensor with an appropriate range for the application to achieve the desired accuracy.

- Manufacturer Specifications:

Manufacturers provide accuracy specifications in sensor datasheets. These specifications typically include accuracy as a percentage of the full-scale pressure range or in absolute pressure units (e.g., psi or bar).

- Installation and Mounting:

The correct installation and mounting of the sensor can impact its accuracy. Ensure that the sensor is properly aligned, sealed, and secured to minimize mechanical stresses and potential errors.

- Aging and Drift:

Over time, sensors may experience aging and drift, causing their accuracy to change. Regular calibration and maintenance can help mitigate these effects.

- Signal Processing:

The accuracy of the final pressure measurement can also depend on the quality of signal processing electronics used with the sensor. High-quality signal conditioning and amplification can improve overall system accuracy.

To achieve the best accuracy from a pressure sensing diaphragm, it's important to select the right sensor for the application, follow manufacturer guidelines for installation and calibration, and perform regular maintenance and calibration to ensure ongoing accuracy. Accuracy requirements vary depending on the specific application, with some industries requiring high levels of accuracy for safety, quality control, or regulatory compliance.

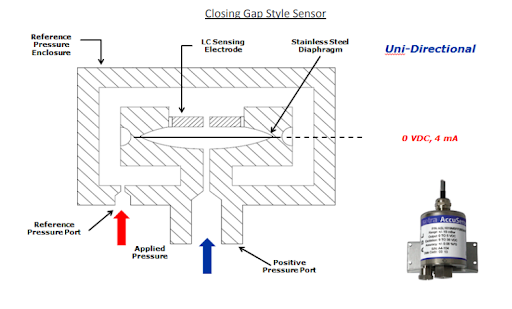

Fig 8. Closing gap stylesensor

Pressure Sensing Diaphragm Advantages

- Accuracy: Pressure sensing diaphragms can provide highly accurate pressure measurements when properly calibrated and maintained. This accuracy is crucial in applications where precise pressure control and monitoring are essential, such as in medical devices, aerospace, and industrial automation.

- Sensitivity: Many pressure sensing diaphragms are highly sensitive and can detect even small pressure changes. This sensitivity makes them suitable for applications where fine adjustments or rapid responses to pressure variations are required.

- Wide Range: Pressure sensing diaphragms are available in a wide range of pressure ratings, from very low pressures to extremely high pressures. This versatility allows them to be used in diverse applications across different industries.

- Durability: Depending on the material and design, pressure sensing diaphragms can be highly durable and capable of withstanding harsh environmental conditions, including temperature extremes, chemical exposure, and mechanical stress.

- Compact Size: Some pressure sensing diaphragms, particularly MEMS (Micro-Electro-Mechanical Systems) sensors, are compact and lightweight, making them suitable for miniaturized devices and applications where space is limited.

- Ruggedness: Diaphragms made from materials like stainless steel and ceramics are rugged and robust, making them suitable for use in demanding industrial environments, including those with high vibration, shock, or pressure.

- Response Time: Many diaphragms have fast response times, making them ideal for applications requiring real-time pressure monitoring and control, such as in automotive systems or industrial processes.

- Cost-Effective: Pressure sensing diaphragms are often cost-effective compared to other types of pressure sensors, making them a practical choice for a wide range of applications, including consumer electronics.

Pressure Sensing Diaphragm Disadvantages

- Limited Pressure Range: Some pressure sensing diaphragms have a limited pressure range, which means they may not be suitable for applications that require measurements beyond their specified range.

- Temperature Sensitivity: The accuracy and performance of pressure sensing diaphragms can be affected by temperature fluctuations. Extreme temperature conditions can lead to errors in measurements if not properly compensated.

- Hysteresis: Pressure sensors, including diaphragms, can exhibit hysteresis, which means their output readings may differ when the pressure is increasing compared to when it is decreasing. This hysteresis error can impact accuracy.

- Non-Linearity: Non-linearity refers to deviations from a linear response to pressure changes. Some pressure sensors may exhibit non-linear behavior, which can affect the accuracy of measurements, especially at the extremes of their pressure range.

- Environmental Influences: Environmental factors such as humidity, vibration, and electromagnetic interference can introduce noise and affect the accuracy of pressure measurements. Proper shielding and environmental protection may be required.

- Drift Over Time: Pressure sensors, including diaphragms, can experience drift over time, meaning their calibration and accuracy may change with prolonged use. Regular recalibration is necessary to mitigate drift effects.

- Shock and Overpressure: Pressure sensing diaphragms can be sensitive to mechanical shock or overpressure events. Exposure to pressures beyond their specified range can damage or permanently deform the diaphragm.

- Complexity of Differential Pressure Measurement: While some diaphragms can measure differential pressure, this requires more complex sensor configurations and may not be ideal for all applications.

How can choose the proper Pressure Sensing Diaphragm for pressure transmitter?

Choosing the proper pressure sensing diaphragm for a pressure transmitter is a critical step in designing an effective pressure measurement system. To make the right choice, consider the following factors:

- Pressure Range:

Determine the range of pressures you need to measure. Pressure sensors are often specified with a minimum and maximum pressure range. Ensure that the diaphragm you choose can cover the entire range of your application.

- Accuracy Requirements:

Define the level of accuracy required for your application. High-precision diaphragms may be necessary for critical applications, while others may tolerate lower accuracy.

- Temperature Range:

Consider the temperature conditions in your application. Ensure that the diaphragm material and design can operate within the specified temperature range without compromising accuracy.

- Compatibility:

Check the compatibility of the diaphragm material with the measured medium (gas or liquid). Ensure that it can withstand any corrosive or aggressive chemicals present in the application.

