From Analog to Digital: The Evolution of Differential Pressure Transmitters

Differential Pressure Transmitters, often hidden behind the scenes in industrial processes, are the unsung heroes of precision measurement and control. These unassuming devices play a vital role in countless industries, from aerospace and petrochemicals to healthcare and HVAC systems. By harnessing the power of pressure differentials, they offer a silent symphony of insights, ensuring that processes are optimized, products are manufactured with impeccable quality, and our environment remains safe.

In this exploration of Differential Pressure Transmitters, we will delve into the fascinating world of these unobtrusive instruments, uncovering their inner workings, applications, and the indispensable role they play in the modern technological landscape. Whether you're an engineer, a curious mind, or someone who's simply intrigued by the unseen marvels of technology, join us as we uncover the secrets and wonders of these unsung champions of measurement and control.

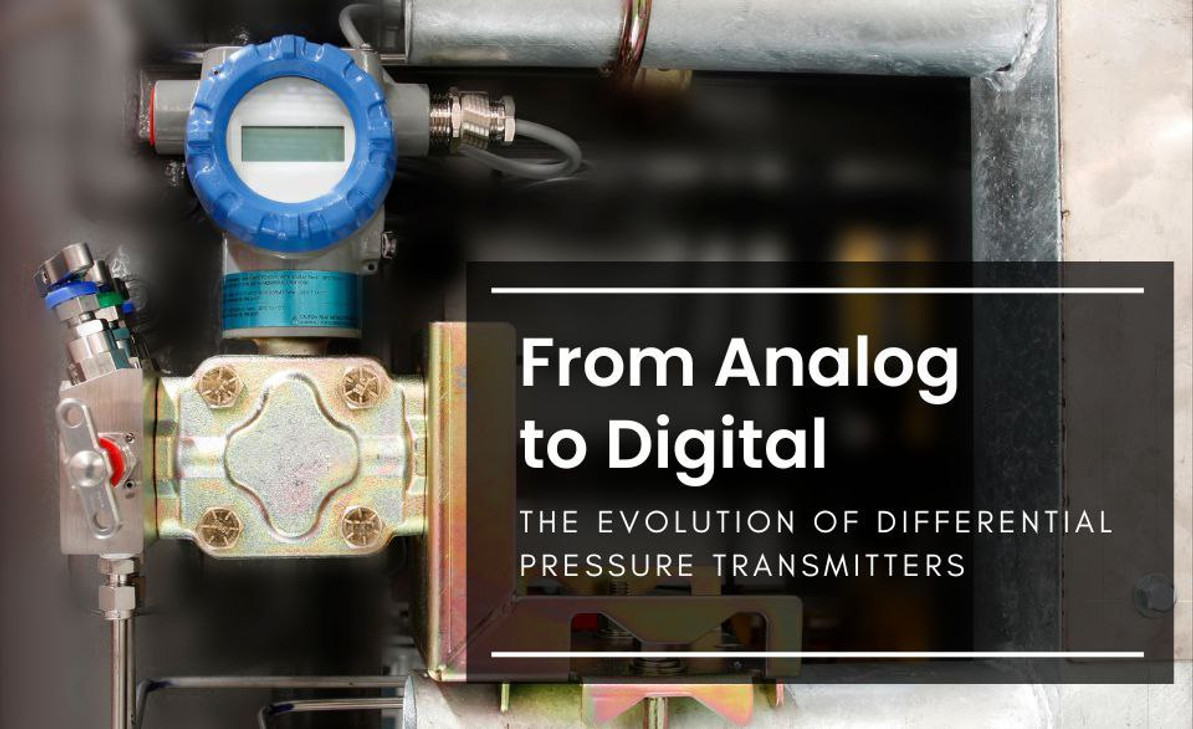

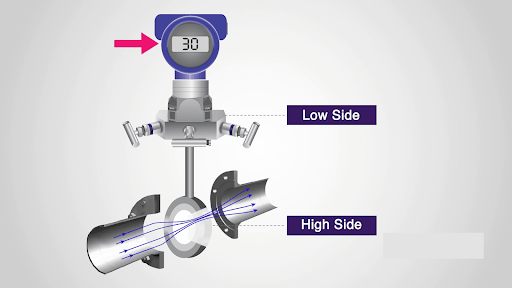

Fig 1. A differential pressure transmitter

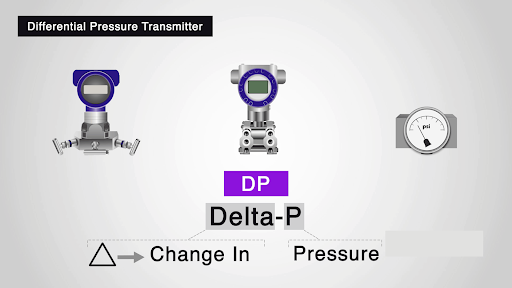

Differential Pressure

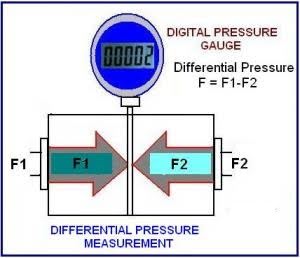

Differential pressure refers to the variation in pressure between two distinct points in a fluid system. It is a crucial concept in engineering and physics, as it provides valuable insights into fluid flow, level measurement, and other applications. Differential pressure is typically measured using devices like pressure gauges, transmitters, or manometers, which compare the pressure at one point to the pressure at another. The resulting pressure difference is used to determine various parameters, such as fluid velocity, flow rate, and liquid level. In fluid dynamics, the principle of Bernoulli's equation relies on differential pressure to describe how the speed of a fluid changes in response to alterations in pressure, making it a fundamental concept in understanding the behavior of fluids in pipes, nozzles, and other flow systems.

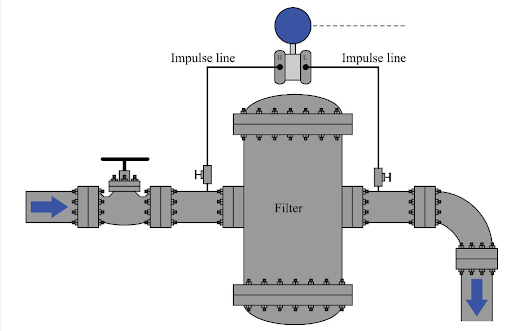

Differential pressure finds extensive applications in many industries, including manufacturing, petrochemical, and HVAC (heating, ventilation, and air conditioning). For instance, in the HVAC system of a building, differential pressure sensors can help monitor air filter conditions. When the filter becomes clogged, it increases the pressure drop across the filter, signaling the need for maintenance or replacement. In industrial processes, differential pressure is also critical for safety monitoring, as it can indicate blockages or leaks in pipelines, helping to prevent accidents and maintain the efficient operation of various systems. Overall, the measurement and understanding of differential pressure play a pivotal role in ensuring the proper functioning and safety of numerous fluid-based applications.

