Resolving Hose-Coupling's Errors in Systems of Fluidized Pneumatic-Transport via RFID Technology with IO-Link Connectivity

Bulk-handling systems are highly dependent on pneumatic conveying systems for transporting fluidized materials. Pneumatic conveyors are ideal for fast and reliable transporting large volumes. A pipe from each source in coupling stations enters the bottom of the station, where it connects. Quick-release tubes, manually connected to the respective outlets, feed materials to machines. Human faults cause the hose to be connected to the wrong outlet. So, we need an industry-standard interface to avoid this matter.

What is the solution?

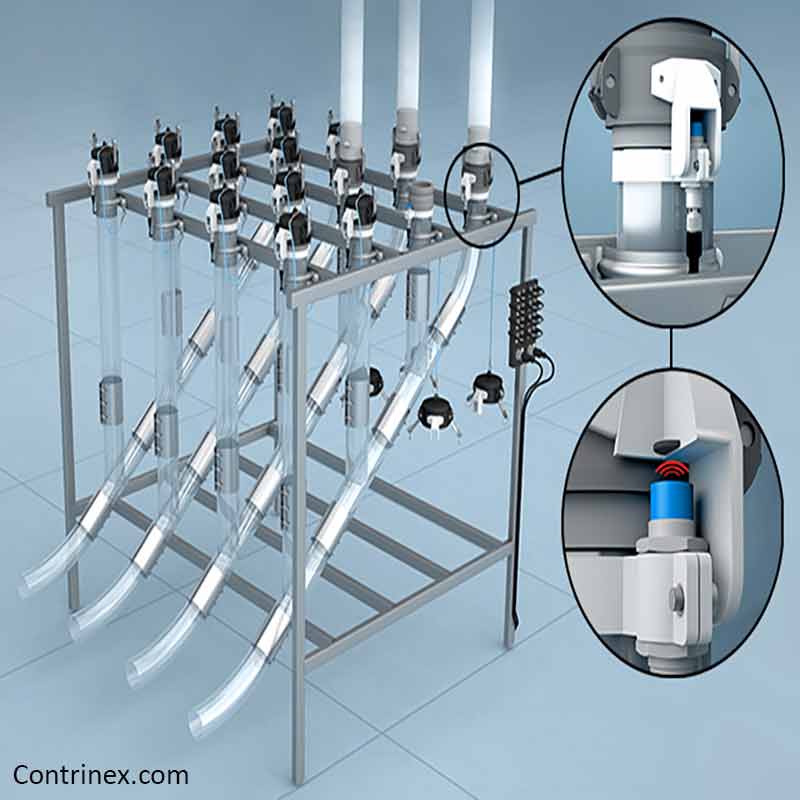

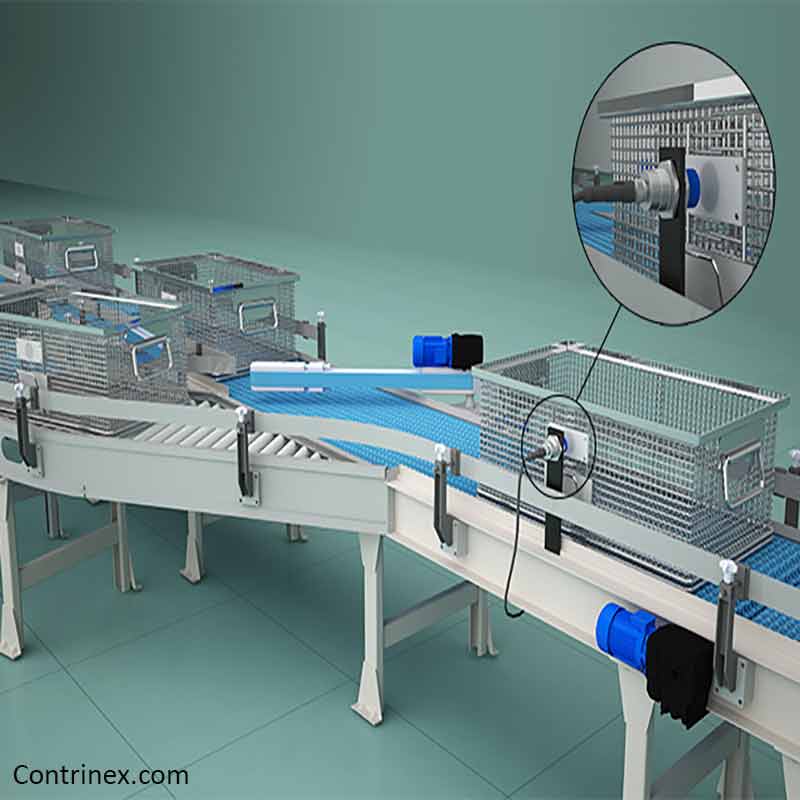

IO-Link-enabled high-frequency (HF) read-write modules (RWMs) and RFID tags are ideal for this application.

Where are they mounted?

The IO-Link-enabled RWM: on each outlet pipe

The RFID tag: integrally within each hose coupling

How do they work?

Each IO-Link-enabled RWM is connected to a control system through two industry-standard 8-way IO-Link master hubs.

An RFID tag detects the hose, letting the outlet/hose combination be verified at connection time. Furthermore, empty caps convey unique RFID tags to admit that unused outlets are capped.

With data-transfer speeds up to 38.4 kbaud, these sensors offer data in real-time. They send an instant alarm if a connection error occurs.

The operating modes of IO-Link RWMs:

IO-Link RWMs can be configurable to work in two switchable modes: IO-Link and standard I/O mode.

How do they work?

Each IO-Link-enabled RWM is connected to a control system through two industry-standard 8-way IO-Link master hubs.

An RFID tag detects the hose, letting the outlet/hose combination be verified at connection time. Furthermore, empty caps convey unique RFID tags to admit that unused outlets are capped.

With data-transfer speeds up to 38.4 kbaud, these sensors offer data in real-time. They send an instant alarm if a connection error occurs.

The operating modes of IO-Link RWMs:

IO-Link RWMs can be configurable to work in two switchable modes: IO-Link and standard I/O mode.

Among the leading manufacturers of automotive sensors, Contrinex is one of the largest. Step in to get to know Contrinex company.

Check out our article for more information on photoelectric sensors:Inductive Proximity Sensor Types

Do you need a sensor? We offer a wide selection of inductive proximity sensors here.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Warranting Safe Status of Load before Starting Platform Lift and during Operation Using Inductive Sensors

Selected Applications From Logistics Industry

Simpler Process Control via Read-Write Modules with IO-Link Connectivity