The Pulse of Pressure: Pressure Transmitters in Action

Pressure is a fundamental force of nature, and harnessing its fluctuations is critical in a multitude of industries, from manufacturing to healthcare. In this age of precision engineering and data-driven decision-making, the pressure transmitter emerges as a silent hero. With the ability to transform physical pressure changes into electronic signals, pressure transmitters are the unassuming giants of measurement technology, quietly ensuring the efficiency, safety, and reliability of countless processes. In this exploration, we delve into the intricate world of pressure transmitters, unraveling their components, technologies, and the profound impact they have across industries. Buckle up as we venture into the heart of this unassuming yet indispensable instrument.

Fig 1. Pressure sensors

What are the pressure transmitter's components?

A pressure transmitter is an instrument used to measure and transmit pressure readings in various industrial and commercial applications. It consists of several key components that work together to accurately measure and transmit pressure data. These components typically include:

- Pressure Sensor or Sensing Element: This is the core component responsible for directly measuring the pressure. Different types of pressure sensors can be used, such as piezoelectric, capacitive, strain gauge, or piezoresistive sensors. The choice of sensor depends on the specific application and the range of pressures to be measured.

- Process Connection: The process connection is the part of the transmitter that comes into direct contact with the fluid or gas whose pressure is being measured. It provides a sealed interface between the sensor and the process medium.

- Diaphragm: In many pressure transmitters, a diaphragm is used to separate the process medium from the pressure sensor. The diaphragm flexes in response to changes in pressure, and this deformation is detected by the sensor.

- Signal Conditioning Circuitry: The raw electrical signal from the pressure sensor needs to be conditioned and amplified to provide a reliable and accurate output. This circuitry may include amplifiers, filters, and analog-to-digital converters.

- Microprocessor or Microcontroller: Modern pressure transmitters often include microprocessors or microcontrollers to process the conditioned signal, linearize it (to account for non-linearity in the sensor's response), and provide digital communication interfaces.

- Output Interface: Pressure transmitters typically have one or more output interfaces to transmit the pressure data to external devices or control systems. Common output signals include analog (e.g., 4-20 mA or 0-10 V), digital (e.g., HART, Modbus, or Profibus), or wireless protocols.

- Housing or Enclosure: The transmitter's electronics and components are enclosed in a housing or enclosure that protects them from environmental factors such as moisture, dust, and temperature variations. The housing also often includes mounting options for installation.

- Power Supply: Pressure transmitters require a power supply to operate, and the type of power supply (e.g., 24 VDC) may vary depending on the transmitter's specifications.

- Display and User Interface (optional): Some pressure transmitters come with built-in displays and user interfaces that allow operators to configure settings and view pressure readings directly on the transmitter.

- Calibration and Compensation Components: Pressure transmitters may include components for calibration and compensation to ensure accuracy over time. This may involve compensating for factors like temperature variations.

- Electrical Connections: Connectors and terminals for wiring the transmitter to power sources and communication networks.

These components work together to accurately measure the pressure in a given application and provide a reliable output signal that can be used for monitoring, control, and data analysis in various industrial processes. The specific design and components used can vary depending on the manufacturer and the intended application of the pressure transmitter.

What are the Electronics in Pressure Transmitters?

Pressure transmitters contain various electronics and components that work together to measure, process, and transmit pressure data accurately. These electronics enable pressure transmitters to convert physical pressure changes into electrical signals, process those signals, and communicate the pressure measurements to external systems or devices. Here are the key electronics and components typically found in pressure transmitters:

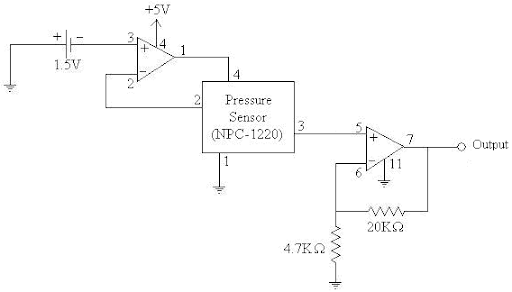

Fig 2. "Hot-chamber" high pressure die casting

What kind of microprocessors are used in pressure transmitters?

The choice of microprocessors or microcontrollers in pressure transmitters can vary depending on the manufacturer, product specifications, and the required functionality of the transmitter. However, pressure transmitters typically use microcontrollers that are designed for the specific needs of the device, which often include low power consumption, accuracy, and signal processing capabilities. Some commonly used microcontroller families or types in pressure transmitters include

- ARM Cortex-M Series: ARM Cortex-M microcontrollers are popular choices in various industrial and embedded applications due to their low power consumption and versatility. Pressure transmitters may use microcontrollers from this series to handle signal processing, communication, and control tasks.

- PIC Microcontrollers: Microcontrollers from Microchip's PIC family are commonly used in a wide range of industrial devices, including pressure transmitters. They offer a variety of options with different capabilities and memory sizes.

- Atmel/Microchip AVR Microcontrollers: AVR microcontrollers are known for their simplicity and ease of use, making them suitable for applications where power consumption and cost-effectiveness are essential considerations.

- Texas Instruments MSP430 Series: The MSP430 series is known for its ultra-low power consumption and can be suitable for battery-powered or energy-efficient pressure transmitters.

- STMicroelectronics STM32 Series: STM32 microcontrollers are based on ARM Cortex-M cores and are widely used in industrial and embedded applications due to their performance and feature-rich peripherals.

- Silicon Labs EFM32 Series: These microcontrollers are known for their low power consumption and are often used in battery-operated or energy-efficient applications, which may include certain pressure transmitter designs.

- Custom ASICs (Application-Specific Integrated Circuits): In some cases, manufacturers may develop custom ASICs specifically designed for their pressure transmitter products to achieve the highest level of integration and performance while minimizing power consumption.

