The Hidden Power of ΔP: Unraveling Differential Pressure's Mysteries!

Welcome to the world of differential pressure! If you've ever wondered how engineers and scientists measure fluid flow rates, monitor pressure differences, or ensure the safety of critical systems, then you've come to the right place.

Differential pressure is a fascinating and essential concept in engineering and industrial applications. It's the key to unlocking the possibilities realm, allowing us to optimize processes, maintain system performance, and ensure efficient operation.

In this exploration, we'll dive into the heart of differential pressure, demystify its principles, and unveil its numerous real-world applications. From flow measurement in pipelines to HVAC systems and safety control, understanding differential pressure opens doors to a world of precise engineering and scientific achievements.

So, whether you're a curious learner, a seasoned professional, or simply seeking to grasp the beauty of fluid dynamics, let's embark on this captivating journey through the world of differential pressure. Get ready to uncover its secrets, applications, and the amazing tools that make it all possible. Let's embrace the power of ΔP and witness how it shapes our modern world!

What is called a "differential pressure"?

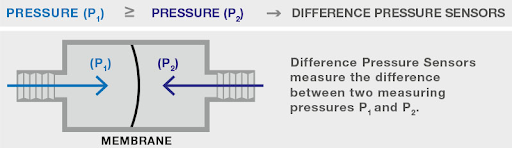

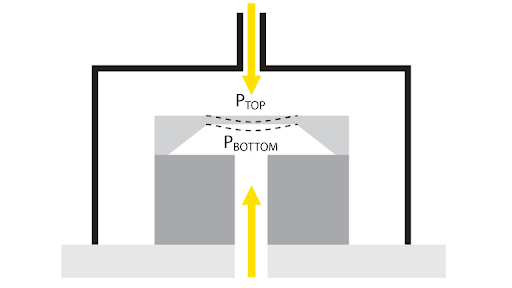

Differential pressure refers to the difference in pressure between two points in a fluid system or across a component or device. It is the contrast between the pressure at one location and the pressure at another location within the same system. This pressure difference is often measured and monitored in various industrial, engineering, and scientific applications to understand flow rates, detect obstructions or blockages, control processes, and ensure the efficient operation of equipment. Differential pressure is commonly denoted as ΔP (delta P), where Δ represents "change" and P represents "pressure."

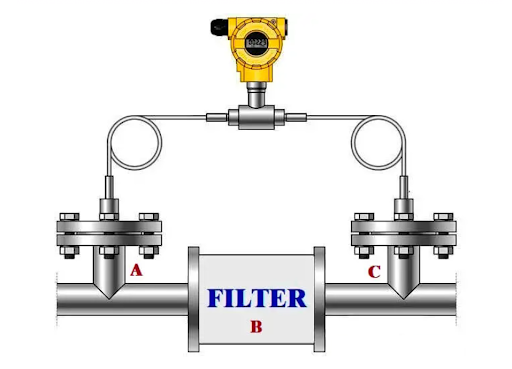

Fig 1. Differential pressure

Browse our wide selection of Pressure Sensor to find the perfect one for your application.

What causes differential pressure?

Differential pressure, a crucial concept in fluid systems, reflects the difference in pressure between two points within a fluid system or across a component or device. This pressure difference can be caused by several factors, including:

- Flow Resistance: When fluid flows through pipes, ducts, or other flow paths, frictional forces between the fluid and the surface of the flow path create resistance. This resistance causes pressure drops along the flow path, resulting in differential pressure between different points in the system.

- Obstructions or Blockages: Any obstructions or blockages in the fluid system, such as filters, valves, or bends in the piping, can cause localized pressure differences. These obstructions create pressure drops and affect the fluid flow, leading to differential pressure.

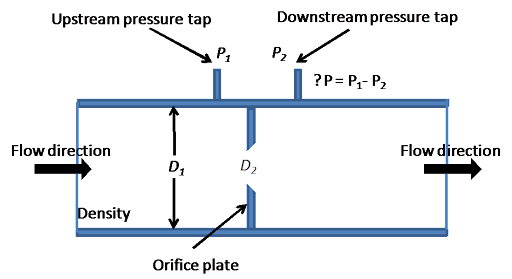

- Fluid Velocity Changes: Changes in fluid velocity within the system can also lead to differential pressure. For example, when fluid accelerates through a narrowing section (e.g., venturi meter or orifice plate), it experiences a pressure drop due to the conservation of energy (Bernoulli's principle). Differential pressure is often used in flow rate monitoring applications. Devices like orifice plates, venturi meters, and pitot tubes create differential pressure based on fluid flow rates, allowing for flow measurement.

- Fluid Density Variations: Variations in fluid density, which can occur due to temperature changes or different fluid compositions, can lead to differential pressure in certain applications.

- Pressure Control and Regulation: In some cases, differential pressure is intentionally created and controlled to achieve specific objectives. For example, a differential pressure regulator may be used to maintain a constant pressure difference across a component or system.

- Leak Detection: In closed systems, a sudden decrease in differential pressure can indicate a leak, prompting necessary actions for maintenance and safety.

In various industrial processes, controlling the differential pressure across components (e.g., pumps, filters, heat exchangers) helps optimize system performance and energy efficiency. Understanding and monitoring differential pressure is essential for many engineering, industrial, and scientific applications. It allows for efficient fluid flow control, detection of system issues, and optimization of processes to ensure smooth and safe operation.

