Troubleshooting Pressure Sensors: From Inaccuracies to Optimal Performance

Pressure sensors serve as vital components across various industries, ensuring accurate measurements essential for safety, efficiency, and precision in countless applications. However, navigating through troubleshooting and resolving issues with these sensors can be a complex endeavor. From erratic readings to environmental influences or calibration challenges, understanding the nuances of pressure sensor functionality and addressing common issues is crucial.

In this guide, we delve into a comprehensive overview of troubleshooting pressure sensors, offering insights, practical tips, and step-by-step approaches to diagnose, rectify, and optimize sensor performance. Whether it's tackling inaccuracies, mitigating environmental factors, or mastering calibration techniques, this guide aims to equip you with the knowledge needed to effectively troubleshoot pressure sensor problems. Join us as we explore the intricacies of pressure sensor diagnostics and uncover strategies to ensure these critical components operate with precision and reliability in diverse operational landscapes.

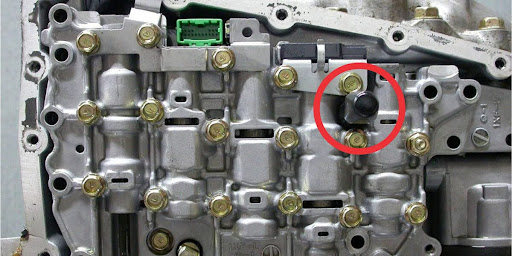

Fig 1. Pressure sensor problems

What are the problems faced when using pressure sensors?

Pressure sensors are incredibly useful but, like any technology, they come with their own set of challenges:

- Calibration and Accuracy: Maintaining accuracy over time can be a challenge. Pressure sensors need regular calibration to ensure their readings remain precise. Environmental factors such as temperature, humidity, and altitude changes can also affect accuracy.

- Temperature Sensitivity: Extreme temperatures can affect the performance of pressure sensors. Some sensors might show variations in readings or even malfunction in very hot or cold conditions.

- Overload and Fatigue: Pressure sensors can get damaged or provide inaccurate readings if subjected to pressures beyond their specified range. Additionally, repeated exposure to high pressures can cause fatigue and reduce the sensor's lifespan.

- Environmental Conditions: Harsh environments, like those with high levels of moisture, corrosive substances, or vibrations, can degrade the sensor's performance or damage it over time.

- Response Time: Some pressure sensors might have slower response times, which can be a limitation in applications where real-time data is crucial.

- Cost and Complexity: Certain high-precision pressure sensors can be expensive. Moreover, integrating pressure sensors into systems or devices might require additional components or expertise, adding to the complexity and cost.

- Signal Interference: Electrical noise or interference from nearby equipment or electromagnetic fields can disrupt the sensor's readings.

Addressing these issues often involves careful selection of the right sensor for the specific application, proper installation, regular maintenance, and sometimes implementing additional measures like shielding or signal processing to mitigate interference and improve accuracy.

What are the common calibration issues of pressure sensors?

Several common calibration issues can affect pressure sensors:

How can troubleshoot the calibration issues?

Troubleshooting calibration issues with pressure sensors involves systematic steps to identify and rectify problems. Here’s a guide to help troubleshoot calibration issues:

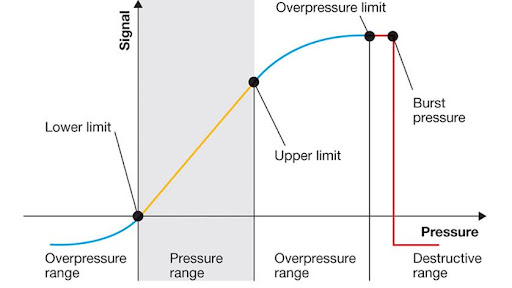

Fig 2. Pressure sensor calibration issues

How can Troubleshoot the pressure sensor Temperature Sensitivity?

Troubleshooting temperature sensitivity in pressure sensors involves identifying how temperature variations affect the sensor readings and implementing measures to compensate for these effects. Here’s a guide to troubleshooting temperature sensitivity:

What are the issues that temperature causes for pressure sensors?

