Connecting the Dots: Demystifying Pressure Sensor Electrical Connections

Pressure sensors are fundamental components in various industrial, automotive, and consumer applications, playing a crucial role in monitoring and controlling pressure levels. Achieving accurate and reliable pressure measurements hinges on the effectiveness of electrical connections. A thorough understanding of the electrical aspects is vital for ensuring optimal sensor performance, system efficiency, and safety.

In this context, this introduction delves into the key considerations surrounding pressure sensor electrical connections. From the types of electrical connections commonly employed to the impact of cable length and the intricacies of connecting sensors in hazardous areas, we explore the essential aspects that users, engineers, and technicians need to navigate for successful pressure sensor integration.

The journey begins with an exploration of the common types of electrical connections, ranging from analog outputs to digital communication protocols and Wheatstone bridge configurations. We then delve into the practical aspects of identifying the correct wiring configuration, emphasizing the importance of referring to datasheets and manuals for precise information.

Moving forward, we address the critical issue of cable selection, emphasizing the need for specialized cables to ensure insulation and signal integrity. The discussion extends to cable considerations for analog and digital output signals, shedding light on the types of cables suitable for each scenario.

Safety takes center stage as we unravel the precautions and measures necessary when connecting pressure sensors to electrical circuits. From proper grounding techniques to the meticulous handling of connections, this section provides insights to mitigate risks and ensure a secure operating environment.

The complexities of connecting pressure sensors in hazardous areas demand a dedicated exploration. We outline the unique challenges, emphasizing explosion protection measures, equipment selection, and compliance with regulatory standards to guarantee safety in potentially volatile environments.

As the connection process unfolds, troubleshooting emerges as a critical skill. We detail the systematic approach to identifying and resolving electrical issues, ensuring a robust and fault-free sensor integration.

Ensuring proper insulation and protection becomes paramount, especially when pressure sensors operate in challenging environments. This introduction outlines the best practices, including cable routing, enclosure selection, and regular maintenance checks, to safeguard against environmental factors and physical stress.

Closing the introduction is a set of frequently asked questions, addressing common queries about pressure sensor electrical connections. From cable types to troubleshooting methods, these FAQs serve as a handy reference for those navigating the intricacies of pressure sensor integration.

In essence, this comprehensive introduction serves as a valuable resource, offering insights and guidance for individuals involved in the installation, maintenance, and optimization of pressure sensor electrical connections across diverse applications. Whether you are an engineer designing a sophisticated industrial system or a technician troubleshooting a sensor network, this introduction provides a solid foundation for success in the realm of pressure sensing.

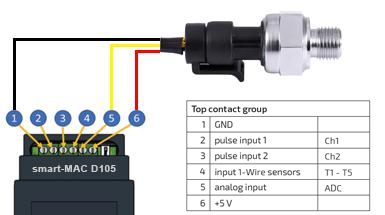

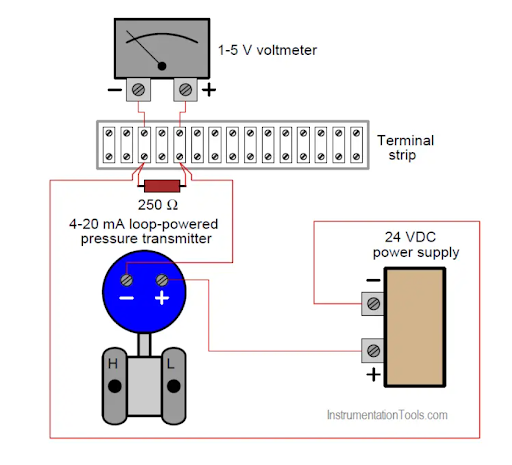

Fig 1. Connection diagram pressure sensor to smart-MAC D105

Pressure sensor electrical connections

Pressure sensors typically have electrical connections that vary depending on the type and model of the sensor. However, there are some common types of electrical connections for pressure sensors:

If you have a particular pressure sensor in mind or specific requirements, I could help with more precise instructions or guidance!

How does a pressure transmitter connect electrically?

A pressure transmitter typically connects electrically in a way that allows it to measure pressure and send the corresponding signal to a monitoring or control system. These transmitters often have standardized wiring configurations, but specifics can vary based on the manufacturer and model. However, I can provide a general idea of how a pressure transmitter might connect electrically:

- Analog Output: If it's an analog output, there will be terminals for the signal output. For instance, a 4-20mA output might have terminals labeled "OUT+" and "OUT-" for the positive and negative sides of the signal, respectively. You'd connect these terminals to your monitoring or control system.