The choice of microcontroller depends on various factors, including the required processing power, memory, communication interfaces (such as HART or Modbus support), and power efficiency. Pressure transmitter manufacturers select microcontrollers that best suit the specific requirements of their product and the intended application, ensuring reliable and accurate pressure measurement and communication capabilities.

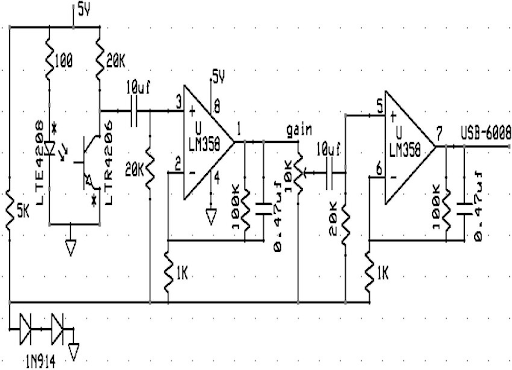

Fig 3. ARM Cortex-M series

ARM Cortex-M Series

- High processing power.

- Energy-efficient.

- Versatile and widely supported.

- Strong developer ecosystem.

- Can be relatively expensive compared to some other microcontrollers.

- Complex for simple applications.

PIC Microcontrollers:

- Easy to learn and use.

- Cost-effective for many applications.

- Extensive product range.

- Limited processing power in some models.

- May not be suitable for very high-performance applications.

Atmel / Microchip AVR Microcontrollers:

- Low power consumption.

- Easy to use and program.

- Cost-effective.

- Limited processing power in some models.

- May not be suitable for high-performance computing tasks.

Texas Instruments MSP430 Series:

- Extremely low power consumption.

- Good for battery-powered and energy-efficient applications.

- Adequate processing power for many tasks.

- Limited processing power compared to some higher-end microcontrollers.

- May not be suitable for computationally intensive applications.

ST Microelectronics STM32 Series

- GoThe balance of processing power and energy efficiency.

- Broad range of model The cost choose from.

- Strong ecosystem and support.

- Cost may be higher than some simpler microcontrollers.

- May be overkill for very basic applications.

Silicon Labs EFM32 Series

- Extremely low power consumption.

- Suitable for battery-powered and energy-efficient applications.

- Limited processing power compared to some higher-end microcontrollers.

- May not be suitable for computationally intensive applications.

Comparing table

Here's a comparative table summarizing the key aspects of the microcontroller families mentioned:

| Microcontroller Family | Description | Operation | Applications | Pros | Cons |

| ARM Cortex-M Series | High-performance, energy-efficient microcontrollers. | ARM Cortex-M instruction set | Industrial automation, IoT, consumer electronics | High processing power, energy efficiency | Relatively expensive for simple apps |

| PIC Microcontrollers | Simple and user-friendly microcontrollers. | MPLAB development environment | Home automation, robotics, embedded control | Easy to learn and use, cost-effective | Limited processing power in some models |

| Atmel/Microchip AVR | Low power consumption, ease of use. | Atmel Studio development environment | Battery-operated deasy-to-program control | Low power consumption, easy to program | Limited processing power in some models |

| Tand texas Instruments MSP430 | Ultra-low power consumption, battery life. | Code Composer Studio (CCS) development environment | Battery-powered devices, IoT, sensor nodes | Extremely low power consumption | Limited processing power compared to some higher-end microCortex-M-based |

| ST Microelectronics STM32 | Versatile ARM Cortex-M based microcontrollers. | STM32CubeIDE, Keil MDK, etc. | Industrial control systems, IoT, consumer electronics | Good balance of power and efficiency | Cost may be higher for some applications |

| Silicon Labs EFM32 | Low energy consumption for battery-powered devices. | Simplicity Studio development environment | Battery-operated sensors, wearables, IoT devices | Extremely low power consumption | Limited processing power compared to some higher-end microcontrollers |

Please note that the suitability of a particular microcontroller family depends on the specific requirements of the application, so the choice should be made based on factors like processing power, power efficiency, ease of development, and cost-effectiveness.

What is the purpose of using microprocessors in pressure transmitters?

Microprocessors are used in pressure transmitters for several important purposes, enhancing the functionality and capabilities of these devices in various industrial and commercial applications:

- Signal Processing: Pressure transmitters often need to process the raw analog signals from pressure sensors to linearize, calibrate, and filter the data. Microprocessors can perform complex signal-processing tasks, allowing for more accurate and stable pressure measurements.

- Data Compensation: Many factors, such as temperature variations, can affect pressure readings. Microprocessors can compensate for these environmental factors by applying correction algorithms to the data, ensuring that the output remains accurate even in changing conditions.

- Digital Communication: Microprocessors enable pressure transmitters to communicate with other devices and control systems. They can support various communication protocols like HART, Modbus, Profibus, or Ethernet/IP, allowing for remote monitoring, control, and integration into larger systems.

- Data Logging and Storage: Some pressure transmitters equipped with microprocessors can store pressure data locally, facilitating data logging and historical analysis. This feature is valuable for process optimization, troubleshooting, and compliance with regulatory requirements.

- Self-Diagnostics: Microprocessors can perform self-diagnostics and continuously monitor the health of the pressure transmitter. If any issues or faults are detected, the microprocessor can trigger alarms or warnings, helping to prevent system failures and downtime.

- User Interface: Microprocessors can support user interfaces, such as displays and buttons, which allow operators to configure settings, view pressure readings, and perform diagnostics directly on the transmitter itself. This simplifies setup and maintenance.

- Remote Configuration: Through digital communication interfaces, microprocessor-equipped pressure transmitters can be configured remotely, reducing the need for on-site adjustments and maintenance.

