Autonics Line Beam Mapping Sensor BWML Series

Line Beam Mapping Sensor

• Line Beam

• CC-Link, EtherCAT Communication

• Various Sensing Channels

• Bright Status Indicator

The Line Beam Mapping Sensor for Industrial automation

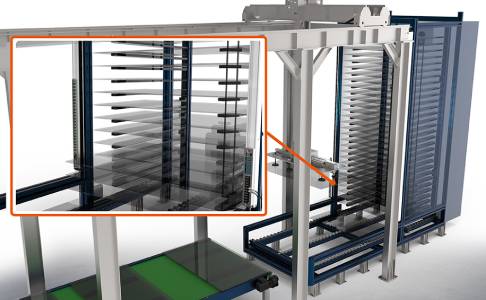

The Autonics BWML series line beam mapping sensors are optimized for glass substrate detection by using location image mapping method to minimize non-detection area and influence from harsh external conditions. The sensors support CC-Link and EtherCAT communication protocols and feature channel editing function which allows users to change pixels or edit sensing channel area with a connected PC. IP67 protection structure allows stable and error-free operation even in wet or dusty environments. The line beam mapping sensors can be used to detect display panels on transport cassettes.

Main Features

- Stable glass substrate detection using line beam detection with minimal non-detection area

- Sensing distance: 95 ±10 mm

- Customized models available: sensing channels (4 to 62 channels), sensing target pitch (min. 20 mm), sensing area (280 to 1,775 mm)

- Communication output: CC-Link (ver 1.1, 2.0), EtherCAT

- Easy installation with installation instruction mode and background sensing mode

- Channel interference alarm, 5-stage sensing level setting, emitter/receiver error alarm

- Bright status indicators

Click the following link to see all Autonics Area Sensor series.

You can also view all Light Curtain products here. Check them out now.

Customized Models Available

Users can order customized models with different sensing channels and sensing target pitch size depending on user requirements. Visit Autonics company to discover more about this manufacturer and its products.

Line Beam Sensing Method for Stable Glass Substrate Detection

The diffuse reflective line beam method with location image mapping minimizes non-detection area and influence from harsh external conditions. This sensing method allows stable detection of ultra-thin glass substrates.

Background Sensing Mode, Installation Instruction Mode and Auto Teaching Function

The installation instruction mode allows users to check if the detection target object is in proper position using the output indicators. The auto teaching function allows all sensing channels to be set in uniform light amount for optimal sensitivity setting.

Sensing Level Setting to Minimize Influence from Bent Glass or Scattered Reflections

The sensing level setting allows optimal sensing with minimal influence from bent glass or scattered reflections. The sensing level can be set between 1 to 5 sensitivity levels for stable detection in various environment settings. If the mapping sensor or cassettes are bent, sensitivity adjustments can be made without removing the glass substrates.

CC-Link, EtherCAT Communication Protocol Support

The units offer support for CC-Link or EtherCAT communication support and also offer options for connector type connection or terminal type connection.

Expanded User Convenience

Various functions and settings available for user convenience on installation or operation.

Channel Interference and External Light Alarm Function

When a sensing channel is interfered by another glass substrate or the receiver receives external light besides the light from the emitter, the status indicator and the channel indicator will blink respectively. This will start the alarm output allowing stable and error-free operation.

Check Operation Status with Bright Indicators

The bright indicators allow users to easily check operation and communication status even from long distances.

Click the links below to read more about Light Curtain in our articles:

Special Offer

Free delivery in UAE areas and above 400$ outside UAE