Beyond the Bar: Selecting the Right Pressure Transmitter for Industrial Success

Pressure transmitters are unsung heroes in the industrial landscape, silently working to ensure that processes run smoothly, equipment stays safe, and products meet the highest standards of quality. While they may not always take the spotlight, the significance of selecting the right pressure transmitter for any given application cannot be overstated. These unassuming devices play a pivotal role in maintaining safety, optimizing processes, and enhancing overall efficiency in a wide range of industries.

In this guide, we delve into the intricate world of pressure transmitter selection criteria and considerations, unraveling the mysteries of pressure ranges, accuracy ratings, environmental conditions, and much more. Whether you're navigating high-temperature environments, corrosive settings, or hazardous zones, this comprehensive exploration will empower you with the knowledge to make informed decisions. Get ready to demystify the intricacies of pressure transmitters and discover how choosing the right one can significantly impact the success and safety of your industrial operations.

Fig 1. BD sensors with UL certifications

What is a Pressure Transmitter?

A pressure transmitter is a device used to measure and transmit information about pressure in various industrial and commercial applications. It is a type of sensor or transducer that converts the mechanical force exerted by a fluid (liquid or gas) on its surface into an electrical signal, typically in the form of a voltage or current, which can be transmitted to a control system, display, or data acquisition system.

Here are some key features and functions of a pressure transmitter:

What are the Pressure Transmitter Types?

Pressure transmitters come in various types, each designed for specific applications and pressure ranges. The choice of pressure transmitter type depends on factors such as the environment, the fluid being measured, the required accuracy, and the intended application. Here are some common types of pressure transmitters:

Selection Criteria and Considerations

Selecting the right pressure transmitter for a specific application requires careful consideration of several factors. Here are some key selection criteria and considerations:

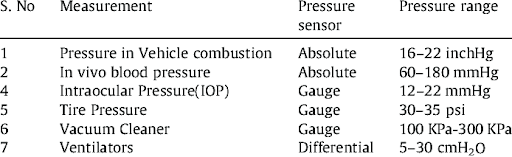

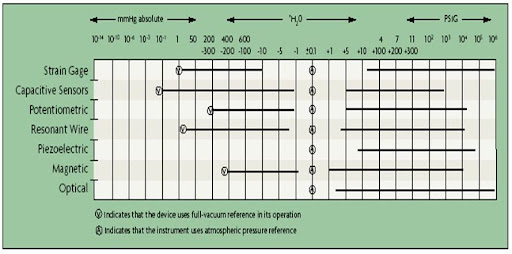

Fig 2. Pressure sensor range

Environmental Considerations

How do Environmental Conditions Affect Pressure Transmitter Choice?

Environmental conditions play a significant role in the selection of an appropriate pressure transmitter because they can affect the performance, accuracy, and longevity of the transmitter. Here's how environmental conditions impact the choice of a pressure transmitter:

When the temperature is important, which pressure transmitter types are useful?

When temperature is a critical consideration in your application, you should select pressure transmitter types that are capable of accurate and reliable pressure measurements while also accounting for temperature variations. The following pressure transmitter types are commonly used when temperature is important:

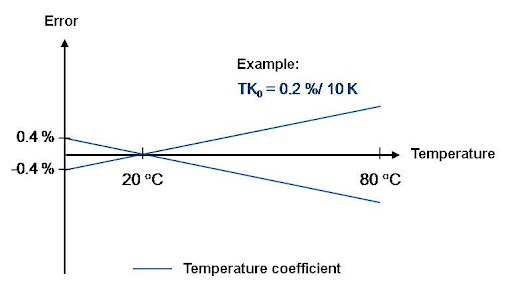

Fig 3. Temperature coefficient

In what types of environments might corrosion-resistant pressure transmitters be necessary?

Corrosion-resistant pressure transmitters may be necessary in environments where exposure to corrosive substances or harsh chemicals can damage standard pressure transmitters. Here are some types of environments and applications where corrosion-resistant pressure transmitters are essential:

What are the challenges and considerations when selecting pressure transmitters for high-vibration environments?