Differential Pressure formula

The formula for calculating differential pressure (ΔP) is quite straightforward:

ΔP = P2 - P1

Where: ΔP = Differential Pressure P2 = Pressure at Point 2 P1 = Pressure at Point 1

Here's a simple example:

Let's say you have a pipe with fluid flowing through it, and you want to measure the differential pressure between two points within the pipe. At Point 1, the pressure is 100 psi (pounds per square inch), and at Point 2, the pressure is 80 psi. To calculate the differential pressure:

ΔP = P2 - P1 ΔP = 80 psi - 100 psi ΔP = -20 ps

In this example, the differential pressure is -20 psi. The negative sign indicates that Point 1 has a higher pressure than Point 2. If you reverse the order (P1 - P2), you would get a positive differential pressure of 20 psi, indicating that Point 2 has a higher pressure than Point 1. Differential pressure measurements are used in various applications, such as monitoring filter clogs, flow rate calculations, and many other scenarios where you need to compare pressures at different points in a fluid system.

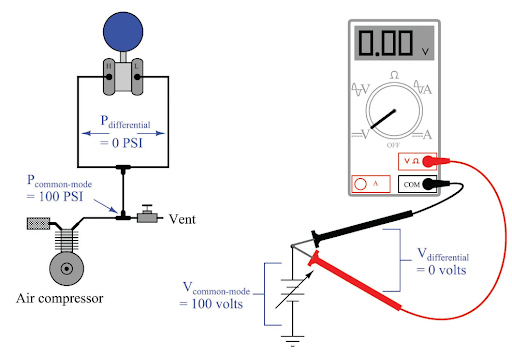

Fig 2. Differential pressure

What is a Differential Pressure Transmitter?

A Differential Pressure Transmitter is a specialized device used in various industrial and process control applications to measure the difference in pressure between two points within a fluid system. It is an instrument that converts the pressure difference (differential pressure) into an electrical signal, typically a voltage or current, which can be used for monitoring, control, or data acquisition purposes. These transmitters are crucial in a wide range of industries, including manufacturing, petrochemical, HVAC, and more, where precise pressure measurements are essential.

Differential Pressure Transmitters consist of a sensing element, which is exposed to the fluid or gas of interest, and an electronic circuit that processes the signal. The sensing element can be based on various technologies, such as strain gauges, capacitive sensors, or piezoelectric elements. When the pressure at one point is higher than at the other, the sensing element detects the pressure difference and produces an electrical output proportional to that difference. This electrical signal can be transmitted to a control system, data acquisition system, or display, where it is used to monitor or control processes. Differential Pressure Transmitters are commonly used for tasks like monitoring filter clogs, measuring flow rates, level measurement, and ensuring the safe operation of various fluid systems.

