Gauge pressure sensor: Your Partner in Precision

Introducing the backbone of precision in pressure measurement – the Gauge Pressure Transmitter. In industries where accuracy and control are paramount, this unassuming device plays a pivotal role. It's the unsung hero behind the scenes, tirelessly monitoring and relaying pressure data to ensure the smooth operation of critical processes. Whether in manufacturing, oil and gas, pharmaceuticals, or countless other fields, the gauge pressure transmitter keeps the pressure under control – quite literally. Join us as we delve into the world of this essential instrument, uncovering its inner workings, applications, and why it's indispensable in the modern industrial landscape. Welcome to the gateway of precision pressure measurement – the Gauge Pressure Transmitter.

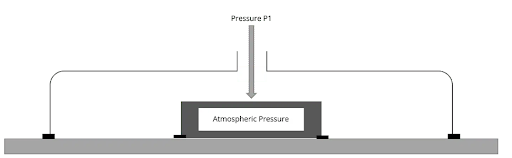

Fig 1. Gauge pressure sensor

Gauge Pressure

Gauge pressure is a measurement of pressure relative to atmospheric pressure. It is a crucial concept in engineering, physics, and various industrial applications. Unlike absolute pressure, which measures pressure relative to a perfect vacuum, gauge pressure measures pressure relative to the atmospheric pressure at a specific location and time. This means that when gauge pressure is zero, it indicates that the pressure being measured is the same as the local atmospheric pressure. Positive gauge pressure values indicate pressures higher than atmospheric, while negative values represent pressures lower than atmospheric.

Gauge pressure is widely used in pressure measurement instruments, like pressure gauges and tire pressure sensors, where it is essential to know the pressure difference from the local atmospheric conditions. For instance, a tire pressure gauge that reads 35 psi (pounds per square inch) on a car tire is giving the gauge pressure above the atmospheric pressure at the location where the measurement was taken. Understanding gauge pressure is vital in various applications, from monitoring industrial processes to ensuring the safe operation of pressure vessels and tires.

Gauge Pressure (P_g) = Absolute Pressure (P_abs) - Atmospheric Pressure (P_atm)

Where:

- Gauge Pressure (P_g) is the pressure relative to atmospheric pressure.

- Absolute Pressure (P_abs) is the total pressure, which includes atmospheric pressure, measured in Pascals (Pa) or any other appropriate pressure unit.

- Atmospheric Pressure (P_atm) is the pressure exerted by the Earth's atmosphere, typically at sea level and a specific location. It is usually around 101.3 kPa (kilopascals) or 14.7 psi (pounds per square inch) in the United States.

For example, if you measure the absolute pressure in a car tire to be 220 kPa and the atmospheric pressure is 101.3 kPa, you can calculate the gauge pressure as

Gauge Pressure (P_g) = 220 kPa - 101.3 kPa = 118.7 kPa

So, the gauge pressure in the car tire is 118.7 kPa above atmospheric pressure, which indicates how much pressure the tire contains relative to the outside air.

Fig 2. Gauge pressure

What is a Gauge Pressure Transmitter?

A gauge pressure transmitter is a specialized instrument used in various industrial and engineering applications to measure and transmit pressure data as a continuous electrical signal. It is designed to monitor the pressure difference between the process it is connected to and the local atmospheric pressure. Gauge pressure transmitters typically contain a pressure sensor that measures the pressure in the system, and then they convert this measurement into an electrical signal, such as a 4-20 mA current or voltage output, which can be easily transmitted to control systems, data loggers, or other monitoring equipment. These transmitters play a crucial role in industries like manufacturing, petrochemical, and HVAC, providing real-time pressure information that helps in process control, safety monitoring, and quality assurance.

Gauge Pressure Transmitter History

The history of gauge pressure transmitters is closely tied to the development of pressure measurement technology and the need for more accurate and reliable pressure monitoring in various industries. The concept of pressure measurement dates back to the 17th century when scientists like Evangelista Torricelli developed the mercury barometer to measure atmospheric pressure. However, the idea of transmitting pressure data electronically through a gauge pressure transmitter evolved in the 20th century with the advent of modern industrial automation.

The mid-20th century marked a significant turning point when electronic components became more accessible and capable. This led to the development of early pressure transmitters that used strain gauges and other technologies to convert pressure into electrical signals. These early devices were often bulky, less accurate, and had limited compatibility with industrial control systems.

As technology continued to advance, the late 20th century saw the emergence of more compact, reliable, and accurate gauge pressure transmitters. The integration of microprocessors and digital signal processing allowed for improved precision and better communication with control systems. Today, gauge pressure transmitters are an integral part of industrial automation, providing real-time data for process control, safety, and quality assurance in a wide range of industries, from manufacturing to petrochemicals. The ongoing developments in materials, electronics, and sensor technologies continue to enhance the performance and capabilities of these devices, making them increasingly indispensable in modern industrial processes.