- Advanced Features: Microprocessors enable the implementation of advanced features, such as multi-sensor integration (e.g., measuring multiple pressures or temperature simultaneously), adaptive filtering, and advanced diagnostics, making pressure transmitters more versatile and adaptable to various applications.

- Customization: Manufacturers can develop firmware updates for microprocessor-based pressure transmitters to add new features or improve existing ones, ensuring that the devices remain up-to-date and adaptable to changing industry requirements.

- Energy Efficiency: Some microprocessors are designed for low power consumption, which is crucial for battery-powered or energy-efficient pressure transmitter applications.

In summary, microprocessors enhance the capabilities of pressure transmitters by providing signal processing, communication, data storage, and advanced features. These capabilities make pressure transmitters more versatile, accurate, and user-friendly, enabling them to meet the demands of various industrial processes and applications while ensuring reliable and precise pressure measurement and control.

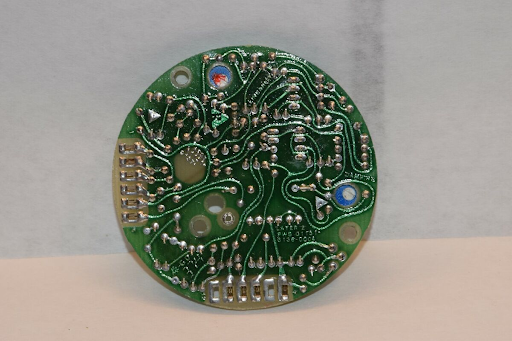

Fig 4. Signal condition circuitry

What are the pressure transmitter microprocessor internal parts?

The internal parts of a microprocessor in a pressure transmitter are similar to those of a typical microprocessor or microcontroller used in embedded systems and industrial applications. These components work together to execute instructions, process data, and manage the functions of the pressure transmitter. While the specific internal architecture may vary depending on the microprocessor's manufacturer and model, here are the key internal parts commonly found in a microprocessor used in a pressure transmitter:

- Central Processing Unit (CPU): The CPU is the core component responsible for executing instructions. It performs arithmetic and logic operations, controls data flow, and coordinates the operation of other internal parts.

- Arithmetic Logic Unit (ALU): The ALU is a component within the CPU that performs arithmetic and logical operations, such as addition, subtraction, multiplication, division, and comparisons.

- Control Unit: The control unit manages the fetch-decode-execute cycle of instructions. It generates control signals to coordinate data movement within the microprocessor.

- Registers: Registers are small, high-speed memory locations used for temporary storage of data and intermediate results during processing. Common registers include the program counter (PC), instruction register (IR), and various general-purpose registers.

- Memory: Microprocessors typically have memory components, including RAM (Random Access Memory) for temporary data storage and ROM (Read-Only Memory) for storing firmware, program instructions, and calibration data.

- Clock and Timing Circuitry: Clock signals are generated by timing circuitry to synchronize the microprocessor's operations. The clock determines the rate at which instructions are executed.

- Control and Status Registers (CSRs): These registers store control and status information that the microprocessor uses to manage operations, handle interrupts, and respond to external events.

- Instruction Decoder: The instruction decoder interprets the binary instructions fetched from memory and decodes them into a form that the CPU can execute.

- Data Bus and Address Bus: These buses are used for transferring data and addresses between the microprocessor and external components, such as memory, sensors, and communication interfaces.

- Input/Output (I/O) Interfaces: Microprocessors often have I/O interfaces that allow them to communicate with external devices, sensors, and peripherals. These interfaces may include serial ports, parallel ports, or specialized communication protocols.

- Interrupt Controller: The interrupt controller manages the handling of interrupts, which are signals generated by external events or devices that require immediate attention from the microprocessor.

- Arithmetic and Logic Unit (ALU): The ALU is responsible for performing arithmetic and logical operations on data. It is a critical component for processing and manipulating pressure readings and other data within the microprocessor.

- Memory Management Unit (MMU): In some microprocessors, especially those with more complex memory hierarchies, the MMU manages virtual memory and memory protection, ensuring that data and instructions are stored and accessed correctly.

- Floating-Point Unit (FPU) (optional): Some microprocessors include an FPU for performing floating-point arithmetic operations with higher precision. This is especially useful in applications that require precise calculations.

These internal parts work together to enable the microprocessor to execute instructions, process data from pressure sensors, perform signal conditioning, apply compensation algorithms, manage communication with external devices, and perform other tasks necessary for the operation of a pressure transmitter. The specific capabilities and features of the microprocessor may vary depending on the design and requirements of the pressure transmitter.

How is the microprocessor working principle?

The working principle of a microprocessor involves a series of steps that enable it to process instructions and data to perform various tasks. Microprocessors are the central processing units (CPUs) of computers and embedded systems, and they execute a set of instructions to perform arithmetic, logic, control, and input/output (I/O) operations. Here's a simplified overview of how a microprocessor works:

- Fetch: The microprocessor fetches the next instruction from memory. The instruction is represented as a binary code, typically stored in the system's RAM (Random Access Memory) or ROM (Read-Only Memory).

- Decode: The microprocessor decodes the fetched instruction to determine what operation needs to be performed. This involves interpreting the binary code to identify the operation code (opcode) and any associated operands or addresses.

- Execute: Once the instruction is decoded, the microprocessor performs the specified operation. This can include arithmetic calculations, logical comparisons, data transfers between registers or memory, and control operations like branching or jumping to different parts of the program.

- Update: After executing the instruction, the microprocessor may update internal registers, flags, or memory locations based on the results of the operation. For example, it may set flags to indicate conditions such as overflow, carry, or zero.

- Repeat: The microprocessor continues to fetch, decode, execute, and update in a repetitive loop. It processes instructions sequentially, one at a time, following the program's control flow.

