Bridging the Gap: Pressure Transmitter and the Digital Frontier

In the intricate symphony of industrial processes and scientific endeavors, a silent sentinel stands guard, capturing the very essence of fluid dynamics and atmospheric forces. Imagine a device that transforms the intangible dance of gases and liquids into a tangible electrical melody—a pressure transmitter. As if endowed with a sixth sense, this unassuming instrument possesses the unique ability to translate the invisible language of pressure into a comprehensible signal, opening doors to precision, safety, and control. From the depths of oil wells to the soaring heights of aircraft, from the heart of manufacturing plants to the delicate realm of medical devices, pressure transmitters emerge as the unsung heroes, orchestrating harmony amid the chaotic forces of nature. So, let us embark on a journey to unravel the symphony of pressure transmitters—the symphony that converts pressure into power, analog into digital, and the ordinary into the extraordinary.

What is a transmitter?

A transmitter is a device or system that generates and sends out signals, usually in the form of electromagnetic waves or electrical pulses, to transmit information or energy from one location to another. Transmitters are widely used in various fields such as telecommunications, broadcasting, wireless communication, and remote control systems.

In the context of telecommunications, a transmitter converts the information (voice, data, video, etc.) into a suitable format for transmission. For example, in radio broadcasting, a transmitter takes an audio signal and modulates it onto a radio frequency carrier wave, which is then transmitted through antennas to be received by radio receivers.

Transmitters can vary in complexity and power, ranging from simple devices like a remote control for a television to complex systems used in satellite communications or radar. The key components of a transmitter typically include a signal source (such as an audio signal or data stream), a modulator (to impose the signal onto a carrier wave), and an amplifier (to boost the signal's power before transmission). The transmitted signal can be received by compatible receivers, which extract the original information from the received signal.

In essence, a transmitter is the starting point of any communication system that involves sending information wirelessly over a distance.

What is a Pressure Transmitter?

A pressure transmitter is a type of device used to measure and transmit pressure information from a process or system to a control or monitoring system. It's commonly used in industrial and commercial applications to monitor and control processes that involve liquids or gases under varying pressures. The pressure information collected by the transmitter can be used for various purposes, such as ensuring safety, maintaining optimal operation, and gathering data for analysis.

Here's how a pressure transmitter typically works:

- Pressure Sensing: The pressure transmitter contains a pressure sensor or sensing element, which is usually a diaphragm or a similar mechanism that reacts to changes in pressure. When the pressure on the diaphragm changes, it causes a mechanical deformation.

- Transduction: The mechanical deformation is converted into an electrical signal. This is often achieved using technologies like piezoelectric, strain gauge, or capacitive sensing. These technologies generate an electrical output that is proportional to the applied pressure.

- Signal Conditioning: The electrical signal from the pressure sensor is typically weak and needs to be amplified and conditioned before transmission. This involves adjusting the signal's range, compensating for temperature effects, and eliminating noise.

- Transmitting: Once the signal is conditioned, the pressure transmitter sends the processed signal to a control system, a monitoring station, or other devices through wired or wireless communication methods. The signal is then interpreted and used for various purposes, such as displaying pressure readings on control panels, activating alarms, or even making automated adjustments to the process based on the pressure information.

Pressure transmitters are essential in industries like oil and gas, manufacturing, chemical processing, water treatment, HVAC (heating, ventilation, and air conditioning), and more. They play a critical role in maintaining operational efficiency, safety, and quality control by ensuring that pressure levels are within acceptable limits and responding to any deviations from the desired values.

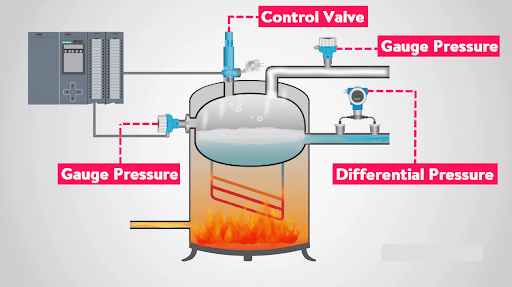

Fig 1. Pressure transmitter types

What is a Pressure Transmitter's purpose?

The purpose of a pressure transmitter is to accurately measure the pressure of gases or liquids in a given system or environment and convert that pressure into an electrical signal that can be easily transmitted, monitored, and controlled. Pressure transmitters play a crucial role in various industries and applications, serving multiple purposes:

- Process Control and Automation: Pressure transmitters are used to monitor and control industrial processes that involve fluids under pressure. By providing real-time pressure measurements, they allow for precise control of variables such as flow rates, levels, and pressures, ensuring optimal process efficiency and product quality.

- Safety and Monitoring: Pressure transmitters are essential for ensuring the safety of equipment, systems, and personnel. They help in detecting abnormal pressure conditions, leaks, overpressure, or under-pressure situations that could lead to hazardous conditions or equipment failure.

- Quality Control: In manufacturing processes, pressure transmitters help maintain consistency and quality by monitoring and controlling pressure-sensitive stages of production. This is critical in industries like food and beverage, pharmaceuticals, and chemicals.

- Energy Efficiency: Pressure transmitters aid in optimizing energy consumption by regulating pressure levels in systems like HVAC (heating, ventilation, and air conditioning) and industrial compressed air systems. This ensures efficient operation and reduces energy wastage.

- Environmental Monitoring: Pressure transmitters are used to measure barometric pressure in meteorology and environmental monitoring. They provide data for weather forecasting, climate studies, and pollution monitoring.

- Fluid Management: Pressure transmitters are employed in water and wastewater treatment facilities to monitor pressure in pipelines, tanks, and pumps. This helps maintain proper fluid flow, manage levels, and prevent overflows or underflows.