Selecting pressure transmitters for high-vibration environments presents several challenges and considerations to ensure the transmitters can provide accurate and reliable measurements. Here are some of the key factors to take into account:

1. Vibration Levels: Understand the magnitude and frequency of vibration in the environment. High-vibration environments can vary significantly, and the transmitter must be chosen to match the specific vibration conditions.

2. Mechanical Resonance: Mechanical resonance can occur when the vibration frequency matches the natural frequency of the transmitter or its mounting system. This can lead to excessive stress and damage. Select transmitters with resonance-avoidance features.

3. Mounting and Installation: Proper mounting and installation are critical. Use secure mounting hardware and techniques to minimize the effects of vibration. Ensure that the transmitter is mounted on a stable structure that can dampen vibrations.

4. Transmitter Design: Choose pressure transmitters designed for high-vibration environments. These transmitters often have reinforced internal components and housings to withstand mechanical stress.

5. Shock and Impact Resistance: In addition to vibration, consider the potential for shock and impact. Transmitters in environments with heavy machinery or equipment may experience sudden impacts. Shock-resistant models are designed to handle such situations.

6. Material Selection: Select transmitters with robust materials and construction that can withstand mechanical stress without deformation or damage.

7. Electrical Connections: Ensure that electrical connections are secure and vibration-resistant. Use strain relief and appropriate cable management to prevent disconnection or damage to wires.

8. Calibration and Testing: Proper calibration and testing are essential in high-vibration environments. Transmitters may require periodic recalibration to maintain measurement accuracy.

9. Remote Monitoring: Consider using pressure transmitters with remote monitoring and diagnostics capabilities to assess their performance and identify any issues without having to access the installation site.

10. Compliance with Standards: Verify that the pressure transmitter meets relevant industry standards for high-vibration applications. Standards such as those provided by the International Electrotechnical Commission (IEC) and the National Electrical Manufacturers Association (NEMA) may be applicable.

11. Consideration of Vibration Isolation: Depending on the severity of the vibration, it may be necessary to incorporate vibration isolation devices or mounts between the transmitter and the mounting structure to reduce the transmission of vibration.

12. Periodic Maintenance: Establish a routine maintenance schedule to inspect and maintain the pressure transmitters in high-vibration environments. Regular checks can help identify issues early.

13. Vendor Expertise: Consult with the pressure transmitter manufacturer or vendor for guidance on selecting a model suitable for the specific vibration conditions in your application.

High-vibration environments can be particularly challenging, as they can lead to premature wear, inaccuracies, and even transmitter failure. By carefully considering the factors mentioned above and selecting pressure transmitters designed for these conditions, you can ensure that your measurements remain accurate and your transmitters have a longer operational life in such challenging environments.

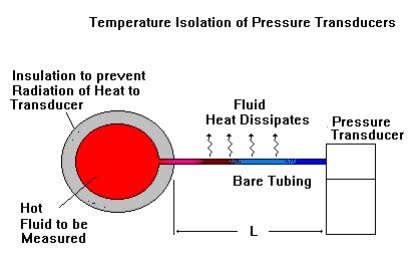

Fig 4. Temperature isolation of pressure transducer

What should be considered when selecting pressure transmitters for hazardous or explosive areas?

Selecting pressure transmitters for hazardous or explosive areas requires careful consideration of safety, regulations, and the specific conditions of the environment. Here are key factors to consider when making this selection:

1. Hazardous Area Classification:

Understand the classification of the hazardous area based on standards like ATEX, IECEx, or NEC (National Electrical Code). Determine whether it is a gas or dust environment and its specific zone or division.

2. Certification and Compliance:

Ensure that the pressure transmitter is certified for use in the identified hazardous area. Look for ATEX, IECEx, FM, CSA, or other relevant certifications based on your location and industry.

3. Explosion Protection Methods:

Consider the explosion protection method used in the pressure transmitter. It may use methods such as intrinsic safety, flameproof enclosures, or increased safety, depending on the classification of the hazardous area.

4. Temperature Classification:

Evaluate the temperature classification of the hazardous area, which indicates the maximum surface temperature allowed for the pressure transmitter. Ensure the transmitter's temperature rating matches or is lower than the area's classification.