History of Differential Pressure Transmitters

The history of Differential Pressure Transmitters is intertwined with the evolution of instrumentation and industrial automation, dating back to the late 19th century. The development of these devices is a testament to the growing need for accurate pressure measurements in various industries. One of the earliest applications was in steam engines, where engineers and inventors sought to optimize the efficiency of these critical machines. Differential pressure was a key parameter for controlling the steam flow in engines, as it directly influenced their performance. Early pressure measurement devices were rudimentary and often relied on mechanical systems. As technology advanced, so did the precision and capabilities of these instruments.

The mid-20th century marked a significant turning point in the history of Differential Pressure Transmitters. With the advent of electronic components and the growth of the industrial sector, the demand for more accurate and reliable pressure measurement tools surged. This period witnessed the development of the first electronic Differential Pressure Transmitters, which converted pressure differences into electrical signals. These early models used analog technologies like resistive strain gauges, offering higher accuracy and better integration into control and monitoring systems.

The late 20th century and early 21st century saw a substantial leap in the sophistication of Differential Pressure Transmitters. Digital technologies and microprocessors enabled more advanced features, greater accuracy, and the ability to communicate with other devices and systems. Furthermore, miniaturization and cost reduction made these transmitters more accessible across various industries, from oil and gas to pharmaceuticals and HVAC. Today, Differential Pressure Transmitters are essential components of automated and smart systems, providing real-time, precise measurements to optimize processes, maintain safety, and reduce energy consumption. The continuous development and refinement of these devices highlight their central role in modern industrial instrumentation and control.

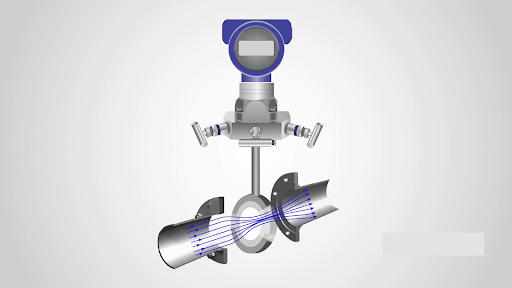

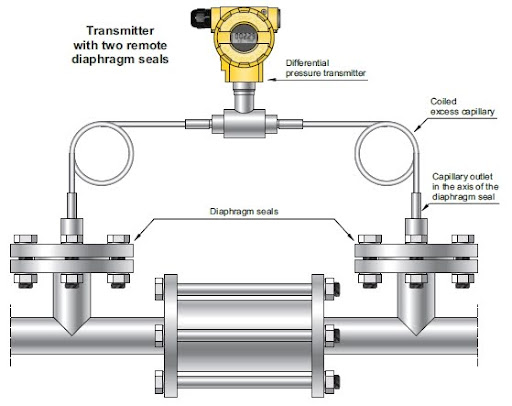

Fig 3. A differential pressure transmitter

What are the Differential Pressure Transmitter internal components?

Differential Pressure Transmitters contain several internal components that work together to measure and transmit the pressure difference between two points in a fluid system. These components may vary slightly depending on the specific design and manufacturer, but the fundamental internal components typically include:

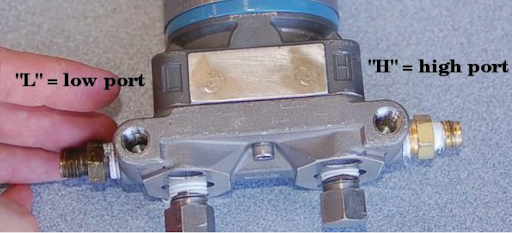

Fig 4. A DP sensor ports

Differential Pressure Transmitter Operation

A Differential Pressure Transmitter operates based on a fundamental principle in which it measures the pressure difference between two distinct points in a fluid system. This measurement is achieved by a sequence of steps within the transmitter.

- Sensing: The process begins with the sensing element, which is exposed to the fluid at the two points of interest. As the pressure varies at these locations, the sensing element deforms in response to these changes. The type of sensing element used may vary (e.g., strain gauges, diaphragms, or capacitive sensors), but the principle is the same: it responds to the pressure difference by physically changing its shape.

- Conversion: The deformation of the sensing element is then translated into an electrical signal. This signal is typically proportional to the magnitude of the differential pressure. The conversion process involves using transducer technology that translates mechanical deformation into an electrical quantity, such as resistance changes in the case of strain gauges or capacitance changes in the case of capacitive sensors.

