New Pressure Transmitting Controllers for Hydropower Stations: Features and Applications

A pressure transmitting controller is a device for measuring and controlling.

These devices are widely used in the hydroelectric industries. New intelligent controllers have been developed that combine display measurement, control, transmission, and pressure. In addition to having IP65 protection, these controllers have many advantages, some of which are mentioned:

• 180̊ rotatable panel

• 14 digits LED display

• Support back, rail, cover, and joint mounting

• Maximum pressure during operation recorded

• Normally close or open contact relay

• Optimal analog output

• Max. 5 relays control independently

• Time-delay function

• Hardware wrong protection operation

These special pressure transmitting controllers apply in the hydropower speed generating system. The pressure control and automatic air make-up of the oil hydraulic system can be achieved independently because of its stability and reliability, which helps develop the system's self-protection ability, so, improving economic benefits and the hydropower automation degree.

The analog and switch signal outputs from these controllers can input relative PLC. This gives vital fundamentals for the automatic system control governor system. In addition, it offers parameters for automatic and manual regulation of the LCU system.

MPM4881 pressure transmitting controller has a terminal protection cover or water-resistant connector for dust-proof and short circuit functions.

MDM4881 differential pressure transmitting controller applies in hydropower plant input water main valve for differential pressure inspection and control.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Using Rapid Precise Sorting of Mixed-Metal Waste by Companies, due to Smart Inductive Sensors

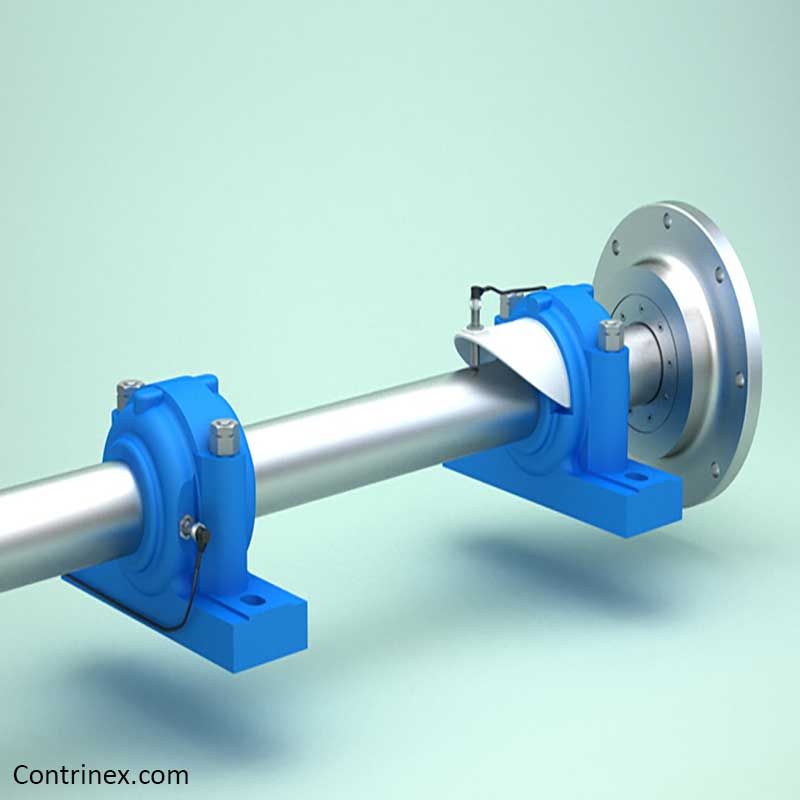

Affordable Condition-Based Monitoring in Rotating Equipment by Multi-Mode Intelligent Sensors

Monitoring Thermo Exchange Stations

Related Products