- Branching: Control flow instructions, like conditional branches and loops, can alter the sequence of execution. These instructions allow the microprocessor to make decisions based on conditions and execute different code paths accordingly.

- Input/Output (I/O): Microprocessors can interact with external devices and peripherals through input and output instructions. These instructions enable data transfer between the CPU and devices like sensors, displays, storage devices, and communication interfaces.

- Interrupts: Microprocessors can respond to interrupts, which are signals generated by external devices or events that require immediate attention. When an interrupt occurs, the microprocessor temporarily suspends its current task to handle the interrupt, often by executing a specific subroutine (interrupt service routine).

- Control Unit: The control unit of the microprocessor manages the execution of instructions, coordinating the fetch-decode-execute cycle. It generates control signals to coordinate data movement and processing within the microprocessor.

- Registers: Microprocessors have a set of internal registers that store data temporarily during processing. These registers are used for data manipulation, arithmetic operations, and holding intermediate results.

The microprocessor's ability to execute instructions rapidly and efficiently allows it to perform complex calculations, data processing, and control tasks in a wide range of applications, from general-purpose computers to embedded systems in various devices and equipment.

It's important to note that the specific architecture, instruction set, and capabilities of microprocessors can vary widely among different processor families and manufacturers. However, the fundamental fetch-decode-execute cycle remains a common principle in microprocessor operation.

Fig 5. Pressure sensor features

What is the pressure transmitter microprocessor usage?

Pressure transmitter microprocessors are used in various industrial and commercial applications where accurate pressure measurement, data processing, communication, and control are essential. These microprocessors play a crucial role in enhancing the capabilities and functionality of pressure transmitters. Here are some common usages of pressure transmitter microprocessors:

- Industrial Process Control: Pressure transmitter microprocessors are widely used in industrial processes to monitor and control pressure within systems. They help maintain optimal operating conditions, ensure safety, and improve efficiency in applications such as chemical processing, oil and gas production, and manufacturing.

- HVAC (Heating, Ventilation, and Air Conditioning) Systems: Pressure transmitters with microprocessors are employed in HVAC systems to monitor and control air and fluid pressures. They contribute to maintaining comfortable indoor environments, energy efficiency, and equipment protection.

- Medical Devices: Pressure transmitters with microprocessors are used in medical devices like ventilators, infusion pumps, and dialysis machines to measure and control pressures for patient treatment and monitoring.

- Automotive: In automotive applications, pressure transmitters with microprocessors are used in various systems, including tire pressure monitoring systems (TPMS), engine management, and transmission control.

- Aerospace: Pressure transmitters are used in aircraft and spacecraft for altitude measurement, cabin pressure control, and engine monitoring. Microprocessors ensure precise data processing and communication with flight systems.

- Water and Wastewater Treatment: Pressure transmitters equipped with microprocessors are used in water treatment plants and wastewater facilities to monitor and control pressure levels in pipes, tanks, and filtration systems.

- Oil and Gas Industry: In the oil and gas sector, pressure transmitter microprocessors are employed in well monitoring, pipeline management, and equipment control to ensure safe and efficient operations.

- Environmental Monitoring: Pressure transmitters are used in environmental monitoring equipment to measure air and water pressures, aiding in weather forecasting, flood control, and pollution management.

- Laboratory and Research: Pressure transmitters with microprocessors are used in laboratory instruments to measure and control pressures in scientific experiments and research applications.

- Food and Beverage Industry: These transmitters are used for pressure monitoring and control in food processing and beverage production, ensuring product quality and safety.

- Energy Generation: Pressure transmitters play a role in power generation applications, including monitoring steam, gas, and hydraulic pressures in power plants.

- Petrochemical Industry: Pressure transmitters with microprocessors are used in petrochemical processes to measure and control pressures in various stages of production and refining.

- Renewable Energy: In renewable energy applications, such as wind turbines and solar power plants, pressure transmitters are used for monitoring hydraulic and pneumatic systems.

In these diverse applications, pressure transmitter microprocessors enable precise pressure measurement, data processing, communication with control systems, and, in some cases, advanced features like compensation, diagnostics, and remote configuration. Their versatility and reliability make them an integral part of modern industrial and technological processes.

What are the advantages and disadvantages of pressure transmitter microprocessors?

Pressure transmitter microprocessors, like microcontrollers used in various industrial applications, come with their own set of advantages and disadvantages. These advantages and disadvantages can impact the performance, functionality, and cost-effectiveness of pressure transmitters. Here are some of the key advantages and disadvantages:

Advantages of Pressure Transmitter Microprocessors

Disadvantages of Pressure Transmitter Microprocessors

Three Top Brands that manufacture pressure transmitter microprocessors

Pressure transmitter microprocessors are typically integrated into the design of pressure transmitters by various manufacturers. These microprocessors are not typically branded as separate products; instead, they are components within the pressure transmitter's electronics. However, when it comes to well-known brands that manufacture high-quality pressure transmitters with microprocessor-based technology, several companies are recognized for their expertise in this field. Here are three top brands that are known for manufacturing pressure transmitters:

How is the PCB of a pressure transmitter microprocessor?

The printed circuit board (PCB) of a pressure transmitter that incorporates a microprocessor is a critical component responsible for providing electrical connections, interconnecting various electronic components, and supporting the functionality of the microprocessor and associated circuitry. The design and layout of the PCB are crucial to the performance, reliability, and functionality of the pressure transmitter. Here's an overview of key considerations in the PCB design of a pressure transmitter with a microprocessor:

- Layer Configuration: The number of layers in the PCB depends on the complexity of the pressure transmitter's electronic circuitry. Multilayer PCBs may be used to accommodate a variety of components, signal traces, and ground/power planes. Layers help reduce interference and noise in the circuit.