5. Material Compatibility:

Verify that the pressure transmitter's materials are compatible with the substances present in the hazardous area. Some chemicals can corrode or react with certain materials.

6. Gas Group and Dust Group:

Determine the gas group (e.g., Group I, II, or III) or dust group (e.g., Group A, B, or C) relevant to your application. The pressure transmitter should be suitable for these groups.

7. Ingress Protection (IP) Rating:

Check the IP rating to ensure the transmitter is adequately protected against ingress of dust, liquids, or foreign objects.

8. Cable and Wiring:

Use appropriately rated cables and wiring to connect the pressure transmitter, ensuring they are suitable for hazardous areas.

9. Enclosure and Housing:

Select pressure transmitters with enclosures or housings that provide additional protection and prevent the release of sparks or heat. Enclosures should be robust and tightly sealed.

10. Grounding and Bonding:

Implement effective grounding and bonding practices to prevent electrostatic discharge and reduce the risk of sparks in the hazardous area.

11. Area Classification Changes:

Consider future changes in the area classification or process that could affect the pressure transmitter requirements. Ensure that the selected transmitter can adapt to these changes.

12. Maintenance and Inspection:

Develop a maintenance and inspection plan to ensure that the pressure transmitter continues to operate safely in the hazardous area. Periodic inspections and testing are essential.

13. Vendor Expertise:

Consult with reputable pressure transmitter manufacturers or vendors with expertise in hazardous areas for guidance and product recommendations.

Safety is paramount in hazardous areas, and choosing the right pressure transmitter is crucial to prevent accidents and ensure compliance with regulations. Failure to do so can result in serious safety breaches and legal issues. Carefully assess the specific requirements and risks of your application and follow relevant safety standards and regulations when selecting pressure transmitters for hazardous or explosive areas.

Why is selecting the right pressure transmitter important for industrial applications?

Selecting the right pressure transmitter is critically important for industrial applications for several reasons:

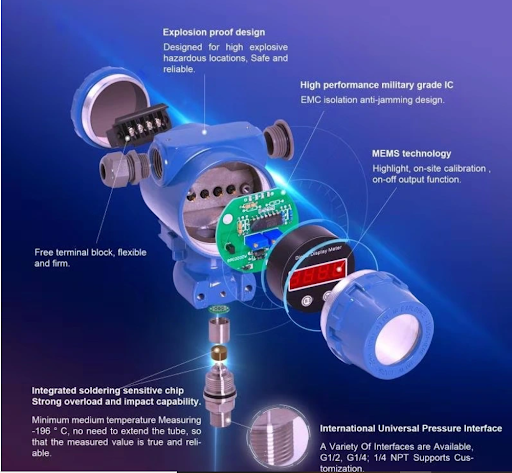

Fig 5. Explosion-proof pressure sensor design

Practical and Cost Considerations:

What are some budget considerations when selecting a pressure transmitter?

Budget considerations are essential when selecting a pressure transmitter, as they can significantly impact the overall cost of your project or system. Here are some key budget-related factors to keep in mind:

How does vendor reputation and product support impact the selection process?

Vendor reputation and product support play a critical role in the selection process when choosing a pressure transmitter. Their impact is significant for several reasons:

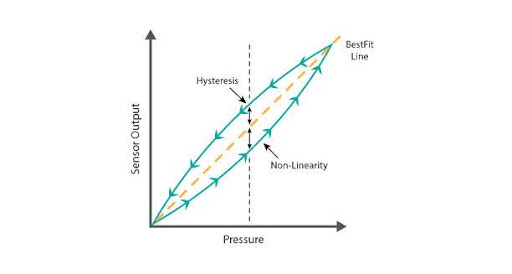

Fig 6. Pressure sensor accuracy

When selecting pressure transmitters for a particular application, what are some trade-offs that may need to be considered between different criteria?