Fig 2. Differential pressure

How is differential pressure measured?

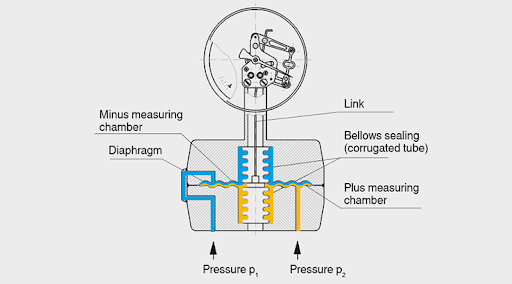

Differential pressure is measured using various instruments and devices, depending on the specific application and the range of pressure being measured. Here are some common methods for measuring differential pressure:

- Manometer: A manometer is a simple and traditional device used to measure differential pressure. It typically consists of a U-shaped tube partially filled with a liquid, such as mercury or colored water. When pressure is applied to one side of the tube, the liquid level in the U-tube changes, providing a visual indication of the pressure difference.

- Digital Pressure Gauge: A digital pressure gauge equipped with two pressure sensors can measure the pressure at two different points and calculate the differential pressure. Modern digital pressure gauges offer accuracy and digital readouts for easy interpretation.

- Differential Pressure Transmitter: A differential pressure transmitter, also known as a differential pressure sensor, is a transducer that directly measures the pressure difference between two points and converts it into an electrical signal suitable for control systems and remote monitoring. These sensors can be based on different technologies, such as strain gauges, capacitive elements, or piezoelectric crystals.

It's important to choose the appropriate method and device based on the specific requirements of the application, the nature of the fluid, and the desired accuracy of the measurement. Calibration and proper installation are essential to ensure accurate and reliable differential pressure measurements.

What are the two ways of measuring differential pressure?

The two primary ways of measuring differential pressure are as follows:

Direct Measurement

In this method, a device called a differential pressure sensor or transducer is directly installed in the fluid system to measure the pressure difference between two points. These sensors can use various technologies such as strain gauges, capacitive elements, or piezoelectric crystals to convert the mechanical force resulting from differential pressure into an electrical signal. The output signal can be in the form of voltage, current, or digital communication protocols (e.g., 4-20mA, HART, Modbus). Direct measurement provides real-time and continuous monitoring of the pressure difference and is commonly used in various industrial and automation applications.

Indirect Measurement

Indirect measurement of differential pressure involves using primary flow measurement devices (such as orifice plates, venturi meters, or flow nozzles) that create a pressure drop when inserted into a fluid flow. The pressure difference across these flow elements is related to the fluid flow rate using established equations. By measuring the differential pressure across the flow element, the flow rate can be calculated indirectly. This method is commonly used in flow measurement applications, especially when the primary objective is to determine flow rates rather than the exact pressure difference.

Both direct and indirect methods of measuring differential pressure have their advantages and are suitable for different applications. The choice between these methods depends on factors such as the accuracy required, the complexity of the system, and the specific purpose of the measurement.

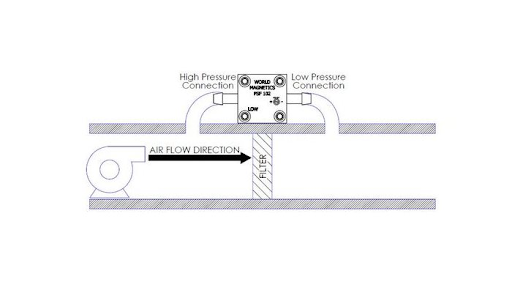

Fig 3. The control panel of the differential pressure sensor

What are the differential pressure formulas?

The differential pressure formulas vary depending on the application and the specific device or flow element used to measure the pressure difference. Here are some commonly used formulas for calculating differential pressure in different scenarios:

- Orifice Plate Differential Pressure Formula:

For an orifice plate used to measure fluid flow, the differential pressure (ΔP) is related to the flow rate (Q) through the following formula:

ΔP = (C * ρ * A * V2) / 2

Where: ΔP = Differential Pressure,

C = Orifice discharge coefficient (dimensionless, depends on the orifice design),

ρ = Fluid density (kg/m³),

A = Cross-sectional area of the orifice (m²), and

V = Fluid velocity at the orifice (m/s).

- Venturi Meter Differential Pressure Formula:

For a venturi meter used to measure fluid flow, the differential pressure (ΔP) is related to the flow rate (Q) through the following formula:

ΔP = (C * ρ * A * (V2 - V22)) / 2

Where: ΔP = Differential Pressure,

C = Venturi discharge coefficient (dimensionless, depends on the venturi design),

ρ = Fluid density (kg/m³),

A = Cross-sectional area of the venturi throat (m²),

V = Fluid velocity before the venturi throat (m/s), and

V 2 = Fluid velocity at the venturi throat (m/s).

- Pitot Tube Differential Pressure Formula:

For a pitot tube used to measure fluid velocity, the differential pressure (ΔP) is related to the fluid velocity (V) through the following formula:

ΔP = 0.5 * ρ * V2

Where: ΔP = Differential Pressure,

ρ = Fluid density (kg/m³), and

V = Fluid velocity (m/s).

- Differential Pressure in a Pipe or Duct:

In a pipe or duct with a fluid flowing, the differential pressure (ΔP) between two points can be directly measured using pressure sensors or gauges. The formula for calculating ΔP is

ΔP = Phigh - Plow

Where: ΔP = Differential Pressure,

P high = Pressure at the higher point, and

P low = Pressure at the lower point.