Gauge Pressure Transmitter Structure

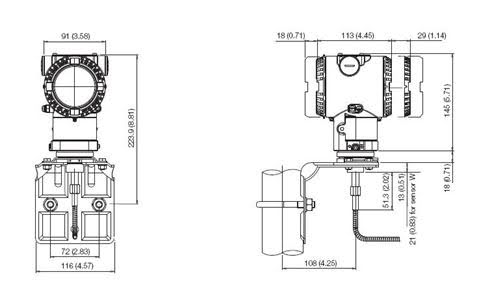

A typical gauge pressure transmitter consists of several key components that work together to accurately measure pressure and convert it into an electrical signal. Here's an overview of the structure of a gauge pressure transmitter:

- Pressure Sensor: At the core of the transmitter is the pressure sensor element. This component is exposed to the process or medium whose pressure needs to be measured. Common pressure sensor types include strain gauges, piezoresistive sensors, or capacitive sensors. When subjected to pressure, these sensors change their electrical properties, such as resistance or capacitance, which is proportional to the applied pressure.

- Diaphragm: In many pressure transmitters, the pressure sensor is mounted on a diaphragm. The diaphragm is a flexible membrane that deforms under the influence of pressure changes. This deformation is transferred to the pressure sensor, which then translates it into an electrical signal. The diaphragm is often made from materials compatible with the measured medium to ensure accuracy and longevity.

- Signal Conditioning Circuitry: The electrical signal generated by the pressure sensor is often very weak. Signal conditioning circuitry is used to amplify, filter, and linearize this signal to make it more suitable for accurate measurement. This circuitry helps compensate for non-linearities in the sensor's response and temperature effects.

- Transmitter Housing: The components of the pressure transmitter are housed in a protective and often hermetically sealed enclosure. The housing shields the delicate components from environmental factors, ensuring the transmitter's durability and reliability. It also typically includes process connections for attaching the transmitter to the system being measured.

- Output Circuitry: The transmitter features output circuitry to convert the conditioned electrical signal into a standardized electrical output, such as a 4-20 mA current loop or a voltage signal (e.g., 0-5 V or 0-10 V). This output can be easily transmitted to control systems, data loggers, or other monitoring equipment for further processing and analysis.

- Calibration and Adjustment Mechanisms: Most gauge pressure transmitters offer calibration and adjustment mechanisms, such as zero and span adjustments, which allow technicians to fine-tune the transmitter's output to ensure accurate pressure measurement.

Gauge pressure transmitters are versatile instruments used in a wide range of industries for monitoring and controlling processes where precise pressure measurement is critical. Their structure is designed to provide accurate, reliable, and durable performance in various environmental conditions.

Fig 3. Gauge pressure typical structure

How does a Gauge Pressure Transmitter Work?

The working principle of a gauge pressure transmitter is based on the deformation of a pressure-sensing element, often a diaphragm when subjected to the pressure of the medium it is measuring. As the process pressure changes, the diaphragm flexes, causing the resistance, capacitance, or another electrical property of the pressure sensor to change. This change is then converted into an electrical signal, typically a voltage or current, through signal conditioning circuitry. The transmitter's electronics linearize and amplify the signal, making it suitable for accurate measurement. The resulting electrical output represents the gauge pressure, which is the pressure above or below atmospheric pressure at the location where the measurement is taken. This output can be sent to control systems or data acquisition devices, providing real-time pressure information for process control and monitoring applications.

Here's a step-by-step explanation of how it operates:

- Pressure Sensing: The core component of the gauge pressure transmitter is the pressure sensor, often a diaphragm or similar flexible element. This sensor is exposed to the process or medium whose pressure needs to be measured. When the process pressure changes, it exerts force on the sensor, causing it to deform. The amount of deformation is directly proportional to the applied pressure.

- Deformation Response: As the diaphragm or pressure sensor element deforms under the influence of pressure changes, its electrical properties change. This change can manifest as alterations in resistance (for strain gauge-based sensors), capacitance (for capacitive sensors), or another electrical property.

- Signal Conversion: The altered electrical properties of the pressure sensor are extremely weak and often nonlinear. To make this signal suitable for accurate measurement, it is passed through signal conditioning circuitry within the transmitter. This circuitry amplifies, filters, and linearizes the signal, compensating for sensor non-linearities and environmental factors such as temperature.

- Electrical Output: After signal conditioning, the transmitter generates a standardized electrical output that corresponds to the measured gauge pressure. Common output options include a 4-20 mA current loop or a voltage signal, such as 0-5 V or 0-10 V. This output can be transmitted to control systems, data loggers, or other monitoring equipment for further processing and analysis.

- Calibration: Gauge pressure transmitters typically include calibration and adjustment mechanisms to fine-tune the transmitter's output. This ensures accurate pressure measurement, allowing for zero and span adjustments to match the transmitter's response to the specific requirements of the application.

In summary, a gauge pressure transmitter works by sensing the deformation of a pressure sensor when exposed to the process pressure, converting this deformation into an electrical signal through signal conditioning and providing a standardized electrical output that represents the gauge pressure. This output can be integrated into control systems and data acquisition systems for various industrial and engineering applications.

