Applications of Load cell

From Weighing Scales to Structural Testing: Exploring the Limitless Applications of Load Cells

A load cell is a transducer widely used in various industries to measure force or weight accurately. It plays a crucial role in converting mechanical force into an electrical signal, making it suitable for applications such as weighing scales, industrial automation, material testing, and process control.

Load cells are designed to withstand heavy loads and provide precise measurements with high reliability. They are typically made of high-quality materials, such as stainless steel or alloy steel, to ensure durability and resistance to environmental factors. Load cells are available in different configurations, including compression, tension, and bending, depending on the type of force they are intended to measure.

The working principle of a load cell is based on strain gauge technology. Inside the load cell, one or more strain gauges are attached to a metal element called the "spring element." When a force is applied to the load cell, it deforms the spring element, causing the strain gauges to change their electrical resistance. This change in resistance is proportional to the applied force and is measured as a small electrical signal.

To obtain accurate measurements, load cells are often used in conjunction with signal conditioning equipment, which amplifies and filters the electrical signal. The conditioned signal can then be further processed and displayed using instrumentation systems or digital interfaces.

Load cells offer numerous advantages, such as high precision, wide measurement range, low maintenance requirements, and compatibility with various industrial applications. They provide reliable and real-time force measurements, allowing for improved quality control, process optimization, and safety in various industries.

In summary, load cells are vital devices used for accurate force and weight measurements in a wide range of applications. Their ability to convert mechanical force into electrical signals has revolutionized industries, enabling better control, efficiency, and safety in various processes.

Fig 1. A load cell

What are the 30 applications of Load cells?

Load cells are versatile devices used for measuring force or weight in a wide range of applications. Here are 30 common applications of load cells:

- Industrial weighing scales

- Truck scales and weighbridges

- Tank and silo weighing

- Material testing machines

- Crane and hoist systems

- Conveyor belt weighing

- Packaging and filling machines

- Tension and compression force measurement

- Medical equipment and devices

- Aerospace and aviation testing

- Automotive testing and research

- Robotics and automation systems

- Offshore and marine industry

- Mining and quarrying equipment

- Structural testing and analysis

- Bridge and dam monitoring

- Rail weighing systems

- Agricultural machinery and equipment

- Food and beverage production

- Pharmaceutical manufacturing

- Waste management and recycling

- Paper and pulp industry

- Construction and building materials

- Material handling and logistics

- Sports and fitness equipment

- Oil and gas exploration

- Energy production and distribution

- Research and development laboratories

- Environmental monitoring and analysis

- Educational and training applications

These are just some examples of how load cells are utilized in various industries and sectors. The versatility of load cells allows them to be applied in countless other scenarios where force or weight measurement is required.

Fig 2. Using a load cell

- Industrial weighing scales:Load cells are extensively used in industrial weighing scales to accurately measure the weight of various objects and materials. This includes bench scales, platform scales, and larger floor scales used in warehouses, factories, and shipping centers.

- Truck scales and weighbridges: Load cells are crucial components of truck scales and weighbridges, where they measure the weight of trucks and their contents. These scales are commonly found in transportation hubs, ports, and industries that require accurate weight measurements for logistics and commerce.

- Tank and silo weighing: Load cells are employed to measure the weight of tanks and silos in industries such as food processing, chemical manufacturing, and agriculture. This allows for precise inventory management, process control, and material tracking.

- Material testing machines: Load cells play a significant role in material testing machines, such as universal testing machines (UTMs), where they measure the force applied to a sample during tensile, compression, or bending tests. This data helps assess the mechanical properties of materials.

- Crane and hoist systems: Load cells are used in crane and hoist systems to measure the load being lifted. They provide feedback to ensure safe lifting operations and prevent overloading.

- Conveyor belt weighing: Load cells integrated into conveyor systems accurately measure the weight of materials being transported. This is important in industries like mining, agriculture, and logistics, where precise weight measurements are required for inventory control and billing.

- Packaging and filling machines: Load cells are utilized in packaging and filling machines to ensure accurate dosing and filling of products. They measure the weight of the contents and control the dispensing process for consistent packaging.