- Digital Output: If the transmitter has a digital output, it may use specific communication protocols like HART, Modbus, etc. In this case, the transmitter will have terminals for data communication (like Tx, Rx, clock, data lines, etc.) that connect to a compatible receiver or controller.

Power supply connections of pressure sensor

The power supply connections for a pressure sensor are crucial for its proper operation and accurate readings. These connections ensure the sensor receives the necessary electrical power to function and transmit pressure-related data reliably.

Typically, pressure sensors require a direct current (DC) power supply within a specified voltage range, commonly between 5 to 36 volts DC, depending on the sensor's design and specifications. The positive and negative terminals of the power supply connect to designated terminals on the pressure sensor. These terminals are usually labeled explicitly, such as "+V" for positive voltage and "GND" for ground or negative.

Ensuring the correct polarity is essential. Reversing the polarity could potentially damage the sensor. Therefore, it's vital to double-check the wiring against the sensor's datasheet or manual before applying power.

Stable and clean power is essential for accurate pressure measurements. Noisy or fluctuating power sources might introduce interference that affects the sensor's output accuracy. Some sensors may have specific requirements for power conditioning or recommend additional measures, such as using a dedicated power regulator or ensuring proper grounding to minimize electrical noise.

Additionally, when connecting the power supply to the pressure sensor, it's crucial to consider the overall system's power requirements and potential power draw from multiple sensors or components sharing the same power source. Ensuring an adequate power supply capacity can prevent voltage drops or fluctuations that might affect sensor performance.

Lastly, proper insulation and protection of the power supply connections are essential, especially in industrial or harsh environments where exposure to moisture, dust, or vibrations can compromise the electrical connections. Adequate insulation and protective measures, such as using suitable enclosures or sealing techniques, help maintain the integrity of the power connections, ensuring the sensor operates reliably over its intended lifespan.

Pressure sensor signal output connections

The signal output connections of a pressure sensor are pivotal as they transmit the measured pressure data to external systems or devices for analysis, monitoring, or control purposes. These connections are where the sensor communicates its readings in a format compatible with the receiving equipment.

- Communication Protocols: Some modern pressure sensors offer digital output using communication protocols like I2C, SPI, UART, HART, Modbus, Profibus, etc.

- Multiple Wires: These sensors often have multiple wires for different purposes, such as power supply, data, clock, and ground. Each wire connects to the corresponding terminal on the receiving device compatible with the sensor's communication protocol.

- Interference Minimization: Proper shielding and grounding techniques help minimize electromagnetic interference that could affect the integrity of the signal. Some sensors have a separate shielding terminal, which connects to the ground to reduce noise in the signal.

- Connectors or Terminal Blocks: Depending on the sensor's design, these connections may use various connector types or terminal blocks for ease of installation and maintenance.

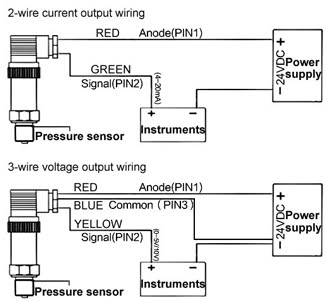

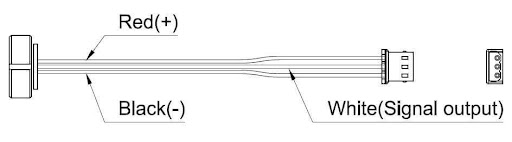

Fig 2. Two wire and three wire pressure sensor wiring diagram

Which type of cable use for analog output signal in electrical connection for pressure sensor?

For transmitting analog output signals from pressure sensors, the choice of cable often depends on factors such as signal integrity, distance, and environmental conditions. Here are some commonly used cables for transmitting analog signals from pressure sensors:

Which type of cable use for digital output signal in electrical connection for pressure sensor?

The type of cable used for transmitting digital output signals from a pressure sensor depends on the communication protocol the sensor employs and the specific requirements of the application. Here are some common cable types for transmitting digital signals:

How can choose the proper electrical cable and connectors for pressure sensor?

Choosing the proper electrical cable and connectors for a pressure sensor involves considering several key factors to ensure reliable and accurate signal transmission. Here's a guide to help in the selection process:

1. Understand Sensor Specifications:

- Check the Datasheet:Review the sensor's datasheet for recommended cable types, connector specifications, and any specific requirements provided by the manufacturer.