- Research and Development: In laboratories and research settings, pressure transmitters are used to measure pressures in experiments, simulations, and tests. They provide accurate data for analyzing the physical properties and behaviors of materials.

- Aerospace and Aviation: Pressure transmitters are integral components of aircraft and spacecraft systems, measuring cabin pressure, engine performance, and fuel systems to ensure safe and efficient flight operations.

- Oil and Gas Industry: Pressure transmitters are used in oil wells, pipelines, and refineries to monitor and control pressures in various stages of exploration, drilling, and refining processes.

- Medical Applications: In medical devices like ventilators and anesthesia machines, pressure transmitters monitor and control the pressure of gases delivered to patients, ensuring safe and precise treatment.

- Utilities and Water Management: Pressure transmitters are used in water distribution systems to monitor water pressure, detect leaks, and ensure the proper functioning of water supply networks.

- Automotive Industry: In vehicles, pressure transmitters are used for tire pressure monitoring systems (TPMS), ensuring optimal tire pressure for safety and fuel efficiency.

The primary purpose of a pressure transmitter is to provide accurate pressure data that can be used for control, monitoring, and decision-making across a wide range of applications and industries. It enhances safety, efficiency, quality, and reliability in various processes and systems.

How important is a Pressure Transmitter?

A pressure transmitter is incredibly important in various industries and applications due to the critical role it plays in ensuring safety, efficiency, accuracy, and control. Here are some reasons why pressure transmitters are so important:

- Safety: Pressure transmitters are crucial for maintaining safe operating conditions. They detect abnormal pressure levels that could lead to equipment failure, leaks, explosions, or other hazardous situations. In industries like oil and gas, chemical, and manufacturing, pressure transmitters prevent catastrophic accidents.

- Process Control: Industries rely on pressure transmitters to monitor and control processes accurately. Proper pressure management is vital for maintaining product quality, reducing waste, and adhering to regulatory standards.

- Energy Efficiency: Pressure transmitters help optimize energy consumption by regulating pressure levels in various systems. For example, they control pressure in HVAC systems, reducing energy usage and operational costs.

- Quality Assurance: In manufacturing, pressure-sensitive processes require precise pressure control to ensure consistent product quality. Pressure transmitters maintain tight tolerances and reduce variations in manufacturing output.

- Environmental Monitoring: Pressure transmitters contribute to environmental studies by providing data on atmospheric pressure, which is crucial for weather forecasting, climate analysis, and pollution monitoring.

- Healthcare: In medical settings, pressure transmitters are essential for delivering accurate and safe treatment. They regulate pressures in medical devices like ventilators and anesthesia machines, ensuring patient safety and comfort.

- Research and Development: Pressure transmitters provide valuable data for research and experiments, helping scientists and engineers understand material properties, behaviors, and physical phenomena.

- Infrastructure Management: Pressure transmitters monitor water pressure in distribution systems, helping utilities manage water resources, prevent leaks, and ensure consistent supply to consumers.

- Aviation and Aerospace: Pressure transmitters are integral to aviation safety, measuring cabin pressure, engine performance, and fuel systems to ensure safe flight operations.

- Data-Driven Decision-Making: Pressure transmitters provide real-time data that enables informed decision-making. This data is used to troubleshoot issues, optimize processes, and plan maintenance.

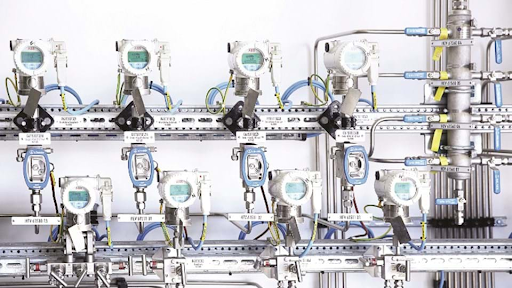

- Remote Monitoring: Pressure transmitters with digital communication capabilities allow remote monitoring of pressure conditions, reducing the need for on-site personnel and enabling proactive maintenance.

- Compliance and Regulations: Industries often operate within regulatory frameworks that mandate pressure monitoring and control. Pressure transmitters help maintain compliance with safety and quality standards.

In summary, pressure transmitters are indispensable tools that impact various aspects of industries, infrastructure, and technology. Their role in maintaining safety, optimizing processes, conserving energy, and ensuring quality makes them a fundamental component of modern engineering and industrial practices.

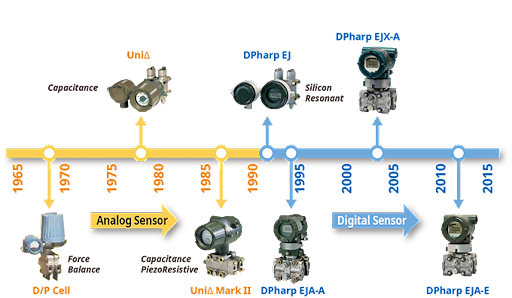

Pressure Transmitter History

The history of pressure transmitters traces the evolution of measurement technology over the centuries. Beginning with basic mechanical gauges like the Bourdon tube in the 19th century, pressure measurement gradually transitioned to electronic sensors in the mid-20th century. These electronic sensors offered greater accuracy and versatility, leading to the development of the first electronic pressure transmitters. With the advent of digital technology in the late 20th century, pressure transmitters became more precise and began communicating digitally with control systems. In the early 21st century, the rise of smart pressure transmitters marked a transformative shift, incorporating microprocessors for advanced diagnostics and self-calibration. Today, pressure transmitters are central to industrial automation, and they continue to evolve with advancements in materials and IoT integration, enabling real-time data monitoring and predictive maintenance in a wide range of industries.