- Tension and compression force measurement: Load cells can measure both tension (pulling) and compression (pushing) forces. They find application in force measurement systems used in research, quality control, and industrial processes.

- Medical equipment and devices: Load cells are used in various medical applications, such as patient weighing scales, rehabilitation equipment, prosthetics, and force monitoring systems for medical research and development.

- Aerospace and aviation testing: Load cells are vital in aerospace and aviation industries for testing and evaluating aircraft components, such as wings, landing gear, and engine parts. They provide accurate force and weight measurements during structural testing and fatigue analysis.

- Automotive testing and research: Load cells are utilized in automotive testing to measure forces exerted on vehicle components during crash testing, suspension analysis, and performance evaluation. They assist in ensuring vehicle safety and improving the design.

- Robotics and automation systems: Load cells are integrated into robotic systems and automated machinery to provide feedback on forces exerted during tasks such as gripping, lifting, and assembly. This allows for precise control and monitoring of robotic movements.

- Offshore and marine industry: Load cells are employed in offshore and marine applications, including mooring systems, rigging, and shipbuilding. They measure forces and loads to ensure safe operations and structural integrity.

- Mining and quarrying equipment: Load cells are used in mining and quarrying equipment to measure the load carried by conveyors, crushers, and screens. This enables efficient material handling and prevents equipment overload.

- Structural testing and analysis: Load cells play a crucial role in structural testing and analysis, such as load-bearing capacity assessments of bridges, buildings, and infrastructure. They measure the applied forces and assist in evaluating structural integrity.

- Bridge and dam monitoring: Load cells are utilized in bridge and dam monitoring systems to measure and monitor the loads acting on these structures. They help assess structural health and detect potential issues.

- Rail weighing systems: Load cells are integrated into rail weighing systems to measure the weight of trains, railcars, and cargo. This data is used for load distribution, determining toll fees, and ensuring compliance with weight regulations.

- Agricultural machinery and equipment: Load cells find applications in agricultural machinery, such as grain silos, animal feeders, and harvesters. They measure weights for inventory management, yield analysis, and process control.

- Food and beverage production: Load cells are extensively used in the food and beverage industry for portion control, batching, and filling operations. They ensure accurate measurements during ingredient weighing and packaging processes.

- Pharmaceutical manufacturing: Load cells are critical in pharmaceutical manufacturing, where precise weight measurements are essential for ingredient mixing, tablet compression, and formulation processes. They assist in ensuring quality and compliance.

- Waste management and recycling: Load cells are employed in waste management and recycling equipment, such as garbage trucks, compactors, and sorting systems. They measure the weight of waste and recyclable materials for billing and process optimization.

- Paper and pulp industry: Load cells are used in the paper and pulp industry to measure tension, force, and weight during paper production, roll handling, and web tension control. This helps maintain product quality and efficiency.

- Construction and building materials: Load cells find applications in the construction industry for measuring loads on cranes, lifting equipment, and scaffolding. They ensure safe lifting operations and assist in load monitoring.

- Material handling and logistics: Load cells are integral to material handling and logistics systems, including conveyor systems, pallet scales, and shipping containers. They accurately measure weights for inventory management, logistics optimization, and freight billing.

- Sports and fitness equipment: Load cells are incorporated into sports and fitness equipment, such as exercise machines, force plates, and fitness trackers. They measure forces and weight distribution for performance monitoring and training purposes.

- Oil and gas exploration: Load cells play a role in oil and gas exploration equipment, including drilling rigs and downhole tools. They measure drilling forces, pipe tension, and load capacity for safe and efficient operations.

- Energy production and distribution: Load cells are used in energy production and distribution systems, such as wind turbines, power plant equipment, and transmission line tension monitoring. They assist in assessing loads and ensuring operational safety.

- Research and development laboratories: Load cells are essential tools in research and development laboratories, enabling accurate force and weight measurements in various scientific experiments, material testing, and product development.

- Environmental monitoring and analysis: Load cells are utilized in environmental monitoring systems to measure forces exerted by natural phenomena, such as wind, water currents, and seismic activities. This data aids in environmental analysis and research.