- Component Placement: The positioning of components, including the microprocessor, pressure sensor, signal conditioning circuitry, memory, and communication interfaces, is essential to minimize signal interference and optimize signal paths. Components should be arranged to reduce noise and ensure proper cooling.

- Signal Traces: The routing of signal traces on the PCB should be carefully designed to minimize electromagnetic interference (EMI) and signal crosstalk. Differential pairs for communication interfaces should be routed together to maintain signal integrity.

- Power Distribution: Proper power distribution, including voltage regulation and decoupling capacitors, ensures a stable power supply for the microprocessor and other components. This is crucial for reliable operation.

- Ground Planes: Ground planes help to minimize noise and provide a stable reference voltage for the circuit. Split ground planes can be used to separate analog and digital ground domains to prevent interference.

- Connector Placement: Connectors for external interfaces, such as communication ports or power supplies, should be strategically placed to facilitate easy integration and maintenance of the pressure transmitter.

- EMI/EMC Considerations: To meet electromagnetic interference (EMI) and electromagnetic compatibility (EMC) requirements, the PCB design should incorporate shielding and filtering techniques to reduce radiated and conducted emissions.

- Temperature Considerations: Pressure transmitters often operate in challenging temperature environments. The PCB should be designed to handle temperature variations while ensuring the stability of components and solder joints.

- Reliability: Ensuring the reliability of the PCB design involves selecting high-quality materials, designing for manufacturability, and incorporating features like conformal coating to protect against moisture and contaminants.

- Safety Standards: Depending on the application, the PCB design may need to comply with safety standards and certifications relevant to the industry, such as ATEX or IECEx for hazardous locations.

- Trace Width and Spacing: The width and spacing of traces on the PCB should be appropriately chosen to handle the required current and voltage levels without causing overheating or voltage drop.

- Testing Provisions: The PCB design should include test points and access points for diagnostic purposes, allowing technicians to perform testing and troubleshooting efficiently.

- Size and Form Factor: The size and form factor of the PCB should be compatible with the pressure transmitter's enclosure and mounting requirements.

PCB design for a pressure transmitter with a microprocessor is a specialized task that requires expertise in electronic design, layout software, and an understanding of the specific requirements of the application and industry standards. Careful consideration of these factors ensures that the pressure transmitter functions reliably and accurately in its intended environment.

Fig 6. Pressure sensor PCB

How is the internal wiring of the pressure transmitter microprocessor?

The internal wiring of a pressure transmitter with a microprocessor involves the interconnection of various electronic components, including the microprocessor itself, sensors, signal conditioning circuitry, communication interfaces, power supply components, and more. The specific wiring layout and connections can vary depending on the design and complexity of the pressure transmitter, as well as the requirements of the application and industry standards. However, I can provide a general overview of the key components and their interconnections within a pressure transmitter:

- Microprocessor: The microprocessor is typically the central component of the pressure transmitter's electronics. It interfaces with other components and manages data processing, communication, and control tasks.

- Pressure Sensor: The pressure sensor is responsible for detecting pressure changes in the environment. It generates analog signals (e.g., voltage or current) proportional to the pressure being measured. These signals are typically routed to the signal conditioning circuitry.

- Signal Conditioning Circuitry: This circuitry includes amplifiers, filters, and analog-to-digital converters (ADCs) that prepare the analog signals from the pressure sensor for digital processing by the microprocessor. The conditioned signals are then passed to the microprocessor.

- Memory Components: The microprocessor may interface with memory components, such as RAM (Random Access Memory) for temporary data storage and ROM (Read-Only Memory) for storing firmware, program instructions, and calibration data.

- Communication Interfaces: Pressure transmitters often have digital communication interfaces (e.g., UART, SPI, I2C) that allow the microprocessor to communicate with external devices, control systems, or remote monitoring systems. These interfaces may require additional wiring for data transmission.

- Power Supply Components: The power supply components, including voltage regulators, capacitors, and voltage references, ensure a stable and reliable power source for the microprocessor and other components.

- Control Logic: The microprocessor uses control logic to manage the operation of various components, including data acquisition, signal processing, communication, and control algorithms.

- Protection and Safety Circuits: Some pressure transmitters include protection and safety features, such as overvoltage protection or fault detection circuits. These circuits may have wiring connections to the microprocessor for monitoring and response.

- Grounding and Shielding: Proper grounding and shielding techniques are employed to minimize electromagnetic interference (EMI) and ensure signal integrity. Ground connections are essential for reference potentials and noise reduction.

- Connectors: Connectors are used to interface the pressure transmitter with external devices, communication ports, and power supplies. Wiring connections from these connectors are routed to the appropriate components on the PCB.

- Diagnostic and Test Points: The PCB may include diagnostic and test points to facilitate testing, calibration, and troubleshooting during manufacturing and maintenance.

- Temperature Sensors (Optional): Some pressure transmitters include temperature sensors to measure ambient or process temperature. These sensors may have wiring connections to the microprocessor for data acquisition and compensation.

- User Interface (Optional): Pressure transmitters with user interfaces, such as displays and buttons, require wiring connections to the microprocessor to enable user interaction and configuration.

The internal wiring must be carefully designed to minimize electromagnetic interference, ensure signal integrity, and meet industry standards and safety regulations. Additionally, the wiring layout and connections should consider factors like temperature stability, reliability, and ease of manufacturing and maintenance. The complexity of the wiring and the specific connections will depend on the design and functionality of the pressure transmitter.

What is a pressure sensor chip?

