Lowering Maintenance Expenses and Raising Efficiency of Concrete Pumps Using High Pressure Resistant Sensors

A double piston pump is used in concrete pumps. Two feed cylinders are required for this process.

They pump the concrete at operating pressures up to 400 bar. These feed cylinders are propelled by hydraulic cylinders.

Cylinder pairs operate in an opposing push-pull manner. The time of this push-pull action needs to be precisely synchronized to achieve maximum efficiency.

It is crucial to monitor the cylinder end position using high-pressure resistant sensors.

What type of sensors can be the best suggestion?

High-pressure resistant sensors

Some features of high-pressure sensors:

Resistant to pressures up to 1000 bar - 14500 psi

Impervious to dynamic stresses.

Minimal maintenance expenditures due to a ten times larger than the average market lifetime

Other specifications:

A patented process in which a solid ceramic disk is incorporated into the stainless steel housing makes these sensors resistant to high pressure.

The Patented technology warrants that all electronic components, including the ferrite core and coil, are on the pressure-free side of the housing.

This results in an exceptionally long life under the stresses of the pressure cycle.

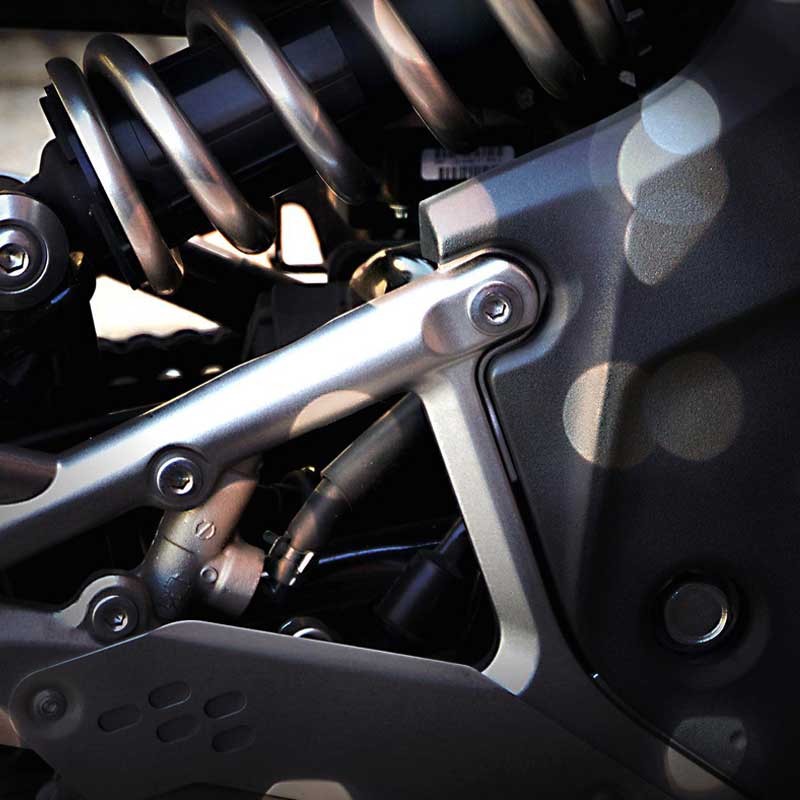

Two sensors are placed and connected to the control system to track the concrete pump's cylinder limit positions.

Among the leading manufacturers of automotive sensors, Contrinex is one of the largest. Step in to get to know Contrinex company.

Check out our article for more information on photoelectric sensors:Inductive Proximity Sensor Types

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Resistance of Inductive Sensors to Loads in Wheel Speed Monitoring for Racing Automobiles

Detecting Retraction of Stabilizer Legs of Mobile Cranes via Inductive Sensors

Analog Inductive Sensors for Permanent Measuring of Primary Spring Status on Tramcar Suspension

Related Products