When selecting pressure transmitters for a particular application, you may encounter trade-offs between various criteria, as it's not always possible to optimize all aspects simultaneously. Here are some common trade-offs that you may need to consider:

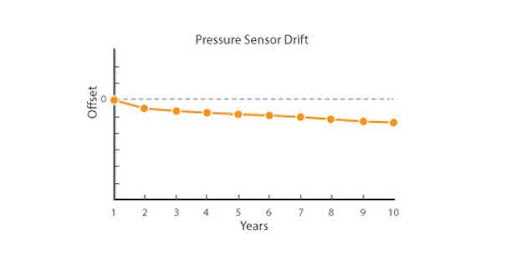

Fig 7. Pressure sensor drift

Safety and Certifications:

Why is it essential to consider safety certifications like ATEX and IECEx in pressure transmitter selection?

Considering safety certifications like ATEX (Atmosphères Explosibles) and IECEx (International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres) is essential in pressure transmitter selection for several reasons:

What are some safety standards or certifications that pressure transmitters may need to adhere to in hazardous environments?

Pressure transmitters used in hazardous environments are subject to various safety standards and certifications to ensure their safe operation. Some of the important safety standards and certifications that pressure transmitters may need to adhere to in hazardous environments include:

Fig 8. ATM.1STEx High Precision Transmitter with ATEXIECEx Certification

When is SIL (Safety Integrity Level) a relevant consideration in pressure transmitter selection?

Safety Integrity Level (SIL) is a relevant consideration in pressure transmitter selection when the application involves critical safety functions, especially in process industries, where failure of equipment could lead to severe consequences, including harm to personnel, environmental damage, or financial losses. SIL is particularly relevant in industries such as oil and gas, petrochemical, chemical, nuclear, and pharmaceutical manufacturing. Here are some scenarios in which SIL is a relevant consideration:

How do you ensure that pressure transmitters in potentially explosive areas meet safety requirements?

To ensure that pressure transmitters in potentially explosive areas meet safety requirements, you should follow a systematic and comprehensive approach that involves careful planning, selection, installation, and ongoing maintenance. Here are the steps to ensure safety compliance:

Pressure Range and Application-Specific Considerations:

When the pressure range is important, which pressure transmitter types are useful?

When the pressure range is a critical consideration in your application, several types of pressure transmitters can be useful. The choice of the pressure transmitter type depends on the specific requirements of your application. Here are some pressure transmitter types that are commonly employed when the pressure range is a significant factor:

Fig 9. Pressure range of pressure transmitters

How do you determine the appropriate pressure range for a given application?

Determining the appropriate pressure range for a given application is a critical step in selecting a pressure transmitter that will provide accurate and reliable measurements. Here's a systematic approach to help you determine the right pressure range:

Fig 10. Pressure transmitter applications

How do pressure transmitters designed for high-temperature applications differ from standard models?

Pressure transmitters designed for high-temperature applications differ from standard models in several ways to ensure they can operate reliably in extreme heat. Here are the key differences:

How does the choice of output signal type affect integration with control systems?

The choice of output signal type for a pressure transmitter can significantly affect its integration with control systems. Different output signal types have varying compatibility, communication protocols, and advantages. Here's how the choice of output signal type can impact integration:

- Compatibility: Analog output signals are widely accepted in the industry and can be easily integrated into most control systems with analog input channels.

- Signal Integrity: Analog signals are relatively immune to interference and noise, which helps maintain signal integrity in long cable runs.

- Signal Scaling: The output range can often be scaled to match the specific requirements of the control system, allowing for customization.

- Compatibility: Digital output signals require compatible communication protocols and hardware at the control system end. The choice of protocol should align with the control system's capabilities.

- Data Richness: Digital outputs offer more extensive data, including diagnostics, configuration, and multiple variables, providing better insight into the performance of the pressure transmitter.

- Two-Way Communication: Some digital protocols, like HART, allow two-way communication, enabling remote configuration and monitoring of the transmitter.

- Simplified Integration: Switch or relay outputs provide a straightforward way to trigger control actions based on pressure thresholds. They are often used in alarm or safety applications.

- Limited Data: These outputs provide limited information beyond an open or closed state, making them less suitable for applications that require detailed data.

- Integration with Counting Systems: Pulse or frequency outputs are commonly used in applications where pressure measurement needs to be integrated with counting or flow measurement systems.

- Communication Infrastructure: Wireless output signals require compatible communication infrastructure, such as a wireless gateway, to integrate with control systems. Compatibility with the control system's wireless technology is crucial.