A pressure sensor chip, also known as a pressure sensor die or pressure sensor element, is a critical component used to measure pressure in various applications. It is a microelectromechanical system (MEMS) device designed to detect and convert pressure changes into an electrical signal, typically a voltage or current. Pressure sensor chips are widely used in a range of industries, including automotive, industrial automation, aerospace, medical devices, and consumer electronics. Here's an overview of how a pressure sensor chip works and its key characteristics:

Working Principle: Pressure sensor chips operate on the principle of piezoresistivity or capacitive sensing, depending on the specific design. Here's how each principle works:

- Piezoresistive Pressure Sensor Chip: In a piezoresistive sensor chip, a thin diaphragm or membrane is exposed to the pressure being measured. As pressure changes, the diaphragm flexes, causing a change in resistance in one or more piezoresistive elements embedded in the diaphragm. This change in resistance is proportional to the applied pressure and is converted into an electrical signal.

- Capacitive Pressure Sensor Chip: In a capacitive sensor chip, a diaphragm with a fixed electrode and a movable electrode (capacitor plates) is subjected to pressure. The distance between the electrodes changes with pressure variations, altering the capacitance of the sensor. This change in capacitance is then translated into an electrical signal.

Key Characteristics and Features: Pressure sensor chips have several important characteristics and features, including

- Sensitivity: The sensitivity of a pressure sensor chip refers to how much the electrical output changes in response to a given change in pressure. It is typically specified in units such as millivolts per volt per unit pressure (mV/V/psi).

- Pressure Range: Pressure sensor chips are available in various pressure ranges, from very low pressures (e.g., a few millibars) to very high pressures (e.g., thousands of psi or more). The range is determined by the design and materials used in the sensor chip.

- Accuracy: The accuracy of a pressure sensor chip indicates how closely its output matches the true pressure value. Accuracy can be expressed as a percentage of the full-scale range (FSR) or as an absolute error in pressure units (e.g., psi or Pa).

- Resolution: Resolution refers to the smallest change in pressure that the sensor can detect and accurately measure. It is often expressed in pressure units (e.g., mbar or kPa) and depends on the sensor's design and signal conditioning.

- Temperature Sensitivity: Pressure sensors can be sensitive to temperature variations. Manufacturers often provide temperature compensation techniques to minimize the effect of temperature changes on pressure measurements.

- Response Time: The response time of a pressure sensor chip indicates how quickly it can react to changes in pressure. It is important in dynamic pressure measurement applications.

- Hysteresis and Nonlinearity: These parameters describe how well the sensor chip maintains accuracy when pressure values change in both increasing and decreasing directions.

Pressure sensor chips are used in a wide range of applications, including tire pressure monitoring systems (TPMS), medical devices (e.g., blood pressure monitors), industrial process control, environmental monitoring, and more. Their small size, low power consumption, and high sensitivity make them versatile tools for measuring and monitoring pressure in various settings.

What is the role of dies in pressure sensors?

In the context of pressure sensors, "dies" refer to the individual components or elements that make up the core sensing mechanism of the sensor. These dies are typically tiny, highly specialized pieces of microelectromechanical systems (MEMS) technology, and they play a crucial role in the operation of pressure sensors. Here's a closer look at the role of dies in pressure sensors:

- Sensing Element: The primary function of a die in a pressure sensor is to serve as the sensing element. The die is designed to detect and respond to changes in pressure. It does so by undergoing mechanical deformation when subjected to pressure variations. This deformation is typically in the form of bending or flexing, and it is directly proportional to the applied pressure.

- Transduction: Once the sensing element (die) undergoes deformation due to pressure changes, it converts this mechanical change into an electrical signal. There are various transduction mechanisms used in pressure sensor dies, such as piezoresistive or capacitive transduction. For example, in a piezoresistive die, changes in pressure cause a change in the resistance of embedded piezoresistors, while in a capacitive die, pressure-induced deformation alters the capacitance between electrodes.

- Signal Generation: The electrical signal generated by the die is typically very small and may be in the form of a voltage, current, or capacitance change. This signal is directly proportional to the applied pressure and serves as the primary output of the pressure sensor.

- Amplification and Conditioning: In most pressure sensors, the raw signal generated by the die is weak and requires amplification and conditioning to produce a usable output. External electronics or signal conditioning circuitry may be used to process the signal, making it suitable for measurement and interpretation.

- Accuracy and Linearity: The design and characteristics of the die directly influence the accuracy and linearity of the pressure sensor. The die must provide consistent and linear responses to pressure changes within the specified pressure range.

- Temperature Compensation: Some pressure sensor dies are equipped with temperature compensation mechanisms to account for the influence of temperature on pressure measurements. Temperature compensation helps maintain measurement accuracy across a wide temperature range.

- Packaging: The die is typically packaged within a protective housing that shields it from environmental factors, such as dust, moisture, and mechanical stress. The housing may also include pressure ports to allow external pressure to act on the sensing element.

- Range and Sensitivity: Different pressure sensor dies are designed for specific pressure ranges and sensitivities. The choice of die depends on the intended application and the pressure range it needs to measure accurately.

Pressure sensor dies are at the heart of pressure sensor technology, and their proper design, construction, and calibration are critical for accurate and reliable pressure measurements. The specific type of die used can vary based on the sensor's design, intended application, and required performance characteristics.

How are a pressure sensor's Data processing capabilities?

The data processing capabilities of a pressure sensor primarily depend on the sensor's design and the presence of integrated electronics. Pressure sensors can be categorized into two main types based on their data processing capabilities:

- Analog Pressure Sensors: Analog pressure sensors do not have built-in data processing capabilities. They directly convert pressure changes into analog electrical signals (e.g., voltage or current) that are proportional to the applied pressure. These analog signals require external signal conditioning and data processing to convert them into usable pressure measurements. Analog pressure sensors are simple and cost-effective but may lack advanced processing features.