Late 19th Century - Early 20th Century: The Birth of Pressure Measurement

During this period, pressure measurement was in its infancy, and instruments were primarily mechanical. Notable developments included:

- Bourdon Tube: Eugène Bourdon's Bourdon tube pressure gauge, patented in 1849, was an early mechanical device that used the deformation of a curved tube to measure pressure. It was widely used in various industries.

- McLeod Gauge: In 1874, Herbert McLeod developed the McLeod gauge, a mercury-based instrument used to measure very low pressures in vacuum systems.

Mid-20th Century: Emergence of Electronic Sensors

The mid-20th century marked the transition from purely mechanical to electronic pressure sensors, bringing greater accuracy and versatility:

- Piezoresistive Sensors: In the 1950s, researchers like Arthur C. Ruge developed piezoresistive sensors, which used changes in resistance in response to mechanical strain to measure pressure. These sensors offered better sensitivity.

- Piezoelectric Sensors: Piezoelectric sensors, which generate electrical charges when subjected to pressure, were also developed during this period.

Notable Transmitter: The Rosemount Engineering Company's Model 1151, introduced in 1966, was one of the early electronic pressure transmitters. It employed piezoresistive technology.

Late 20th Century: The Rise of Pressure Transmitters

In the latter part of the 20th century, electronic pressure transmitters began to replace mechanical gauges in many industrial applications:

- Digital Electronics: Pressure transmitters evolved to incorporate digital electronics, improving accuracy and providing self-diagnostic capabilities.

Notable Transmitter: The Honeywell ST 3000 Series pressure transmitter, released in the late 1980s, was an early example of a digital pressure transmitter, featuring microprocessor-based technology for precise measurements.

Late 20th Century - Early 21st Century: Microelectronics and Digital Communication

This era witnessed the miniaturization of pressure transmitters and advancements in communication protocols:

- Miniaturization: Advances in microelectronics allowed for the development of smaller pressure sensors, making them suitable for a broader range of applications.

- Digital Communication: Digital communication protocols like HART (Highway Addressable Remote Transducer) and FOUNDATION Fieldbus were introduced, enabling pressure transmitters to communicate digitally with control systems.

Notable Transmitter: The Yokogawa EJA Series, launched in the late 1990s, incorporated digital communication protocols and offered enhanced diagnostics for industrial applications.

Early 21st Century: Smart Pressure Transmitters and Industry 4.0

The early 21st century saw the advent of smart pressure transmitters, which marked a significant leap in capabilities:

- Smart Transmitters: Smart pressure transmitters feature microprocessors for advanced diagnostics, self-calibration, and communication capabilities. They became integral to industrial automation and Industry 4.0.

Notable Transmitter: The Emerson Rosemount 3051S series, introduced in the early 2000s, was a smart transmitter that supported Wireless HART communication, allowing for greater flexibility in industrial settings.

Present and Future: Advanced Materials and IoT Integration

In the present day and looking into the future, pressure transmitters continue to evolve:

- MEMS Technology: Microelectromechanical systems (MEMS) technology allows for the production of miniature pressure sensors, reducing size, cost, and power consumption while maintaining high performance.

- IoT Integration: Pressure transmitters are increasingly integrated into IoT ecosystems, enabling remote monitoring, predictive maintenance, and real-time data analysis.

Notable Trend: The use of advanced materials like silicon-on-insulator (SOI) and silicon carbide (SiC) is on the rise, enhancing sensor performance and durability, particularly in harsh environments.

Fig 2. Timeline of Yokogawa's Pressure Sensor Advances.

Pressure Transmitter Internal Parts

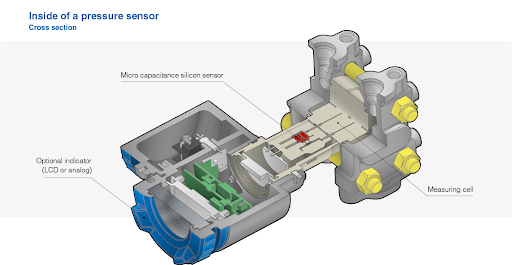

A pressure transmitter is a complex device that consists of various internal components working together to measure and transmit pressure information accurately. While designs may vary between manufacturers and specific models, here are the common internal parts you'll find in a typical electronic pressure transmitter:

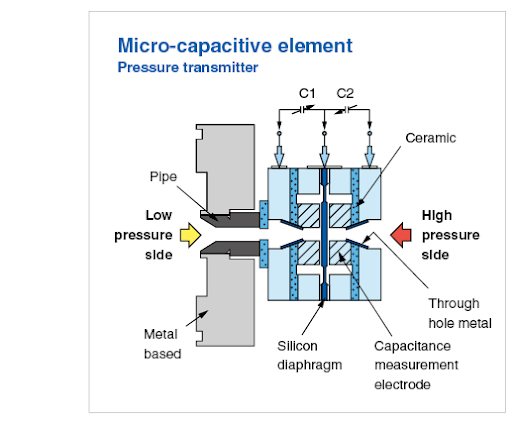

- Pressure Sensor or Sensing Element: This is the core component responsible for directly sensing the pressure changes. Various technologies, such as strain gauges, piezoelectric crystals, and capacitive sensors, can be used as the sensing element. When pressure is applied, the sensing element undergoes a mechanical deformation that is converted into an electrical signal.

- Diaphragm or Sensing Element Housing: The sensing element is often protected by a diaphragm or housing that separates the pressure medium from the sensitive electronics. This diaphragm is designed to transmit the pressure changes to the sensing element without affecting its accuracy.

- Signal Conditioning Circuitry: The raw electrical signal produced by the pressure sensor may need to be amplified, filtered, and conditioned before further processing. Signal conditioning circuitry ensures that the signal is accurate, stable, and within a suitable range for measurement and transmission.