Temperature can have various effects on pressure sensors, potentially leading to issues in their performance. Some of the common issues related to temperature in pressure sensors include:

Fig 3. Oil pressure sensor problems

How can fix the overload and fatigue problems of pressure sensors?

Fixing overload and fatigue problems with pressure sensors primarily involves preventive measures and careful handling to avoid damaging the sensor due to excessive pressure or extended exposure to high-pressure conditions. Here's how you can address these issues:

- Stay Within Specified Limits: Ensure that the pressure sensor operates within its specified pressure range. Avoid subjecting the sensor to pressures beyond its maximum limit as indicated by the manufacturer.

- Use Protective Measures: Employ protective measures such as pressure relief valves or dampeners in systems where pressure spikes or fluctuations are common. These mechanisms can prevent the sensor from being exposed to extreme pressures.

- Regular Maintenance and Inspection: Perform routine checks to inspect the sensor for signs of damage or fatigue. Regular maintenance can help identify issues early, allowing for timely repairs or replacements if needed.

- Implement Redundancy or Redundant Safety Measures: In critical applications, consider employing redundant sensors or safety systems. Having backup sensors or fail-safes can prevent damage due to overloading by diverting or mitigating excessive pressure.

- Calibration and Monitoring: Regularly calibrate the sensor to ensure its accuracy in measuring pressures. Implement monitoring systems that alert operators or shut down processes when pressures approach or exceed the sensor's limits.

- Consider Sensor Material and Design: Some sensors are designed with materials or structures that resist fatigue better than others. Consider sensors specifically engineered to withstand high-pressure environments or those less prone to fatigue.

- Training and Procedures: Train personnel involved in handling systems with pressure sensors about the sensor's limitations and safe operating procedures. Awareness and adherence to operating guidelines can prevent overloading and damage.

- Consult Manufacturer Guidelines: Refer to the manufacturer's guidelines for recommendations on preventing overload and fatigue issues specific to your sensor model. They might offer insights or specific instructions on how to safeguard the sensor from damage.

Preventive measures and careful monitoring of pressure levels are key to mitigating overload and fatigue problems in pressure sensors. Incorporating safety mechanisms, adhering to operating limits, and implementing regular maintenance practices can significantly extend the sensor's lifespan and reliability in high-pressure environments.

What happens if overload happens in the pressure sensor?

If a pressure sensor experiences overload, it means that the pressure applied to the sensor exceeds its specified maximum operating range. The consequences of overload in a pressure sensor can vary depending on the design and construction of the sensor. Here are some potential outcomes:

Fig 4. Overload problems

What are the issues that Environmental Conditions make for pressure sensors?

Environmental conditions can pose several challenges for pressure sensors, affecting their accuracy, performance, and longevity. Some common issues include

- Moisture and Condensation: High humidity or exposure to moisture can lead to condensation within the sensor or on its diaphragm, affecting accuracy and potentially causing corrosion or damage to sensitive components.

- Corrosive Substances: Exposure to corrosive gases, liquids, or chemicals can degrade sensor materials, leading to malfunctions, inaccurate readings, or physical damage.

- Temperature Variations: Extreme temperatures can impact sensor performance. Thermal expansion or contraction might affect the sensor's calibration or structural integrity, leading to inaccuracies in readings.

- Vibration and Shock: In environments with high levels of vibration or mechanical shock, pressure sensors may experience physical damage or drift in calibration, impacting their accuracy.

- Electromagnetic Interference (EMI): Nearby electrical equipment or strong electromagnetic fields can interfere with sensor signals, leading to erratic readings or malfunctions.

- Dust and Particulates: Accumulation of dust, dirt, or other particulates on the sensor's surface or within its components can affect its accuracy and potentially lead to mechanical issues.

- Altitude Changes: Pressure sensors relying on barometric pressure for reference can be affected by changes in altitude, which alters ambient pressure levels.

To mitigate these issues, several measures can be taken:

- Protective Enclosures: Use protective housings or enclosures to shield sensors from moisture, chemicals, dust, and other environmental factors.

- Regular Maintenance: Implement a maintenance schedule to clean and inspect sensors for any signs of damage or contamination.