- Educational and training applications: Load cells are incorporated into educational and training equipment to teach principles of force, weight, and measurement. They allow students to conduct hands-on experiments and learn about various applications of load cells.

These comprehensive explanations highlight the diverse applications of load cells across multiple industries and sectors. Load cells play a crucial role in ensuring accurate force and weight measurements, enabling improved safety, efficiency, and quality control in a wide range of processes and systems.

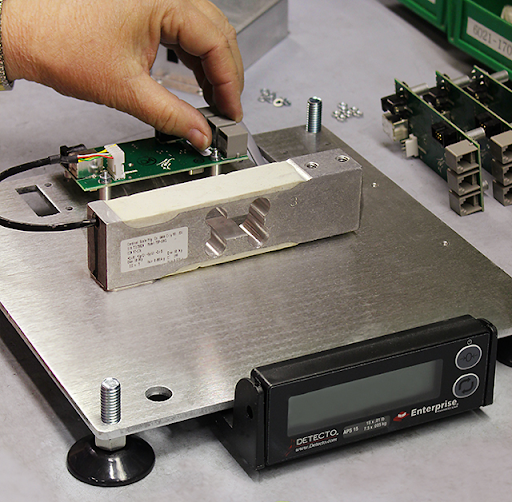

Fig 3. Digital load cell

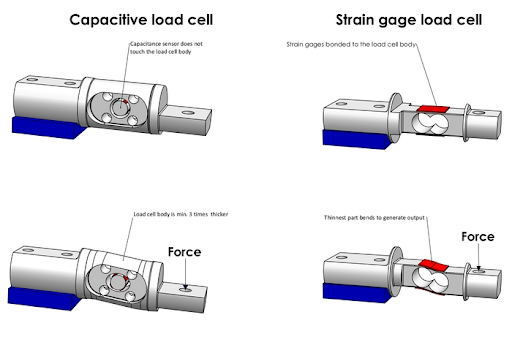

What are the applications of Strain Gauge Load Cells?

Strain gauge load cells find numerous applications across various industries due to their accuracy, reliability, and versatility in measuring forces. Some common applications of strain gauge load cells include

- Industrial Weighing: Strain gauge load cells are extensively used in industrial weighing applications, such as platform scales, bench scales, and conveyor systems. They provide accurate and precise measurements of weights for inventory control, production monitoring, and quality assurance.

- Material Testing: Strain gauge load cells are utilized in material testing machines and equipment to measure forces during tension, compression, or bending tests. They enable the evaluation of material strength, elasticity, and performance characteristics in industries like construction, automotive, aerospace, and manufacturing.

- Tank and Hopper Weighing: Strain gauge load cells are employed in tank and hopper weighing systems for measuring the weight of liquids, granular materials, or bulk solids. These systems are commonly used in industries such as food processing, agriculture, chemicals, and pharmaceuticals.

- Force Monitoring and Control: Strain gauge load cells are used in force monitoring and control applications to ensure proper force application, such as in robotics, assembly lines, and material handling equipment. They enable real-time feedback and control for maintaining precise force levels and preventing overloading.

- Crane and Hoist Scales: Strain gauge load cells are utilized in crane and hoist scales to measure the weight of lifted loads. These scales are widely used in industries such as logistics, construction, shipping, and warehousing for load monitoring, safety compliance, and load distribution optimization.

- Automotive Testing: Strain gauge load cells are crucial in automotive testing applications, including vehicle component testing, crash testing, and suspension analysis. They provide accurate measurements of forces and loads to assess structural integrity, performance, and safety aspects.

- Medical and Healthcare: Strain gauge load cells find applications in medical devices and healthcare equipment, such as patient lifting systems, rehabilitation devices, and physiotherapy equipment. They enable the precise measurement of applied forces for safe and effective patient handling and therapy.

- Aerospace and Defense: Strain gauge load cells are used in aerospace and defense industries for various applications, including aircraft weight and balance calculations, structural testing, wind tunnel testing, and aerospace component testing. They ensure accurate measurement and control of forces critical for aircraft performance and safety.

These are just a few examples of the wide-ranging applications of strain gauge load cells. Their ability to measure forces accurately and reliably makes them essential in industries where precise force measurement is vital for quality control, safety, performance optimization, and compliance with industry standards.

