Special Transmitters for Petrochemical Oil and Gas Industry

Due to the lack of global resources, rising production costs, high ratio of demand to supply, and the strong need for industrial integration, it is necessary for the petrochemical industry to become more intelligent. As the industry becomes smarter, special practical instruments have been developed for the industry. The four most important areas in which these instruments are used are:

1- Monitoring Oil/gas storage and transportation system

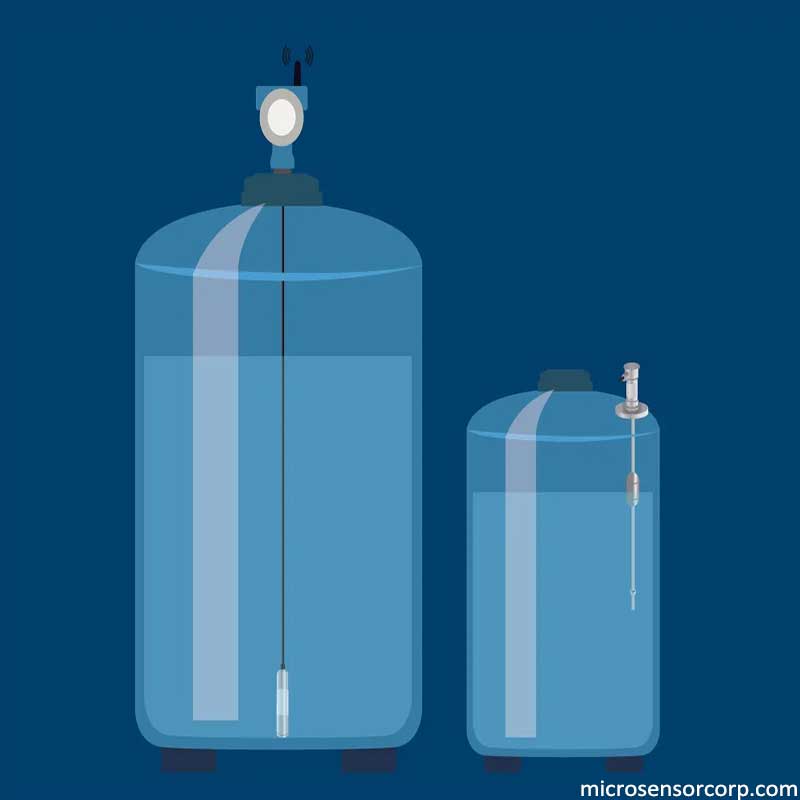

For this purpose, pressure transmitters, differential pressure transmitters, level transmitters, and special temperature transmitters have been produced. These tools monitor the condition of oil storage tanks and pipelines. As a result, there is no need to use traditional manual methods to inspect the system. In addition, with the help of other types of level transmitters and pressure transmitters, the oil level of the tanks can be monitored in real-time.

It should be noted that by adjusting the pressure of pipelines, the risk of leakage can be controlled and by adjusting the temperature of pipelines and reservoirs, unexpected accidents can be prevented.

2- Online monitoring of oil and gas

Special differential pressure transmitters are used to measure hydraulic resistance pressure in the oil and gas pipeline. Based on the real-time data of the negative pressure value, we can monitor the oil and gas recovery of the oil tank and the automobile to avoid oil and gas leakage.

3- Oil and gas recovery at gas stations

Oil and gas recovery is essential for safety, economic savings, and environmental protection.

Two types of pressure transmitters are designed to monitor the pressure of oil and gas tanks in real-time. The measured pressure value is considered the pressure value as the start-stop input signal of the recovery processing instrument.

4- Measurement and control of oilfield water injection

High-pressure water injection is one of the critical links in oilfield development currently.

The water injection volume is one of the key factors of water injection in oilfields, hence measuring and controlling water injection in oilfields are very critical.

Previously, oilfield water injection used conventional mechanical water meters, vortex or Magnetoelectric flow meters, and other products. These devices are easy to block, which will lead to a large maintenance workload. The principle of the electromagnetic flowmeter prevents such troubles properly.

Special high-pressure electromagnetic flowmeters are designed for this purpose.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

The Monitoring Process of Diesel Generators

Three Types of Liquid Level Transmitters for Monitoring Oil Tanks

A Smart Solution for Monitoring the Level of Oil Tanks

Related Products