- Calibration and Compensation: Employ calibration techniques that account for environmental factors or implement compensation algorithms to adjust readings based on environmental changes.

- Material Selection: Choose sensors specifically designed or coated to withstand harsh environmental conditions.

- Isolation or Dampening: Use isolation mounts or dampening materials to minimize the effects of vibrations or shocks on the sensor.

Understanding the environmental challenges a pressure sensor might encounter and taking proactive measures to protect and maintain the sensor can significantly enhance its reliability and lifespan in various operating conditions.

Issue troubleshooting

Here's a breakdown of troubleshooting steps for each environmental issue affecting pressure sensors:

For all troubleshooting, refer to the sensor's documentation or manufacturer guidelines for specific instructions on how to address environmental issues. Preventive measures, regular maintenance, and implementing protective measures suited for the specific environmental challenge can help maintain the sensor's accuracy and reliability.

How can repair the pressure sensor response time problem?

Repairing pressure sensor response time issues often involves identifying the underlying causes and implementing corrective measures. Here are some steps to address and improve pressure sensor response time:

- Issue: Mechanical obstructions in the sensor's diaphragm or movement mechanism can slow down response time.

- Troubleshoot: Inspect the sensor for any physical blockages, debris, or mechanical issues. Clean or repair the diaphragm and movement components if necessary.

- Issue: Incorrect positioning of the pressure sensor can affect its response time.

- Troubleshoot: Ensure the sensor is correctly installed and aligned with the pressure source. Verify that the sensor is positioned in a way that allows for optimal pressure transmission.

- Issue: Improper calibration can lead to sluggish response times.

- Troubleshoot: Re-calibrate the sensor using a certified calibration standard. Adjust calibration settings to improve the accuracy and response time. Follow the manufacturer's calibration guidelines.

- Issue: Temperature changes can affect the viscosity of fluids and impact the sensor's response time.

- Troubleshoot: Implement temperature compensation techniques to account for temperature variations. Use correction algorithms or adjust calibration based on temperature changes.

- Issue: Inadequate signal conditioning or amplification can contribute to slow response times.

- Troubleshoot: Check the signal conditioning circuitry. Ensure that amplifiers and signal processing components are functioning correctly. Consider upgrading or adjusting the signal conditioning system for faster response.

- Issue: Poor electrical connections or damaged wiring can lead to delayed signal transmission.

- Troubleshoot: Inspect the electrical connections, terminals, and wiring for any signs of damage or poor contact. Repair or replace damaged components and ensure secure connections.

- Issue: Different sensor types and technologies have varying response times.

- Troubleshoot: If applicable, consider upgrading to a sensor with faster response characteristics. Choose a sensor type that aligns with the speed requirements of the application.

- Issue: The control system parameters may not be optimized for the sensor's response characteristics.

- Troubleshoot: Review and adjust control system parameters, such as sampling rates and feedback loops, to ensure they are compatible with the desired response time.

- Issue: Lack of information on the optimal operating conditions and troubleshooting steps.

- Troubleshoot: Refer to the manufacturer's documentation for guidelines on improving response time. Manufacturers often provide specific recommendations for optimizing sensor performance.

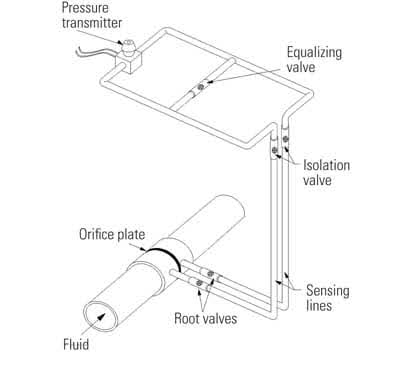

Fig 5. Different response problem

What are the problems that may faced while installing a pressure sensor?

Several challenges might arise during the installation of a pressure sensor, each potentially impacting its performance:

Fig 6. Pressure sensor installation problem

How can we resolve common installation issues?

Certainly! Resolving common installation issues with pressure sensors involves systematic troubleshooting and corrective measures. Here's a step-by-step guide to address these problems:

- Issue: Improper mounting or misalignment.