- Signal Type: Determine whether the sensor outputs analog or digital signals.

- Voltage/Current Ratings: Note the voltage and current requirements for the sensor's power supply and signal output.

2. Consider Environmental Conditions:

- Temperature and Moisture: Select cables and connectors rated for the operating temperature range and environmental conditions where the sensor will be installed.

- Chemical Exposure: If the sensor will be exposed to chemicals, choose cables and connectors that resist corrosion and degradation.

3. Cable Type Selection:

- Analog Signals: For analog signals, consider shielded cables like shielded twisted pair (STP) or coaxial cables for better noise immunity.

- Digital Signals: Choose cables appropriate for the digital communication protocol used by the sensor (e.g., twisted pair, high-speed data cables, or specialized cables for specific protocols).

4. Connector Selection:

- Compatibility: Ensure the connectors match the cable type and are compatible with the sensor's connector specifications.

- Sealing and Durability: Select connectors with appropriate sealing against moisture and dust if the sensor will be installed in harsh environments.

- Correct Pin Configuration: Verify that the connectors match the pin configuration of the sensor's output (analog or digital) and power supply.

5. Cable Length and Shielding:

- Length: Keep cable lengths within the specified limits to maintain signal integrity, especially for analog signals prone to interference over longer distances.

- Shielding: Choose cables with adequate shielding to minimize electromagnetic interference, especially in industrial settings with potential sources of noise.

6. Compliance and Standards:

Compliance: Ensure that the selected cables and connectors comply with relevant industry standards for electrical safety and performance.

7. Consult Manufacturer Guidelines:

Manufacturer Recommendations: If available, follow the manufacturer's guidelines and recommendations for cable and connector selection to ensure optimal performance and reliability.

8. Test and Validate:

Testing: Before deployment, conduct tests to ensure the selected cables and connectors perform as expected and meet the sensor's requirements.

By considering these factors and consulting the sensor's documentation or manufacturer guidelines, you can choose electrical cables and connectors that suit the sensor's specifications, environmental conditions, and intended application, ensuring reliable signal transmission and accurate readings.

Installation of appropriate electrical cables and connectors

Installing electrical cables and connectors for a pressure sensor requires attention to detail and following best practices to ensure reliable operation and accurate signal transmission. Here's a step-by-step guide for their installation:

1. Gather Required Components:

- Cables: Select the appropriate cables based on the sensor's specifications and environmental conditions.

- Connectors: Choose connectors that match the cable type and are compatible with the sensor's connector specifications.

2. Prepare the Area:

- Safety: Ensure the area is safe for installation, following proper safety protocols and wearing necessary protective gear.

- Clean Environment: Work in a clean environment, free from dust, moisture, or potential contaminants.

3. Cut and Strip Cables:

- Measure and Cut: Measure and cut the cables to the required lengths, ensuring they aren't excessively long or too short.

- Strip Insulation: Use wire strippers to carefully remove the outer insulation of the cables, exposing the inner wires for connection.

4. Connect Cables to Connectors:

- Follow Guidelines: Refer to the sensor's datasheet or manufacturer guidelines for the correct pin configuration.

- Soldering or Crimping: Depending on the connector type, solder or crimp the wires securely to the connector pins, ensuring proper connections without any loose wires.

5. Ensure Proper Insulation:

- Insulate Connections: Use heat shrink tubing, electrical tape, or appropriate insulation material to cover and secure the connections, preventing short circuits or exposure to external elements.

6. Test Connections:

- Check Continuity: Use a multimeter to check for continuity and ensure there are no short circuits or loose connections in the cables and connectors.

- Functional Test: Test the sensor's output to verify that the electrical connections are properly transmitting the signal.

7. Secure Cables and Connectors:

Secure Mounting: Securely fasten the cables and connectors in place using suitable mounting brackets, cable ties, or clamps to prevent movement or strain on the connections.

8. Seal and Protect:

- Weatherproofing: If the installation is outdoors or in a harsh environment, apply appropriate sealants or weatherproofing materials around the connectors to prevent moisture ingress.

- Use Protective Covers: Employ protective covers for connectors or use enclosures to shield connections from environmental hazards.

9. Document and Label:

- Documentation: Maintain records of the installation, including cable types, connector specifications, and connection diagrams for future reference.