It's important to note that the discharge coefficients (C) and other factors in the formulas may vary depending on the specific design of the measuring device or flow element. Additionally, some applications may require accounting for additional factors like temperature, altitude, or viscosity for more accurate differential pressure calculations.

Examples of using these formulas

Sure, let's see some examples of using the differential pressure formulas in different scenarios:

Example 1: Orifice Plate Flow Measurement Suppose you have an orifice plate installed in a water pipe, and you want to calculate the flow rate based on the measured differential pressure and other known parameters. The orifice plate has a diameter of 100 mm, and the measured differential pressure is 500 Pa. The water density is 1000 kg/m³, and the orifice discharge coefficient (C) is 0.6.

Using the orifice plate differential pressure formula: ΔP = (C * ρ * A * V2) / 2

We can rearrange the formula to solve for the fluid velocity (V): V = √((2 * ΔP) / (C * ρ * A))

Now, let's plug in the values:

A = π * (diameter/2) 2 = π * (0.1 m / 2)2 ≈ 0.00785 m²

V = √((2 * 500 Pa) / (0.6 * 1000 kg/m³ * 0.00785 m²)) ≈ 8.91 m/s

So, the water flow velocity is approximately 8.91 m/s.

Example 2: Venturi Meter Flow Measurement In this example, let's consider a venturi meter installed in a gas pipeline. The venturi meter's throat diameter is 50 mm, and the differential pressure measured across the venturi is 2000 Pa. The gas density is 1.2 kg/m³, and the venturi discharge coefficient (C) is 0.98.

Using the venturi meter differential pressure formula: ΔP = (C * ρ * A * (V2 - V22)) / 2

Since the venturi meter's throat area (A) can be calculated similarly to the orifice plate example, we can rearrange the formula to find the gas velocity (V) before the venturi throat: V = √((2 * ΔP) / (C * ρ * A)) + V2

Now, let's calculate the throat area:

A = π * (diameter/2) 2 = π * (0.05 m / 2)2 ≈ 0.0019635 m²

Then, find the gas velocity before the venturi throat (V): V = √((2 * 2000 Pa) / (0.98 * 1.2 kg/m³ * 0.0019635 m²)) + V2

Assuming the velocity at the venturi throat (V2) is negligible, we can simplify the equation:

V ≈ √(2679.78) ≈ 51.77 m/s

Therefore, the gas flow velocity before the venturi throat is approximately 51.77 m/s.

These are just two examples of how the differential pressure formulas can be used in flow measurement applications using orifice plates and venturi meters. The formulas can also be applied in other scenarios like pitot tube velocity measurements or general pressure difference calculations across different points in a fluid system.

Formulas table

Here's a table summarizing the differential pressure formulas for various applications and devices:

| Application/Device | Formula |

| Orifice Plate Flow Measurement | ΔP = (C * ρ * A * V 2) / 2 |

| Venturi Meter Flow Measurement | ΔP = (C * ρ * A * (V 2 - V22)) / 2 |

| Pitot Tube Velocity Measurement | ΔP = 0.5 * ρ * V 2 |

| Differential Pressure in a Pipe/Duct | ΔP = P high - Plow |

Where: ΔP = Differential Pressure C = Discharge Coefficient (for orifice plate and venturi meter) ρ = Fluid Density (kg/m³) A = Cross-sectional Area of the device or flow element (m²) V = Fluid Velocity (m/s) V2 = Fluid Velocity at the throat of the venturi meter (m/s) - assumed negligible in some cases P_high = Pressure at the higher point in the pipe or duct P_low = Pressure at the lower point in the pipe or duct

These formulas are fundamental for measuring differential pressure in various engineering and industrial applications, and they provide valuable insights into flow rates, fluid velocities, and pressure differences within fluid systems.

What are the units of measurement for differential pressure?

Differential pressure is typically expressed in various units depending on the application and industry conventions. Some of the common units of measurement for differential pressure are:

- Pascals (Pa): The SI unit of pressure. 1 Pascal is equal to the force of 1 Newton per square meter.

- Pounds per square inch (psi): A commonly used unit in engineering and industrial applications. 1 psi is approximately equal to 6894.76 Pa.

- Inches of water column (inH2O): Commonly used in HVAC systems and low-pressure applications. 1 inH2O is approximately equal to 248.84 Pa.

- Millimeters of mercury (mmHg): Often used in medical and meteorological applications. 1 mmHg is approximately equal to 133.322 Pa.

- Bars (bar): A unit of pressure often used in Europe and the metric system. 1 bar is equal to 100,000 Pa or 0.1 MPa.

In industrial settings, differential pressure instruments and gauges are typically calibrated to display readings in one of these units. It's essential to ensure consistency in the units used to prevent confusion and errors in measurements and data analysis. Conversion factors can be used to convert between different units of differential pressure if needed.