- Digital Pressure Sensors: Digital pressure sensors are equipped with integrated electronics, including microcontrollers or microprocessors, which enable data processing and digital communication. Here's how digital pressure sensors typically handle data:

- Signal Conditioning: Digital pressure sensors often include signal conditioning circuitry to preprocess the raw sensor data. This can involve amplification, filtering, and temperature compensation to improve measurement accuracy.

- Analog-to-Digital Conversion (ADC): The conditioned analog signal from the pressure sensor is digitized using an ADC. This conversion transforms the analog signal into a digital format that can be processed by the sensor's microcontroller or processor.

- Data Processing: The microcontroller or processor inside the digital pressure sensor performs various data processing tasks. This may include linearization (correcting nonlinearity in the sensor's response), temperature compensation, and error correction. Some digital sensors can also apply calibration coefficients to enhance measurement accuracy.

- Communication: Digital pressure sensors often have built-in communication interfaces, such as I2C, SPI, UART, or others. These interfaces allow the sensor to communicate directly with external devices, microcontrollers, or host systems.

- Data Output: The processed and digitized pressure data can be accessed through the sensor's communication interface in a digital format. This data is typically easier to work with and may be ready for direct integration into control systems or data acquisition systems.

- Diagnostic Features: Many digital pressure sensors offer diagnostic capabilities, such as detecting sensor faults, out-of-range conditions, or communication errors. These diagnostics can be useful for system health monitoring and troubleshooting.

- User Configuration: Some digital sensors allow users to configure measurement parameters and set thresholds or alarm conditions through the communication interface, enabling flexibility and customization.

Digital pressure sensors with integrated data processing capabilities offer advantages in terms of accuracy, ease of integration, and flexibility in various applications, including industrial automation, automotive systems, and medical devices. The specific data processing features and capabilities can vary among different digital sensor models and manufacturers, so it's essential to consult the sensor's datasheet and documentation to understand its functionality and how to interface with it effectively.

What are the advanced features of microprocessors and die in pressure transmitters?

Advanced features in pressure transmitters, which involve both the microprocessor and the pressure sensor (die), are designed to enhance the accuracy, reliability, functionality, and versatility of these devices. Here are some advanced features often found in modern pressure transmitters:

Advanced Features of the Microprocessor:

Advanced Features of the Pressure Sensor (Die):

What is the role of DSP in pressure sensors?

Digital Signal Processing (DSP) plays a significant role in enhancing the performance and functionality of pressure sensors, especially in modern digital pressure sensor designs. Here are the key roles of DSP in pressure sensors:

- Data Conditioning: DSP is used to condition the raw sensor data received from the pressure sensor. This conditioning may involve amplification, filtering, and noise reduction to improve the quality of the measured signal. DSP algorithms can effectively process the analog signal generated by the sensor die.

- Digital Conversion: In many pressure sensors, the analog output from the pressure sensor die is converted into digital form using an Analog-to-Digital Converter (ADC). DSP can handle this conversion, providing a digital representation of the pressure signal that is more easily processed and transmitted.

- Linearization: Pressure sensors often exhibit nonlinear behavior over their measurement range. DSP can apply linearization algorithms to correct for this nonlinearity, ensuring that the pressure measurements are accurate and proportional to the applied pressure.

- Temperature Compensation: Temperature changes can affect the accuracy of pressure measurements. DSP can incorporate temperature compensation algorithms to adjust the pressure readings based on temperature data, enhancing measurement accuracy over a wide temperature range.

- Error Correction: DSP can perform error correction to account for any systematic errors or offsets in the sensor's output. This ensures that the pressure sensor provides precise and consistent measurements.

- Filtering and Noise Reduction: DSP algorithms can implement digital filters to remove unwanted noise and interference from the pressure signal. This is particularly important in noisy industrial environments.

- Calibration: DSP can handle calibration processes, allowing the pressure sensor to be precisely calibrated during manufacturing or in the field. Calibration coefficients can be stored in memory and applied to pressure measurements to improve accuracy.

- Communication: DSP enables digital communication with external devices, control systems, and microcontrollers. It can format pressure data for transmission via communication protocols like I2C, SPI, UART, or others, making it easier to integrate the sensor into a larger system.

- Advanced Features: DSP can support advanced features such as digital self-diagnostics, data logging, and predictive maintenance. These features enhance the reliability and functionality of the pressure sensor.

- Response Time Control: DSP can be used to control the response time of the pressure sensor, ensuring that it reacts appropriately to changes in pressure, especially in dynamic applications.

- User Configuration: Some pressure sensors with DSP capabilities allow users to configure measurement parameters, thresholds, and alarms through digital interfaces, offering flexibility and customization.

In summary, DSP in pressure sensors plays a crucial role in converting, conditioning, and enhancing the accuracy of pressure measurements. It enables various data processing tasks, including linearization, temperature compensation, noise reduction, and error correction, resulting in more reliable and accurate pressure sensor readings. Additionally, DSP facilitates digital communication, calibration, and the implementation of advanced features that meet the demands of various applications and industries.

What are the advantages and disadvantages of using DSP in pressure transmitters?

Using Digital Signal Processing (DSP) in pressure transmitters offers several advantages and some potential disadvantages. Here's a breakdown of both:

Advantages of Using DSP in Pressure Transmitters:

Disadvantages and Challenges of Using DSP in Pressure Transmitters:

What is wire bonding in pressure transmitters?

Wire bonding is a crucial semiconductor packaging technique used in the manufacturing of pressure transmitters and other electronic devices. It involves the attachment of tiny wires (typically made of gold or aluminum) to connect semiconductor devices, such as integrated circuits (ICs) or microchips, to the conductive pads or leads on a semiconductor package or printed circuit board (PCB). Wire bonding serves several essential functions in pressure transmitters and other electronic applications:

- Electrical Connection: Wire bonding provides the electrical pathways that connect semiconductor devices to other components within the pressure transmitter's electronic circuitry. This allows for the transmission of electrical signals between different parts of the device.

