Aspect to Consider for Choosing Flow meter

Just like every other measuring and controlling system in the industry we need to take into consideration a few matters before choosing the right component. In flow measurement technology type of the fluid, pressure, temperature and the location of the flow meter is important before we make a decision.

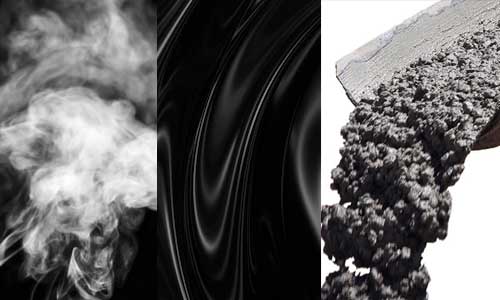

Phase of the fluid: gas/ liquid/ vapor

Flow meters must be used in a system with the fluids compatible with them. The below list introduce some of the common flow meter types compatible with the fluid type they can measure:

- Gas – Ultrasonic, Variable Differential Pressure, Variable Area, Coriolis Mass, Turbine, Thermal Mass, Positive Displacement

- Liquid – Coriolis Mass, Turbine, Positive Displacement, Thermal Mass, Ultrasonic, Variable Differential Pressure, Electromagnetic

- Slurry – Ultrasonic, Coriolis Mass, Differential Pressure, some types of Variable Electromagnetic

- Vapor – Diaphragm, Ultrasonic, Floating Element, Vortex

Type of the fluid

Physical and chemical characteristics of the fluid have an impact on the material of the flow meter and its function.

Hence, these characteristics including the viscosity of the fluid, its density, and dispersion (solid content) that must be taken into consideration.

For instance, electromagnetic flow meters can only be used for conductive liquids.

Note that MEMS or CMOS (chip) sensors which are used in some gas flow meters are appropriate for only some non-aggressive gas types.

The flow rate

The flow rate is the most critical point to consider.

You must be aware of the reference condition you are working with. The minimum and maximum full-scale range of a product are indicated which should fulfill your process demands.

The inlet and outlet pressure

It is essential to know whether you require a low-pressure drop or not. The pressure drop is the distinction between the inlet and the outlet pressure.

Furthermore, flow meters have a maximum operating pressure that must be considered when you have a high-pressure application.

The ambient temperature and the temperature of the fluid

Too high or too low environmental temperatures can damage the electronic components of flow meters.

Therefore, check the temperature specifications before choosing a flow meter to see if the device can tolerate these extreme temperatures.

Additionally, Variations in fluid temperature may have an impact on the flow meter's accuracy of measurement. On the occasion of temperature fluctuations, it is better to choose a flow meter with temperature compensation.

Location of the flow meter

Another factor that should be considered in choosing a flow meter is the installation location, which can be indoors, outdoors, in a laboratory, or for a specific industry.

For laboratories different specifications are applicable than for the oil and gas industry.

• NEMA

• IP-rating

• The Probable need for particular certificates or approvals for the flow meter installation location.

For instance: IECex or ATEX certifications (for use in unsafe areas) or FDA approval, etc.

The reference conditions for measuring volumetric flow rate:

There are two distinct reference conditions.`

One is N.T.P. and the other is called S.T.P.

Normal condition of Pressure and Temperature is NTP, while Standard condition of Pressure and Temperature is STP.

The definitions for these conditions are as described but are interchangeable in different countries. In India they may be described as follows,

NTP: 1 Atmosphere Pressure and 0° C Temperature.

STP: 1 Atmosphere Pressure and 15° C Temperature.

Using density in converting mass flow to volume flow:

To apply density in converting mass flow to volumetric flow, a set of specific temperature and pressure conditions at which we use the density value for the gas must be picked.

Three types of reference:

There are conditions which are agreed upon to comprise different references which are used in American or European style.

- Normal reference, European style

Based on ‘European’ definition, a temperature of 0°C and a pressure of 1,013 bar are selected as ‘normal’ reference conditions, shown by the underlying letter “n” in the unit of volume (mln/min or m3n/h).

The direct thermal mass flow calculation method is based on these reference conditions unless otherwise demanded.

Example for conversion to volumetric units using Normal reference conditions:

The mass flow meter shows 100 g/h of Air flow.

- Density Air (@ 0°C) = 1.293 kg/m3

- X ln/m Air = 100 g/h / (60 minutes x 1.293 kg/m3)

- Flow = 1.29 ln/m Air

- Standard reference, European style

On the other hand, a pressure of 1,013 bar and a temperature of 20°C are used to refer to ‘standard’ reference conditions, shown by the underlying letter ‘s’ in the unit of volume used (mls/min or m3s/h)

An instance conversion to volumetric units by use of Standard conditions:

The mass flow meter shows 100 g/h Air flow.

• Density Air (@ 20°C): 1.205 kg/m3

• X ls/m Air = 100 g/h / (60 minutes x 1.205 kg/m3)

• Flow = 1.38 ls/m Air

If the prefix ‘s’ has been utilized, it refers back to the American style.

- Standard reference, American style

According to the ‘American’ definition the prefix ‘s’ in SCCM, SLM, SCFH refers to ‘standard’ conditions, pressure of 101.325 kPa absolute and temperature of 0°C.

You should be cautious about the reference conditions when buying a flow measuring device. ‘Standard’ and ‘Normal’ may be relative to every client.

Attention to reference conditions is important, Because incorporating these reference conditions contributes to an offset in what the customer expects to see by over 7%!

Other points that need to be considered more closely are:

Characteristics of a Fluid and Its Flow:

Flow meters can measure different parameters including viscosity, pressure, temperature, density, and vapor pressure, which are displayed as a single reading.

A core characteristic of flow meters is to monitor protection situations which include toxicity, bubbles, the presence of abrasives, and transmission qualities.

Pressure & Temperature Ranges:

In addition to normal operating values, expected minimum and maximum pressure and temperature values must be given while choosing flow meters. Whether flow can reverse, whether or not it does continually fill the pipe, whether or not slug flow can develop (air-solids-liquid), whether or not pulsation or aeration is likely, whether or not unexpected temperature adjustments can occur, or whether or not unique precautions are required throughout cleansing and maintenance, those facts, too, must be expressed.

Ranges of Pressure:

It is a part of Newton‘s Second Law of Motion that any mass requires force to transport. In the case of fluids, in a restrained pipe, the force that is carried out to transport the liquid is pressure. The density of the liquid determines the essential pressure, which shows the flow rate. When a flow meter is measuring density and pressure, it makes use of that information to calculate the flow rate.

Ranges of Temperature:

In terms of flow meters, the calculation of temperature is called thermal flow measurement, which estimates heat transfer as gas flows pass a surface. A temperature sensor offers a measurement of the gasses or liquids' temperature, whilst a heated flow sensor estimates the quantity of heat transfer of the material‘s flow.

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025