Special Manometers for the Process of Regulating Pressure in Gas and Liquid Pipes

Increased pressure in pipes containing gas or liquid is an inevitable phenomenon. For example, the pressure inside lead and stone pipes can be so severe that it breaks the stone blocks.

Today, due to the increase in the capacity of production lines, the issue of increasing the pressure of pipes has become a challenge for engineers. In 2009, for example, the failure of water pumps caused a sharp increase in pressure in water pipelines and pushed the pipelines to their limits. When the power returned and the water supply system started working, the high pressure in the pipes destroyed the pipes that had been damaged before.

Recently, special manometers have been designed through which the pressure peak can be detected very quickly and the necessary precautions can be taken.

Pressure dampers and sensors are installed to detect damage to pipelines, but this is not enough. Because these two are not suitable for detecting extreme pressure peaks. Since in practice the compression of water can not be avoided, its pressure increases rapidly. In addition, pressure fluctuations cannot be avoided in either gas or liquid piping systems.

Because the valves can not be closed infinitely slowly. The only thing that can be done is to minimize this pressure. That is why pressure dampers are installed in pipe systems.

Overpressure valves respond when the pressure exceeds a certain limit. However for pressure peaks, they are too slow. So the engineers thought of installing manometers.

Today, special manometers are designed that can measure the pressure flow up to 5000 bar per second. Analysis can show the exact trend of pressure during the day, hours, minutes and seconds to find the causes of peak pressure.

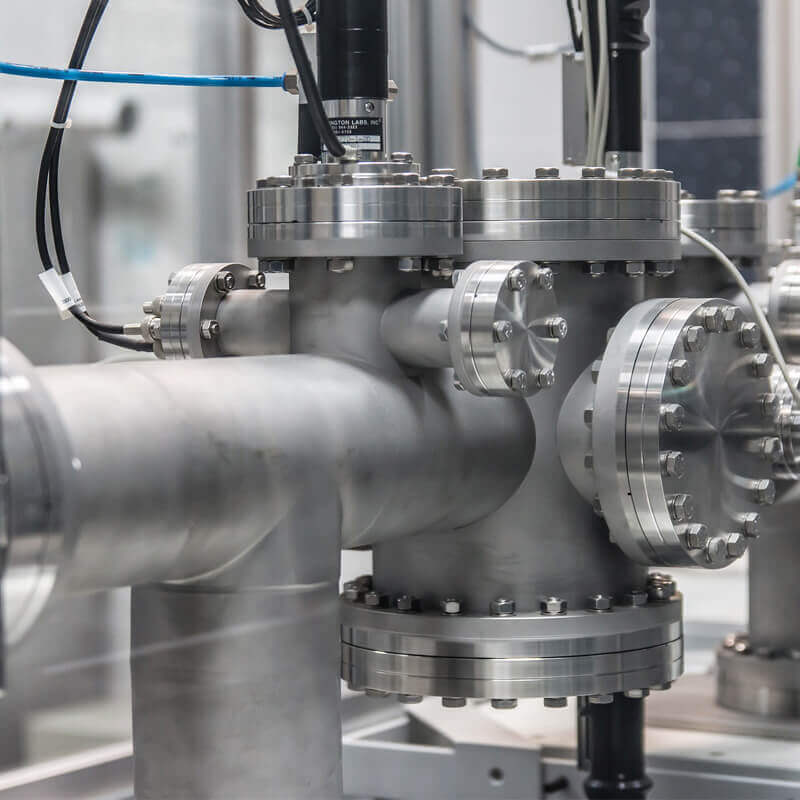

These manometers combine precision sensors with fast high-resolution signal processing, peak recording and time-stamped memory, all housed in a sturdy stainless steel enclosure with safety glass. Touch buttons allow the user to scroll through measurements and settings.

Modern manometers have an IP rating of 66 due to continuous monitoring of effective damage protection. Industrial systems, on the other hand, are usually installed with IP54 only.

These systems can easily adapt to customer demands thanks to their electronic modular structure and serial interface. In addition, these manometers bring more security and cost savings.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

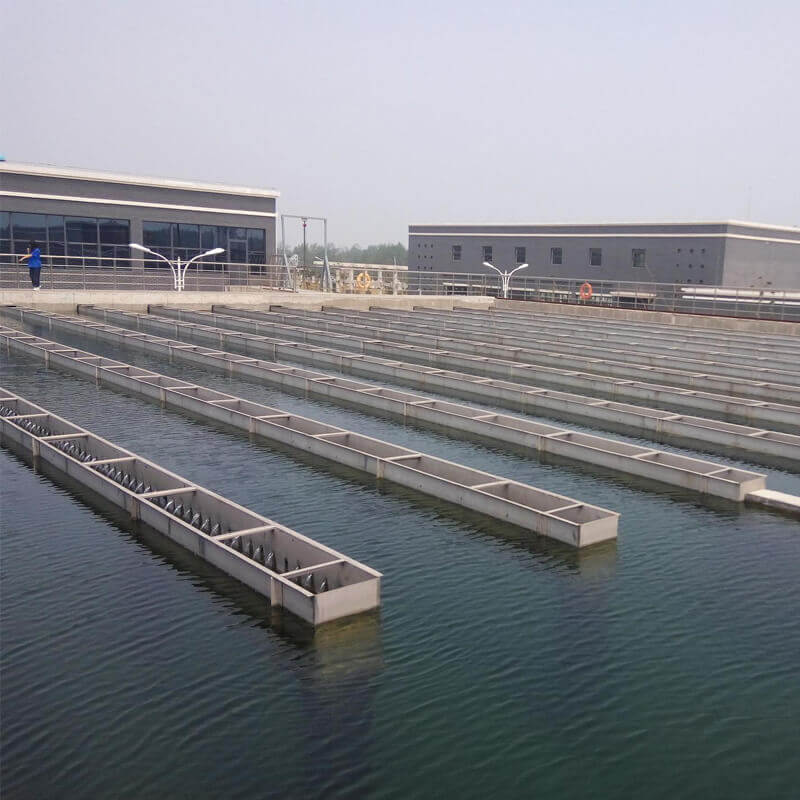

Facilitating the Measurement of Wastewater Levels via Special Level Transmitters

Pressure Sensors for Smart Water Loss Measurement Systems

Special Sensors for Hydraulic Network Analysis Systems

Related Products