- Custom Integration: Non-standard output signals may require custom hardware or software adaptations in the control system for proper integration.

- System Compatibility: Ensure that the chosen output signal is compatible with the existing or planned control system. The control system should have the necessary input channels, communication protocols, and signal conditioning for the selected output type.

- Data Requirements: Consider the data requirements of your application. Do you need additional data beyond the pressure measurement, such as diagnostics, temperature, or configuration information? Digital output signals may be more suitable in such cases.

- Noise and Interference: Evaluate the noise and interference conditions in your application. Analog signals are generally more robust in noisy environments, while digital signals may require extra attention to signal integrity.

- Remote Monitoring and Control: If remote monitoring and control are essential, digital protocols like HART or Modbus can provide valuable two-way communication and remote configuration capabilities.

- Industry Standards: Some industries or applications may have specific standards or requirements for the output signal type. Ensure that your choice aligns with these standards.

The choice of output signal type should be made based on a comprehensive assessment of the control system's capabilities and the specific needs of the application to ensure seamless integration and reliable communication.

Output Signals and Communication:

What are the common types of output signals for pressure transmitters, and when is each type preferred?

Pressure transmitters can generate various types of output signals, each with its advantages and ideal applications. Here are some common types of output signals for pressure transmitters and when each type is preferred:

- Long-distance transmission is required, as 4-20 mA signals are less susceptible to signal degradation over long cable runs.

- High noise immunity is essential, making it suitable for industrial environments with electromagnetic interference.

- Compatibility with a broad range of control systems and data acquisition equipment is necessary.

- The control system or data acquisition equipment uses voltage-based input signals.

- Voltage-based signals are more convenient for integration into the existing system architecture.

- Enhanced diagnostics, configuration, and additional data are required for predictive maintenance and process optimization.

- Two-way communication for remote configuration and monitoring is necessary.

- Integration with a digital communication infrastructure is available, and the control system supports the chosen digital protocol.

- Simple on/off control or alarm based on pressure thresholds is required.

- Safety interlock applications or basic process control rely on discrete signals.

- Detailed data beyond open or closed states is not needed.

- The pressure measurement needs to be integrated with counting or flow measurement systems.

- Applications such as flow meters or level sensors require a frequency-based signal.

- Wireless communication is necessary due to remote or inaccessible locations.

- Running cables or wires is impractical or costly.

- Data transfer can be achieved efficiently using wireless technology, and the control system supports it.

- Specific signal requirements exist that do not conform to standard output options.

- Custom hardware or software integration is feasible in the control system.

The choice of output signal type should align with the specific needs of your application and the compatibility of the control system or data acquisition equipment. Consider factors like data requirements, transmission distance, noise susceptibility, and the availability of communication infrastructure when making your selection. In many cases, the decision also involves considering the existing architecture and compatibility with other sensors and devices in the system.

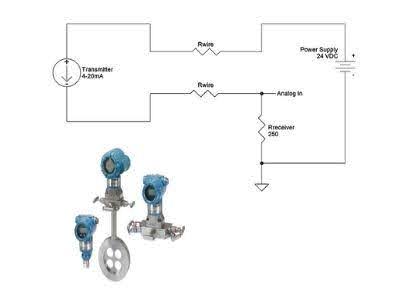

Fig 11. 4 to 20mA signal in a pressure transmitter

When accuracy is important, which pressure transmitter types are used?

When accuracy is a critical consideration in your application, you should choose pressure transmitter types that are known for their precision and reliability. The following pressure transmitter types are commonly used when high accuracy is essential:

Conclusion

In conclusion, pressure transmitters are integral components in various industries, and selecting the right one is crucial for ensuring safety, process control, efficiency, and compliance with regulations. To make informed decisions when choosing pressure transmitters, it's essential to consider a range of factors:

- Pressure Range: Match the transmitter's range to the specific needs of your application, considering safety margins.

- Accuracy: Choose a transmitter with the required level of precision, considering factors like calibration and drift.

- Output Signal Type: Select an output signal type that is compatible with your control system and communication requirements.

