Remote Monitoring of the Filling Level of Fuel Tanks

The EasyOil® system offers a practical way to remotely monitor the filling level of oil and gasoline tanks. This is a system for measuring the filling level of the oil tank, which is equipped with a GSM modem. This system brings a lot of convenience to busy customers and, in addition, has major economic benefits for corporate facility managers and real estate managers who have to coordinate fuel supply for multiple properties. Gas station operators as well as oil companies also benefit from EasyOil®.

EasyOil® designers searched for a suitable supplier who could deliver the measuring probes as well as the transmission module.

Now, for this company, the new variant (modified at the customer’s request) which also offers the option of SMS communication with consumers is designed. Customer surveys have confirmed that this is the most reliable version, and the one that customers prefer.

Intrinsically safe and temperature resistant for areas subject to explosion hazards (EX areas)

The new variant comprises the modem itself and what is known as the SB box, to which as many as three pressure transmitters (with voltage outputs of 0.5…4.5 V) can be connected. The box contains three built-in safety barriers (SBs). These circuits also make it possible to process the electrical measurement signals to gas stations, where an electrical spark could cause an explosion due to the gases contained in the atmosphere. This is why any pressure transmitter that performs measurements in an environment of this sort must be intrinsically safe. . The new variant itself may only be installed outside of the EX area. As part of the complete package, the level sensor cables used to transmit the measurement signals are designed.

Intrinsically safe level sensors are designed for EasyOil® systems at gas stations, whereas the conventional version is used for heating oil tanks in locations not classified as EX areas. The transmitters in these devices are based on the piezoresistive silicon measuring cell. In these sensors, the temperature error (as it is known) is compensated electronically.

One-stop expertise

these pressure transmitters guarantee long service lifetimes, even in an aggressive medium such as gasoline, because of their robust stainless steel housing (degree of protection: IP68) and a design whereby the silicon measuring cell is protected against the measured medium by a stainless steel diaphragm.

These sensors are highly reliable and have excellent function.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Pressure and Level Sensors for the System of Chemical Injection

Gas Volume Corrector

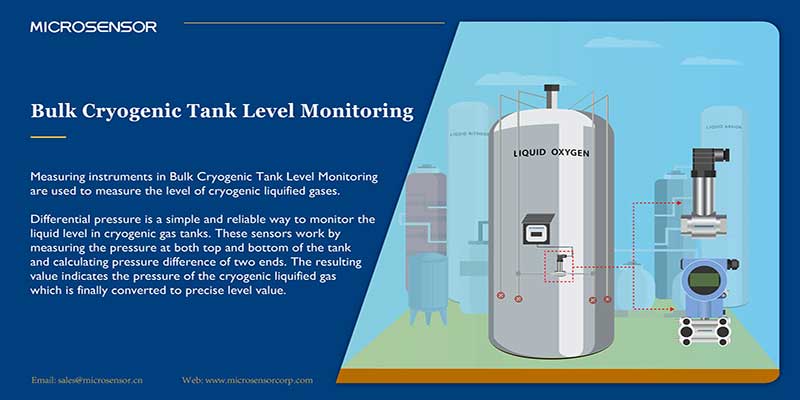

Monitoring the Level of Bulk Cryogenic Tanks

Related Products