Fig 4. Strain gauge load cell

Hydraulic Load Cells Applications

Hydraulic load cells find applications in various industries where accurate and reliable force measurement is required. Some common applications of hydraulic load cells include

- Industrial Weighing: Hydraulic load cells are widely used in industrial weighing applications, such as platform scales, tank weighing systems, and hopper scales. They provide accurate and precise measurements of weights for inventory management, production control, and quality assurance.

- Material Testing: Hydraulic load cells play a crucial role in material testing machines and equipment. They are used to measure forces during tension, compression, or bending tests to assess the mechanical properties and strength of materials. Material testing applications include construction, automotive, aerospace, and manufacturing industries.

- Heavy Machinery and Equipment: Hydraulic load cells are employed in heavy machinery and equipment to monitor and control forces. They are used in hydraulic presses, cranes, hoists, and lifting systems to ensure safe operation and prevent overloading. Hydraulic load cells help in load monitoring, weight distribution optimization, and safety compliance.

- Construction and Engineering: Hydraulic load cells are used in construction and engineering applications, such as structural load testing, pile testing, and concrete strength testing. They provide accurate force measurements for assessing the structural integrity, performance, and safety of buildings, bridges, and other infrastructure.

- Research and Development: Hydraulic load cells are extensively utilized in research and development settings for various scientific experiments and studies. They are used in laboratories, universities, and research institutions to measure forces in fields like biomechanics, material science, physics, and engineering.

- Aerospace and Defense: Hydraulic load cells have applications in the aerospace and defense industries. They are used in aircraft weight and balance calculations, structural testing, and aerospace component testing. Hydraulic load cells help ensure the safety, performance, and integrity of aircraft structures and systems.

- Marine and Offshore: Hydraulic load cells are employed in marine and offshore industries for applications such as shipbuilding, offshore platform installation, and load monitoring of marine equipment. They enable accurate force measurement in challenging environments, including saltwater, high pressures, and corrosive conditions.

- Automotive and Vehicle Testing: Hydraulic load cells are used in automotive testing and vehicle development. They are utilized in crash testing, suspension analysis, and durability testing to measure forces and loads on vehicle components. Hydraulic load cells provide critical data for assessing vehicle performance, safety, and design optimization.

These are just a few examples of the applications of hydraulic load cells. Their ability to accurately measure forces under various conditions makes them essential in industries that require precise force measurement for quality control, safety compliance, and performance optimization.

Fig 5. Hydraulic load cell

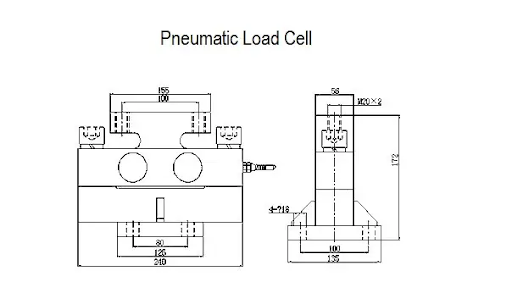

Pneumatic Load Cells usage

Pneumatic load cells find applications in various industries and force measurement scenarios where accurate and reliable force monitoring is required. Some common uses of pneumatic load cells include:

- Weighing Systems: Pneumatic load cells are often used in weighing systems for precise weight measurement. They can be employed in industrial scales, platform scales, truck scales, and other weighing equipment. Pneumatic load cells offer high accuracy and stability, making them suitable for applications where precise weight measurement is essential.

- Material Testing: Pneumatic load cells are utilized in material testing applications to measure the strength, durability, and deformation characteristics of materials. They are employed in compression testing machines, tensile testing machines, and other material testing equipment. Pneumatic load cells provide accurate force measurement during material testing procedures.

- Process Control: Pneumatic load cells play a crucial role in process control systems where force monitoring is required. They are used to measure and control forces in various industrial processes, such as assembly lines, robotics, and material handling systems. Pneumatic load cells ensure that the applied forces remain within desired ranges, helping to maintain process efficiency and product quality.

