Three Types of Liquid Level Transmitters for Monitoring Oil Tanks

In the process of monitoring oil tanks, we need to be able to measure the level of the tank. This is an important step in ensuring storage security. Due to different oil storage conditions, different climates, and unpredictable conditions, monitoring oil reservoirs faces challenges. In addition, there are several requirements for monitoring refined oil products:

1- The equipment used for monitoring must be explosion-proof

2- The equipment must be easy to deploy without changing the tank structure;

3- There must be a Multi-party linkage, which can facilitate on-time alarm and corresponding failure;

4- The monitoring equipment must be debugged and easy to use;

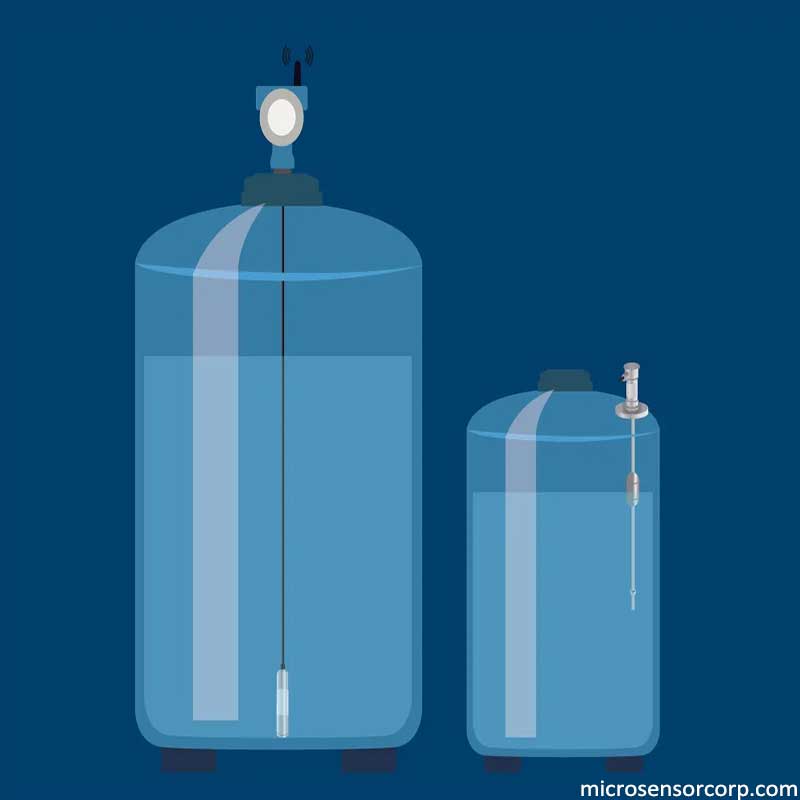

Three types of liquid level transmitters are designed and manufactured for this purpose:

1- The first type of liquid level transmitters:

This type of transmitter is integrated, small in size, environmentally friendly, without the need to change the tank structure, and has obtained several certifications, including the ATEX explosion-proof certificate. The housing of the sensor part is IP68 rated and the junction box housing is IP65 rated. These types of transmitters do not need external adjustment, are energy-saving, reliable, and have good quality.

2- The second type of liquid level transmitters:

These transmitters are suitable for areas with variable climates. They operate with High precision (±1%FS(≤3.5mH2O); ±0.5%FS(>3.5mH2O) ), their Output signal is 0.5V ~4.5V DC (three wires) with temperature output, have numerous compatible media, are suitable for monitoring in different situations, are completely welded submersible liquid level transmitter and their cable and the shell are sealed and connected. They can be applied for long times in a liquid compatible with the structural material of the transmitter, with reliable performance and stronger sealing performance, and are suitable for field use and automatic control.

3- The third type of liquid level transmitters:

They are suitable for areas with severe weather. (Conventional equipment cannot measure the liquid level in extreme temperature.)

They perform with High precision (±0.25%FS or ±0.5%FS (including endpoint error, nonlinearity, hysteresis, repeatability, and temperature error within the compensation temperature range) ), are made of stainless steel, have an all-welded structure, are vigorous and durable, and have good sealing. So that oil is not easy to penetrate. Furthermore, they have a Wide temperature range (-40~85℃), Can operate within 200 meters underwater (IP68) for long times, and are suitable for various oil tank monitoring environments, and under low-temperature environments. Their accuracy is guaranteed.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

A Wireless Remote System for Natural Gas Monitoring

Special Differential Pressure Transmitters for Oil and Gas Recovery

Special Transmitters for Petrochemical Oil and Gas Industry

Related Products