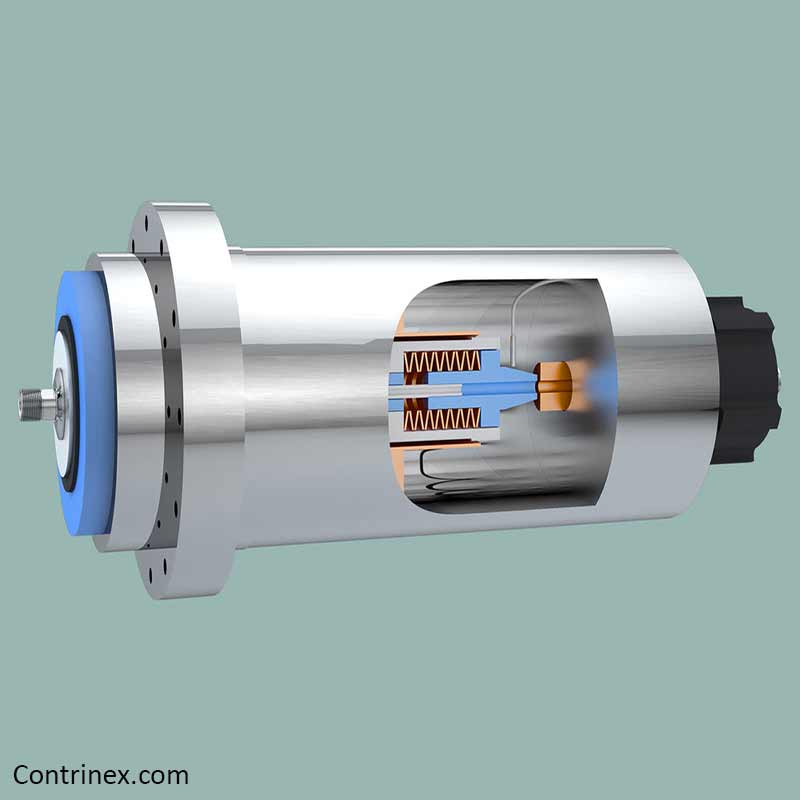

Inhibiting wrong Engagement During Automatic Tool Changes for Compact Machine-Tool Spindles Using Smart Inductive Sensors

Sometimes when designing a CNC machine, the collet does not retract completely, preventing the new tool from thoroughly engaging.

Failure to detect and correct the problem will damage the tool, the workpiece, and possibly the spindle. So, the spindle producers need a method for identifying imperfect tool retraction.

The adopted solution must be vigorous and fail-safe.

What would be the best suggestion to overcome this challenge?

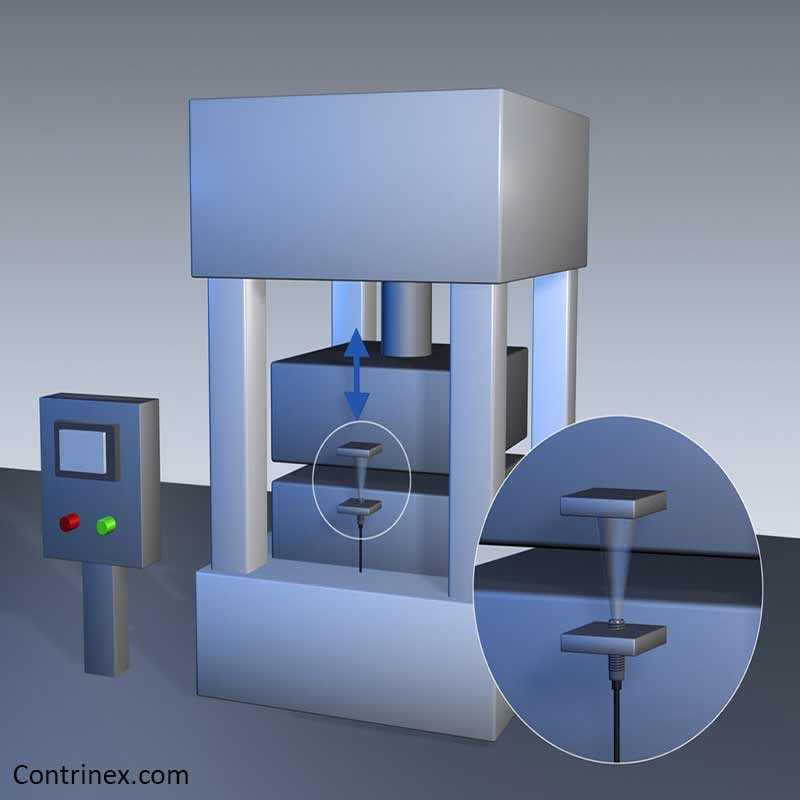

Rugged inductive sensors that are metal-cased are suitable for this application. These smart sensors all feature IOLink connectivity, offering a single industry-standard interface to the machine control system. The sensors act as a highly accurate rangefinder.

Some features of these sensors:

• Detection distance: up to 6mm

• Dynamic resolution: ±5.5 micrometers

• A precise 16-bit digital output helps determine • the drawbar's status in real time.

How the sensor works:

At the time of preliminary calibration, the drawbar positions are saved inside the sensor's local data store. As soon as the travel intensity is reached in both directions, the sensor de-energizes the actuator and starts a new process step. Any non-compliant measurements will cut the process off and sound an alarm.

Note: On-board data storage holds cumulative operational data for user-specified aims.

Among the leading manufacturers of automotive sensors, Contrinex is one of the largest. Step in to get to know Contrinex company.

Check out our article for more information on photoelectric sensors:Inductive Proximity Sensor Types

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Detecting the Status of Ram for Manual Punch-Riveting Instrument

Warranting Thorough Closure of Tools Using Inductive Proximity Sensors

Controlling Reflow Soldering Process through Detecting Circuit Boards

Related Products