- Analog-to-Digital Converter (ADC): Many modern pressure transmitters convert the analog signal from the pressure sensor into a digital signal using an ADC. This digital representation is easier to process, transmit, and manipulate within electronic circuits.

- Microcontroller or Digital Signal Processor (DSP): A microcontroller or DSP processes the digital signal from the ADC. It performs calculations, calibration, and compensation for factors like temperature variations, and may also implement communication protocols for interaction with external systems.

- Memory and Calibration Data: Some pressure transmitters include memory to store calibration data and parameters. This ensures accurate measurement by compensating for factors affecting the sensor's performance, such as temperature drift.

- Digital Communication Interface: Pressure transmitters often include built-in communication interfaces like HART, Foundation Fieldbus, Profibus, or more modern wireless protocols. These interfaces allow the transmitter to communicate with control systems, display panels, and other devices, providing real-time pressure information and diagnostics.

- Power Supply Circuitry: Pressure transmitters require power to operate. Depending on the application, they might be powered by various sources, including loop power from the communication loop or an external power supply.

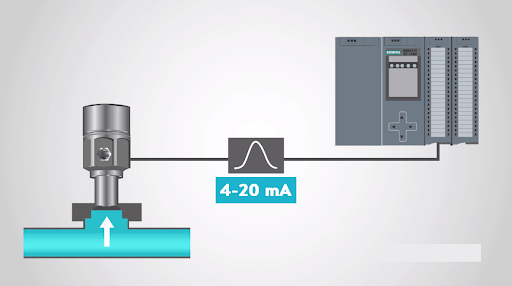

- Output Circuitry: The final step is generating an output signal that can be transmitted to other systems. This could be a standardized analog signal (such as 4-20 mA), a digital signal, or both.

- Housing and Enclosure: The internal components are enclosed in a protective housing, which is designed to withstand the environmental conditions of the application. The housing provides mechanical protection, and ingress protection (e.g., against dust and water), and often features mounting options for easy installation.

Pressure transmitters may also incorporate features like self-diagnostics, fault detection, and digital displays for local readings. The complexity and features of pressure transmitter internals will vary based on the specific application and the desired level of accuracy, reliability, and functionality.

Fig 3. Pressure transmitter structure

Pressure Transmitter Working Principle

The working principle of a pressure transmitter involves converting the mechanical force exerted by a fluid's pressure into an electrical signal that can be accurately measured and transmitted for monitoring or control purposes. Here's a step-by-step explanation of how a pressure transmitter works:

- Pressure Sensing: The pressure transmitter is exposed to the fluid or gas whose pressure needs to be measured. The pressure acts on a sensing element within the transmitter. This sensing element could be a diaphragm, Bourdon tube, piezoelectric crystal, or any other technology sensitive to mechanical deformation due to pressure changes.

- Mechanical Deformation: The pressure exerted by the fluid causes the sensing element to deform. This deformation might be in the form of bending, stretching, or other mechanical changes that depend on the specific type of sensing element used.

- Transduction: The deformation of the sensing element causes a change in its mechanical properties, such as strain, resistance, or capacitance. For example, strain gauge sensors experience changes in resistance proportional to the mechanical strain. This change in a mechanical property is converted into an electrical signal.

- Signal Amplification and Conditioning: The raw electrical signal produced by the sensing element is typically weak and needs to be amplified, filtered, and conditioned for accuracy. Signal conditioning circuitry adjusts the signal's range, compensates for temperature effects, and removes noise.

- Analog-to-Digital Conversion: If the signal is analog, it's converted into a digital signal using an analog-to-digital converter (ADC). This allows for easier processing, transmission, and manipulation of the signal using digital electronics.

- Processing and Compensation: The digital signal is processed by a microcontroller or digital signal processor (DSP). The processor applies compensation algorithms to account for factors such as temperature variations and non-linearity in the sensing element's response.

- Calibration and Scaling: The processed signal is then calibrated to ensure accuracy. Calibration involves comparing the output signal to known pressure standards and adjusting it accordingly. Scaling is also performed to represent the pressure value in the desired engineering units.

- Output Generation: The calibrated and scaled signal is then converted into an output format suitable for communication with external systems. This could be an analog voltage or current signal (e.g., 4-20 mA) or a digital signal compatible with communication protocols like HART, Profibus, or Foundation Fieldbus.

- Communication Interface: The pressure transmitter may include communication interfaces that allow it to transmit the pressure information to control systems, data loggers, or other devices. These interfaces enable real-time monitoring, remote control, and data collection.

- Power Supply: The pressure transmitter requires power to operate its internal electronics. Depending on the design, it might be powered by an external power source or by the current loop used for communication.

Overall, the pressure transmitter's working principle revolves around the conversion of pressure-induced mechanical deformation into a measurable and communicable electrical signal. This enables accurate pressure measurement and monitoring across various industrial applications.

Fig 4. Pressure transmitter operation

Pressure Transmitter Types

Pressure transmitters come in various types and designs to suit different applications, environments, and pressure ranges. Here are some common types of pressure transmitters:

- Absolute Pressure Transmitter: Measures pressure relative to a perfect vacuum (absolute zero pressure). This type is used in applications where pressure measurements must account for atmospheric pressure. Common in meteorology, altitude sensing, and vacuum systems.

- Gauge Pressure Transmitter: Measures pressure relative to atmospheric pressure. It's often used for measuring pressure in closed systems. A common example is tire pressure measurement in vehicles.

- Differential Pressure Transmitter: Measures the difference in pressure between two points. This type is useful for applications like flow measurement, filter monitoring, and level measurement in tanks.