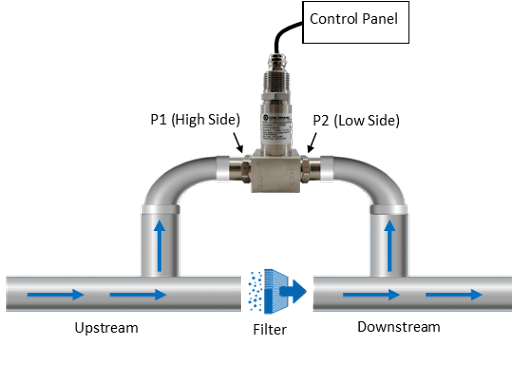

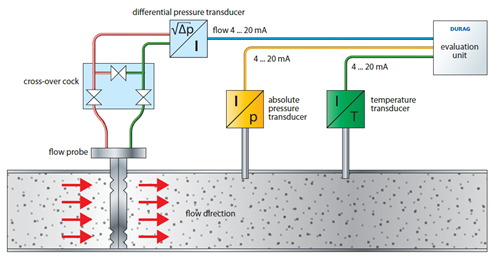

Fig 4. Differential pressure system

Differential pressure types

Differential pressure can be classified into different types based on its characteristics and applications. Some common types of differential pressure measurements include

- Positive Differential Pressure: This is the most common type of differential pressure, where the pressure at one point is higher than the pressure at another point in a fluid system. Positive differential pressure is often used in flow measurements, pressure control, and various industrial applications.

- Negative Differential Pressure: In this type, the pressure at one point is lower than the pressure at another point. Negative differential pressure can occur in flow reversal situations, vacuum systems, and instances where pressure imbalances lead to lower pressures at specific locations.

- Zero Differential Pressure: Zero differential pressure means that there is no pressure difference between the two points being measured. This can occur when there is no fluid flow or when the system is in a static state.

- Dynamic Differential Pressure: Dynamic differential pressure refers to pressure fluctuations caused by varying flow rates or dynamic changes in a fluid system. It is commonly encountered in flow measurement applications and systems with fluctuating fluid velocities.

- Static Differential Pressure: Static differential pressure refers to the pressure difference between two points in a fluid system when the fluid is not in motion (i.e., at rest or in a static state). This type of differential pressure is relevant in situations where flow is not a factor, such as in pressure control systems or closed vessels.

- Gauge Differential Pressure: Gauge differential pressure refers to the pressure difference measured relative to atmospheric pressure. It indicates the pressure above or below the atmospheric pressure at the reference point. Positive gauge differential pressure means the pressure is above atmospheric, while negative gauge differential pressure means the pressure is below atmospheric.

- Absolute Differential Pressure: Absolute differential pressure is measured relative to a perfect vacuum as the reference point. It provides the absolute pressure difference without considering atmospheric pressure. Absolute differential pressure readings are commonly used in vacuum systems and critical pressure applications.

These types of differential pressure measurements help engineers and operators understand the behavior of fluid systems and make informed decisions regarding flow, pressure control, and safety in various industrial processes and applications.

Positive Differential Pressure

- Usage: Positive differential pressure occurs when the pressure at one point is higher than the pressure at another point in a fluid system. It is the most common type of differential pressure and is often the desired condition for flow measurement and pressure control applications.

- Applications: Positive differential pressure is used in flow measurement devices like orifice plates, venturi meters, and flow nozzles. It is also crucial in pressure control systems to regulate pressure levels in various industrial processes.

- Measurement Range: The measurement range for positive differential pressure can vary widely based on the specific application, ranging from a few pascals to several thousand pascals or even higher.

Negative Differential Pressure

- Usage: Negative differential pressure occurs when the pressure at one point is lower than the pressure at another point. It can be encountered in situations where flow reversal occurs or in vacuum systems.

- Applications: Negative differential pressure is relevant in certain processes where pressure imbalances lead to lower pressures at specific locations. In vacuum systems, it is used to measure pressure differences in low-pressure environments.

- Measurement Range: The measurement range for negative differential pressure depends on the specific application, but it typically covers a range similar to positive differential pressure.

Zero Differential Pressure

- Usage: Zero differential pressure means there is no pressure difference between two points. It can occur when there is no fluid flow or when the system is in a static state.

- Applications: Zero differential pressure is useful for confirming that a fluid system is at rest or not experiencing any flow. It can also be used as a reference point for other pressure measurements.

- Measurement Range: Zero differential pressure is a specific point, and its measurement range is limited to a value of exactly zero.

Dynamic Differential Pressure

- Usage: Dynamic differential pressure refers to pressure fluctuations caused by varying flow rates or dynamic changes in a fluid system.

- Applications: Dynamic differential pressure is commonly encountered in flow measurement applications, where fluid velocities change over time. It is also relevant in systems with rapidly changing process conditions.

- Measurement Range: The measurement range for dynamic differential pressure can vary widely, depending on the specific application and flow dynamics.

Static Differential Pressure

- Usage: Static differential pressure refers to the pressure difference between two points in a fluid system when the fluid is not in motion (i.e., at rest or in a static state).

- Applications: Static differential pressure is relevant in situations where flow is not a factor, such as in pressure control systems or closed vessels where pressure needs to be maintained.

- Measurement Range: The measurement range for static differential pressure can vary based on the application, ranging from very low pressures to high pressures in industrial processes.

Gauge Differential Pressure

- Usage: Gauge differential pressure refers to the pressure difference measured relative to atmospheric pressure.

- Applications: Gauge differential pressure is commonly used in pressure measurement applications where atmospheric pressure is the reference point. It is used for pressure control, monitoring, and safety applications.

- Measurement Range: The measurement range for gauge differential pressure can vary widely, from very low pressures to several bars or more, depending on the specific application.

Absolute Differential Pressure

- Usage: Absolute differential pressure is measured relative to a perfect vacuum as the reference point, providing the absolute pressure difference without considering atmospheric pressure.