- Amplification and Conditioning: The raw electrical signal may be quite weak and susceptible to interference, so it is typically amplified and conditioned within the transmitter. Amplifiers and filters adjust the signal's amplitude and quality to ensure accurate and stable measurements.

- Digital Processing: In modern Differential Pressure Transmitters, the amplified signal is often further processed by an embedded microprocessor. This digital processing can include compensation for factors like temperature and calibration errors. It also facilitates various communication and diagnostic features.

- Output: The processed signal is then converted into an output that can be read or transmitted to external devices. Common output options include analog signals (e.g., 4-20 mA or 0-10 V), digital communication protocols (e.g., HART or Modbus), and wireless interfaces in some advanced models.

- Display (optional): Some transmitters have an integrated display that provides local readouts of the differential pressure for on-site monitoring and configuration.

- Communication: If the transmitter is equipped with digital communication capabilities, the data can be transmitted to a central control system, enabling real-time monitoring and control from a remote location.

In summary, Differential Pressure Transmitters work by detecting pressure differences at two distinct points in a fluid system through a sensing element, converting this mechanical deformation into an electrical signal, amplifying and conditioning the signal, and then providing it as an output, often with digital communication options. This enables precise measurement and control of processes and systems where monitoring differential pressure is crucial for safety, efficiency, or quality control.

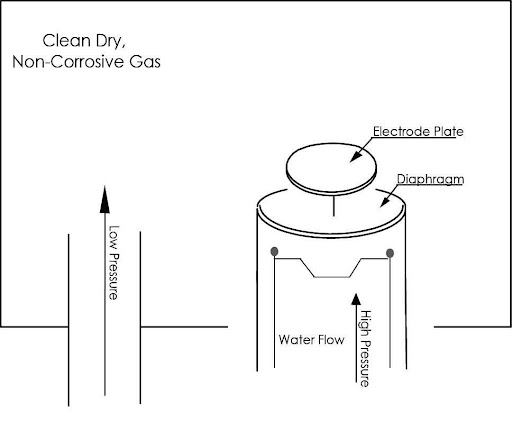

Fig 5. A differential pressure sensor working principle

What are the Differential Pressure Transmitter Types?

Differential Pressure Transmitters come in various types, each designed for specific applications and operational requirements. The key types of Differential Pressure Transmitters include

Fig 6. A wireless DP transmitter

What are the wet/wet Differential Pressure Transmitters?

A wet/wet Differential Pressure Transmitter is a specific type of pressure transmitter designed to handle and measure differential pressure between two pressure points while being in direct contact with the process fluid on both the high-pressure and low-pressure sides. The term "wet/wet" refers to the fact that both sides of the transmitter are exposed to the process fluid, which can be a liquid or gas. This design is particularly useful in applications where there is a need to measure the pressure difference between two fluids or environments and where it's essential for the transmitter to withstand direct contact with those fluids.

Key features and considerations of wet/wet Differential Pressure Transmitters include

- Direct Fluid Contact: Both sides of the transmitter are in direct contact with the process fluid, which means it must be compatible with the fluid's properties and materials. This design is often used when measuring differential pressure in aggressive or corrosive environments.

- Diaphragm or Sensing Element: Wet/wet transmitters often use two diaphragms, one on the high-pressure side and one on the low-pressure side. The differential pressure deforms these diaphragms, and this deformation is measured to determine the pressure difference.

- Isolation and Compatibility: To ensure accurate and reliable measurements, wet/wet transmitters need proper isolation between the two diaphragms and the internal components. The materials used must be compatible with the process fluid to prevent damage or contamination.

- Applications: Wet/wet transmitters are commonly used in industries like chemical processing, oil and gas, petrochemicals, and pharmaceuticals, where there is a need to measure differential pressure across filters, membranes, or within pipelines where different fluids are involved.

- Maintenance and Cleaning: In applications where the process fluid can lead to fouling or contamination, wet/wet transmitters may require more frequent maintenance or cleaning to maintain their accuracy.

Overall, wet/wet Differential Pressure Transmitters are valuable in applications where precise differential pressure measurements are required, and the transmitter needs to be in direct contact with the process fluid on both sides to provide accurate readings. Proper selection and maintenance are crucial to ensure the long-term performance and reliability of these transmitters in such demanding environments.

Fig 7. A wet to wet differential sensor

What are the wet/dry Differential Pressure Transmitters?

Wet/dry Differential Pressure Transmitters, also known as dry/wet Differential Pressure Transmitters, is a specific type of pressure transmitter designed to measure the pressure difference between two points, with one side (the "wet" side) exposed to the process fluid, and the other side (the "dry" side) isolated from the process fluid. This design allows for the accurate measurement of differential pressure while protecting the sensitive internal components from direct contact with the process fluid. Wet/dry transmitters are commonly used in applications where the process fluid is incompatible with the transmitter's internal materials, or where it is necessary to prevent contamination or clogging of the sensing elements.