- Resolution: Recheck the sensor's positioning and alignment with the pressure source. Ensure proper mounting hardware is used and that the sensor is securely fastened without applying excessive force. Adjust the position if necessary, ensuring a direct and secure connection to the pressure point.

- Issue: Inadequate sealing or exposure to harsh elements.

- Resolution: Inspect the sealing integrity around the sensor. Reapply or reinforce seals as needed to prevent moisture, dust, or corrosive substances from entering. Use protective enclosures or housings if the environment poses a threat. Ensure the sensor is installed in a location that minimizes exposure to damaging elements.

- Issue: Incorrect or faulty electrical connections.

- Resolution: Check all electrical connections and wiring for proper insulation, tightness, and correct polarity. Repair or rewire any damaged or loose connections. Use appropriate tools and techniques to ensure secure and error-free electrical connections as per the manufacturer's guidelines.

- Issue: Lack of calibration or incorrect setup.

- Resolution: Perform calibration following the manufacturer's recommended procedures. Set up parameters such as pressure range, units, and response time as per the application requirements. Ensure the sensor is configured correctly for its intended use.

- Issue: Electromagnetic interference or excessive vibrations.

- Resolution: Install the sensor away from sources of electromagnetic interference. Use shielding or EMI filters if needed. Employ isolation mounts or dampeners to minimize the impact of vibrations on sensor performance. Ensure the installation environment meets the specified operating conditions outlined by the manufacturer.

- Resolution: After making adjustments and addressing installation issues, conduct thorough testing. Verify the sensor's readings against known pressure sources or standards. Ensure the sensor operates accurately and reliably in the intended conditions. Monitor its performance over time to confirm stability.

- Resolution: If issues persist or for specific guidance, refer to the sensor's user manual or contact the manufacturer's technical support. They might offer troubleshooting steps or recommendations tailored to the sensor model and the encountered issues.

Troubleshooting guide for inaccurate or unstable pressure measurements

Certainly! Inaccurate or unstable pressure measurements from a sensor can stem from various issues. Here's a troubleshooting guide to address these problems:

- Issue: Misalignment, improper mounting, or incorrect positioning.

- Troubleshoot: Recheck the sensor's installation. Ensure proper alignment and secure mounting without mechanical stress. Confirm the sensor is positioned correctly to receive accurate pressure readings.

- Issue: Sealing breaches or exposure to environmental elements.

- Troubleshoot: Examine seals for damage or gaps. Reapply or reinforce seals to prevent moisture, dust, or contaminants from entering. Consider using protective enclosures if the environment poses risks.

- Issue: Incorrect calibration or parameter settings.

- Troubleshoot: Perform calibration using certified standards. Check and adjust parameters such as pressure range, units, or compensation settings according to the manufacturer's guidelines or application requirements.

- Issue: Faulty or loose electrical connections.

- Troubleshoot: Inspect all electrical connections for proper insulation and tightness. Repair or replace damaged or loose connections. Ensure correct polarity and secure wiring as per manufacturer recommendations.

- Issue: Interference from vibrations, electromagnetic fields, or temperature changes.

- Troubleshoot: Install the sensor in a stable, interference-free location. Use isolation mounts, shielding, or EMI filters if necessary. Consider temperature compensation techniques for accuracy in varying conditions.

- Issue: Internal sensor damage or mechanical faults.

- Troubleshoot: Inspect the sensor for physical damage or signs of wear. Ensure the diaphragm and internal components are functioning properly. Replace or repair damaged parts as needed.

- Issue: Incorrect interpretation or processing of sensor data.

- Troubleshoot: Analyze the recorded data and readings from the sensor. Verify if the readings align with expectations or known pressure conditions. Ensure the data acquisition system or processing software interprets the sensor output correctly.

- Issue: Persistent problems without resolution.

- Troubleshoot: Refer to the sensor's documentation or contact the manufacturer's technical support for specialized guidance or troubleshooting steps tailored to the sensor model and encountered issues.