- Sealed Pressure Transmitter: Also known as vented gauge pressure transmitters, they measure pressure relative to a reference pressure, which is sealed inside the transmitter at the time of manufacturing. This design compensates for local atmospheric pressure changes.

- Submersible Pressure Transmitter: Designed for use underwater or in liquids, these transmitters are often used in water level measurement applications, like wells, tanks, and reservoirs.

- Hydrostatic Pressure Transmitter: Used for measuring the level or depth of a liquid by sensing the hydrostatic pressure exerted by the fluid. Common in industrial tanks and reservoirs.

- Sanitary Pressure Transmitter: Designed for use in hygienic or sterile environments, such as food and pharmaceutical industries, where cleanliness and prevention of contamination are critical.

- High-Pressure Transmitter: Engineered to handle high-pressure environments, often found in industrial applications like hydraulic systems, pressure vessels, and oil and gas processes.

- Low-Pressure Transmitter: Optimized for measuring very low pressures, often used in applications like HVAC systems, cleanrooms, and leak detection.

- Vacuum Pressure Transmitter: Specifically designed to measure pressures below atmospheric pressure, common in applications like vacuum systems, vacuum furnaces, and scientific research.

- Smart Pressure Transmitter: Incorporates digital communication protocols, such as HART, Profibus, Foundation Fieldbus, or wireless technologies. These transmitters provide additional functionality like remote calibration, diagnostics, and real-time monitoring.

- Flush Diaphragm Pressure Transmitter: Designed for applications where the process medium might clog or damage a standard diaphragm. The flush design prevents particles from obstructing the pressure-sensing element.

- High-Temperature Pressure Transmitter: Engineered to operate in high-temperature environments such as engines, furnaces, and industrial processes where the temperatures exceed the capabilities of standard transmitters.

- Corrosion-Resistant Pressure Transmitter: Constructed with materials that resist corrosion, making them suitable for aggressive or corrosive media found in chemical, petrochemical, and industrial applications.

These are just a few examples of pressure transmitter types. Each type is designed to cater to specific requirements and challenges posed by different industries and applications. The choice of a pressure transmitter type depends on factors like the nature of the medium, pressure range, temperature, environmental conditions, and the precision required for measurement.

Fig 5. Pressure sensors

- Working Principle: Measures pressure relative to a perfect vacuum. It includes a reference chamber with a vacuum sealed inside. The pressure exerted on the sensor diaphragm counteracts the vacuum, producing an output signal.

- Pressure Range: Varies widely depending on the application, from near-zero pressure to high vacuum levels.

- Applications: Used in meteorology for barometric pressure measurements, altitude sensing in aircraft, vacuum systems, and scientific research.

- Pros: Useful for applications where the atmospheric pressure needs to be accounted for, provides a true zero reference point.

- Cons: Not as common as other types due to specific applications, requires accurate vacuum reference calibration.

- Working Principle: Measures pressure relative to atmospheric pressure. The pressure on the sensing element deflects due to the difference between process pressure and atmospheric pressure.

- Pressure Range: Typically spans a few psi (pounds per square inch) to hundreds of psi.

- Applications: Commonly used for monitoring industrial processes, HVAC systems, tire pressure, and pressure control systems.

- Pros: Simple to understand, widely used, cost-effective.

- Cons: Doesn't work well in applications where atmospheric pressure changes are significant.

- Working Principle: Measures the difference in pressure between two points. The pressure difference across a restrictive element (e.g., an orifice or a venturi) causes the diaphragms on either side of the element to deflect.

- Pressure Range: Depending on the application, can range from low pressures to high pressures.

- Applications: Used for flow measurement, filter monitoring, and level measurement in tanks, and HVAC systems.

- Pros: Excellent for applications involving flow and level measurement, compensates for common-mode pressure fluctuations.

- Cons: Requires additional components like an orifice plate, installation, and calibration complexity.

- Working Principle: Similar to a gauge pressure transmitter, the reference chamber contains a sealed pressure that compensates for atmospheric pressure variations.

- Pressure Range: Similar to gauge pressure transmitters.

- Applications: Useful when atmospheric pressure changes could affect the measurement, like in weather-sensitive applications.

- Pros: Compensation for local atmospheric pressure changes, more accurate in varying environments.

- Cons: Complexity compared to a standard gauge pressure transmitter.

- Working Principle: Measures the pressure of a liquid by immersing the sensor directly into the liquid. Hydrostatic pressure at a specific depth is measured.

- Pressure Range: Typically designed for low to moderate pressures.

- Applications: Water level measurement in wells, tanks, and reservoirs.

- Pros: Provides accurate liquid level measurement, suitable for continuous submersion.

- Cons: Limited to liquid applications, and may require regular maintenance to prevent fouling.

- Working Principle: Measures liquid pressure using the hydrostatic pressure exerted by the liquid column. The pressure difference between the bottom and top of a column is proportional to the liquid level.

- Pressure Range: Generally suited for low to moderate pressures.

- Applications: Level measurement in tanks, ponds, and open reservoirs.

- Pros: Simple and reliable for liquid level measurement, unaffected by fluid density changes.

- Cons: Limited to liquid-level applications, not suitable for gases.

Absolute Pressure Transmitter:

Gauge Pressure Transmitter:

Differential Pressure Transmitter:

Sealed Pressure Transmitter:

Submersible Pressure Transmitter:

Hydrostatic Pressure Transmitter:

These are the details for some of the pressure transmitter types. If you're interested, I can continue explaining the rest of the types. Just let me know!