Key features and considerations of wet/dry Differential Pressure Transmitters include:

- Wet and Dry Sides: The "wet" side is exposed to the process fluid, typically using a diaphragm or sensor that comes into direct contact with the fluid. The "dry" side is isolated from the process fluid, ensuring that the sensitive internal components remain protected.

- Diaphragm or Sensing Element: The diaphragm or sensing element on the wet side measures the pressure from the process fluid, while the dry side remains separated from it. The differential pressure between these two sides is then used for measurement.

- Isolation and Compatibility: Wet/dry transmitters require a strong and reliable barrier between the wet and dry sides to prevent leakage and contamination. The materials used on the dry side must be compatible with the process fluid.

- Applications: These transmitters are used in situations where the process fluid may be corrosive, toxic, or could damage the transmitter's internal components. Common applications include chemical processing, wastewater treatment, and industrial processes with harsh fluids.

- Maintenance and Cleaning: While the internal components are protected from direct contact with the process fluid, wet/dry transmitters may still require occasional maintenance and cleaning, particularly on the wet side, to ensure continued accuracy.

In summary, wet/dry Differential Pressure Transmitters are suitable for applications where precise differential pressure measurements are required, but it is necessary to protect the transmitter's internal components from direct exposure to the process fluid. This design provides the advantages of accurate pressure measurement while mitigating the risks associated with the harsh or incompatible nature of the process fluid.

Fig 8. A wet to dry differential pressure transmitter

What are the dry/dry Differential Pressure Transmitters?

A dry/dry Differential Pressure Transmitter, also known as a dry cell Differential Pressure Transmitter, is a type of pressure transmitter specifically designed to measure the pressure difference between two points while keeping both sides (high-pressure and low-pressure) isolated from the process fluid. Unlike wet/wet or wet/dry transmitters, dry/dry transmitters do not have direct contact with the process fluid at either pressure port. This design offers several advantages, making it suitable for applications where contamination, corrosion, or process fluid compatibility are concerns.

Key features and considerations of dry/dry Differential Pressure Transmitters include:

- Isolation from Process Fluid: In a dry/dry transmitter, both pressure ports remain isolated from the process fluid. This isolation prevents the sensitive internal components from coming into contact with potentially aggressive, corrosive, or contaminated process fluids.

- Diaphragm or Sensing Element: These transmitters typically use diaphragms or sensing elements on both sides to measure the differential pressure. The deformation of the diaphragms in response to the pressure difference is used for measurement.

- Isolation Barrier: Dry/dry transmitters require a robust isolation barrier between the pressure ports and the internal components. This barrier ensures that the process fluid cannot penetrate the sensitive parts of the transmitter.

- Applications: Dry/dry Differential Pressure Transmitters are commonly used in applications where the process fluid is highly corrosive, toxic, or where contamination must be prevented to maintain accurate measurements. Examples include applications in chemical processing, pharmaceuticals, and semiconductor manufacturing.

- Low Maintenance: Because of the absence of contact with the process fluid, dry/dry transmitters often require less maintenance compared to wet/wet or wet/dry transmitters, which may need periodic cleaning or maintenance on the "wet" side.

In summary, dry/dry Differential Pressure Transmitters are suitable for applications where accurate differential pressure measurements are required, and it's crucial to keep both sides of the transmitter isolated from the potentially harsh or incompatible process fluid. This design provides a high level of protection for the internal components, making it ideal for demanding and corrosive environments.

Comparing table

Here's a comparison table of wet/wet, wet/dry, and dry/dry Differential Pressure Transmitters based on various parameters and features:

| Parameter/Feature | Wet/Wet Transmitter | Wet/Dry Transmitter | Dry/Dry Transmitter |

| Direct Contact with Process | Yes (Both Sides) | Yes (One Side) | No (Neither Side) |

| Isolation Barrier | Minimal or None | Yes | Yes |

| Diaphragm or Sensing Element | Typically Both Sides | Typically One Side | Both Sides |

| Process Fluid Compatibility | Important Consideration | Important Consideration | Less Critical |

| Cleaning and Maintenance | May Require Frequent | Moderate | Less Frequent |

| Corrosion and Contamination | Potential Issues | Potential Issues | Minimized |

| Applications | Corrosive or Harsh Environments | Versatile, General Use | Highly Corrosive or Sensitive Environments |

Please note that the suitability of a particular type of Differential Pressure Transmitter (wet/wet, wet/dry, dry/dry) depends on the specific requirements and challenges of the application. Factors such as the type of process fluid, corrosion risk, and maintenance considerations will influence the choice of transmitter type for a given application.

Where can use the Differential Pressure Transmitter?

