All-Metal Inductive Sensors for Identifying Fill Level of Molten Metals

Engineers have developed a sensor cooling system that encases the sensor in the same ceramic material as the tiles that insulate space shuttles against significantly excessive temperatures on re-entry to the earth’s atmosphere. The routine industrial sensor chosen for the Sensor Cooling System (SCS) should display reliability in environments as much as 1200°C, be insensitive to collected dirt and mechanical stresses, and adapt simply to pre-existing installations and controllers.

Extreme range inductive sensors are suitable for this application. With all-metal, stainless steel housing (including sensing face) and IP68 and IP69K class protection they are suitable for harsh environments. With working distances as much as 40 mm and factor 1 for steel and aluminum, they fulfill application- particular requirements. In the first test phase, the water-cooled test piece was equipped with multiple temperature sensors and heated in a tube furnace to 1100°C. This test confirmed the computer simulations of the cooling system model. By optimizing sensors isolation, it was feasible to compensate temperatures as much as 1200°C. Additional cooling of air in the tube is carried out with an air exchanging instrument.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Warranting Utilization of Appropriate Cannulas during Robot-Assisted Laparoscopic Surgeries

Convenient Operation in Manufacturing Process of N95 Face Masks Using Rugged Inductive Sensors

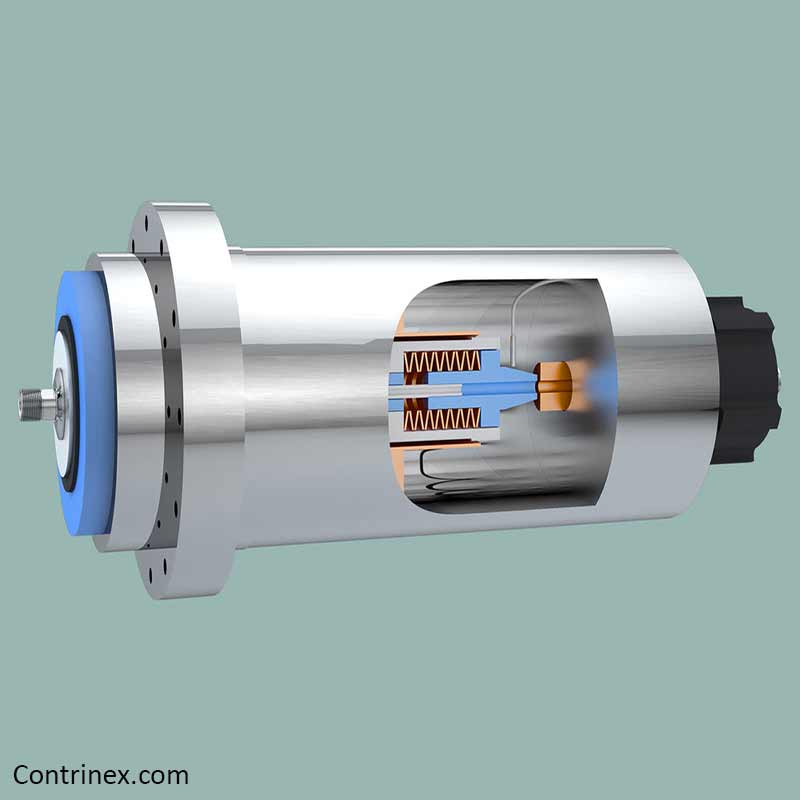

Inhibiting Imperfect Engagement during Automatic Tool Changes for Compact Machine-Tool Spindles Using Intelligent Inductive Sensors

Related Products