Checking the Presence of Cans in Cardboard Boxes by Means of Analog Inductive Sensors

Checking the product quality within the boxes of cans is necessary to reduce product errors that can arise during packaging procedures. The adopted solution must be capable of handling cans made of various materials and sizes. Normal on-off switching sensors are therefore inappropriate for this purpose. Carton rejection or acceptance should be instantaneous throughout the verification procedure.

The best solution:

Analog inductive sensors

The features of analog inductive sensors:

• Good environmental stability (especially to • temperature)

• Applying Condist® oscillator technology

• An operating distance up to 3 times the standard (40 mm)

• High reliability

• High durability

• High adaptability

• Easy installation

Note: These sensors' longer operating distance allows them to receive signals through multiple layers of cardboard and from different conductive metals at varying distances.

Where are these sensors mounted?

Both above and below the passing lanes of cans

How do these sensors function?

When these sensors are used, the double layer of cans in each carton can be detected. The best sensing distance is provided due to the M30 size of these sensors.

Connection of these sensors to PLCs:

A fast analog input card provides the direct connection of continuous outputs from these sensors to a PLC.

Among the leading manufacturers of automotive sensors, Contrinex is one of the largest. Step in to get to know Contrinex company.

Check out our article for more information on photoelectric sensors:Inductive Proximity Sensor Types

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Warranting Safe Status of Load before Starting Platform Lift and during Operation Using Inductive Sensors

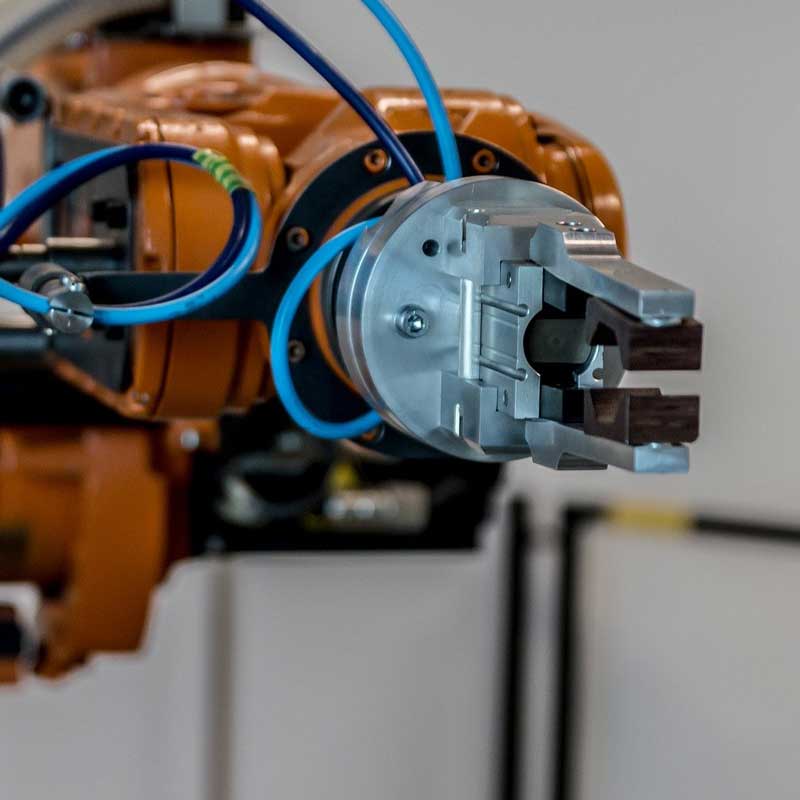

Figuring Out the Jaw Position for High Precision Robot Grippers by Miniature Inductive Sensors

Checking Functions in High-Reach Forklift Trucks via Inductive Sensors

Related Products