Differential Pressure Transmitters are versatile instruments that find application in various industries and scenarios where precise measurement of the pressure difference between two points in a fluid system is necessary. Here are some common applications where Differential Pressure Transmitters are used:

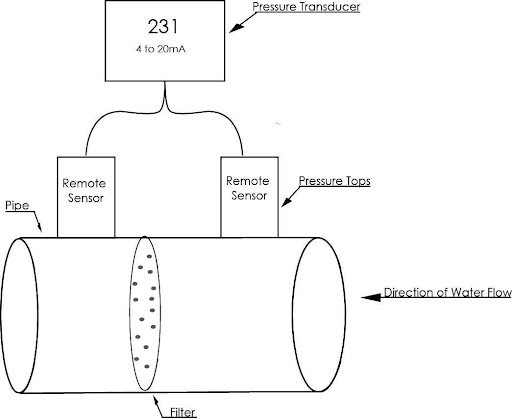

Fig 9. Differential pressure across filter

A real example of a Differential Pressure Transmitter in the industry

A real-world example of a Differential Pressure Transmitter in an industrial application is its use in monitoring and controlling air filters in HVAC (Heating, Ventilation, and Air Conditioning) systems. In HVAC systems, maintaining air quality and efficient operation is crucial for comfort and energy savings. Here's how a Differential Pressure Transmitter is used:

Application: Air Filter Monitoring in HVAC

How it works:

- Installation: A Differential Pressure Transmitter is installed in an HVAC system with one pressure port on the upstream (clean air) side of the air filter and the other pressure port on the downstream (filtered air) side.

- Measuring Differential Pressure: As the HVAC system operates, air flows through the filter. Over time, the filter gradually accumulates dust and particles, causing a restriction to airflow. The Differential Pressure Transmitter continuously measures the pressure difference between the upstream and downstream sides of the filter.

- Pressure Change: As the filter becomes clogged, the pressure drop across it increases. The Differential Pressure Transmitter detects this change and converts it into an electrical signal.

- Monitoring and Control: The electrical signal is then transmitted to the HVAC system's controller. If the measured differential pressure exceeds a predetermined threshold, the controller triggers an alert or takes action to address the issue.

Benefits:

- Maintenance Alerts: The Differential Pressure Transmitter provides an early warning system. When the pressure drop reaches a certain level, it signals that the filter needs cleaning or replacement.

- Energy Efficiency: By ensuring that filters are replaced or cleaned only when necessary, energy consumption is optimized, and HVAC system performance is maintained.

- Air Quality: Monitoring air filters with Differential Pressure Transmitters helps maintain a healthy indoor environment by ensuring that filters are effective in removing contaminants from the air.

This real-world application illustrates how Differential Pressure Transmitters play a pivotal role in optimizing the efficiency and performance of HVAC systems while ensuring air quality and reducing maintenance costs.

What are the input/output of a Differential Pressure Transmitter?

Differential Pressure Transmitters typically have both input and output parameters that allow them to function effectively in various applications. The primary input parameter is the differential pressure it measures, and the output parameters are the signals or data it provides as a result of that measurement.

Input Parameters:

- Differential Pressure: This is the primary input parameter for a Differential Pressure Transmitter. It is the pressure difference between two points in a fluid system and is typically measured in units like Pascals (Pa), PSI (Pounds per Square Inch), inches of water column (inH2O), or millibars (mbar), depending on the specific application.

Output Parameters:

- 4-20 mA (milliamp) Output: A widely used current signal for transmitting measurement data. A reading of 4 mA often corresponds to the lower measurement limit, and 20 mA corresponds to the upper limit.

- 0-10 V (Volt) Output: Another common analog voltage signal that provides measurement data within the 0-10 V range.

- HART (Highway Addressable Remote Transducer): Combines analog and digital communication in the same signal, allowing for additional data and diagnostics.

- Foundation Fieldbus: A digital protocol used in industrial automation and process control.

- Profibus: Another digital communication protocol commonly used in industrial settings.

- Modbus: A popular communication protocol used for connecting industrial equipment.

Fig 10. DP-transmitters-high-side-and-low-side

Installation and Maintenance

How can use a Differential Pressure Transmitter? explain in paragraphs

Using a Differential Pressure Transmitter involves several steps to ensure accurate measurements and effective monitoring or control in your specific application. Here's how you can use a Differential Pressure Transmitter:

- Select the Right Transmitter: The first step is to choose the appropriate Differential Pressure Transmitter for your application. Consider factors such as the pressure range, fluid compatibility, accuracy requirements, and environmental conditions. The selected transmitter should meet the specific needs of your process.

- Installation: Proper installation is critical for accurate measurements. Place the transmitter in a location where it can access both the high-pressure and low-pressure points you want to measure. Connect the pressure ports to the respective points in the fluid system using suitable tubing or piping.

