Special Sensors for Hydraulic Network Analysis Systems

Hydraulic network analysis can be used to prevent damage to parts of municipal water supply networks and to maintain water pressure at an optimal level.

Calibrated models are used in hydraulic network analysis, which is measured based on actual pressure and flow data. In this type of analysis, the performance of the water supply and distribution system is improved and the energy loss due to insufficient water storage technology and inefficient feed pumps is minimized.

Water supply network models are like snapshots of a situation.

Each hydraulic water supply version must be reviewed every time big changes occur. To do this, we can subject the real network to known operating situations and compare calculated and actual flow rates and flow pressure to detect significant errors. . Discrepancies from the calculated model might show mistakes in elevation data or large unknown leaks. In a high-load situation, the hydraulic resistances of the main network pipes are checked, wherein variations here show hydraulic blockages due to faulty fittings or clogs, for instance.

Field measurements are a fundamental aspect of hydraulic network analyses, as they offer the maximum vital data. A critical parameter here is the Darcy friction factor formula (λ), which has to be gained to calculate the pressure drop in a pipe flow. To calculate the real friction coefficient, the performance of various system parts has to be tested and documented.

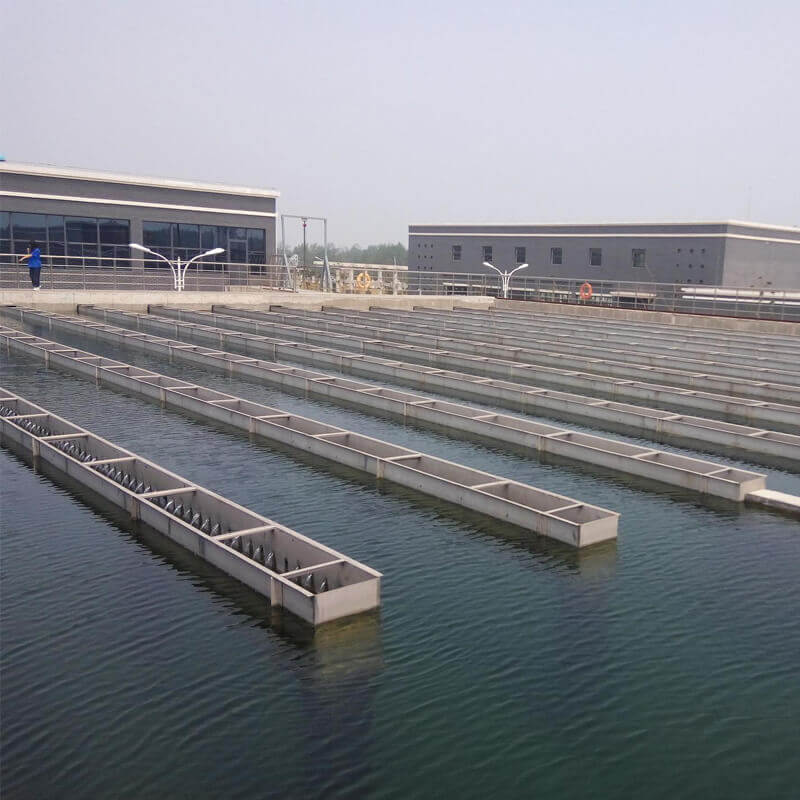

To this end, the pressure, flow, and water consumption values should be recorded, wherein this physical data collection is supplemented through operation data collection. Several measurements are applicable here, along with non-stop 24-hour flow rate recording at chosen key locations, like water catchment sites and the main network pipes.

To this is added flow data gathered from different key pipes and selected nodes, like fire hydrants, which are evenly spread over the network. The storage level (hydraulic elevation) additionally requires to be monitored as well as other elements that impact the measured pressure values.

Water supply systems need smart management. The approval and calibration of network models lead to detecting hydraulic problems in the network.

Recently, special data loggers and pressure sensors have been designed to assist engineers in smartly managing water supply systems.

Data from Data loggers can be used to detect accurate resistances in the pipe system and to calculate and adjust the values of pipe roughness. This can be used to obtain the calculated hydraulic scores for calibration.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Special Data Loggers for Monitoring Groundwater in Open-Pit Mining

Level Sensors Designed for Monitoring the Level of Water in Fish Farms

Special Level Sensors for Water Wells

Related Products