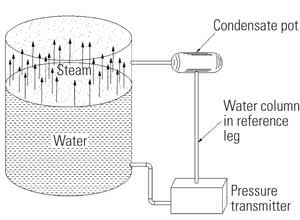

Fig 7. Steamy scene

Troubleshooting guide for inaccurate or unstable pressure measurements

When troubleshooting inaccurate or unstable pressure measurements from a sensor, a systematic approach is crucial to identify and resolve underlying issues. Start by reviewing the installation setup. Ensure the sensor is correctly positioned, securely mounted, and aligned with the pressure source. Any misalignment or improper mounting can significantly impact the accuracy of measurements. Verify the sealing to prevent environmental factors like moisture or contaminants from affecting sensor performance. Adequate protection and sealing are pivotal to maintaining the sensor's functionality in varying conditions.

Next, focus on calibration and settings. Check the calibration of the sensor against certified standards and adjust parameters like pressure range, compensation settings, or units as per the manufacturer's guidelines or specific application requirements. Inaccuracies in calibration or incorrect parameter settings can lead to erratic pressure readings. Simultaneously, assess the electrical connections, ensuring they are properly insulated, securely connected, and aligned as per the manufacturer's instructions. Faulty or loose electrical connections can result in signal disruptions, impacting the sensor's output stability.

Environmental factors play a crucial role in pressure sensor performance. Evaluate the environment for potential sources of interference such as vibrations, electromagnetic fields, or temperature fluctuations. Install the sensor in an environment that minimizes these interferences, using isolation mounts, shielding, or compensation techniques to mitigate their effects. Considering these factors and systematically troubleshooting each aspect—from installation to calibration, electrical connections, and environmental conditions—helps pinpoint and rectify issues affecting the sensor's accuracy and stability in pressure measurements.

What are the Tips for optimizing performance and accuracy?

Optimizing the performance and accuracy of pressure sensors involves several considerations and practices. Here are some tips to enhance their functionality:

Fig 8. Pressure sensor connection problem

A real example of a pressure sensor issue and its troubleshooting

Certainly! Here's an example of a pressure sensor issue and its troubleshooting:

Issue: In an industrial setting, a pressure sensor installed in a hydraulic system provides erratic and fluctuating readings, impacting the system's performance. The pressure readings intermittently spike or drop unexpectedly, affecting the accuracy of the system's operations.

Troubleshooting Steps:

- Observation: The sensor is properly installed and sealed, but the erratic readings persist.

- Troubleshooting: Begin by checking the sensor's electrical connections and wiring integrity. A visual inspection reveals loose wiring connections, likely due to vibrations from the hydraulic machinery.

- Observation: The hydraulic system operates in a high-vibration environment.

- Troubleshooting: Apply shock-absorbing materials or isolation mounts to minimize the impact of vibrations on the sensor. This step aims to stabilize the sensor's measurements despite the surrounding machinery vibrations.

- Observation: Despite addressing the wiring and environmental issues, fluctuations in pressure readings persist.

- Troubleshooting: Conduct a calibration check using a certified pressure standard. Calibration reveals that the sensor's settings require adjustment due to inconsistencies caused by the vibrations. Adjust the sensor's calibration to compensate for these variations in readings.

- Resolution: After recalibration, integrate the sensor back into the hydraulic system and perform functional tests. Monitor the sensor's readings while the system operates. The readings now remain stable and consistent, accurately reflecting the pressure variations within the hydraulic system.

When a pressure sensor gets in trouble what should do at first?

When a pressure sensor encounters trouble, the initial steps involve a systematic approach to diagnose and isolate the issue. Start by conducting a visual inspection of the sensor and its connections for any visible damage, loose wiring, or signs of wear. Simultaneously, assess the sensor's operating environment, considering factors like temperature, vibrations, moisture, and potential electromagnetic interference. These assessments help identify potential external influences affecting the sensor's performance.

Next, conduct initial tests or measurements to evaluate the sensor's output. Compare the readings against expected values or known standards to identify deviations or inconsistencies. If feasible, isolate the sensor from the system or circuit it's monitoring to determine whether the issue persists when the sensor operates independently. Refer to the manufacturer's documentation or user manual for specific troubleshooting steps and guidelines. Keeping detailed records of observations and tests conducted will aid in documenting the identified issues, and facilitating further troubleshooting or technical support if necessary. These initial steps serve as a foundation for a more targeted investigation and resolution of the pressure sensor's problem.