- Calibration: Before using the transmitter, it's essential to calibrate it to ensure accurate measurements. Calibration involves applying known pressures to the transmitter and adjusting it to match these known values. This step helps eliminate measurement errors.

- Zero Adjustment: Zero adjustment is often part of the calibration process. It ensures that the transmitter reads zero differential pressure when no pressure difference exists between the two pressure ports.

- Connection to a Control System: Connect the output of the transmitter to a control system, data acquisition system, or monitoring equipment, depending on your application. The connection may be via analog signals (4-20 mA or 0-10 V) or digital communication protocols (HART, Modbus, etc.), depending on the transmitter's capabilities.

- Set Measurement Range: Configure the Differential Pressure Transmitter to measure within the desired range for your application. Ensure that the range is suitable for the expected pressure differences in your process.

- Start Monitoring or Control: Once the transmitter is installed, calibrated, and connected, it will continuously measure the differential pressure and transmit the data to your control or monitoring system. You can use this data to monitor the state of your fluid system, optimize processes, or trigger alarms and control actions when necessary.

- Maintenance: Regular maintenance is essential to keep the transmitter performing accurately. Depending on the application, you may need to clean the pressure ports, inspect the diaphragms or sensing elements, and recalibrate the transmitter periodically to maintain its performance.

- Data Analysis and Action: Utilize the data provided by the Differential Pressure Transmitter to make informed decisions and take appropriate actions in your process. This could involve adjusting system parameters, triggering maintenance, or ensuring safety by responding to pressure variations.

- Safety and Troubleshooting: Be aware of the safety implications of the measurements provided by the transmitter. If you encounter unusual readings or suspect a malfunction, follow appropriate troubleshooting procedures to maintain safe and efficient operations.

In summary, using a Differential Pressure Transmitter involves selecting the right model, proper installation, calibration, connecting to control or monitoring systems, and using the data to optimize processes or ensure safety. Regular maintenance and careful analysis of the measurements are essential for reliable and effective use.

Fig 11. DP sensor installation

Differential Pressure Transmitter Calibration

Calibrating a Differential Pressure Transmitter is a crucial step to ensure the accuracy and reliability of pressure measurements. Calibration involves adjusting the transmitter's output to match known reference pressures. Here's a step-by-step guide on how to calibrate a Differential Pressure Transmitter:

- Ensure that you have the necessary calibration equipment, including a pressure source (e.g., a hand pump or pressure calibrator), pressure gauges with known accuracy, and tubing or connectors to link the transmitter to the calibration equipment.

- Review the transmitter's documentation, including the manufacturer's guidelines and specifications, to understand the recommended calibration procedure.

- Ensure that you are working in a safe environment and that you are familiar with the hazards associated with pressure calibration.

- Wear appropriate personal protective equipment (PPE) as needed for your specific situation.

Record the output signal (e.g., in mA or V) from the transmitter as indicated by the monitoring equipment connected to it.

Compare the measured output to the expected output based on the known applied pressure. The deviation between the two values indicates the calibration error.

Calibrating a Differential Pressure Transmitter ensures that it provides reliable and accurate measurements, which is vital for maintaining the safety and efficiency of various industrial and process control systems. It is recommended to perform calibrations by trained personnel or in conjunction with certified calibration services to guarantee accurate and precise results.

Differential Pressure Transmitter Accuracy

Differential Pressure Transmitter accuracy is a critical specification that indicates how closely the transmitter's measurements match the true values of the pressure difference it is intended to measure. Accurate measurements are essential in various industrial and process control applications to ensure the safety, efficiency, and quality of processes. Here are some key points to understand about Differential Pressure Transmitter accuracy:

- Accuracy Specification: Manufacturers provide accuracy specifications for Differential Pressure Transmitters, usually expressed as a percentage of the full-scale range. For example, an accuracy of ±1% of the full-scale range means that the transmitter's measurements can deviate by up to 1% from the true pressure difference.

- Types of Accuracy:

- Static Accuracy: This is the maximum error that can occur at a specific pressure value within the transmitter's range, usually at room temperature.

- Total Accuracy: Total accuracy accounts for static accuracy, as well as other factors like temperature, humidity, and other environmental conditions that can affect the measurement accuracy.

- Factors Affecting Accuracy:

- Temperature: Changes in ambient or process temperature can impact the accuracy of the transmitter. Some transmitters are equipped with temperature compensation to minimize errors.

- Environmental Conditions: Factors such as humidity, barometric pressure, and vibration can also influence accuracy.

- Aging: Over time, the accuracy of a transmitter may degrade due to component wear or changes in calibration.

