Radio Frequency Identification (RFID) for components in Optimized Process Control

The process of washing automotive components is a crucial stage of manufacturing automobiles. In this process, RFID transponders and read/write modules constitute an identification system. Since the carriers do not always contain the same components, this identification system detects the component type inside the basket and initiates the correct washing cycle.

The Identification system encounters risks like mechanical shocks, hot water, corrosive chemicals, and high-pressure jetting.

Passive transponders are used in the ConIdent® range. They need no internal source of energy and a range of read/write modules rated up to IP67.

What can help us as a solution?

RFID tags with nylon housings seem to be the proper solution.

These tags are IP67/IP69K rated .

How does the solution work?

Every carrier has a holder for an RFID tag.

The customer's PLC control system checks the tag information when unloading components from the carrier. Then, it writes that information on the tag in preparation for the next batch.

Click on the following link to see the proximity sensor category.

Among the leading manufacturers of automotive sensors, Contrinex is one of the largest. Step in to get to know Contrinex company.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

The All-Metal Lye-, Oil- And Aluminum Filings-Resistant RFID System

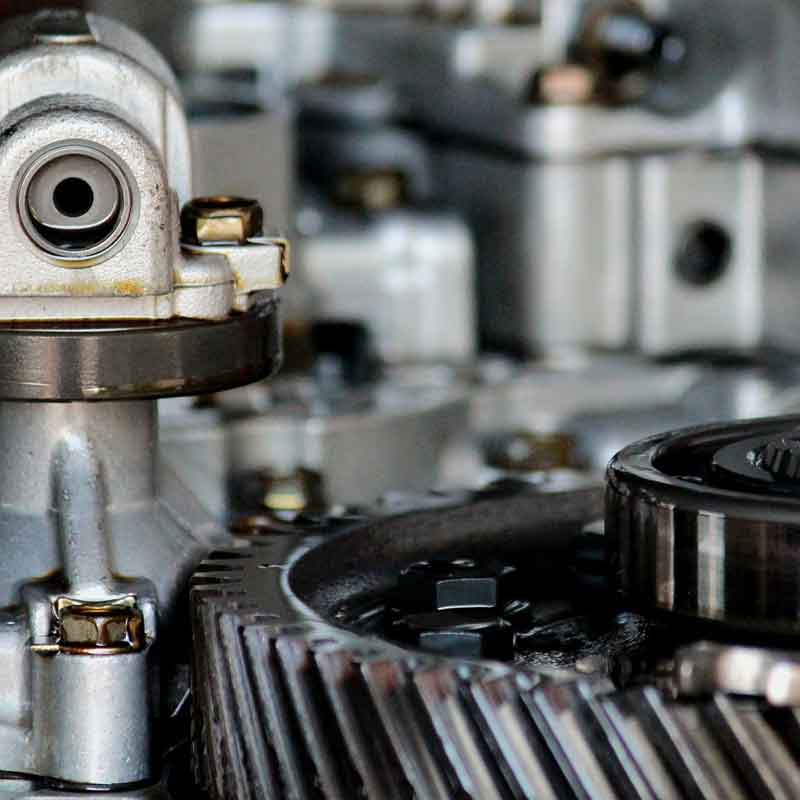

Detecting Height to Check Gear Assembly Versions in the Manufacturing Process

Figuring the model of vehicles out by detecting the type of chassis