Gauge Pressure Transmitter Types

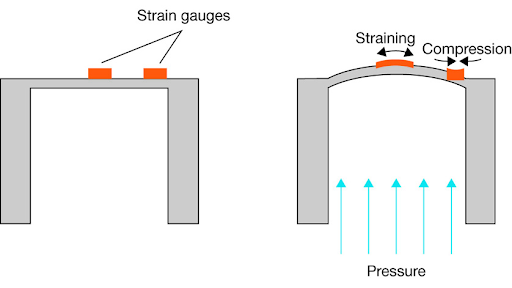

Strain Guage Pressure Transmitters

Strain Gauge Pressure Transmitters are integral components in industries where precise pressure measurements are critical. These transmitters employ strain gauges, which are sensitive elements that change resistance when subjected to mechanical stress, to convert pressure-induced deformations into electrical signals. This innovative technology ensures accuracy and reliability in pressure measurement, making Strain Gauge Pressure Transmitters suitable for a wide range of applications, from automotive crash testing to industrial process control.

In addition to their precision, these transmitters are favored for their adaptability in harsh environments. They can be designed to withstand extreme conditions, making them reliable in applications where temperature variations, high pressures, or corrosive substances are encountered. Whether it's ensuring safety in structural testing or maintaining quality control in manufacturing processes, Strain Gauge Pressure Transmitters play a crucial role in numerous industries by delivering precise and consistent pressure data.

Here are some points about Strain Gauge Pressure Transmitters:

Description: Strain Gauge Pressure Transmitters are specialized instruments designed to measure pressure with a focus on precision and accuracy. They use a diaphragm that flexes under the influence of applied pressure. Attached to this diaphragm are strain gauges, which change their electrical resistance in response to the mechanical deformation of the diaphragm. This change in resistance is proportional to the pressure applied, allowing the transmitter to convert it into an electrical signal for measurement and control purposes.

Operation: When pressure is applied to the diaphragm, it causes mechanical strain, deforming the strain gauges. This deformation results in a change in the resistance of the strain gauges, which can be measured as an electrical signal. This signal is then conditioned and amplified by the transmitter to provide an accurate and precise measurement of the pressure applied to the diaphragm. The transmitter often features a microprocessor and advanced digital communication protocols for enhanced performance and remote monitoring capabilities.

Applications: Strain Gauge Pressure Transmitters are used in applications that demand high precision and reliability, such as aerospace, automotive crash testing, materials testing, and industrial process control. They are suitable for monitoring hydraulic systems, controlling pressure in manufacturing processes, ensuring structural integrity in materials under stress, and more. These transmitters are versatile and adaptable for use in environments with extreme conditions and stringent requirements for accuracy.

Limitations:

- Sensitivity to Overpressure: Strain Gauge Pressure Transmitters can be sensitive to overpressure conditions, which can damage the diaphragm and strain gauges.

- Limited Range: These transmitters may have a limited pressure range, which can make them unsuitable for high-pressure applications.

- Environmental Sensitivity: They can be affected by temperature variations, making temperature compensation necessary in some cases.

Pros:

- Precision: Strain Gauge Pressure Transmitters offer exceptional accuracy and repeatability.

- Reliability: They are known for their reliability, especially in demanding environments.

- Wide Application Range: These transmitters are used in a variety of industries and applications due to their precision and adaptability.

Cons:

- Cost: Strain Gauge Pressure Transmitters can be more expensive than other pressure measurement options.

- Limited Pressure Range: They may not be suitable for very high-pressure applications, which require absolute pressure transmitters.

Fig 4. Strain gauge pressure sensors

Fig 5. Strain gauge sensor operation

Sealed Gauge Pressure Transmitters

Sealed gauge pressure transmitters, also known as sealed pressure transmitters or sealed reference pressure transmitters, are a specific type of pressure measurement instrument. Unlike gauge pressure transmitters that measure pressure relative to atmospheric pressure, sealed gauge pressure transmitters measure pressure relative to a sealed reference pressure, which can be a vacuum or a controlled reference pressure within the transmitter itself. This reference pressure is usually established during the manufacturing process and remains constant throughout the transmitter's operation.

Sealed gauge pressure transmitters are commonly used in applications where variations in atmospheric pressure are not a concern, and precise pressure measurements are required. They offer advantages such as improved accuracy, stability, and the ability to operate at high altitudes or in vacuum conditions without the need for external compensation.

For example, in applications like vacuum chambers, altitude measurement, or pressure control within sealed containers, sealed gauge pressure transmitters are preferred because they provide pressure measurements that are not influenced by changes in atmospheric pressure. These transmitters are especially valuable when consistent and accurate pressure readings are critical, regardless of external environmental conditions.

Here are some points about Sealed gauge pressure transmitters:

Description: A sealed gauge pressure transmitter, also known as a sealed reference pressure transmitter, is designed to measure pressure relative to a sealed reference pressure, which is typically a controlled vacuum or a reference pressure established within the transmitter itself. Unlike traditional gauge pressure transmitters that measure pressure relative to atmospheric pressure, sealed gauge transmitters eliminate the influence of atmospheric pressure variations.

