Special Differential Pressure Transmitters for Oil and Gas Recovery

You can often smell it in gas stations, which is oil and gas. If we smell a strong gasoline smell in a gas station, we must pay attention that perhaps the gas station's gas recovery is not working well.

There are three main reasons for the importance of oil and gas recovery:

1- The importance of oil and gas recovery in the environment

A photochemical reaction takes place between the oil and gas and nitrogen oxides to make photochemical smog, which will raise the ozone in the atmosphere. Furthermore, the benzene aromatic hydrocarbons in oil and gas are carcinogenic.

2- The importance of oil and gas recovery in safety oil and gas recovery will prevent explosions.

3- The economic importance of oil and gas recovery

the whole process of receiving, dispatching, storing, and transporting gasoline from the oil storage tank in the refinery to the filling of the automobile tank has a lot of economic expenses.

How to recover and gas:

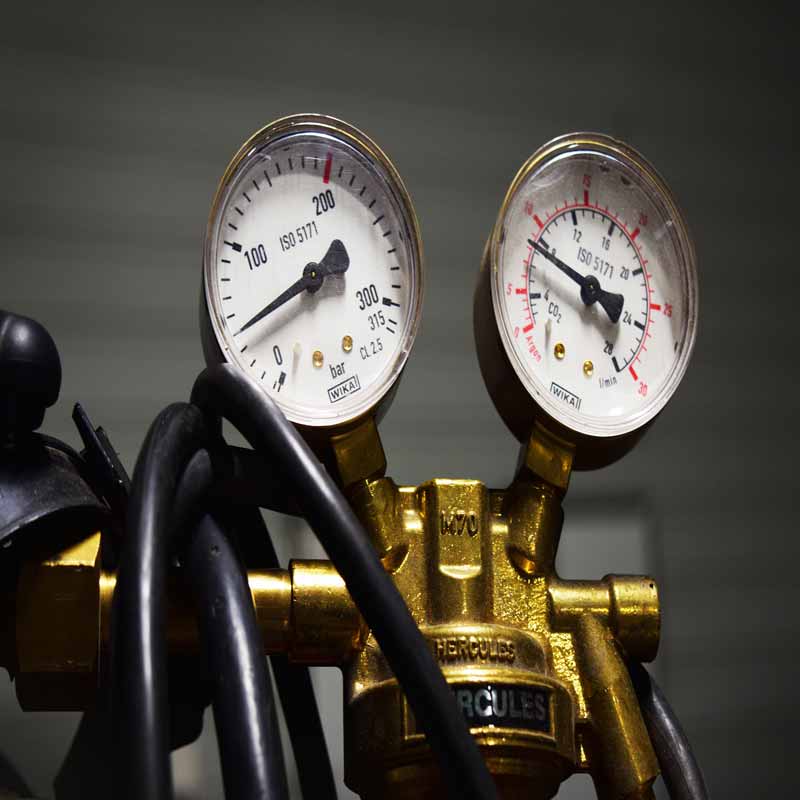

For this purpose, the internal pressure of the pipelines must be controlled. In fact, by monitoring the pressure and the process of pressure changes, it is possible to find out possible leaks in the recovery system, possible blockage of the pressure vacuum valve, and whether post-processing equipment is working or not.

It should be noted that the pipeline pressure should be negative.

We need precise monitoring tools to control the internal pressure of the pipeline and create negative pressure in it. Intelligent pressure/differential pressure transmitters have been produced and are suitable for this purpose.

Some of the features of this type of transmitter are as follows:

1. High precision silicon sensor technology, which can communicate with field equipment via micro-processing electronic components, and on-time transfer the internal conditions of the pipeline.

2. It has high accuracy due to a Wide temperature compensation and its stable performance.

3. The One-way overpressure can reach the rated pressure, and the static pressure limit may reach the rated working pressure. Very good static pressure performance.

4. From 35mbar absolute pressure to rated pressure, protection pressure can be pressurized to both the high and low side of the transmitter; and it can be higher than 1.5 times of rated pressure.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Special Gas Pressure Measurement: Pressure Sensors and Transmitters

Measuring the Flow of Wastewater in Oilfields

Remote Monitoring of the Filling Level of Fuel Tanks

Related Products