- Force Monitoring and Safety Systems: Pneumatic load cells are employed in force monitoring and safety systems to detect and monitor forces exerted on structures, machinery, or equipment. They are used in load limiters, overload protection systems, and force monitoring devices to prevent equipment damage, ensure operator safety, and maintain operational efficiency.

- Automotive Industry: Pneumatic load cells are used in the automotive industry for various applications. They are employed in vehicle testing, crash testing, suspension testing, and brake testing equipment to measure forces accurately. Pneumatic load cells help evaluate automotive components' and systems' performance and safety aspects.

- Aerospace and Defense: Pneumatic load cells are utilized in aerospace and defense applications, including aircraft testing, structural analysis, and missile launch systems. They help measure and monitor forces during the testing and operation of aerospace and defense equipment, ensuring safety and performance standards are met.

- Construction and Civil Engineering: Pneumatic load cells find application in construction and civil engineering projects. They are used to measure forces during load testing of structures such as bridges, dams, and buildings. Pneumatic load cells help ensure structural integrity and safety by accurately monitoring forces exerted on these structures.

These are just a few examples of the diverse applications of pneumatic load cells. The versatility, accuracy, and reliability of pneumatic load cells make them suitable for a wide range of force measurement needs across various industries.

Fig 6. Pneumatic load cell

Capacitive Load Cells Applications

Capacitive load cells find applications in various industries and settings where precise force measurement is required. Some common applications of capacitive load cells include:

- Industrial Weighing Systems: Capacitive load cells are used in weighing systems for accurate measurement of weight in industrial processes. They are employed in platforms, hoppers, tanks, and conveyor belts for material handling and inventory control.

- Force and Load Testing: Capacitive load cells are used in force and load testing applications to determine the strength and performance of various materials, components, and structures. They are used in material testing machines, tension/compression testing equipment, and structural testing applications.

- Medical and Healthcare: Capacitive load cells are utilized in medical and healthcare applications where precise force measurement is necessary. They are used in medical devices such as surgical instruments, orthopedic equipment, and rehabilitation devices.

- Robotics and Automation: Capacitive load cells play a role in robotics and automation systems. They are used to measure and control forces in robotic arms, grippers, and assembly line processes, ensuring accurate and controlled movements.

- Aerospace and Aviation: Capacitive load cells find applications in the aerospace and aviation industries for force measurement in testing and research activities. They are used in structural testing of aircraft components, materials testing for space applications, and flight simulation systems.

- Automotive Industry: Capacitive load cells are employed in the automotive industry for various applications, including brake testing, suspension testing, engine component testing, and crash testing. They enable accurate force measurement in these critical areas.

- Packaging and Material Handling: Capacitive load cells are used in packaging and material handling equipment to monitor and control the forces involved in packaging processes, pallet handling, and conveyor systems.

- Research and Development: Capacitive load cells are utilized in research and development activities across various fields, including materials science, biomechanics, physics, and engineering. They enable precise force measurement in experimental setups and research studies.

These are just a few examples of the many applications of capacitive load cells. Their high accuracy, wide load range, and fast response time make them suitable for a diverse range of industries and force measurement needs.

Fig 7. Capacitive load cell

What are the Piezoelectric Load Cells used for?

Piezoelectric load cells find applications in various industries and fields where accurate and reliable force measurements are required. Some common uses of piezoelectric load cells include:

- Material Testing: Piezoelectric load cells are extensively used in material testing applications to measure and analyze forces exerted on materials during tensile, compression, or bending tests. They provide precise force measurements for determining material properties, quality control, and research purposes.

- Industrial Automation: Piezoelectric load cells are used in industrial automation systems for force monitoring, feedback control, and process optimization. They can be employed in robotic systems, assembly lines, and machinery to ensure accurate force application, safety, and quality control.

- Aerospace and Aviation: Piezoelectric load cells are used in the aerospace and aviation industries for applications such as aircraft structural testing, wind tunnel testing, and aerospace component testing. They provide critical force measurements for structural integrity analysis, load testing, and performance evaluation.

- Biomechanics and Medical Research: Piezoelectric load cells are utilized in biomechanics and medical research for studying forces exerted by biological systems. They help measure forces during gait analysis, joint movement studies, and muscle force measurement, aiding in understanding human movement, rehabilitation, and sports performance analysis.