Operation: Sealed gauge pressure transmitters have a reference port connected to a sealed reference pressure. They measure the absolute pressure (total pressure) and then subtract the sealed reference pressure to obtain the gauge pressure reading. This design allows them to provide accurate measurements, even in environments where atmospheric pressure fluctuations are significant.

Applications: Sealed gauge pressure transmitters are commonly used in applications where precise pressure measurements are required, and variations in atmospheric pressure are not a concern. Some typical applications include

- Industrial processes where consistent and accurate pressure readings are crucial.

- Vacuum systems, where precise vacuum level monitoring is necessary.

- High-altitude applications, where atmospheric pressure changes with altitude.

- Laboratories and research environments, particularly in experiments involving pressure-sensitive experiments.

- Pressure monitoring in controlled environments, such as cleanrooms.

Limitations:

- Sealed gauge pressure transmitters are not well-suited for applications where the influence of atmospheric pressure is a critical factor.

- Their operation can be affected by variations in the sealed reference pressure, so it's crucial to maintain the reference pressure at a constant level.

- These transmitters may be more expensive than traditional gauge pressure transmitters due to the need for a sealed reference system.

Pros:

- They provide highly accurate and stable gauge pressure measurements, unaffected by atmospheric pressure changes.

- Suitable for applications in challenging environments or where atmospheric pressure fluctuations are significant.

- Useful in applications that require precision and consistency in pressure readings.

Cons:

- Inappropriate for applications where changes in atmospheric pressure need to be considered.

- May have a higher initial cost due to the added complexity of the sealed reference system.

The choice to use a sealed gauge pressure transmitter should be made based on the specific requirements of the application, especially when precision and stability in pressure measurements are critical.

Fig 6. Sealed Gauge Pressure Transmitters

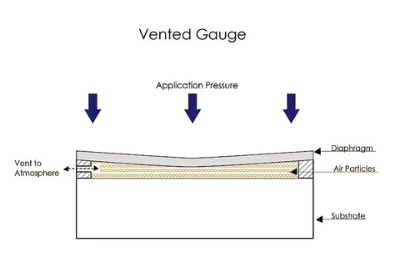

Vented Gauge Pressure Transmitters

Vented gauge pressure transmitters, also known as vented pressure transmitters, are a specific type of pressure measurement instrument that takes into account both the process pressure and atmospheric pressure. These transmitters are designed to measure the pressure difference between the process pressure and atmospheric pressure and provide a reading that includes the atmospheric pressure as a reference point. In other words, vented gauge pressure transmitters measure the absolute pressure (total pressure) and then subtract the atmospheric pressure to give the gauge pressure reading.

The vented reference to atmospheric pressure is achieved by incorporating a vent or reference port that is exposed to the local atmospheric pressure. This allows the transmitter to compensate for changes in atmospheric pressure and provide accurate gauge pressure readings even in environments where atmospheric pressure fluctuations are significant.

Vented gauge pressure transmitters are commonly used in applications where variations in atmospheric pressure need to be considered to ensure the precision of the pressure measurement. This includes applications such as weather monitoring, altitude measurement, and industrial processes where atmospheric pressure changes may affect the accuracy of the pressure data.

Here are Some points about Vented gauge pressure transmitters:

Description: Vented gauge pressure transmitters, also known as vented pressure transmitters, are designed to measure the pressure difference between the process pressure and atmospheric pressure. Unlike traditional gauge pressure transmitters, which measure pressure relative to atmospheric pressure, vented gauge transmitters incorporate a vent or reference port that is exposed to the local atmospheric pressure.

Operation: These transmitters measure the absolute pressure (total pressure) and then subtract the local atmospheric pressure to provide a gauge pressure reading. The reference port allows them to compensate for changes in atmospheric pressure, ensuring accurate measurements even in environments where atmospheric pressure fluctuations are significant.

Applications: Vented gauge pressure transmitters are commonly used in applications where variations in atmospheric pressure need to be considered to ensure the precision of the pressure measurement. Some typical applications include

- Meteorology and weather monitoring, where accurate pressure readings are essential for weather forecasting.

- Altitude measurement, aviation, and aerospace applications, where atmospheric pressure changes with altitude.

- Industrial processes where pressure readings must be corrected for changes in atmospheric pressure.

- Pressure monitoring in laboratory environments where atmospheric conditions impact results.

- Monitoring pressure in HVAC systems to ensure efficiency and safety.

Limitations:

- They are not ideal for applications where atmospheric pressure is stable and constant.

- The reference port needs to be exposed to the local atmospheric pressure for accurate measurements, so they may not be suitable for sealed or vacuum applications.

- Their accuracy can be affected if the reference port is clogged or obstructed.

Pros:

- They provide accurate gauge pressure measurements, compensating for atmospheric pressure fluctuations.

- Suitable for applications where precise, corrected pressure readings are crucial.

- Valuable in fields like meteorology and aviation for altitude measurements.

Cons:

- Inappropriate for applications with a stable and constant atmospheric pressure.