- Signal Transmission: Wire bonds enable the transmission of electrical signals, including pressure sensor signals, to and from the microprocessor or other electronic components within the pressure transmitter. This is essential for data processing and communication.

- Power Supply: Wire bonding is used to connect the semiconductor devices to the power supply lines, ensuring they receive the necessary electrical power to operate.

- Miniaturization: Pressure transmitters often require compact and space-efficient designs, and wire bonding contributes to miniaturization by allowing precise connections within a small footprint.

- Reliability: Properly executed wire bonding provides a reliable and durable connection between semiconductor devices and the package or PCB. This reliability is crucial for the long-term performance of the pressure transmitter.

Wire bonding can be performed using different techniques, including

- Ball Bonding: In ball bonding, a tiny ball of wire is melted onto a bonding pad on the semiconductor device and then connected to another pad on the package or PCB. This method is commonly used for the first bond (the wire's initial attachment).

- Wedge Bonding: Wedge bonding involves using a wedge-shaped tool to bond the wire directly to the bonding pads on the semiconductor device and the package or PCB. This method is typically used for the second bond (the wire's final attachment).

Wire bonding is a precise and delicate process that requires specialized equipment and skilled technicians. The choice between ball bonding and wedge bonding depends on the specific requirements of the semiconductor package and the application. It's important to note that wire bonding is just one step in the overall manufacturing process of pressure transmitters, which involves many other components and processes to create a functional and reliable device for pressure measurement and control.

Conclusion

In conclusion, pressure transmitters are vital instruments used in a wide range of industrial, commercial, and scientific applications to measure and transmit pressure data. They consist of various components, including a pressure sensor or die, signal conditioning circuitry, a microprocessor or microcontroller, and communication interfaces. These components work together to accurately convert physical pressure changes into electrical signals, process the signals, and communicate pressure measurements to external systems.

Pressure transmitters can be equipped with advanced features such as digital signal processing (DSP), temperature compensation, calibration, and self-diagnostics, enhancing their accuracy, reliability, and functionality. The choice of pressure transmitter depends on the specific application requirements and industry standards.

Wire bonding is a critical semiconductor packaging technique used in pressure transmitter manufacturing to connect semiconductor devices and ensure electrical connectivity. It plays a crucial role in miniaturization and reliability.

The integration of microprocessors, DSP, and advanced features in pressure transmitters offers numerous advantages, including improved accuracy, noise filtering, and flexibility. However, it also introduces challenges such as complexity, cost, and power consumption.

Overall, pressure transmitters are essential tools in industries such as industrial automation, automotive, aerospace, and healthcare, where precise and reliable pressure measurements are crucial for process control, safety, and quality assurance. Understanding the components and technologies within pressure transmitters is essential for selecting and utilizing these instruments effectively in various applications.

To recap

1. What is a pressure transmitter?

A pressure transmitter is a sensing device used to measure and transmit pressure data in various industrial, commercial, and scientific applications.

2. How does a pressure transmitter work?

Pressure transmitters typically use a pressure sensor to detect pressure changes. The sensor converts these changes into electrical signals, which are then processed and transmitted by the transmitter's electronics.

3. What are the common types of pressure sensors used in transmitters?

Common types of pressure sensors include piezoresistive, capacitive, and piezoelectric sensors. Each type operates based on different principles.

4. What is the role of a microprocessor in a pressure transmitter?

A microprocessor in a pressure transmitter manages data processing, calibration, communication, and control functions, enhancing the transmitter's accuracy and versatility.

5. What are the advantages of using DSP in pressure transmitters?

Digital Signal Processing (DSP) in pressure transmitters improves accuracy, noise filtering, and temperature compensation, and enables advanced features like data logging and self-diagnostics.

6. What is wire bonding in pressure transmitters?

Wire bonding is a semiconductor packaging technique used to connect semiconductor devices and establish electrical connections in pressure transmitter manufacturing.

7. What are the key electronics in a pressure transmitter?

Key electronics in a pressure transmitter include the pressure sensor, signal conditioning circuitry, microprocessor, memory, communication interfaces, power supply components, and more.

8. How are pressure transmitters used in industrial applications?

Pressure transmitters are used in industrial applications for tasks like process control, monitoring, and safety in industries such as manufacturing, oil and gas, and chemical processing.

9. What are some advanced features of pressure transmitters?

Advanced features in pressure transmitters include self-diagnostics, data logging, predictive maintenance, remote configuration, and digital communication capabilities.

10. What are the advantages and disadvantages of using DSP in pressure transmitters?

Advantages of DSP in pressure transmitters include enhanced accuracy and noise filtering. Disadvantages include increased complexity and power consumption.

References

https://www.researchgate.net/figure/Signal-conditioning-Circuit-for-Pressure-sensor_fig2_286056823

https://en.wikipedia.org/wiki/ARM_Cortex-M

https://i.ebayimg.com/images/g/UiUAAOSwlTheDMsb/s-l1200.jpg

https://www.variohm.com/images/content/slides/363_700x400.jpg?17:12:00&_e=.jpg

Recent Posts

-

From Lab to Launchpad: Pressure Sensor Industry Certifications

In the intricate world of technology and precision engineering, where every measurement matters a …16th Mar 2024 -

Stand Out, Stand Certified: The Art of Pressure Sensor Safety

Stand Out, Stand Certified: The Art of Pressure Sensor Safety Welcome to the world of performance …9th Mar 2024 -

Robotics in Food and beverage Industry

Our lives depend on the food and beverage industry and it is in a constant state of evolution, …5th Mar 2024