Inductive Sensors for Extreme Temperature Ranges

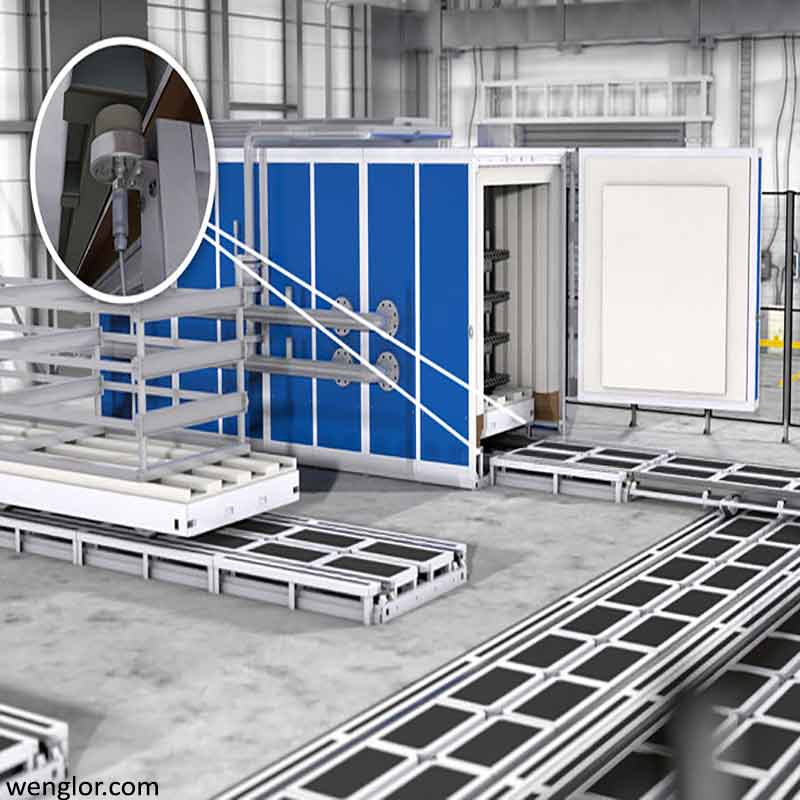

After the extrusion process, aluminum profiles are cured for some hours in furnaces at high temperatures (approximately 200 ºC.)

Before transferring the product carrier to the hot chamber, it must be empty.

We need special equipment to detect the presence of product carriers in this situation. The equipment used must be capable of reliable operation at high temperatures.

Inductive sensors for extreme temperature ranges are specially designed for this purpose. These sensors have stable performance at extreme temperatures, are vigorous, and are positioned laterally relative to the feet of the carrier system.

Due to having an intuitive push-pull connector easy replacement of the sensor head is provided without complex cabling.

These sensors figure out metallic objects in extreme temperature ranges without direct contact. Due to a very vigorous design and high switching distances, the sensors are highly durable.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Special Inductive Sensors for Figuring out the Baking Trays under High Temperatures

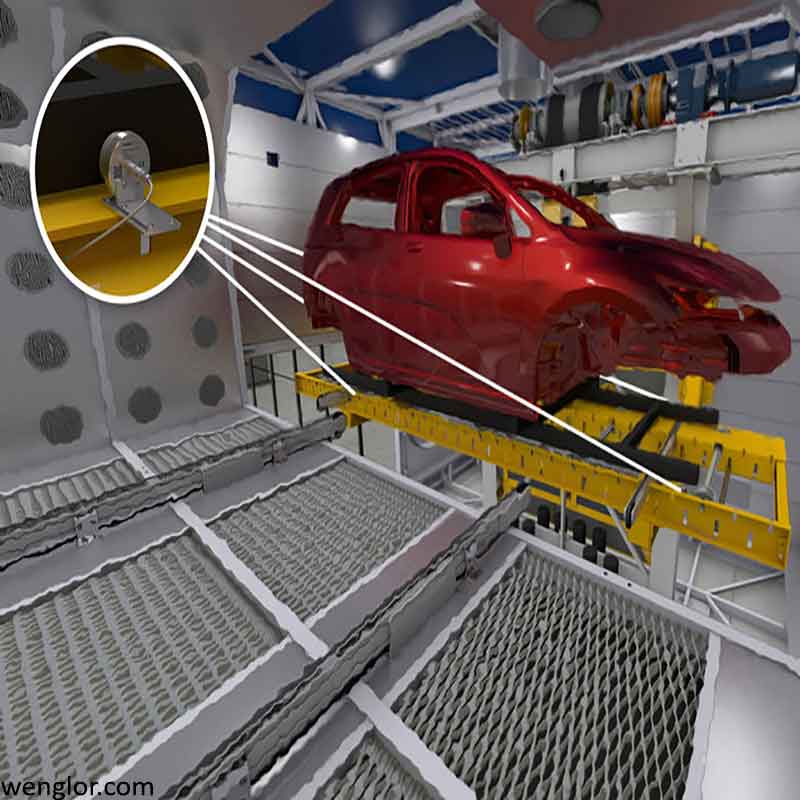

Special Inductive Sensors for Figuring out the Position of Skids in Automotive Painting Industry

Detecting the Position of Skid Carriers in Automotive Industry via Inductive High-Temperature Sensors

Related Products