- Applications: Absolute differential pressure is commonly used in vacuum systems and critical pressure applications, where the pressure is referenced to a true vacuum condition.

- Measurement Range: The measurement range for absolute differential pressure can span from very low pressures in vacuum applications to high pressures in certain industrial processes.

Measurement Instruments: For measuring differential pressure, various instruments, and devices are used, including:

- Differential Pressure Transmitters: These are electronic instruments that directly measure differential pressure and provide an output signal (e.g., 4-20mA) for monitoring and control systems.

- Manometers: Traditional U-tube manometers and digital manometers are simple devices used to visually indicate differential pressure.

- Orifice Plates, Venturi Meters, and Flow Nozzles: These are flow measurement devices that create differential pressure based on fluid flow rates.

- Pitot Tubes: Used to measure fluid velocity and create differential pressure based on the velocity and static pressure.

- Pressure Gauges: Differential pressure gauges are specific gauges designed to measure pressure differences.

- Pressure Sensors: These sensors are used in various applications to measure differential pressure and convert it into an electrical signal.

The selection of the appropriate measurement instrument depends on the specific application, the range of pressure to be measured, accuracy requirements, and the environmental conditions in which the measurement is performed.

Comparing table

Here's a comparison table of the different types of differential pressure measurements, including their characteristics, usage, applications, measurement range, and common measurement instruments:

| Type of Differential Pressure | Characteristics | Usage and Applications | Measurement Range | Common Measurement Instruments |

| Positive Differential Pressure | Pressure at one point > Pressure at another point | Flow measurement, pressure control, process monitoring | Low to high pressures | Orifice plates, Venturi meters, transmitters |

| Negative Differential Pressure | Pressure at one point < Pressure at another point | Flow reversal, vacuum systems, pressure imbalances | Low to high pressures | Transmitters, pressure gauges, manometers |

| Zero Differential Pressure | Pressure at one point = Pressure at another point | Verifying static or no-flow conditions | Exact zero (no pressure difference) | Manometers, transmitters |

| Dynamic Differential Pressure | Pressure fluctuations due to varying flow rates | Flow measurement, dynamic process monitoring | Varies with flow dynamics | Transmitters, orifice plates, flow meters |

| Static Differential Pressure | Pressure difference at rest or in a static state | Pressure control closed vessel monitoring | Low to high pressures | Transmitters, pressure gauges, manometers |

| Gauge Differential Pressure | Pressure difference relative to atmospheric pressure | Pressure monitoring, safety applications | Low to high pressures | Transmitters, pressure gauges, manometers |

| Absolute Differential Pressure | Pressure difference relative to a perfect vacuum | Vacuum systems, critical pressure applications | Very low to high pressures | Transmitters, vacuum gauges, pressure sensors |

Please note that the measurement range and instruments listed in the table are general guidelines and may vary depending on the specific application and industry standards. When selecting a differential pressure measurement system, it's crucial to consider factors such as the fluid type, flow dynamics, accuracy requirements, and environmental conditions to ensure the chosen instrument suits the intended purpose effectively.

Fig 5. Understanding Common-Mode Differential Pressure

What is a differential pressure used for?

Differential pressure is used for a wide range of applications in various industries and engineering fields. Some of the common uses of differential pressure include

- Flow Measurement: Differential pressure is frequently utilized to measure fluid flow rates in pipes and ducts. Devices like orifice plates, venturi meters, and flow nozzles create pressure drops based on flow rates, allowing engineers to calculate the flow velocity or volume.

- Filter Monitoring: In air or liquid filtration systems, differential pressure is used to determine when filters become clogged or need replacement. As filters trap contaminants, the pressure drop across them increases, indicating the need for maintenance.

- HVAC Systems: Differential pressure plays a vital role in heating, ventilation, and air conditioning (HVAC) systems. It helps to control and optimize air and water flow rates, ensuring proper ventilation and temperature regulation.

- Leak Detection: In closed systems, a sudden change in differential pressure can indicate a leak. Leak detection systems use this principle to identify leaks and prevent potential hazards or losses.

- Pressure Control: Differential pressure regulators are used to maintain a constant pressure difference across a system or component. This is essential in various processes to achieve specific objectives and ensure safety.

- Pump and Compressor Operation: Differential pressure is critical for the operation of pumps and compressors. It determines the pump head, efficiency, and performance, allowing engineers to optimize energy consumption.

- Level Measurement: In applications involving liquid level measurement, differential pressure can be employed to determine the liquid level in a tank or vessel.

- Process Control: In industrial processes, monitoring and controlling differential pressure across equipment and systems help optimize performance and maintain desired process conditions.

- Fluid Velocity Measurement: Devices like pitot tubes use differential pressure to measure fluid velocity in flow applications, such as aircraft speed measurement or wind speed monitoring.

- Safety and Control: Differential pressure switches and relief valves are used for safety purposes, triggering alarms, shutdowns, or pressure relief when pressure variations exceed set thresholds.

Overall, differential pressure is a versatile and essential parameter in numerous applications, enabling engineers and operators to monitor, control, and optimize fluid systems, ensuring efficient and safe operation.

Where can use the differential pressure?

Differential pressure can be used in a wide range of applications across various industries. Some common areas where differential pressure is used include

- Fluid Flow Measurement: Differential pressure is used to measure flow rates in pipelines, ducts, and channels using devices like orifice plates, venturi meters, flow nozzles, and pitot tubes.