- Labeling: Label cables and connectors clearly for easy identification during maintenance or troubleshooting.

10. Follow Regulations and Standards:

Compliance: Ensure compliance with electrical codes, standards, and regulations applicable to your installation.

By following these steps and paying attention to detail during the installation process, you can establish reliable electrical connections for your pressure sensor, promoting accurate signal transmission and ensuring the longevity of the sensor system. If unsure, consulting an electrician or following specific industry guidelines can further enhance the installation process.

Wiring considerations for analog and digital output signals

Wiring considerations for analog and digital output signals from pressure sensors involve different factors due to the nature of these signals. Here are some considerations for each:

Analog Output Signals:

- Noise Reduction: Use shielded cables (like shielded twisted pair or coaxial) to minimize electromagnetic interference (EMI) and maintain signal integrity, especially for longer cable runs.

- Proper Grounding: Ensure proper grounding techniques to reduce noise and interference in the analog signal.

- Signal Degradation: Longer cable lengths can lead to signal degradation due to increased resistance and capacitance. Keep cable lengths within recommended limits.

- Higher Gauge Wires: For longer distances, consider using wires with a larger gauge to minimize resistance.

- High-Quality Connectors: Use high-quality connectors to maintain a secure and reliable connection, preventing signal loss or interference.

Digital Output Signals:

- Match Impedance: Ensure proper impedance matching between the sensor, cable, and receiving device to prevent signal reflection and loss.

- Twisted Pair for Noise Reduction: Twisted pair cables help reduce electromagnetic interference for digital signals.

- Type of Digital Cable: Select cables appropriate for the digital protocol used (e.g., twisted pair, high-speed data cables).

- Length Consideration: Maintain cable lengths within the specified limits to prevent signal degradation.

- Correct Connectors: Use connectors compatible with the digital signal type and ensure they meet the required specifications.

- Proper Termination: Ensure proper termination of digital signal cables to prevent signal reflections.

Common Considerations for Both Analog and Digital:

- Separation from Power Cables: Keep signal cables away from high-voltage power cables to prevent interference.

- Avoiding Sharp Bends: Minimize sharp bends and kinks in the cables to avoid signal distortion or damage.

- Protection from Environmental Hazards: Use appropriate cable insulation and protection against moisture, chemicals, temperature extremes, and physical damage.

- Use of Cable Conduits or Enclosures: Protect cables in harsh environments with conduits or enclosures.

- Functionality Testing: Before final installation, test the cables and connections to ensure proper functionality and signal transmission.

- Periodic Maintenance: Regularly inspect and maintain the cables and connections to avoid signal disruptions due to wear or damage.

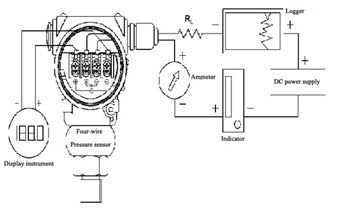

Fig 3. Four wire pressure sensor wiring diagram

Grounding requirements for pressure transmitters

Grounding for pressure transmitters is crucial for system safety, signal integrity, and interference reduction. Here are grounding requirements to consider:

Safety Grounding:

Signal Integrity and Noise Reduction:

Grounding Best Practices:

Pressure sensor Grounding techniques

Grounding pressure sensors properly is critical for signal accuracy, minimizing noise interference, and ensuring electrical safety. Here are some grounding techniques specific to pressure sensors:

Signal Grounding

Electrical Safety Grounding

Grounding Practices

Manufacturer Recommendations

Always refer to the sensor's datasheet or manufacturer's guidelines for specific grounding instructions or recommendations. Manufacturers often provide detailed information on the sensor's grounding requirements to ensure proper installation and operation.

Professional Assistance

For complex grounding setups or if uncertain about the grounding requirements for your specific application, seek guidance from qualified electricians, engineers, or professionals with expertise in electrical systems and sensor installations.

By implementing these grounding techniques and following manufacturer guidelines, you can establish effective grounding for pressure sensors, ensuring accurate signal transmission and electrical safety within your system.

Important factors to choose the appropriate grounding techniqes

Choosing the appropriate grounding techniques involves considering various factors to ensure effective signal transmission, electrical safety, and interference reduction. Here are important factors to consider:

1.Signal Integrity

What are the safety tips should observe about electrical connections?