- May have slightly more complex installation and maintenance requirements due to the need for a reference port.

The choice to use a vented gauge pressure transmitter should be based on the specific requirements of the application, particularly when atmospheric pressure changes can impact the accuracy of pressure measurements. These transmitters are a valuable solution for applications that require corrected gauge pressure readings in varying atmospheric conditions.

Fig 7. Vented gauge

Comparing table

| Characteristic | Gauge Pressure Transmitter | Sealed Gauge Pressure Transmitter | Vented Gauge Pressure Transmitter |

| Description | Measures pressure relative to atmospheric pressure. | Measures pressure relative to a sealed reference point, typically set at atmospheric pressure during manufacturing. | Measures pressure relative to atmospheric pressure, compensating for changes in local atmospheric pressure. |

| Operation | Measures the difference between process pressure and atmospheric pressure. | Measures the difference between process pressure and a sealed reference point. | Measures the difference between process pressure and local atmospheric pressure, with compensation for atmospheric pressure variations. |

| Applications | Widely used in various industrial and commercial applications. | Suitable for applications with consistent atmospheric pressure, such as automotive tire pressure monitoring and certain industrial processes. | Ideal for applications where accurate measurements are required, and local atmospheric pressure changes significantly, such as altimetry and meteorology. |

| Limitations | Sensitive to atmospheric pressure changes. Limited for extreme vacuum or high-pressure applications. May require compensation in some cases. | Inaccurate at high altitudes or locations with significant atmospheric pressure variations. Limited for applications requiring vacuum measurements. | More complex and potentially expensive than standard gauge pressure transmitters. Affected by environmental conditions. |

| Pros | Versatile, cost-effective, and easy to install. Suitable for a wide range of applications. | Stable and reliable for applications with consistent atmospheric pressure. | Provides accurate measurements even when atmospheric pressure changes occur. Ideal for altimetry and meteorology. |

| Cons | Sensitive to atmospheric pressure changes. Limited for extreme vacuum or high-pressure applications. Potential temperature sensitivity. | May not be suitable for high-altitude or varying atmospheric pressure conditions. Potential for calibration. | More complex and potentially costly. Affected by environmental conditions. Additional maintenance is required for the vented reference port. |

This comparison table highlights the key differences and characteristics of these three types of pressure transmitters, helping you understand their suitability for various applications and their relative advantages and limitations.

What are the Gauge Pressure Transmitter Applications?

What are the gauge pressure measurement cases in industrial processes

Gauge pressure measurement is commonly employed in various industrial processes where pressure is measured relative to atmospheric pressure. Here are some typical cases where gauge pressure measurements are used in industrial settings:

- Petrochemical Industry: Gauge pressure transmitters are used to monitor and control pressure in various processes such as distillation, chemical reactors, and storage tanks, ensuring the safety and efficiency of petrochemical operations.

- Manufacturing and Quality Control: In manufacturing processes, gauge pressure measurements are essential for tasks like monitoring hydraulic systems, controlling pressure in molding and casting, and ensuring consistent product quality.

- Pharmaceutical and Biotechnology: These industries utilize gauge pressure transmitters to control and monitor pressure in bioreactors, filtration systems, and sterile processes, which are critical for pharmaceutical and biotechnological manufacturing.

- Food and Beverage Production: Pressure measurements are important in industries such as brewing, winemaking, and food processing, where gauge pressure transmitters help maintain product consistency and quality.

- Water and Wastewater Treatment: Gauge pressure measurements are used in water and wastewater treatment plants to monitor and regulate pressure in filtration systems, pumps, and pipelines, ensuring the efficient and safe treatment of water.

- Energy Generation: Power plants rely on gauge pressure transmitters for the measurement and control of pressures in boilers, turbines, and other critical components to ensure the efficient generation of electricity.

- Mining and Minerals Processing: In the mining industry, gauge pressure transmitters are used for tasks such as monitoring hydraulic systems and controlling pressure in mineral processing equipment.

- HVAC Systems: Gauge pressure measurements are crucial in heating, ventilation, and air conditioning systems, helping to regulate air and fluid pressures, maintain indoor climate control, and optimize energy usage.

- Oil and Gas Exploration and Production: These industries use gauge pressure transmitters to measure and control pressures in drilling operations, wellhead equipment, pipelines, and storage tanks to ensure safe and efficient oil and gas extraction.

- Pulp and Paper Manufacturing: In pulp and paper mills, pressure measurements are used to monitor and control pressure in various processes, such as paper machine drying sections, chemical pulping, and black liquor recovery.

- Automotive and Aerospace Manufacturing: The automotive and aerospace industries rely on gauge pressure transmitters for engine management, tire pressure monitoring systems (TPMS), brake systems, and aircraft cabin pressure control.

- Metalworking and Welding: Gauge pressure measurements are important in metalworking processes and welding applications to monitor and control pressure in hydraulic systems, cutting, and welding equipment.

- Chemical Processing: In chemical manufacturing, pressure measurements are used for reaction vessel control, pump and compressor operation, and other processes to ensure product quality and safety.

