Providing Feedback from Web Dancer to Manage Web Tension by Analog Inductive Sensors

As a web unwinds and feeds material into the process, the control system should compensate for minor changes in tension. The web tension control system registers these tension changes thru a dancer roll. previously, both a feedback potentiometer or an encoder-type product has been utilized by the purchaser to offer a signal to the machine controller, which adjusts drive speed/braking consequently that Both are subject to wear and tear on delicate bearing surfaces. To avoid this challenge, we need non-contact sensors.

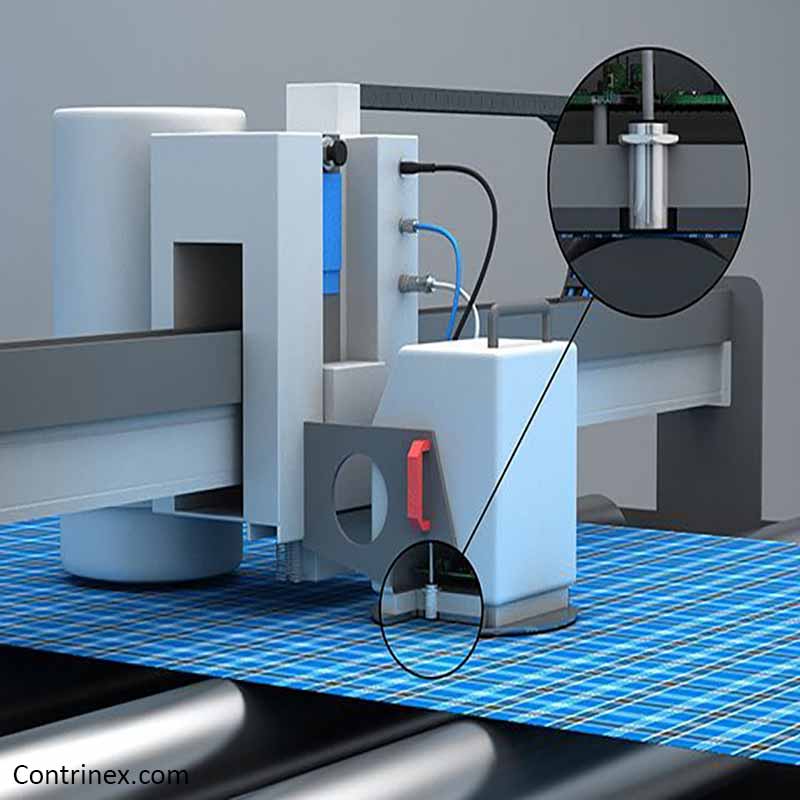

Analog Inductive sensors are perfect for this application. Available in a variety of standard housings, their Condist® oscillator technology guarantees plenty longer working distances than standard ((as much as 40 mm). The sensors’ analog output offers resolution in the µm variety with high-quality temperature balance and repeat accuracy. The continuous, non-digitized output of those sensors is ideally fitted to recording the accurate movement of a constantly ‘dancing’ roll.

The approach using an analog inductive sensor needs no mechanical touch. It is then feasible to interface the sensor output straightly to a controller, with multiple switch points included in a single device. This significantly simplifies set up, whilst the challenges of damage and tear related to mechanical touch are avoided.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Access Control Barriers Used by Tanneries at Gateways to Automated Stock Zone

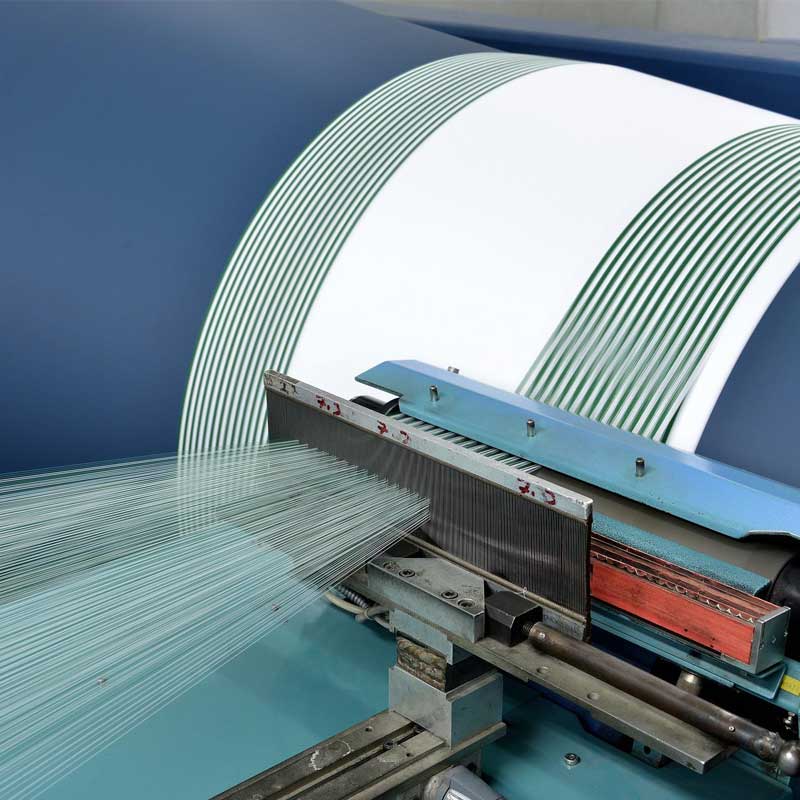

Measuring Thickness of Moving Textile Webs by High-Resolution Analog Inductive Sensors

Minimizing the Probability of Collision with Vacuum Cleaning Robots on Textile Machines through Non-Contact Obstruction Sensing

Related Products