Absolutely, electrical connections demand careful handling to ensure safety. Here are some crucial safety tips:

1. Power Off Before Working:

Fig 4. Electrical connection of pressure sensor

What are the common types of electrical connections for pressure sensors?

Pressure sensors typically feature various types of electrical connections based on the sensor's design, application, and the desired method of signal transmission. Here are some common types of electrical connections for pressure sensors:

1. Analog Output:

How can identify the correct wiring configuration for pressure sensor?

Identifying the correct wiring configuration for a pressure sensor involves several steps:

1. Review the Datasheet or Manual:

Terminals or Pins: Physically inspect the sensor for labeled terminals or pins. Common labels might include "+V" for positive voltage, "GND" for ground, "OUT" for signal output, etc.

4. Wiring Color Codes (if applicable):

Standardized Codes: Some sensors use standardized color codes for wiring. For instance, red for positive voltage, black for ground, white for signal, etc.

5. Consult Manufacturer Support:

Technical Support: Contact the manufacturer's technical support team for assistance in identifying the correct wiring configuration if there's uncertainty.

6. Use Multimeter or Continuity Tester:

Testing Continuity: Use a multimeter or continuity tester to check for connectivity between different terminals or wires to verify their functions.

7. Reference Wiring Diagrams:

Available Diagrams: Look for any wiring diagrams or installation guides provided by the manufacturer that detail the correct wiring configuration.

8. Previous Experience or Expertise:

Experience: If you have previous experience with similar sensors or systems, you might identify similarities in wiring configurations.

9. Avoid Guesswork:

Caution: Avoid making assumptions about the wiring configuration. Incorrect connections can damage the sensor or affect its performance.

By following these steps and referring to the sensor's documentation or seeking assistance from the manufacturer's support, you can identify the correct wiring configuration for a pressure sensor. Ensuring accurate connections is crucial for the sensor's proper operation and accurate signal transmission.

What are the standards of pressure sensor electrical connections?

The standards for pressure sensor electrical connections can vary based on industry, application, and region. While there might not be specific universal standards solely for pressure sensor electrical connections, various overarching standards and guidelines apply to electrical connections in general, including those for pressure sensors. Here are some relevant standards and guidelines:

1. National and International Electrical Standards:

Industrial Electrical Codes: Some industries have specific electrical codes or regulations that govern equipment installations and electrical connections.

Important Considerations:

What precautions should take when connecting a pressure sensor to an electrical circuit?

When connecting a pressure sensor to an electrical circuit, taking specific precautions ensures safety, accuracy, and the integrity of the sensor's operation. Here's a detailed guide:

Before Starting:

What is the significance of shielded cables in pressure sensor connections? in paragraphes

Shielded cables play a crucial role in pressure sensor connections due to their ability to mitigate electromagnetic interference (EMI) and ensure signal integrity. In pressure sensor applications, where accurate and reliable data transmission is paramount, shielded cables offer several significant advantages.

Firstly, these cables feature an additional layer of shielding, typically made of conductive material, surrounding the insulated wires carrying the signal. This shielding acts as a barrier, effectively blocking external electromagnetic fields from interfering with the signal transmitted by the pressure sensor. By doing so, shielded cables minimize the risk of signal distortion or corruption caused by EMI generated from nearby electrical equipment, power lines, or other sources of electromagnetic noise prevalent in industrial environments.

Secondly, pressure sensors often deal with low-level analog signals susceptible to interference. Shielded cables provide a protective shield that helps maintain the integrity of these sensitive signals over longer distances. By reducing the impact of external interference, these cables ensure that the pressure sensor accurately captures and transmits the pressure data without distortion or inaccuracies caused by electrical noise.

Moreover, shielded cables contribute to system reliability by improving the overall performance of the pressure sensor. They help maintain a stable and consistent signal, enhancing the sensor's precision and reducing the chances of erroneous readings or signal disruptions. This reliability is particularly critical in applications where precise pressure measurements are vital for safety, control systems, or sensitive industrial processes.

In essence, the use of shielded cables in pressure sensor connections is indispensable for ensuring reliable, accurate, and noise-free transmission of signals. Their ability to mitigate electromagnetic interference significantly contributes to the sensor's performance, enabling it to deliver dependable pressure readings essential for various industrial and monitoring applications.

Fig 5. Electrical connectors

Can pressure sensors be connected in series or parallel in a circuit?

Pressure sensors can be connected in series or parallel in a circuit, depending on the specific application requirements and the nature of the sensors being used. However, the approach to connecting pressure sensors in series or parallel can differ based on the sensor type, the intended measurement setup, and the desired outcome.