- Environmental Monitoring: Gauge pressure transmitters are employed in meteorology, oceanography, and environmental monitoring equipment to measure atmospheric pressure for weather forecasting and environmental research.

Fig 8. Gauge pressure transmitter

Installation and Maintenance

How can use a Gauge Pressure Transmitter?

Using a gauge pressure transmitter involves a series of steps to ensure proper installation, operation, and data monitoring. Here's a general guide on how to use a gauge pressure transmitter:

- Select the Appropriate Transmitter:

Choose a gauge pressure transmitter that suits your specific application, considering factors such as pressure range, material compatibility, accuracy requirements, and environmental conditions.

- Installation:

Properly install the transmitter in the desired location within the process system. Ensure that the process connection is tightly sealed to prevent leakage.

- Calibration and Configuration:

Calibrate the transmitter to ensure accurate measurements. This may involve adjusting zero and span settings. Many modern transmitters are digitally configurable, allowing for precise calibration via digital communication protocols like HART or Fieldbus.

- Electrical Connection:

Connect the transmitter's electrical output to your data acquisition system, control panel, or monitoring equipment. Common outputs include 4-20 mA current loops or voltage signals (e.g., 0-5 V or 0-10 V).

- Power Supply:

Provide the transmitter with the necessary power supply voltage, typically 24 VDC or as specified by the manufacturer.

- Reference Atmospheric Pressure:

In the case of traditional gauge pressure transmitters, ensure that the atmospheric reference port is open to the local atmospheric pressure. For vented gauge transmitters, this is critical for accurate measurements.

- Data Monitoring and Control:

Monitor the pressure readings from the transmitter through your control system or monitoring software. Configure alarms or control strategies as needed to respond to pressure changes.

- Maintenance and Calibration Checks:

Regularly inspect and maintain the transmitter to ensure it is operating correctly. Periodic recalibration may be necessary to maintain accuracy, especially if the application or environmental conditions change.

- Safety Precautions:

Follow safety protocols and guidelines relevant to your industry or application, especially when working with pressurized systems.

- Data Analysis and Reporting:

- Use the data collected from the gauge pressure transmitter to analyze system performance, detect anomalies, and generate reports as needed for quality control, safety assessments, or process optimization.

It's important to follow the manufacturer's instructions and any industry-specific regulations when using a gauge pressure transmitter. Additionally, regular maintenance and calibration checks are essential to ensure accurate and reliable pressure measurements over time.

Gauge Pressure Transmitter Calibration

Calibrating a gauge pressure transmitter is a critical process that ensures accurate and reliable pressure measurements. Here are the general steps involved in calibrating a gauge pressure transmitter:

- Prepare Calibration Equipment:

Gather the necessary calibration equipment, including a pressure source (calibrator or test pump), a reference pressure gauge with known accuracy, and connecting hoses or fittings.

- Establish a Controlled Environment:

Ensure the calibration environment is stable and controlled. Temperature, humidity, and pressure should be maintained within specified tolerances.

- Verify and Document Pre-Calibration Data:

Record the transmitter's pre-calibration data, such as the model number, serial number, and any previous calibration values. This information is essential for traceability and future reference.

- Zero Calibration:

Begin with zero calibration. Connect the transmitter to the calibration equipment and apply zero pressure (usually 0 psi or 0 kPa) while ensuring the process is stable. Adjust the transmitter's output to match the reference gauge's reading, effectively setting the zero point.

- Span Calibration:

Next, apply a known pressure (usually the upper end of the measurement range) to the transmitter. Adjust the transmitter's output to match the reference gauge's reading at this pressure point. This sets the span or full-scale calibration.

- Intermediate Points Calibration (Optional):

If required, calibrate the transmitter at one or more intermediate pressure points within its range. This ensures linearity and accuracy across the entire measurement range.

- Verify Hysteresis and Repeatability (Optional):

Check the transmitter's hysteresis and repeatability by applying pressure incrementally and then decreasing it while comparing the readings to the reference gauge. Adjust if necessary.

- Final Verification:

Repeat zero and span calibration to ensure that the transmitter's response remains stable and accurate.

- Adjustment and Documentation:

Make any necessary adjustments to the transmitter's output to match the reference gauge. Document the calibration results, including before and after values, and provide a calibration certificate.

- Post-Calibration Verification:

After calibration, perform a final check to ensure that the transmitter accurately reflects changes in pressure within its specified range.

- Quality Control and Certification:

Verify that the calibration process complies with industry standards and quality control procedures. Ensure that the calibration equipment is traceable to national or international standards.

- Seal and Protect:

Seal the transmitter and mark it as calibrated to prevent accidental adjustments or tampering.

- Calibration Interval and Record Keeping:

Establish a calibration interval based on industry standards and the specific application. Keep thorough records of each calibration for traceability and future reference.

Calibrating a gauge pressure transmitter is typically conducted by trained personnel or calibration experts. The frequency of calibration depends on factors such as the application, regulatory requirements, and the manufacturer's recommendations. Accurate calibration is essential for maintaining the performance and reliability of pressure measurement systems.