- Force Control and Actuation: Piezoelectric load cells can be used in force control and actuation systems. By converting electrical signals into precise forces, they enable precise force feedback and closed-loop control in applications such as haptic feedback devices, force-feedback robotic systems, and active vibration control systems.

- Structural Monitoring: Piezoelectric load cells are employed in structural monitoring applications to measure forces and loads on structures such as bridges, buildings, and dams. They provide valuable data for structural health monitoring, load analysis, and fatigue life assessment.

- Automotive Testing: Piezoelectric load cells are used in automotive testing for measuring forces during vehicle crash testing, suspension analysis, brake testing, and component testing. They help ensure vehicle safety, performance evaluation, and optimization of automotive systems.

- Research and Development: Piezoelectric load cells find extensive use in research and development across various fields, including materials science, physics, engineering, and more. They aid in studying material behavior, force analysis, prototype testing, and experimental investigations.

These are just a few examples of the wide range of applications for piezoelectric load cells. Their high sensitivity, fast response time, and ability to measure both static and dynamic forces make them valuable tools in many industries that require accurate force measurements for analysis, control, and optimization.

Fig 8. Piezoelectric load cell

Magnetic Load Cells Applications

Magnetic load cells find applications in various industries and fields where accurate force measurement is required. Some common applications of magnetic load cells include:

- Industrial Automation: Magnetic load cells are used in industrial automation systems to measure and control forces in robotic arms, conveyor belts, material handling equipment, and assembly lines. They ensure precise force monitoring and feedback for efficient and safe operation.

- Material Testing: Magnetic load cells are utilized in material testing and quality control applications, such as tension and compression testing of materials, torque measurement, fatigue testing, and load monitoring. They provide accurate force measurements for assessing material properties and performance.

- Aerospace and Aviation: Magnetic load cells play a crucial role in the aerospace and aviation industries. They are used for force measurement in aircraft assembly, structural testing, engine testing, landing gear testing, and other critical applications where precise and reliable force data is required.

- Automotive Industry: Magnetic load cells find application in the automotive industry for testing and quality control purposes. They are used in brake testing, suspension testing, crash testing, component testing, and other automotive-related force measurement applications.

- Research and Development: Magnetic load cells are utilized in research and development laboratories for studying material behavior, investigating mechanical properties, and conducting experiments that require accurate force measurements. They are employed in fields such as materials science, biomechanics, civil engineering, and physics research.

- Medical and Healthcare: Magnetic load cells are used in medical and healthcare applications for force measurement and monitoring in devices such as prosthetics, orthotics, rehabilitation equipment, patient lifting systems, and ergonomic assessment tools. They ensure precise force control and patient safety.

- Packaging and Weighing: Magnetic load cells are employed in packaging and weighing applications, such as filling machines, check weighers, bagging machines, and dosing systems. They provide accurate weight measurement and control for efficient packaging processes.

Conclusion

In conclusion, load cells are versatile devices with numerous applications across various industries and sectors. They are utilized to measure force and weight accurately, enabling precise control, monitoring, and analysis in diverse processes and systems. From industrial weighing scales and truck scales to material testing machines, packaging equipment, and structural analysis, load cells are vital in ensuring safety, efficiency, and quality control. They are found in industries such as manufacturing, transportation, healthcare, aerospace, automotive, and many more. Load cells continue to be an essential tool for force and weight measurement, contributing to advancements in technology, research, and development.

References

https://detecto.com/news/news-events-article/home-page-category/load-cell-manufacturing-capabilities

https://buffalohydraulic.com/product/enerpac-lh10006-200000-lbs-hydraulic-load-cell/

https://instrumentationtools.com/pneumatic-load-cell-principle/

https://rstinstruments.com/product/strain-gauge-load-cells/

https://acuityprocess.com/products/eilersen-digital-load-cells/eilersen-technology/

https://www.te.com/usa-en/product-CAT-FLS0001.html

https://5.imimg.com/data5/SELLER/Default/2021/5/ZI/GL/SU/41395391/digital-load-cell-250x250.jpg

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025