- Calibration: Regular calibration is essential to maintain and verify the accuracy of Differential Pressure Transmitters. Calibration ensures that the transmitter's measurements align with the true values and helps correct for any deviations.

- Accuracy Classes: Differential Pressure Transmitters are often classified based on their accuracy, with different classes indicating the allowable error range. Common classes include 0.1%, 0.2%, 0.5%, 1%, and 2% accuracy.

- Application-Specific Accuracy: The required accuracy level may vary depending on the specific application. For instance, some applications may tolerate a 2% accuracy, while others, like aerospace or medical equipment, demand much higher accuracy levels.

- Use of Redundancy: In critical applications, multiple transmitters may be used redundantly to cross-check measurements and enhance accuracy. Redundancy helps ensure that measurements remain reliable even if one transmitter fails or provides inaccurate readings.

- Regular Maintenance: To maintain accuracy, it is important to follow a maintenance schedule as recommended by the manufacturer. This may include periodic calibration, cleaning, and inspection of the transmitter.

- NIST Traceability: Some applications require that measurements are traceable to standards established by organizations like the National Institute of Standards and Technology (NIST) for maximum accuracy and reliability.

The accuracy of a Differential Pressure Transmitter is a fundamental consideration when selecting an appropriate device for your specific application. Ensuring that the transmitter's accuracy meets the requirements of your process is essential to obtaining reliable measurements and maintaining operational efficiency.

Fig 12. Differential-Pressure-Transmitters-Terminology

Differential Pressure Transmitter Limitation

Differential Pressure Transmitters are valuable instruments for measuring pressure differences in various applications, but like any technology, they come with certain limitations and considerations. Here are some common limitations associated with Differential Pressure Transmitters:

What are the advantages and disadvantages of Differential Pressure Transmitters?

Differential Pressure Transmitters offer various advantages and disadvantages, depending on the specific application and requirements. Understanding these pros and cons is essential when considering their use in industrial and process control systems.

Advantages of Differential Pressure Transmitters:

Disadvantages of Differential Pressure Transmitters:

Fig 13. A smart differential pressure transmitter

Important factors for choosing the right Differential Pressure Transmitter

Choosing the right Differential Pressure Transmitter is crucial to ensure accurate measurements and the success of your industrial or process control application. Here are some important factors to consider when selecting a Differential Pressure Transmitter:

Five best brands of Differential Pressure Transmitters

The choice of the best brand for Differential Pressure Transmitters can vary depending on your specific requirements, application, and industry. However, several reputable brands have a strong reputation for producing high-quality and reliable differential pressure measurement instruments. Here are five well-regarded brands known for their differential pressure transmitters:

Conclusion

In conclusion, Differential Pressure Transmitters are invaluable instruments used across a wide range of industries and applications to measure and monitor pressure differences in fluid systems. They offer precise and accurate measurements, making them crucial for maintaining the safety, efficiency, and quality of various processes. By understanding the principles, types, components, and limitations of Differential Pressure Transmitters, and by considering factors like range, accuracy, fluid compatibility, and environmental conditions, you can select the right transmitter for your specific needs.

Regular calibration and maintenance are essential to ensure the accuracy and reliability of these instruments. While there are advantages to using Differential Pressure Transmitters, such as their versatility and early warning capabilities, they also have limitations, including sensitivity to environmental factors and the need for proper care and maintenance.

Choosing the best brand for Differential Pressure Transmitters is a crucial decision, and reputable manufacturers like Emerson Rosemount, Yokogawa, Siemens, ABB, and Honeywell offer high-quality options. The brand you select should align with your application requirements and industry standards.

Ultimately, Differential Pressure Transmitters play a pivotal role in industries ranging from HVAC and chemical processing to aerospace and healthcare, enabling better control, safety, and efficiency in diverse processes. Understanding their principles and selecting the right transmitter for your needs is fundamental for achieving optimal results in your specific application.

To recap

References

https://realpars.com/differential-pressure-transmitter/

https://www.coulton.com/beginners_guide_to_differential_pressure_transmitters.html

http://www.measurement-solutions.com" rel="nofollow"/Differential_pressure_transmitters.html

https://oleumtech.com/oleumtech-products/differential-pressure-transmitter-dp-sensor

https://control.com/textbook/continuous-pressure-measurement/differential-pressure-transmitters/

Recent Posts

-

From Lab to Launchpad: Pressure Sensor Industry Certifications

In the intricate world of technology and precision engineering, where every measurement matters a …16th Mar 2024 -

Stand Out, Stand Certified: The Art of Pressure Sensor Safety

Stand Out, Stand Certified: The Art of Pressure Sensor Safety Welcome to the world of performance …9th Mar 2024 -

Robotics in Food and beverage Industry

Our lives depend on the food and beverage industry and it is in a constant state of evolution, …5th Mar 2024