Comparing table

Here's a comparison table summarizing the key features of different types of pressure transmitters:

| Type | Working Principle | Pressure Range | Applications | Pros | Cons |

| Absolute Pressure | Measures pressure relative to vacuum | Wide range, from near-zero to high | Meteorology, altimeters, vacuum systems | Provides true zero reference, accurate | Specialized application, vacuum calibration |

| Gauge Pressure | Measures pressure relative to the atmosphere | Few psi to hundreds of psi | Industrial processes, HVAC, tire pressure | Simple, cost-effective, widely used | Limited use in fluctuating atmospheric pressure |

| Differential Pressure | The measures pressure difference between points | Depends on application | Flow measurement, level, HVAC systems | Useful for flow and level measurement | Requires additional components, calibration complexity |

| Sealed Pressure | Compensates for atmospheric pressure changes | Similar to the gauge pressure range | Weather-sensitive applications | Accurate in varying environments | More complex than standard gauge transmitters |

| Submersible Pressure | Measures liquid pressure when immersed | Typically low to moderate pressures | Water level measurement in wells, tanks | Accurate liquid level measurement | Limited to liquid applications, maintenance |

| Hydrostatic Pressure | Measures liquid pressure using column height | Typically low to moderate pressures | Liquid level measurement in tanks | Reliable for liquid-level measurement | Limited to liquid-level applications, not for gases |

Please note that this table provides a general overview, and the specific features and performance of pressure transmitters within each type can vary based on the manufacturer, model, and technological advancements. Additionally, the "Pros" and "Cons" listed are not exhaustive and may vary in different scenarios. Always refer to product specifications and consult experts when choosing the right pressure transmitter for your application.

What is the Pressure Transmitter used for?

Pressure transmitters are used for a wide range of applications across various industries due to their ability to accurately measure and transmit pressure information. Here are some common uses of pressure transmitters:

- Industrial Processes: Pressure transmitters are essential in industries like manufacturing, chemical processing, and pharmaceuticals. They monitor and control pressure in production processes to ensure product quality and process efficiency.

- HVAC Systems: Pressure transmitters regulate air and fluid pressures in heating, ventilation, and air conditioning systems. This helps maintain comfortable indoor environments and energy efficiency.

- Oil and Gas: Pressure transmitters are used in oil wells, pipelines, refineries, and offshore platforms to monitor and control pressures in extraction, processing, and transportation operations.

- Water Management: Pressure transmitters monitor water pressure in distribution systems, helping utilities manage water resources, detect leaks, and ensure consistent water supply.

- Aerospace and Aviation: Pressure transmitters measure cabin pressure, engine performance, and hydraulic systems in aircraft and spacecraft, contributing to safe and efficient flight operations.

- Automotive Industry: In vehicles, pressure transmitters are used in tire pressure monitoring systems (TPMS) to ensure proper tire inflation, improving safety and fuel efficiency.

- Medical Devices: Pressure transmitters regulate pressures in medical equipment like ventilators, anesthesia machines, and dialysis machines, ensuring precise and safe treatment.

- Energy Generation: Pressure transmitters are used in power plants to monitor steam and gas pressures, contributing to efficient power generation and preventing equipment failure.

- Environmental Monitoring: Pressure transmitters provide atmospheric pressure data for weather forecasting, climate studies, and pollution monitoring.

- Research and Development: Scientists and engineers use pressure transmitters in laboratories to study material properties, fluid dynamics, and physical phenomena.

- Process Automation: Pressure transmitters play a key role in process automation, allowing for remote monitoring, control, and optimization of various processes.

- Safety Systems: Pressure transmitters are integrated into safety systems to detect abnormal pressure conditions and trigger alarms or shut down processes to prevent accidents.

- Hydraulics and Pneumatics: Pressure transmitters are used to monitor and control pressures in hydraulic and pneumatic systems, ensuring precise movement and control of machinery.

- Food and Beverage Industry: Pressure transmitters are used to monitor and control pressures in various stages of food and beverage production, ensuring quality and safety.

- Chemical Industry: Pressure transmitters are vital for monitoring pressures in chemical reactors, distillation columns, and other critical processes.

- Pharmaceuticals: Pressure transmitters are used to monitor and control pressures in pharmaceutical manufacturing processes, ensuring product quality and regulatory compliance.

These are just a few examples of the numerous applications where pressure transmitters are used. Their versatility, accuracy, and reliability make them indispensable tools across industries that rely on precise pressure measurements for operational efficiency, safety, and quality control.

Fig 6. Inside of a pressure transmitter

In which industry we can use the pressure transmitter?

Pressure transmitters find applications in a wide range of industries where pressure measurement and control are crucial. Here are some industries where pressure transmitters are commonly used:

- Oil and Gas: Pressure transmitters monitor pressures in oil wells, pipelines, refineries, and offshore platforms to ensure safe operations, optimize production, and prevent leaks.

- Manufacturing: Pressure transmitters are used in various manufacturing processes to maintain consistent pressure levels, ensuring product quality and process efficiency.

- Chemical Industry: Pressure transmitters are essential for controlling pressures in chemical reactors, distillation columns, and other chemical processes.

- Pharmaceuticals: Pressure transmitters monitor and control pressures in pharmaceutical manufacturing processes to ensure product quality and regulatory compliance.

- Aerospace and Aviation: Pressure transmitters measure cabin pressure, engine performance, and hydraulic systems in aircraft and spacecraft for safe and efficient operations.

- Automotive Industry: Pressure transmitters are used in tire pressure monitoring systems (TPMS) to ensure proper tire inflation, improving safety and fuel efficiency.

- Water and Wastewater Treatment: Pressure transmitters monitor pressures in water distribution systems, tanks, and pipes to manage water resources, detect leaks, and ensure proper treatment.

- HVAC (Heating, Ventilation, and Air Conditioning): Pressure transmitters regulate air and fluid pressures in HVAC systems, contributing to indoor comfort and energy efficiency.