Series Connection:

In a series connection, multiple pressure sensors are linked sequentially, one after another, along a single path within a circuit. This arrangement allows for cumulative measurement across the sensors. Each sensor contributes to the total output or measurement, and the combined effect of all sensors' readings is measured as a single output. Series connections are often used when there's a need to measure pressure levels across multiple points in a system and obtain a total or cumulative pressure reading.

Parallel Connection:

In a parallel connection, multiple pressure sensors are connected separately to a circuit, running independent paths but sharing the same input source or measurement conditions. Each sensor operates autonomously and provides its individual output. Parallel connections are useful when simultaneous readings from multiple sensors are required, allowing for comparisons or monitoring of different pressure points without affecting the other sensors' measurements.

Considerations:

Application-Specific Use:

The choice between series or parallel connections depends on the specific application's needs, whether it's for cumulative pressure measurement, simultaneous monitoring at different points, redundancy in critical systems, or other specific requirements dictated by the operational setup.

While pressure sensors can be connected in series or parallel, careful consideration of the sensors' characteristics, the intended measurements, and the impact on signal integrity is crucial to ensure accurate and reliable readings within the system. Consulting sensor specifications and understanding the system's requirements are essential before implementing series or parallel connections of pressure sensors.

What's the impact of cable length on the performance of a pressure sensor?

The impact of cable length on the performance of a pressure sensor can be significant, particularly concerning signal integrity and accuracy. Several factors come into play when considering the cable length's effect on a pressure sensor's performance:

Signal Attenuation:

How can troubleshoot electrical issues with pressure sensor connections?

Troubleshooting electrical issues with pressure sensor connections involves a systematic approach to identify and resolve potential problems. Here's a step-by-step guide:

1. Visual Inspection:

Isolation Test: Disconnect individual components (cables, connectors, etc.) one by one and test the sensor's signal to identify any specific components causing issues.

7. Signal Conditioning:

Conditioning Devices: Check signal conditioning devices, if used, for proper configuration and functionality.

8. System Test:

Environmental Checks: Consider environmental conditions (temperature, humidity) that might affect the electrical connections and the sensor's performance.

10. Document Findings:

Record Observations: Maintain a log of observations, tests conducted, and any changes made during the troubleshooting process.

Conclusion:

Troubleshooting electrical issues with pressure sensor connections involves a methodical approach, combining visual inspection, testing equipment, adherence to manufacturer guidelines, and systematic isolation of potential problems. By following these steps, you can identify and address electrical issues affecting pressure sensor connections, ensuring accurate and reliable operation within the system.

How do ensure proper insulation and protection for pressure sensor electrical connections?

Ensuring proper insulation and protection for pressure sensor electrical connections is crucial for maintaining signal integrity, preventing electrical hazards, and safeguarding the sensor's performance. Here's how to achieve proper insulation and protection:

1. Use Suitable Cables and Insulation:

Where can find detailed information about pressure sensor electrical connections for a specific model or brand?

You can find detailed information about pressure sensor electrical connections for a specific model or brand in several places:

Manufacturer's Website:

Product Documentation: Visit the manufacturer's website and navigate to the product page for the specific pressure sensor model. Look for downloadable datasheets, manuals, or technical specifications provided by the manufacturer.

Product Datasheets and Manuals:

Contact Manufacturer: Reach out to the manufacturer's technical support or customer service team. They can provide detailed guidance, answer specific questions, or offer assistance regarding electrical connections for the sensor model.

Online Forums and Communities:

Industry Forums: Explore online forums or communities related to instrumentation, sensors, or industrial applications. Sometimes, professionals share insights or experiences regarding specific sensor models and their electrical connections.

Distributors or Resellers:

Distributor Resources: If you purchased the sensor through a distributor or reseller, they might have additional resources or documentation available for the specific product.

Application Notes and Whitepapers:

Manufacturer's Resources: Some manufacturers publish application notes, whitepapers, or technical articles that delve into specific aspects of their sensor products, including electrical connections and installation.

Catalogs and Brochures:

Product Catalogs: Look through manufacturer catalogs or brochures, which may provide an overview of the sensor's electrical specifications.

Online Resources and Libraries:

Online Libraries: Online libraries or repositories might contain technical documents or guides related to pressure sensors, including electrical connections.