- Environmental Conditions:

Evaluate the environmental conditions, including humidity, vibration, and electromagnetic interference. Choose a diaphragm that can handle these conditions or take steps to protect the sensor from them.

- Mechanical Considerations:

Assess mechanical factors, such as size, shape, and mounting options. Ensure that the diaphragm can fit into your system and be properly mounted.

- Response Time:

Determine the required response time for pressure measurements. Some diaphragms have faster response times than others, which is critical for applications with rapidly changing pressure conditions.

- Cost Constraints:

Consider your budget constraints. Pressure sensing diaphragms can vary in cost, and higher accuracy and performance may come at a higher price.

- Long-Term Stability:

Evaluate the long-term stability and drift characteristics of the diaphragm. Some diaphragms may exhibit less drift over time, reducing the need for frequent recalibration.

- Output Signal:

Consider the type of output signal required for your application, such as analog voltage or current, digital signals (e.g., I2C, SPI), or frequency modulation. Ensure compatibility with your data acquisition or control system.

- Hygienic Requirements:

If your application demands strict hygiene standards (e.g., food processing or pharmaceuticals), choose a diaphragm that is designed for hygienic use with smooth, easy-to-clean surfaces.

- Overpressure Tolerance:

Determine whether the diaphragm needs to withstand occasional overpressure events. Select a diaphragm that can handle overpressure conditions without damage.

- Electrical Power:

Consider the power requirements of the diaphragm, especially if it is an active sensor (e.g., piezoelectric). Ensure that your system can provide the necessary power.

- Signal Conditioning:

Determine whether signal conditioning and amplification are needed to process the diaphragm's output signal. Some diaphragms may require additional electronics to achieve the desired accuracy and resolution.

- Certifications and Standards:

Check if your application requires specific certifications or compliance with industry standards. Some industries, such as aerospace and healthcare, have strict regulatory requirements.

- Manufacturer Reputation:

Research and choose a reputable manufacturer known for producing high-quality pressure sensing diaphragms and pressure transmitters.

- Calibration and Maintenance:

Plan for the regular calibration and maintenance of the pressure transmitter to ensure ongoing accuracy.

Conclusion

Pressure sensing diaphragms are critical components in various industries and applications where accurate and reliable pressure measurements are essential. These diaphragms offer a range of advantages, including accuracy, sensitivity, durability, and customization options. However, they also have limitations, such as temperature sensitivity, hysteresis, and the need for regular calibration.

Choosing the right pressure sensing diaphragm for a pressure transmitter involves careful consideration of factors like pressure range, accuracy requirements, temperature conditions, and environmental factors. It's crucial to select a diaphragm that aligns with the specific needs and constraints of your application.

Regular maintenance, calibration, and adherence to manufacturer guidelines are essential for ensuring the long-term accuracy and performance of pressure sensing diaphragms. By taking these factors into account and making informed choices, you can create effective pressure measurement systems that contribute to safety, quality control, and operational efficiency in various industries.

To recap

1. What is a Pressure Sensing Diaphragm?

Answer: A Pressure Sensing Diaphragm is a thin, flexible, and typically circular membrane or element used in pressure sensors to detect and measure pressure changes in various applications.

2. How does a Pressure Sensing Diaphragm work?

Answer: Pressure Sensing Diaphragms work on the principle that when pressure is applied to one side of the diaphragm, it deflects or deforms. This deformation is converted into an electrical or mechanical signal, which is then measured to determine the pressure.

3. What are the common materials used for Pressure Sensing Diaphragms?

Answer: Common materials include stainless steel, silicon, ceramic, and various elastomers. The choice depends on factors like pressure range, temperature, and compatibility with the measured medium.

4. What is the importance of calibration in Pressure Sensing Diaphragms?

Answer: Calibration is crucial to ensure the accuracy of pressure measurements. It involves adjusting the diaphragm's output to match known reference values under controlled conditions.

5. What is the difference between absolute and gauge Pressure Sensing Diaphragms?

Answer: Absolute diaphragms measure pressure relative to a vacuum, while gauge diaphragms measure pressure relative to the surrounding atmospheric pressure.

6. What are the advantages of using Pressure Sensing Diaphragms in pressure measurement?

Answer: Advantages include accuracy, sensitivity, durability, compact size, and suitability for a wide range of applications and pressure ranges.

7. What are the main disadvantages of Pressure Sensing Diaphragms?

Answer: Disadvantages include temperature sensitivity, hysteresis, non-linearity, susceptibility to environmental factors, and the need for regular calibration.

8. How do you choose the right Pressure Sensing Diaphragm for a specific application?

Answer: Consider factors like pressure range, accuracy requirements, temperature conditions, and environmental factors. Consult with manufacturers or suppliers for guidance.

9. What is the typical lifespan of a Pressure Sensing Diaphragm?

Answer: The lifespan varies depending on usage, environmental conditions, and diaphragm quality. With proper care and maintenance, many diaphragms can last for several years.

10. In what industries and applications are Pressure Sensing Diaphragms commonly used?

Answer: Pressure Sensing Diaphragms find applications in industries such as automotive, aerospace, industrial automation, medical devices, oil and gas, and many more, where accurate pressure measurement is critical.

References

https://www.mdpi.com/1424-8220/16/7/1025

https://appmeas.co.uk/products/pressure-sensors/

https://www.azom.com/article.aspx?ArticleID=18253

https://www.instrumentationtoolbox.com/2011/02/pressure-sensors-used-in-industrial.html

https://control.com/textbook/continuous-pressure-measurement/electrical-pressure-elements/

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025