- Filtration Systems: Differential pressure is employed to monitor the condition of filters in air, gas, and liquid filtration systems, indicating when filters need to be replaced or cleaned.

- HVAC Systems: Differential pressure is used in heating, ventilation, and air conditioning systems to control air and water flow rates, ensuring proper ventilation and temperature regulation.

- Leak Detection: Differential pressure is utilized to identify leaks in closed systems by monitoring pressure changes, and alerting operators to potential issues.

- Level Measurement: Differential pressure is employed to determine the level of liquids in tanks or vessels using differential pressure level transmitters.

- Pressure Control: Differential pressure regulators are used to maintain a constant pressure difference across a system or component, ensuring stable operation.

- Pump and Compressor Monitoring: Differential pressure is critical for assessing the performance and efficiency of pumps and compressors.

- Industrial Process Control: Differential pressure is used in various industrial processes to monitor and control pressures and flows.

- Safety Applications: Differential pressure switches and relief valves are used for safety purposes to activate alarms, shut down processes, or relieve pressure in case of abnormal conditions.

- Water Management: Differential pressure is used in water distribution systems to monitor and control water flow rates, ensuring efficient use and preventing overpressure.

- Oil and Gas Industry: Differential pressure is used in well testing, flow measurement, pipeline monitoring, and safety applications in the oil and gas industry.

- Aerospace and Aviation: Differential pressure is utilized in aircraft pitot-static systems for airspeed and altitude measurements.

- Medical Devices: Differential pressure is used in medical devices like respiratory equipment and blood pressure monitors.

- Laboratory Equipment: Differential pressure is used in various laboratory applications, such as fluid flow studies and pressure differential measurements.

These are just a few examples of the many applications where differential pressure is used. Its versatility and reliability make it a valuable parameter in engineering, industrial, and scientific fields for monitoring, controlling, and optimizing various fluid systems.

A real example of differential pressure in the industry

A real example of differential pressure application in the industry is its use in a Venturi Flow Meter for measuring fluid flow rates in a process plant.

In a process plant, accurate measurement of fluid flow rates is crucial for efficient operation and process control. The Venturi Flow Meter is a widely used differential pressure-based flow measurement device in industrial applications.

Here's how it works:

- Construction: A Venturi Flow Meter consists of a constricted section (known as the throat) in a pipe or duct. The diameter of the pipe decreases at the throat and then expands again to the original diameter. This constricted design creates a pressure drop in the fluid flow as it passes through the Venturi meter.

- Pressure Taps: Pressure taps are located at the inlet (upstream) and the throat (downstream) of the Venturi meter. These pressure taps are connected to a differential pressure transmitter.

- Fluid Flow: As the fluid flows through the Venturi meter, it accelerates as it passes through the constricted throat, causing a decrease in pressure in that area.

- Differential Pressure Measurement: The pressure taps measure the pressure difference (differential pressure) between the inlet and throat sections. The differential pressure is directly proportional to the square of the fluid flow rate passing through the Venturi meter.

- Calculation: The differential pressure transmitter provides an electrical signal representing the pressure difference to a flow computer or control system. The flow computer uses a calibrated relationship between the flow rate and differential pressure to calculate the actual flow rate.

A real example comes from an industrial process plant where a Venturi Flow Meter is used to measure the flow of process fluid (such as water, oil, or gas) through a pipeline. The differential pressure transmitter continuously measures the pressure difference across the Venturi meter and sends this information to a central control room.

In the control room, the flow computer interprets the differential pressure data and calculates the actual flow rate. Operators and process engineers can monitor the flow rate in real-time and make adjustments to optimize process efficiency, ensure proper distribution, or detect anomalies.

Using differential pressure-based flow meters like the Venturi meter offers several advantages, such as low-pressure loss, high accuracy, and robustness, making it suitable for a wide range of industrial applications, including chemical, oil, and gas, water treatment, and more.

Fig 6. Differential pressure gauges

What are the safety considerations for differential pressure measurements?

Safety considerations for differential pressure measurements are essential to ensure accurate readings, prevent accidents, and protect personnel and equipment. Here are some key safety considerations to keep in mind when working with differential pressure measurements:

- Use Properly Rated Equipment: Ensure that the pressure sensors, gauges, transmitters, and other instruments used for differential pressure measurements are rated for the specific pressure range and fluid being measured. Using equipment with the wrong pressure rating can lead to equipment failure or inaccurate readings.

- Correct Installation: Properly install the pressure measurement devices, ensuring they are securely mounted and sealed to prevent leaks and ensure accurate readings. Follow manufacturer guidelines and industry standards for installation procedures.

- Venting and Bleeding: When connecting or disconnecting pressure measurement devices, ensure that the system is depressurized, and the pressure is vented or bled off to prevent sudden pressure releases.

- Avoid Overpressure: Install appropriate pressure relief devices, such as relief valves, to protect the system from overpressure situations. Set the relief pressure to a safe level above the expected differential pressure.

- Regular Calibration and Maintenance: Regularly calibrate pressure measurement devices to ensure accuracy. Perform routine maintenance and inspections to identify and address any potential issues promptly.

- Safety Training: Ensure that personnel working with differential pressure measurement equipment are adequately trained in the proper use, handling, and safety procedures. Familiarize them with potential hazards and emergency protocols.

- Hazardous Fluids: When working with hazardous fluids or substances, take extra precautions to protect personnel and the environment. Use appropriate safety equipment, such as protective clothing, goggles, or gloves.