- Energy Generation: Pressure transmitters monitor steam and gas pressures in power plants to optimize power generation, prevent equipment failure, and ensure safety.

- Medical Devices: Pressure transmitters are used in medical equipment like ventilators, anesthesia machines, and dialysis machines to provide accurate and safe treatment.

- Research and Development: Pressure transmitters are used in laboratories for studying fluid dynamics, material properties, and physical phenomena.

- Environmental Monitoring: Pressure transmitters provide atmospheric pressure data for weather forecasting, climate studies, and pollution monitoring.

- Food and Beverage Industry: Pressure transmitters monitor and control pressures in various stages of food and beverage production, ensuring product quality and safety.

- Pulp and Paper Industry: Pressure transmitters are used to control pressure in paper processing and pulp production processes.

- Mining and Minerals: Pressure transmitters monitor pressure levels in various mining processes and equipment to ensure safe operations and prevent equipment failure.

- Utilities: Pressure transmitters are used in utilities for managing water supply, gas distribution, and wastewater systems.

- Marine Industry: Pressure transmitters are used in marine applications for monitoring pressures in ship systems and underwater equipment.

- Automated Manufacturing: Pressure transmitters contribute to process automation by providing real-time pressure data for remote monitoring and control.

These are just a few examples, and the versatility of pressure transmitters makes them valuable tools in many other industries as well. Their accuracy and reliability play a vital role in ensuring operational efficiency, safety, and quality across various applications.

Fig 7. Pressure transmitter applications

Advantages and disadvantages of pressure transmitters

Pressure transmitters offer numerous advantages, but they also come with certain limitations. Here are the key advantages and disadvantages of pressure transmitters:

Advantages:

- Accurate Measurement: Pressure transmitters provide accurate and reliable pressure measurements, making them essential for maintaining precise control and ensuring safety.

- Real-time Monitoring: They offer real-time pressure data, enabling operators and systems to monitor processes continuously and make informed decisions.

- Automation: Pressure transmitters are crucial for process automation, allowing systems to adjust pressure levels automatically for optimal performance.

- Remote Monitoring: Many pressure transmitters come with digital communication capabilities, enabling remote monitoring and control from a central location.

- Data Integration: Pressure transmitters can be integrated into control systems, SCADA (Supervisory Control and Data Acquisition) systems, and other monitoring platforms for seamless data integration.

- Safety Enhancement: They contribute to safety by detecting abnormal pressure conditions, triggering alarms, and initiating safety shutdowns to prevent accidents.

- Energy Efficiency: By regulating pressure levels in systems like HVAC and hydraulic machinery, pressure transmitters help optimize energy consumption.

- Quality Control: In manufacturing, pressure-sensitive processes rely on accurate pressure control to ensure consistent product quality.

- Process Optimization: Pressure transmitters assist in optimizing processes by providing data for adjustments and improvements.

- Diagnostics: Some pressure transmitters offer self-diagnostic capabilities, helping to identify issues and malfunctions.

Disadvantages:

- Calibration and Maintenance: Pressure transmitters require periodic calibration to maintain accuracy. Maintenance and calibration can be time-consuming and costly.

- Limited Pressure Ranges: Some pressure transmitters have specific pressure ranges they can measure accurately. Using them outside these ranges may lead to inaccuracies.

- Compatibility: Integrating pressure transmitters into existing systems may require compatibility with communication protocols, which can be complex and require additional hardware.

- Environmental Conditions: Extreme temperatures, humidity, and corrosive environments can affect the performance and lifespan of pressure transmitters.

- Initial Cost: High-quality pressure transmitters with advanced features can be expensive to purchase initially.

- Mechanical Wear: Mechanical components, like diaphragms, can wear out over time due to continuous pressure cycles, affecting accuracy.

- Complexity: Some applications require complex installations with additional components like pressure regulators, isolators, or manifolds.

- Electromagnetic Interference: In certain environments, electromagnetic interference can affect the accuracy of pressure transmitters.

- Specific Applications: Some pressure transmitter types are designed for specific applications and may not be suitable for others.

In summary, pressure transmitters offer a multitude of benefits, ranging from accurate measurements to process control and safety enhancement. However, they also have limitations, including calibration needs, environmental considerations, and compatibility challenges. The choice of a pressure transmitter should be based on careful consideration of its advantages and disadvantages in the context of the specific application.

Fig 8. Pressure transmitters

What are the important factors for choosing the proper pressure transmitter?

Choosing the proper pressure transmitter involves considering several important factors to ensure it meets the requirements of your specific application. Here are the key factors to consider:

- Pressure Range: Determine the range of pressures your application requires. Choose a transmitter with a range that covers the expected operating pressure while allowing some headroom for safety and accuracy.

- Type of Pressure: Decide whether you need to measure absolute, gauge, differential, or other types of pressure based on the specifics of your application.

- Accuracy: Consider the required level of accuracy for your application. High-precision applications might need transmitters with lower accuracy tolerances.

- Temperature Range: Evaluate the temperature extremes in your environment. Choose a transmitter that can operate reliably within the temperature range you need.

- Media Compatibility: Ensure the transmitter's wetted materials (diaphragm, seals, etc.) are compatible with the fluid or gas being measured. Some media can be corrosive, abrasive, or reactive, necessitating specialized materials.

- Environmental Conditions: Consider the environmental conditions the transmitter will be exposed to, including humidity, dust, vibration, and potential exposure to chemicals or harsh elements.

- Installation: Choose a transmitter that can be easily installed in your specific setup. Consider factors like mounting options, process connections, and available space.

- Output Signal: Decide whether you need an analog signal (e.g., 4-20 mA, 0-10 V) or a digital signal with communication capabilities (HART, Profibus, etc.).