Specific Manufacturer Portals:

Manufacturer Portals: Some manufacturers provide access to secure portals or databases for registered users, offering in-depth technical information, support documents, or FAQs specific to their products.

By exploring these sources and directly engaging with the manufacturer or authorized channels, you can access detailed information and documentation about the electrical connections for a specific pressure sensor model or brand.

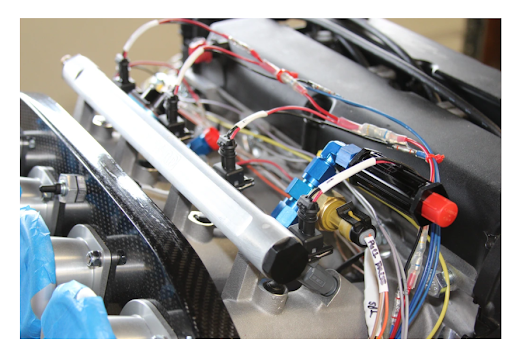

Fig 6. Pressure sensor connection

Which factors affect pressure sensor electrical connections?

Several factors can influence pressure sensor electrical connections, impacting their performance, reliability, and accuracy:

1. Cable Quality and Type:

Are there any points to be considered regarding the electrical connection of the pressure sensor in dangerous areas?

Absolutely, electrical connections for pressure sensors in hazardous or dangerous areas require special attention and adherence to stringent safety protocols. Here are key points to consider:

Hazardous Area Classification:

Conclusion

When it comes to electrical connections for pressure sensors, attention to detail and adherence to specific guidelines are paramount. Proper installation, selection of appropriate cables, connectors, and following manufacturer recommendations ensure optimal performance and reliability. Factors like cable quality, length, environmental conditions, and grounding significantly impact signal integrity.

Additionally, in hazardous areas, stringent safety measures, compliance with regulations, and specialized equipment become imperative to prevent potential hazards. Intrinsically safe components, proper grounding, and compliance with hazardous area classifications are essential in such environments.

Regular inspections, maintenance, and adherence to safety standards play a pivotal role in sustaining the efficiency and safety of pressure sensor electrical connections. By prioritizing safety, following best practices, and staying informed about specific sensor models or hazardous area requirements, one can establish reliable and secure electrical connections for pressure sensors across diverse applications.

To recap

1. What types of electrical connections are common for pressure sensors?

Common connections include analog (voltage or current) outputs, digital communication protocols (I2C, SPI), and Wheatstone bridge configurations.

2. How do I identify the correct wiring configuration for a pressure sensor?

Refer to the sensor's datasheet or manual for detailed wiring diagrams and pinout information provided by the manufacturer.

3. Can I use standard electrical cables for connecting a pressure sensor?

It's recommended to use cables specified by the sensor's manufacturer to ensure proper insulation and signal integrity.

4. What precautions should I take when connecting a pressure sensor to an electrical circuit?

Ensure power is off, use insulated tools, check polarity, and securely tighten connections to prevent hazards or signal disruptions.

5. Are there specific grounding requirements for pressure sensors?

Yes, proper grounding is crucial. Follow manufacturer guidelines for effective grounding to minimize electrical noise and ensure safety.

6. How can cable length impact the performance of a pressure sensor?

Longer cables may introduce signal degradation, leading to accuracy issues or signal interference due to increased resistance and capacitance.

7. What factors affect pressure sensor electrical connections?

Cable quality, environmental conditions, grounding, connector integrity, and compliance with specifications significantly impact electrical connections.

8. What should be considered when connecting a pressure sensor in hazardous areas?

Adherence to hazardous area classifications, using intrinsically safe components, proper sealing, and compliance with safety regulations are vital.

9. How can I troubleshoot electrical issues with pressure sensor connections?

Start with visual inspections, use testing equipment like multimeters, check grounding, and refer to manufacturer guidelines for troubleshooting steps.

10. Where can I find detailed information about pressure sensor electrical connections for a specific model or brand?

Detailed information is available in the sensor's datasheet, manuals, manufacturer's website, technical support, and industry forums related to instrumentation.

References

https://www.pressuresensor.org" rel="nofollow"/pressure-sensor-correct-wiring.html

https://www.eastsensor.com" rel="nofollow"/blog/pressure-sensor-electrical-connection/

https://instrumentationtools.com" rel="nofollow"/pressure-transmitter-circuit/

https://junkyardzetec.com/fuel-pressure-sensor-placement-and-wiring/

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025