- Electrical Safety: If using electrical components, adhere to electrical safety standards to prevent electric shocks or hazards. Keep electrical connections secure and ensure proper grounding.

- Pressure Damping: In certain applications, pressure fluctuations can occur rapidly. Use appropriate pressure-dampening devices or equipment to prevent damage or rapid wear on components.

- Monitor Operating Conditions: Regularly monitor the operating conditions of the fluid system to detect any abnormal changes in pressure. Implement alarms or control systems to trigger alerts for critical situations.

- Remote Monitoring: In hazardous or hard-to-reach locations, consider using remote monitoring systems to avoid exposure to potential risks during measurements and maintenance.

By following these safety considerations, operators and engineers can conduct differential pressure measurements safely, accurately, and efficiently, contributing to the overall safety and productivity of fluid systems and industrial processes.

How does altitude affect differential pressure measurements?

Altitude can have an impact on differential pressure measurements, particularly when measuring pressure in open systems that are exposed to the atmosphere. The effect of altitude on differential pressure measurements is primarily due to changes in atmospheric pressure with elevation. As altitude increases, the atmospheric pressure decreases, which can influence the differential pressure readings in the following ways:

- Reduced Atmospheric Pressure: At higher altitudes, the atmospheric pressure is lower than at sea level. This decrease in atmospheric pressure affects the reference pressure in open systems, leading to smaller pressure differences between the measurement points.

- Absolute vs. Gauge Pressure: Differential pressure measurements can be classified as either absolute or gauge pressure readings. Absolute pressure measurements are referenced to a perfect vacuum, while gauge pressure measurements are referenced to atmospheric pressure. As altitude increases, the atmospheric pressure decreases, and thus the reference point for gauge pressure measurements changes, affecting the differential pressure readings.

- Barometric Changes: Changes in atmospheric pressure due to weather patterns, such as high or low-pressure systems, can also impact differential pressure measurements. Variations in atmospheric pressure can cause fluctuations in the reference pressure used for gauge pressure measurements.

- Differential Pressure Transmitters: Some differential pressure transmitters or sensors may be calibrated at specific altitudes or reference pressure levels. If used at significantly different altitudes, the accuracy of these instruments may be affected.

To mitigate the effects of altitude on differential pressure measurements, consider the following steps:

- Calibration: If accuracy is critical, calibrate the pressure measurement instruments at the actual operating altitude or reference pressure to account for the atmospheric pressure variations.

- Absolute Pressure Measurements: In applications where altitude changes are significant, consider using absolute pressure measurements to eliminate the influence of varying atmospheric pressure.

- Remote Monitoring: For remote or high-altitude locations, consider using differential pressure transmitters with built-in atmospheric pressure compensation or remote monitoring systems that automatically account for altitude-related variations.

- Check Local Conditions: Be aware of local atmospheric pressure conditions and consider the impact of weather changes on differential pressure measurements, especially in critical applications.

Overall, understanding the influence of altitude on differential pressure measurements is crucial, especially in applications where high accuracy is essential. By considering and compensating for the effects of altitude, operators can obtain more accurate and reliable differential pressure readings in various operating conditions.

Fig 7. Differential pressure transducer

How does temperature affect differential pressure measurements?

Temperature can have a significant impact on differential pressure measurements, especially when working with gas or vapor applications. The relationship between temperature and differential pressure is influenced by the Ideal Gas Law, which describes how the properties of gases change with temperature.

Here's how temperature affects differential pressure measurements:

- Gas Density Changes: In gas or vapor applications, an increase in temperature causes the gas molecules to gain kinetic energy, leading to higher velocities and increased molecular spacing. As a result, the gas density decreases with higher temperatures.

- Impact on Fluid Velocity: Differential pressure measurements in flow applications (e.g., Venturi meters, orifice plates) depend on the fluid's velocity. When the gas density decreases with increasing temperature, the fluid velocity can change, affecting the pressure difference across the flow element.

- Temperature Compensation: To ensure accurate differential pressure readings, it is essential to account for temperature variations and compensate for the effect on gas density. This compensation is especially crucial when using differential pressure to measure gas flow rates.

- Material Expansion: The temperature can also influence the dimensions of the pressure measurement equipment, such as pressure transmitters and sensors. Materials may expand or contract with temperature changes, potentially affecting measurement accuracy.

- Calibration: Differential pressure instruments, especially those used in gas applications, may require calibration at specific temperatures to ensure accurate readings across the operating temperature range.

To mitigate the effects of temperature on differential pressure measurements, consider the following steps:

- Temperature Compensation: Implement temperature compensation algorithms or use differential pressure transmitters with built-in temperature sensors to correct gas density changes.

- Instrument Calibration: Calibrate pressure measurement equipment at the expected operating temperatures to account for any temperature-related changes in accuracy.

- Material Selection: Choose pressure measurement devices made of materials with low coefficients of thermal expansion to minimize the impact of temperature changes.

- Temperature Control: In critical applications, maintain a stable and controlled temperature environment to minimize temperature-related variations in the gas properties.

- Operating Range Consideration: Be aware of the operating temperature range of the pressure measurement equipment and ensure it aligns with the temperature conditions of the application.

By understanding the influence of temperature on differential pressure measurements and taking appropriate measures to compensate for its effects, operators can obtain more accurate and reliable differential pressure readings in various temperature conditions.

Can Differential pressure be negative?