- Communication Protocols: If remote monitoring and control are required, choose a transmitter that supports the communication protocol used in your system.

- Electrical Requirements: Ensure the transmitter's electrical requirements (voltage, current, power supply) match your existing infrastructure.

- Response Time: Consider the speed at which pressure changes need to be detected. Some applications might require faster response times than others.

- Protection Ratings: Choose a transmitter with the appropriate ingress protection (IP) and environmental protection (e.g., NEMA) ratings for your application.

- Certifications and Compliance: If your industry requires specific certifications (ATEX, UL, CE, etc.), ensure the transmitter meets those standards.

- Maintenance and Calibration: Consider the ease of maintenance and calibration. Some transmitters require periodic recalibration, so choose one that fits your maintenance schedule.

- Cost: Compare the features and benefits of various transmitters within your budget. While cost is a factor, it should be balanced against performance and reliability.

- Additional Features: Some transmitters offer extra features like self-diagnostics, digital displays, and built-in temperature compensation. Assess whether these features are beneficial for your application.

- Vendor Reputation: Choose a reputable manufacturer known for producing reliable and high-quality pressure transmitters.

- Future Scalability: Consider whether your needs might change in the future. Choosing a transmitter that can adapt to new requirements can save costs down the line.

By carefully evaluating these factors, you can select a pressure transmitter that is well-suited to your application's demands and helps you achieve accurate and reliable pressure measurements.

Fig 9. Pressure transmitters

Conclusion

Pressure transmitters are vital instruments that play a pivotal role in a wide array of industries and applications. These devices provide accurate and real-time pressure measurements, allowing for precise control, process optimization, safety enhancement, and quality assurance.

In industries ranging from oil and gas, manufacturing, and chemical processing to healthcare, aerospace, and environmental monitoring, pressure transmitters contribute significantly to operational efficiency, product quality, and personnel safety. They enable remote monitoring, automation, and data integration, facilitating informed decision-making and proactive maintenance.

However, the selection of the proper pressure transmitter requires careful consideration of various factors such as pressure range, accuracy, environmental conditions, media compatibility, and communication protocols. The advantages of pressure transmitters include accurate measurement, process control, energy efficiency, and safety enhancement. On the other hand, limitations like calibration requirements, compatibility challenges, and maintenance considerations must also be taken into account.

In conclusion, pressure transmitters are indispensable tools that empower industries to achieve precision, safety, and control in pressure-related processes. Their role in maintaining operational excellence and contributing to various sectors underscores their importance in modern engineering, manufacturing, and technology.

To recap

1. What is a pressure transmitter?

A pressure transmitter is a sensor device that converts the mechanical force of fluid or gas pressure into an electrical signal, providing accurate pressure measurements for monitoring, control, and analysis.

2. How does a pressure transmitter work?

Pressure transmitters work by using a sensing element (like a diaphragm or strain gauge) that deforms in response to pressure changes. This deformation is converted into an electrical signal, which is then processed and transmitted for measurement.

3. What are the main types of pressure transmitters?

The main types include absolute, gauge, differential, sealed, submersible, and more, each catering to specific pressure measurement needs and applications.

4. Where are pressure transmitters used?

Pressure transmitters find applications in industries like oil and gas, manufacturing, aerospace, healthcare, environmental monitoring, and more, where precise pressure measurement is essential.

5. How accurate are pressure transmitters?

Pressure transmitter accuracy varies by model and manufacturer. High-quality transmitters can achieve accuracies within a fraction of a percent of the full scale.

6. What factors affect pressure transmitter accuracy?

Factors include calibration, temperature variations, media compatibility, environmental conditions, and manufacturing quality.

7. Can pressure transmitters measure both gases and liquids?

Yes, pressure transmitters are designed to measure both gases and liquids, provided they are compatible with the wetted materials.

8. Do pressure transmitters require calibration?

Yes, pressure transmitters need periodic calibration to maintain accurate measurements over time.

9. How do pressure transmitters communicate with control systems?

They communicate via analog signals (e.g., 4-20 mA, 0-10 V) or digital protocols like HART, Profibus, Foundation Fieldbus, and more.

10. What is the difference between absolute and gauge pressure transmitters?

Absolute pressure transmitters measure pressure relative to a vacuum, while gauge pressure transmitters measure pressure relative to atmospheric pressure.

11. Can pressure transmitters work in extreme temperatures?

Some pressure transmitters are designed for high-temperature or low-temperature applications, but their performance may be affected by extreme conditions.

12. How are pressure transmitters protected against environmental factors?

Pressure transmitters are often equipped with appropriate ingress protection (IP) and environmental protection (e.g., NEMA) ratings to safeguard against dust, moisture, and other environmental factors.

13. What is the lifespan of a pressure transmitter?

The lifespan varies based on usage, quality, and environmental conditions. With proper maintenance, pressure transmitters can last many years.

14. Can pressure transmitters be used in hazardous areas?

Yes, some pressure transmitters are designed to be intrinsically safe and can be used in hazardous environments with flammable gases or vapors.

15. How do pressure transmitters contribute to energy efficiency?

Pressure transmitters help regulate pressure in systems like HVAC, hydraulic machinery, and industrial processes, reducing energy consumption and operational costs.

References

https://sabadejlah.com/what-is-a-pressure-transmitter/

https://realpars.com/pressure-sensor/

https://www.transmittershop.com/blog/factors-of-consideration-when-choosing-pressure-transmitters/

https://www.chemengonline.com/pressure-transmitter-basics-selection-guidelines/

https://realpars.com/differential-pressure-transmitter/

https://www.transmittershop.com/blog/factors-of-consideration-when-choosing-pressure-transmitters/

https://americas.fujielectric.com/products/instrumentation/pressure/

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025