Gauge Pressure Transmitter Accuracy

The accuracy of a gauge pressure transmitter is a critical factor in its performance and reliability. It refers to how closely the transmitter's output readings match the actual pressure value. Accuracy is typically specified as a percentage of the transmitter's full-scale pressure range and is often described in terms of a percentage of the reading or a percentage of the full scale. The key components that contribute to the accuracy of a gauge pressure transmitter include

- Linearity: Linearity refers to how closely the transmitter's output follows a straight line when plotted against the actual pressure applied. An ideal linear response means that the transmitter's output is directly proportional to the pressure, with no deviation.

- Hysteresis: Hysteresis is the maximum difference in output when pressure is applied consecutively, first increasing and then decreasing. It quantifies the transmitter's memory effect. A lower hysteresis indicates better accuracy.

- Repeatability: Repeatability measures the transmitter's consistency in providing the same output for the same pressure under identical conditions. It assesses the transmitter's precision and ability to provide consistent results.

- Zero Offset: Zero offset, or zero error, represents the difference between the transmitter's output at zero pressure and the ideal zero output. It is essential to eliminate this offset during calibration.

- Span Error: Span error indicates the deviation of the transmitter's output at full-scale pressure from the ideal full-scale output. It is necessary to calibrate the transmitter to minimize span error.

- Temperature Effects: Accuracy can be affected by temperature variations. Temperature-related errors may be accounted for through compensation or correction factors. Some transmitters have a specified accuracy over a certain temperature range.

- Non-linearity Errors: Non-linearity errors result from the transmitter's deviation from an ideal linear response. Non-linearity correction may be required in some applications to enhance accuracy.

It's essential to consult the manufacturer's specifications and calibration procedures to understand the accuracy characteristics of a specific gauge pressure transmitter. Accuracy requirements vary greatly depending on the application. Critical applications, such as safety systems or precision instruments, may demand high accuracy, while others may tolerate a lower level of accuracy.

Gauge pressure transmitters with high accuracy are often used in applications where precision is essential, such as laboratory experiments, aerospace, and industrial processes where safety and quality control are paramount. Proper calibration and regular maintenance are key to ensuring that a gauge pressure transmitter maintains its specified accuracy throughout its operational life.

Gauge Pressure Transmitter Limitation

Gauge pressure transmitters, like any measurement instrument, have certain limitations that should be considered when selecting and using them in various applications. Some of the primary limitations of gauge pressure transmitters include

- Dependence on Atmospheric Pressure: Gauge pressure transmitters measure pressure relative to atmospheric pressure. This means they are affected by changes in atmospheric pressure, which can lead to inaccuracies in pressure readings, especially in applications where atmospheric pressure variations are significant.

- Inaccuracy in Vacuum or High-Pressure Environments: Gauge pressure transmitters may not be suitable for applications that involve measurements in extreme vacuum conditions or very high-pressure environments. Absolute pressure transmitters are better suited for such applications.

- Temperature Sensitivity: Some gauge pressure transmitters can be sensitive to temperature fluctuations, which can affect measurement accuracy. Compensation or temperature correction may be necessary for certain applications to maintain accuracy.

- No Absolute Pressure Measurement: Gauge pressure transmitters do not provide measurements of absolute pressure, which is essential in specific applications like scientific experiments, vacuum systems, and altimetry.

- Limited Compatibility with High-Purity Processes: In applications that require ultra-clean or high-purity environments, the vented reference port in some gauge pressure transmitters may not be suitable, as it introduces the risk of contamination.

- Environmental Impact: In outdoor or exposed applications, gauge pressure transmitters may be influenced by weather conditions, such as changes in barometric pressure due to weather systems or altitude changes, impacting measurement accuracy.

- Application-Specific Requirements: The suitability of gauge pressure transmitters depends on the application and its specific requirements. In some cases, alternative pressure transmitter types, such as absolute or differential pressure transmitters, maybe a better fit.

- Calibration and Compensation: Frequent calibration and compensation may be necessary in applications with varying atmospheric pressure to maintain measurement accuracy. The reference atmospheric pressure should be regularly checked and adjusted.

It's crucial to thoroughly assess the specific needs of an application and its operating environment to determine whether gauge pressure transmitters are the appropriate choice. In some cases, considering the limitations mentioned above, alternative pressure transmitter types may be more suitable for achieving precise and reliable pressure measurements.

Fig 9. Different gauge pressure sensors

What are the Advantages of a Gauge Pressure Transmitter?

Gauge pressure transmitters offer several advantages in a wide range of applications due to their ability to measure pressure relative to atmospheric pressure. Some of the key advantages of gauge pressure transmitters include

What are the disadvantages of a Gauge Pressure Transmitter?

While gauge pressure transmitters have many advantages, they also come with certain disadvantages and limitations, depending on the specific application and requirements. Some of the disadvantages of gauge pressure transmitters include

Why Gauge Pressure Transmitter is Steal Used?