- Environmental Conditions: Account for temperature, humidity, and other environmental factors to ensure the transmitter's reliability.

- Corrosion Resistance: In corrosive environments, opt for corrosion-resistant transmitters to prevent damage.

- High-Vibration Environments: Select transmitters designed to withstand high levels of vibration and mechanical stress.

- Hazardous Areas: Ensure that the transmitter is certified and suitable for the area's classification and conditions.

- Safety Standards: Comply with safety standards and regulations to prevent accidents and ensure safety.

Choosing the right pressure transmitter not only ensures that industrial processes run smoothly but also contributes to energy efficiency, product quality, equipment protection, and environmental responsibility. It's a critical decision that impacts the overall success of industrial operations. By carefully considering the selection criteria and environmental factors, you can make informed choices that align with your specific needs and industry standards, resulting in safer, more efficient, and more reliable industrial processes.

To recap

1. What is the importance of selecting the correct pressure range for a pressure transmitter?

Answer: Selecting the correct pressure range ensures that the transmitter can accurately measure the expected pressures in the application, preventing under or over-ranging, which can lead to measurement errors and equipment damage.

2. How does accuracy affect pressure transmitter selection?

Answer: Accuracy is crucial for obtaining reliable measurements. The level of accuracy needed depends on the application's requirements, and selecting a transmitter with the appropriate accuracy rating is essential to meet those needs.

3. What role does the output signal type play in pressure transmitter selection?

Answer: The output signal type determines how the pressure data is transmitted to the control system. The choice of signal type should align with the control system's capabilities and communication requirements.

4. What are the key considerations when selecting a pressure transmitter for high-temperature applications?

Answer: Considerations include the temperature rating, materials, thermal isolation, and cooling mechanisms to ensure the transmitter can operate reliably in extreme heat.

5. Why are corrosion-resistant pressure transmitters necessary, and in what environments are they commonly used?

Answer: Corrosion-resistant transmitters are essential in environments where exposure to aggressive chemicals, acids, or bases can damage standard pressure transmitters. Common applications include chemical processing, petrochemical plants, and marine environments.

6. How do you select pressure transmitters for high-vibration environments?

Answer: Selection considerations include evaluating vibration levels, addressing mechanical resonance, proper mounting and installation, choosing shock-resistant models, and selecting pressure transmitters designed for high-vibration conditions.

7. What factors should be taken into account when selecting pressure transmitters for use in hazardous or explosive areas?

Answer: Considerations include area classification, certification and compliance, explosion protection methods, material compatibility, and the use of appropriate enclosures and grounding methods to ensure safety and compliance.

8. Why is it important to consider environmental conditions like temperature and humidity in pressure transmitter selection?

Answer: Environmental conditions can affect the performance and longevity of pressure transmitters. Selecting transmitters suitable for the temperature and humidity levels in the application ensures accurate and reliable measurements.

9. What are the primary safety standards and certifications for pressure transmitters in hazardous areas?

Answer: Safety standards and certifications such as ATEX, IECEx, FM (Factory Mutual), CSA (Canadian Standards Association), and NEC (National Electrical Code) are crucial for ensuring pressure transmitters' suitability for use in hazardous areas.

10. What is the significance of choosing the right pressure transmitter for industrial applications?

Answer: Selecting the right pressure transmitter is vital for ensuring safety, process control, efficiency, product quality, regulatory compliance, and overall operational excellence in industrial applications. It contributes to minimizing risks and optimizing processes.

References

https://www.researchgate.net/figure/Pressure-sensors-and-pressure-ranges_tbl1_347087214

https://blog.wika.com/products/pressure-products/accuracy-pressure-sensors/

https://www.transmittershop.com/blog/test-4-to-20ma-signal-in-a-pressure-transmitter/

https://blog.wika.com/general/temperature-coefficients-tc/

https://www.validyne.com/blog/temperature-isolation-pressure-sensors/

http://www.pressure-sensor.com/prd-application.html

https://www.stssensors.com/products/gp-sts-pressure-2/pressure-sensors-atex-iecex/atm_1st_ex/

https://pubs.rsc.org/en/content/articlehtml/2015/mh/c4mh00147h

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025