Yes, differential pressure can be negative. Negative differential pressure means that the pressure at one point is lower than the pressure at another point in a fluid system. It indicates a pressure difference in the opposite direction than what is typically considered positive differential pressure.

Negative differential pressure can occur in various situations, such as:

- Flow Reversal: In certain flow systems, such as pumps or fans operating in reverse, the pressure at one point may be lower than at another point, leading to negative differential pressure.

- Pressure Imbalance: In some cases, pressure imbalances in a fluid system can result in negative differential pressure across components or between different sections of the system.

- Negative Gauge Pressure: Differential pressure measurements are often referenced to a specific pressure point. If the reference point is at a higher pressure than the measurement point, the differential pressure can be negative.

- Vacuum Systems: In vacuum systems, the pressure may be lower at certain points relative to other areas, causing negative differential pressure.

While positive differential pressure is more common in many fluid systems and is often the desired condition, negative differential pressure can occur under specific conditions and may be intentionally engineered in certain applications. Understanding and monitoring both positive and negative differential pressure is crucial for maintaining system performance and safety in various industrial and engineering processes.

Fig 8. A differential pressure sensor measures the difference in pressure at its two ports

Conclusion

In conclusion, differential pressure is a crucial parameter in various engineering, industrial, and scientific applications. It represents the pressure difference between two points in a fluid system and is denoted by the symbol "ΔP" (delta P). Differential pressure measurements can be positive, negative, or zero, depending on the pressure conditions at the measurement points.

The applications of differential pressure are diverse and include flow measurement, pressure control, filtration monitoring, level measurement, leak detection, and more. Differential pressure is commonly measured using instruments such as differential pressure transmitters, manometers, orifice plates, venturi meters, and pressure gauges.

It's important to consider safety considerations when working with differential pressure measurements, such as using properly rated equipment, proper installation, venting and bleeding, and regular calibration and maintenance.

Temperature and altitude can also affect differential pressure measurements. Temperature influences gas density, while altitude affects atmospheric pressure, both of which can impact the accuracy of measurements. Proper temperature compensation and consideration of altitude changes are essential to obtain accurate readings.

Understanding the different types of differential pressure and their specific applications helps engineers and operators make informed decisions for efficient and safe operation in various fluid systems and industrial processes. By carefully selecting appropriate measurement instruments and adhering to best practices, accurate and reliable differential pressure measurements can be achieved, contributing to the optimization and safety of fluid systems in numerous industries.

To recap

- What is differential pressure, and how is it measured?

Differential pressure is the difference in pressure between two points in a fluid system. It is measured using instruments like differential pressure transmitters, manometers, or specialized flow measurement devices.

- What are some common applications of differential pressure measurements?

Common applications include flow measurement, pressure control, filtration monitoring, level measurement, leak detection, and HVAC systems.

- How does temperature affect differential pressure measurements?

Temperature affects gas density, which can impact fluid velocity and differential pressure readings. Temperature compensation is essential for accurate measurements.

- Can differential pressure be negative, and what does it indicate?

Yes, differential pressure can be negative, indicating that the pressure at one point is lower than at another point. It may occur in flow reversal or vacuum systems.

- What safety considerations should be taken into account when working with differential pressure measurements?

Safety considerations include using properly rated equipment, proper installation, venting and bleeding, and regular calibration and maintenance.

- How is differential pressure used in flow measurement applications?

Devices like orifice plates, venturi meters, and pitot tubes create differential pressure based on fluid flow rates, allowing for flow measurement.

- What is the difference between gauge differential pressure and absolute differential pressure?

Gauge differential pressure is measured relative to atmospheric pressure, while absolute differential pressure is measured relative to a perfect vacuum.

- How does altitude affect differential pressure measurements?

Altitude affects atmospheric pressure, which can influence differential pressure measurements. Altitude compensation is important for accurate readings.

- What are the advantages of using differential pressure transmitters over traditional manometers?

Differential pressure transmitters provide continuous electronic readings and can be integrated into control systems, offering greater convenience and accuracy.

- What factors should be considered when selecting a differential pressure measurement instrument for a specific application?

Factors to consider include the type of fluid, flow dynamics, accuracy requirements, pressure range, temperature, and environmental conditions.

These FAQs cover the essential aspects of differential pressure measurements, their applications, and considerations for accurate and reliable readings in various industrial and engineering contexts.

References

https://www.amsys-sensor.com/products/pressure-sensor/differential-pressure-sensors/

https://www.variohm.com/news-media/technical-blog-archive/what-is-differential-pressure-

https://core-sensors.com/differential-pressure-transducers-for-filter-monitoring/

https://instrumentationtools.com/differential-pressure-sensor-filtration-monitoring/

https://www.wika.com/en-tr/lp_differential_pressure_gauge.WIKA

https://airloq.flsmidth.com/shop/differential-pressure-556c1.html

https://realpars.com/differential-pressure-transmitter/

Recent Posts

-

From Lab to Launchpad: Pressure Sensor Industry Certifications

In the intricate world of technology and precision engineering, where every measurement matters a …16th Mar 2024 -

Stand Out, Stand Certified: The Art of Pressure Sensor Safety

Stand Out, Stand Certified: The Art of Pressure Sensor Safety Welcome to the world of performance …9th Mar 2024 -

Robotics in Food and beverage Industry

Our lives depend on the food and beverage industry and it is in a constant state of evolution, …5th Mar 2024