Gauge pressure transmitters are still widely used for several reasons:

![]()

Fig 10. TM silicon strain gauge pressure transducer

Steps for Choosing the Best Gauge Pressure Transmitter

Choosing the best gauge pressure transmitter for your specific application involves careful consideration of various factors to ensure accurate and reliable pressure measurements. Here are the steps to help you make the right choice:

By following these steps, you can make an informed decision when selecting the best gauge pressure transmitter for your specific application, ensuring that it meets your requirements for accuracy, reliability, and compatibility with your industrial or scientific processes.

Five Best Brands of Gauge Pressure Transmitters

Several reputable brands offer high-quality gauge pressure transmitters for various industrial and scientific applications. Here are five well-regarded brands known for their reliable pressure measurement instruments:

When choosing a pressure transmitter, it's essential to consider the specific requirements of your application and consult with the manufacturer or authorized distributors to select the most suitable model. Additionally, factors like technical support, calibration services, and after-sales support should be part of your evaluation process.

Conclusion

In conclusion, gauge pressure transmitters are essential instruments used in various industrial, scientific, and commercial applications to measure pressure relative to atmospheric pressure. They offer several advantages, including cost-effectiveness, versatility, and ease of installation, making them widely used across different industries. However, they also come with limitations, such as sensitivity to atmospheric pressure changes and limited suitability for vacuum or high-pressure applications.

Selecting the best gauge pressure transmitter involves a systematic process of defining application requirements, considering factors like pressure range, material compatibility, accuracy, and environmental conditions. It's crucial to choose a reputable brand and carefully evaluate the specifications and features of the transmitter to ensure it meets the specific needs of your application.

Proper calibration, maintenance, and compliance with industry standards are essential for ensuring the accuracy and reliability of gauge pressure transmitters. By following best practices and considering the advantages and limitations of these transmitters, you can make informed decisions and maximize their effectiveness in pressure measurement applications.

To Recap

1.What is a gauge pressure transmitter?

A gauge pressure transmitter is a device used to measure pressure relative to atmospheric pressure. It provides information about the difference between the process pressure and the local atmospheric pressure.

2.How does a gauge pressure transmitter work?

Gauge pressure transmitters typically have a reference port exposed to atmospheric pressure. They measure the absolute pressure and subtract the reference pressure to provide a gauge pressure reading.

3.What are the key applications of gauge pressure transmitters?

Gauge pressure transmitters are used in a wide range of applications, including industrial process control, HVAC systems, automotive, aviation, environmental monitoring, and more.

4.What's the difference between gauge pressure and absolute pressure?

Gauge pressure is measured relative to atmospheric pressure, while absolute pressure is measured relative to a perfect vacuum (no pressure).

5.Can gauge pressure transmitters be used in high-pressure or vacuum applications?

Gauge pressure transmitters are generally not suitable for extreme high-pressure or vacuum applications. In such cases, absolute pressure transmitters are preferred.

6.How do you compensate for atmospheric pressure changes in gauge pressure measurements?

Some applications use vented gauge pressure transmitters, which incorporate a reference port exposed to local atmospheric pressure, allowing for compensation of atmospheric pressure variations.

7.What are the common output signals for gauge pressure transmitters?

Common output signals include 4-20 mA current loops, voltage signals (e.g., 0-5 V or 0-10 V), and digital communication protocols like HART or fieldbus.

8.How often should gauge pressure transmitters be calibrated?

Calibration frequency depends on the application, industry regulations, and the manufacturer's recommendations. In critical applications, more frequent calibration may be necessary.

9.What are the advantages of using gauge pressure transmitters?

Advantages include cost-effectiveness, ease of installation, versatility, and compatibility with many applications. They are widely used in various industries.

10.What factors should be considered when choosing a gauge pressure transmitter?

Factors to consider include pressure range, material compatibility, accuracy requirements, environmental conditions, output signal type, special features, budget constraints, and the reputation of the manufacturer.

These FAQs provide a general overview of gauge pressure transmitters and address common questions related to their use and application.

References

https://www.transmittershop.com/product-category/transmitters/gauge-pressure-transmitters/

https://theinstrumentguru.com/pressure-transmitter/

https://www.pci-instruments.com/product/gauge-with-built-in-pressure-transmitter/

https://www.transmittershop.com/product-category/transmitters/gauge-pressure-transmitters/

https://blog.wika.us/knowhow/what-is-gauge-pressure/?doing_wp_cron=1698770024.1526689529418945312500

https://www.britannica.com/technology/pressure-gauge

https://www.setra.com/blog/what-is-the-difference-between-vented-and-sealed-gauge-reference-pressure

Recent Posts

-

From Lab to Launchpad: Pressure Sensor Industry Certifications

In the intricate world of technology and precision engineering, where every measurement matters a …16th Mar 2024 -

Stand Out, Stand Certified: The Art of Pressure Sensor Safety

Stand Out, Stand Certified: The Art of Pressure Sensor Safety Welcome to the world of performance …9th Mar 2024 -

Robotics in Food and beverage Industry

Our lives depend on the food and beverage industry and it is in a constant state of evolution, …5th Mar 2024