When a pressure sensor encounters trouble, it's crucial to address the issue promptly and systematically. Here are the initial steps to take when a pressure sensor is suspected to be faulty:

Initial Troubleshooting: Perform a diagnostic check to ensure the issue is indeed with the sensor. Verify the sensor's connections, wiring, and environmental conditions to rule out external factors causing the problem.

These initial steps help in assessing the sensor's condition, identifying potential causes of the problem, and determining whether the issue lies with the sensor itself or external factors. It sets the stage for a more targeted and effective troubleshooting process to address the problem and restore the sensor's functionality. If the issue persists or requires more in-depth investigation, seeking guidance from technical support or professionals experienced with sensor diagnostics might be necessary.

Conclusion

When a pressure sensor faces issues, prompt and systematic action is essential for diagnosing and resolving the problem effectively. Starting with a thorough visual inspection and environmental assessment, followed by initial tests to evaluate sensor output, sets the stage for identifying potential causes of trouble. Isolating the sensor if feasible and referencing manufacturer guidelines aid in narrowing down the issue's root cause. Documenting observations and findings during this initial assessment provides a clear record for further troubleshooting or seeking technical assistance if needed. These initial steps lay the groundwork for a comprehensive and targeted approach to address the pressure sensor's trouble, ensuring accurate and reliable performance within its intended application.

To recap

1.Q: What are the common causes of inaccurate pressure readings from a sensor? A: Inaccurate pressure readings can result from improper installation, calibration issues, environmental factors like moisture or temperature variations, electrical wiring faults, or sensor damage.

2.Q: How often should pressure sensors be recalibrated? A: Recalibration frequency depends on usage, environmental conditions, and sensor specifications. Generally, sensors are recalibrated annually or as recommended by the manufacturer.

3.Q: What could cause sudden spikes or drops in pressure readings? A: Sudden fluctuations might stem from mechanical stress, environmental changes, wiring faults, or sensor overload due to pressure spikes beyond the sensor's limit.

4.Q: What are the signs that a pressure sensor needs replacement? A: Signs include consistent inaccurate readings despite calibration, physical damage, corrosion, or persistent issues after thorough troubleshooting.

5.Q: How can I minimize interference affecting pressure sensor accuracy? A: Shield the sensor from electromagnetic interference, use proper grounding, implement EMI filters, and ensure secure, insulated electrical connections.

6.Q: How does temperature impact pressure sensor accuracy? A: Temperature changes affect sensor accuracy due to material expansion/contraction or changes in fluid properties, necessitating temperature compensation techniques.

7.Q: What preventive maintenance can enhance sensor longevity? A: Regular cleaning, sealing checks, monitoring environmental conditions, and conducting periodic calibration are key for sensor maintenance.

8.Q: What steps should be taken if a pressure sensor provides inconsistent readings? A: Begin by checking for loose wiring, environmental factors, or calibration issues. Isolate the sensor, perform tests, and refer to manufacturer guidelines for troubleshooting.

9.Q: How do I know if a pressure sensor's zero offset is affecting accuracy? A: Check if the sensor reads zero when there's no applied pressure. Any deviation from zero might indicate a zero offset, which requires nullification through calibration.

10.Q: What role does proper grounding play in pressure sensor performance? A: Proper grounding minimizes electrical noise, and interference, and ensures stable sensor operation, contributing to accurate and reliable readings.

References

https://www.samarins.com/glossary/oil-pressure-sensor.html

https://www.transmissiondigest.com/fixing-jf011e-primary-pulley-pressure-sensor-issues/

https://www.youcanic.com/mercedes-dpf-exhaust-pressure-sensor-problem-p1402-code-2078/

https://www.vacuubrand.com/blog/en/products-services-en/dakks-calibration-service/

https://aeroenginesafety.tugraz.at/doku.php?id=19:192:1921:1921

https://www.powermag.com/pressure-sensing-line-problems-and-solutions/

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025